High-speed permanent magnet motor

A permanent magnet motor, high-speed technology, applied in the direction of electromechanical devices, wind power generation, electrical components, etc., to achieve the effect of low viscosity coefficient, reduce pressure loss, and improve bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

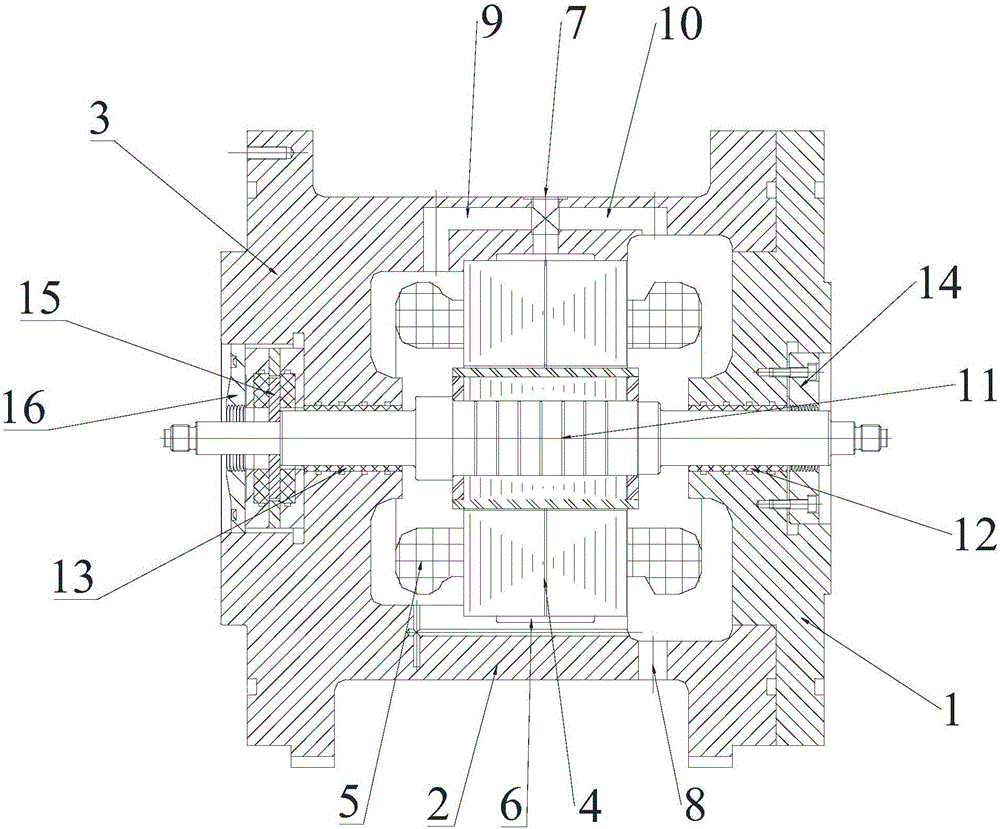

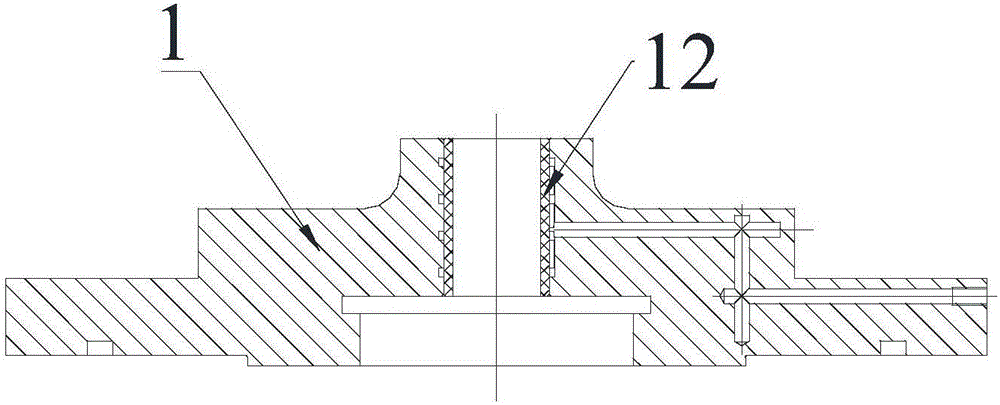

[0039] This embodiment provides a motor, especially a high-speed permanent magnet motor, which includes a motor housing and a radial bearing seat 1;

[0040] The motor casing includes a casing part 2 and an end cover part 3, and the casing part is cylindrical in shape, and in the casing part, there is a hole extending through the casing along the axial direction of the casing part. part, the end cover part is arranged on the left end of the case part, and closes the opening of the left end of the case part, in this embodiment, the case part and the end cover part can be integrated Forming, such as forming the motor housing by die casting.

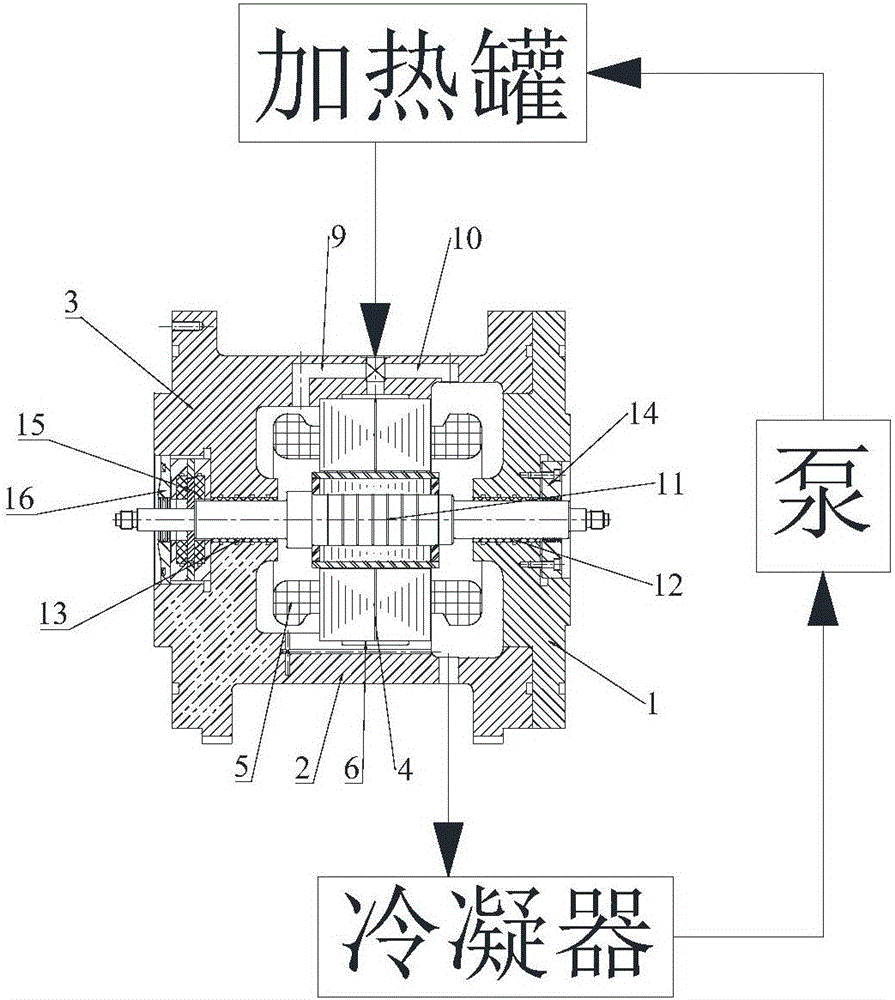

[0041]The radial bearing seat is fixed on the right end of the motor housing (housing part), and closes the opening at the right end of the housing part. In this embodiment, the motor housing and the radial bearing seat sealing the accommodating space, so as to prevent the low-viscosity two-phase fluid entering the accommodating space from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com