Natural compound humectant with cigarette sensory humectation function

A humectant and sensory technology, which is applied in the field of tobacco, can solve the problem of less compound formula of humectants, achieve enhanced physical and sensory moisturizing, improve cigarette smoking comfort, and have obvious physical and sensory moisturizing effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Embodiment 1 prepares compound humectant A solution, B solution, C solution

[0047] The prepared 3,3',4',5,7-pentahydroxyflavone-3-rutinoside, seabuckthorn flavonoids and seabuckthorn polysaccharides are uniformly mixed according to 20 parts by weight, 20 parts and 60 parts to make a natural compound moisturizer A, and dissolved in 60% ethanol to obtain natural compound moisturizer A solution.

[0048] The prepared 3,3',4',5,7-pentahydroxyflavone-3-rutinoside, seabuckthorn flavonoids and seabuckthorn polysaccharides are uniformly mixed according to 20 parts, 10 parts and 70 parts by weight to make a natural compound moisturizer B, dissolved in 50% ethanol to obtain natural compound moisturizer B solution.

[0049] The prepared 3,3',4',5,7-pentahydroxyflavone-3-rutinoside, seabuckthorn flavonoids and seabuckthorn polysaccharides are uniformly mixed according to 15 parts by weight, 75 parts and 10 parts to make a natural compound moisturizer C, dissolved in 40% ethanol...

Embodiment 2

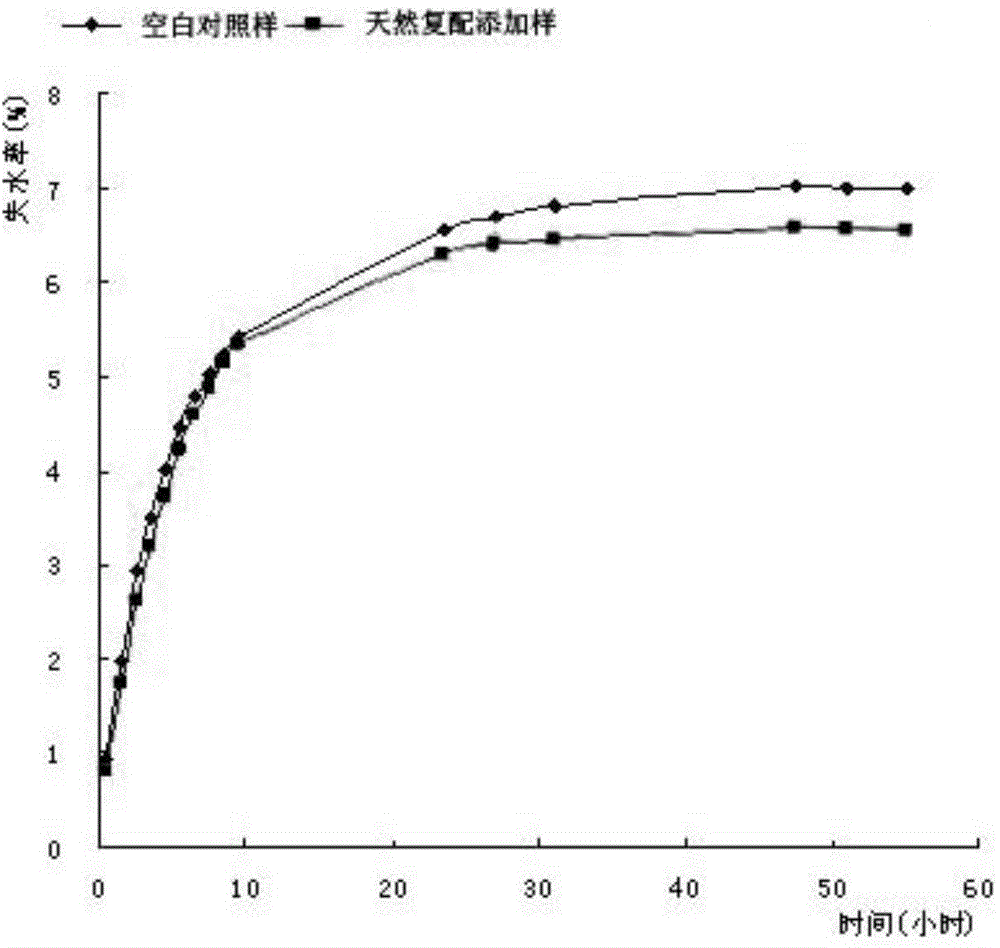

[0051] Add in the shredded tobacco with the compound humectant B in embodiment 1 with 0.1% consumption, take the shredded tobacco sample that does not add compounded humectant and add equal amount of propylene glycol as blank and contrast, then put the shredded tobacco sample after the treatment in In a constant temperature and humidity chamber with a temperature of 28° C. and a relative humidity of RH 22%, the samples were continuously weighed several times at intervals of a certain period of time, and the water loss rate of cut tobacco was calculated respectively. The test results show that under the conditions of temperature 28°C and relative humidity RH 22%, the order of water loss rate of cut tobacco samples is: blank sample > propylene glycol control sample > compound humectant added sample.

Embodiment 3

[0053] The compound humectant A prepared in Example 1 was added to the shredded tobacco according to the amount of humectant at 0.1%, and the shredded tobacco without adding the humectant was used as a blank control, and rolled into cigarettes. The results of cigarette sensory quality evaluation and smoking showed that compared with the blank control, the dryness and irritation of cigarettes added with the compound humectant were reduced, the smoke was more mellow and soft, and the aftertaste was comfortable.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com