Method and system for removing solvents from isocyanates obtained from phosgenation reaction

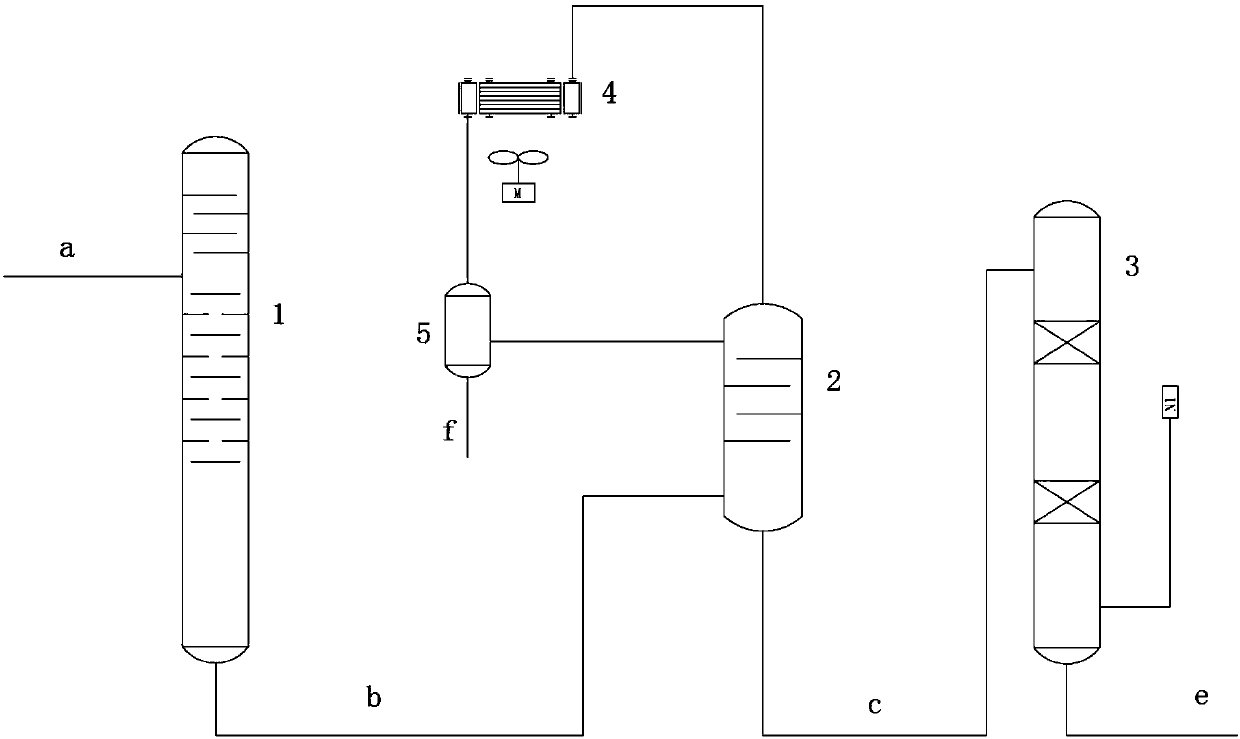

An isocyanate and solvent removal technology, which is applied in the field of nitrogen stripping system to remove remaining solvent, can solve the problems of extremely high operating flexibility, the application of guide float valve trays has not been disclosed, and the product yield is decreased.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

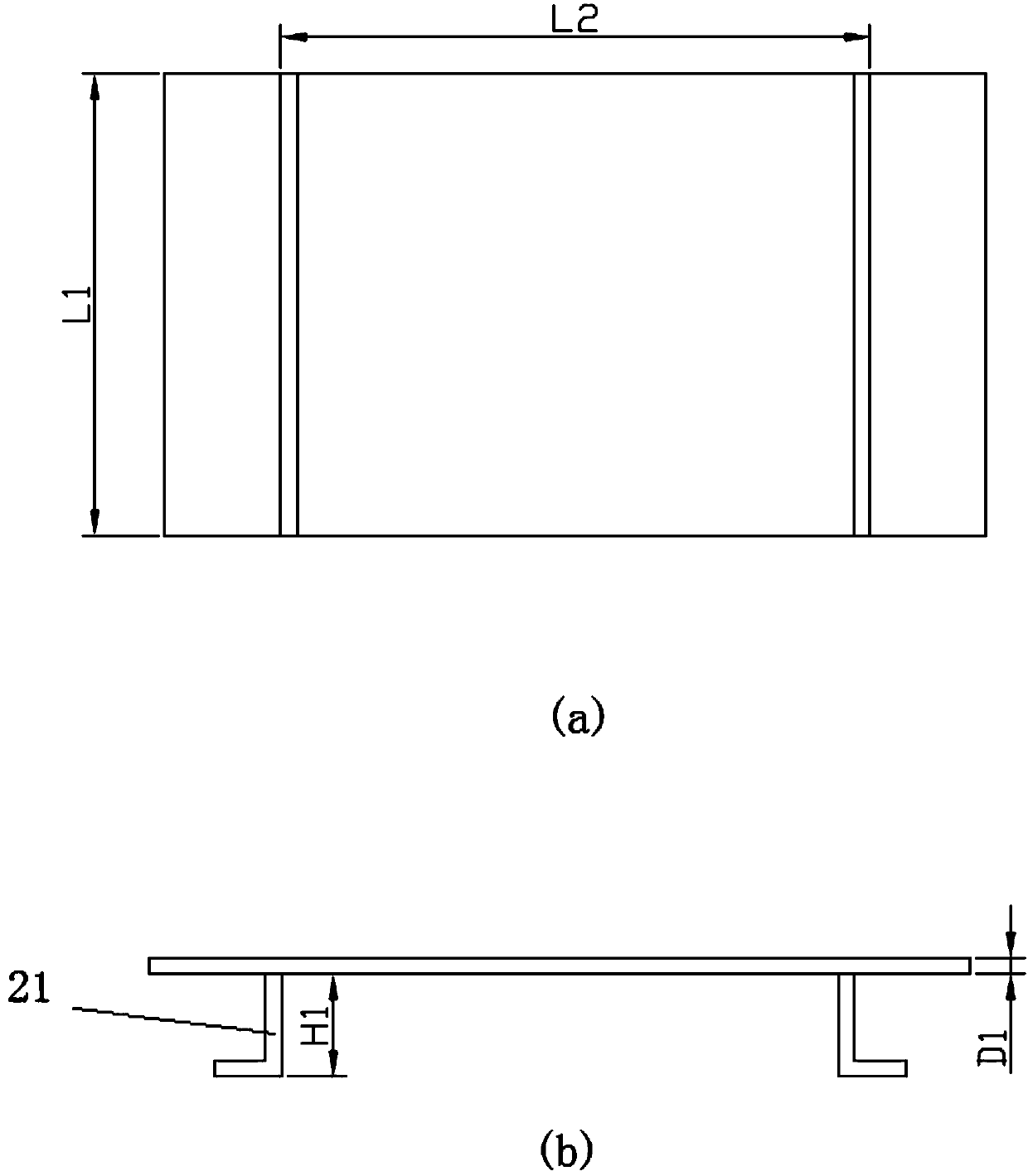

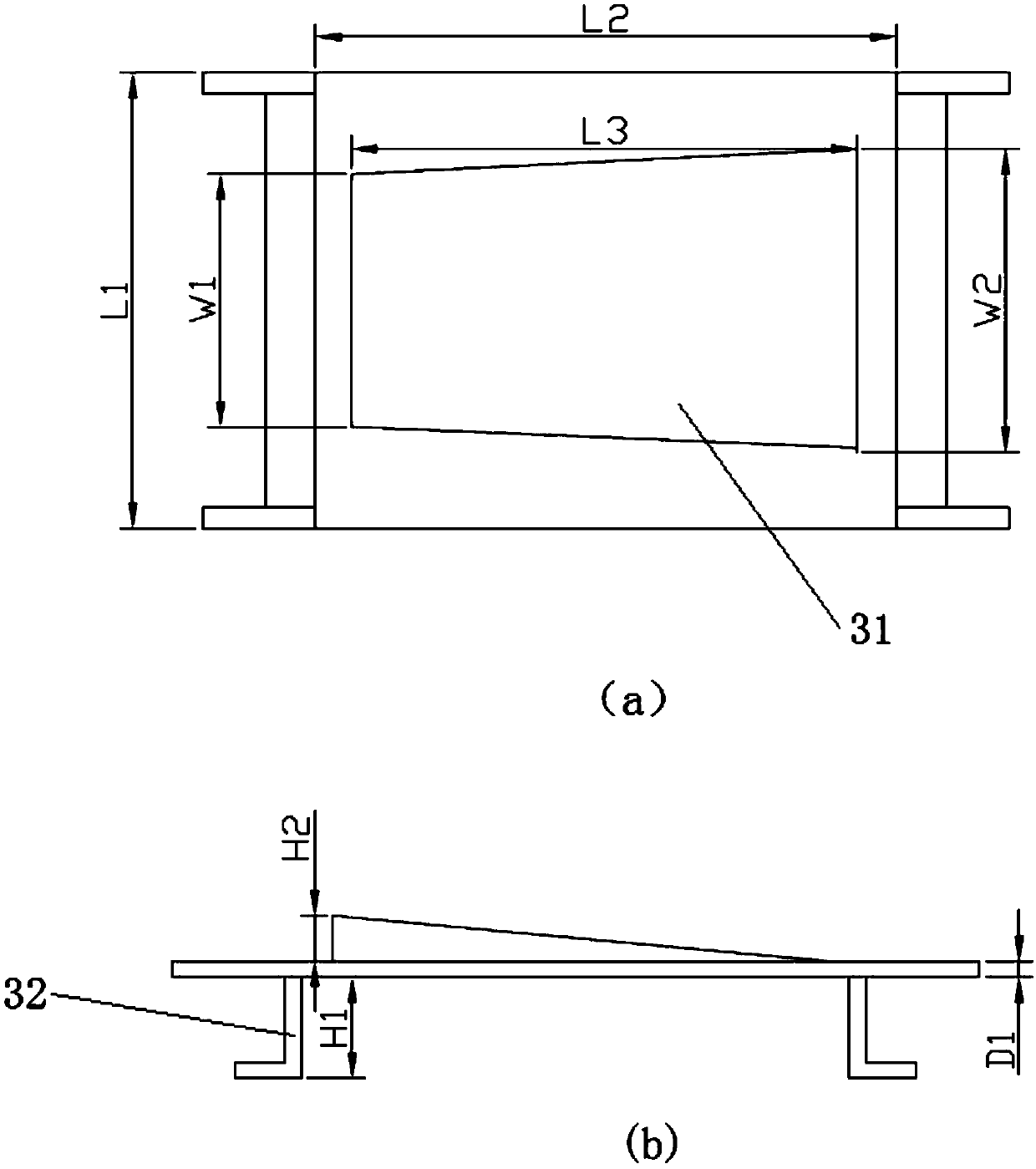

[0086] The bottom discharge of the thermal reactor in this embodiment is 38t / h photochemical solution containing diphenylmethane polyisocyanate (crude MDI), phosgene and chlorobenzene, wherein the crude MDI content is 29.3%, and the chlorobenzene content is 65.5%. , the content of phosgene is 4.5%, and the content of HCl is 0.7%. , 80mm in length, 1.2mm in thickness, and a valve plate lift height of 12mm. The weight of the heavy valve is 33g, the width is 45mm, the length is 80mm, and the thickness is 1.6mm. , The porosity is 16%. The temperature at the bottom of the tower is 140°C, the pressure at the top of the tower is 130kpa, and the phosgene content in the discharge at the bottom of the tower is 150ppm. : The ratio of the number of new guide float valves to blisters is 0.18; the light valve accounts for 10%, the light valve has a mass of 24g, a width of 45mm, a length of 80mm, a thickness of 1.2mm, and a valve plate lifting height of 12mm. A guide hole, the width of th...

Embodiment 2

[0088] The bottom discharge of the thermal reactor in this embodiment is 80t / h photochemical liquid containing diphenylmethane polyisocyanate (crude MDI), phosgene and chlorobenzene, wherein the crude MDI content is 28.3%, and the chlorobenzene content is 66.5% , the content of phosgene is 4.5%, and the content of HCl is 0.7%. , 80mm in length, 1.2mm in thickness, and a valve plate lift height of 12mm. The weight of the heavy valve is 33g, the width is 45mm, the length is 80mm, and the thickness is 1.6mm. , The porosity is 16%. The temperature at the bottom of the tower is 140°C, the pressure at the top of the tower is 130kpa, and the phosgene content in the discharge at the bottom of the tower is 150ppm. : The ratio of the number of new guide float valves to blisters is 0.18; the light valve accounts for 10%, the light valve has a mass of 16g, a width of 40mm, a length of 60mm, a thickness of 1.2mm, and a valve plate with a lifting height of 12mm. A guide hole, the width o...

Embodiment 3

[0090] The bottom discharge of the thermal reactor of this embodiment is the photochemical liquid containing toluene diisocyanate (crude TDI), phosgene and dichlorobenzene of 30t / h, wherein the crude TDI content is 20.5%, and the dichlorobenzene content is 76.6%. The content of phosgene is 1.5%, and the content of tar is 1.4%. The photochemical liquid enters the dephosphorization tower. The internal parts of the dephosphorization tower adopt a combination of light and heavy bar float valves, of which light valves account for 20%. The light valves have a mass of 24g and a width of 45mm. The length is 80mm, the thickness is 1.2mm, and the raised height of the valve plate is 12mm. The weight of the heavy valve is 33g, the width is 45mm, the length is 80mm, and the thickness is 1.6mm. , The porosity is 15%. The temperature at the bottom of the tower is 205°C, the pressure at the top of the tower is 30kpa, and the phosgene content in the discharge at the bottom of the tower is 150...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com