Ganoderma lucidum polysaccharide, extraction and purification method and its application as tobacco humectant

A technology of Ganoderma lucidum polysaccharide and humectant, which is applied in the fields of tobacco, application, and treatment of tobacco, etc., to achieve the effect of obvious moisturizing effect, broad promotion and application prospects, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

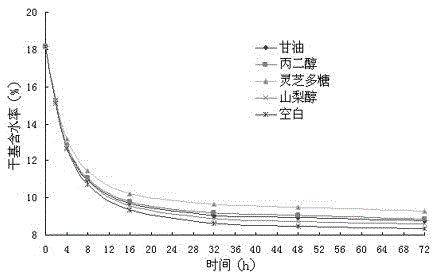

Image

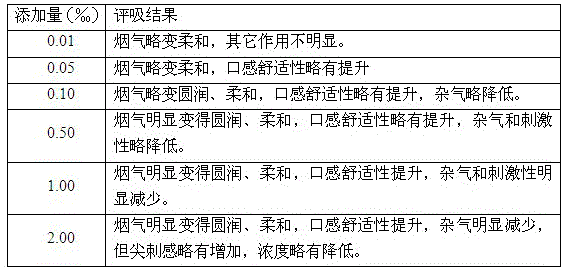

Examples

Embodiment 1

[0018] A method for extracting and purifying Ganoderma lucidum polysaccharides, comprising the following steps: extract 300 g of dried Ganoderma lucidum with 1800 ml of ether Soxhlet for 2 hours to remove oil, and evaporate the residue to dryness. The residue after evaporating to dryness was extracted three times with 750ml boiling water, combined the boiling water extracts obtained three times, concentrated, centrifuged, and the supernatant was taken, and the supernatant was added with absolute ethanol 3 times the volume of the clear liquid for alcohol precipitation, and stood overnight (12h), again. The precipitate was washed three times with 300ml ethanol and 300ml acetone in turn, and then dissolved in distilled water, then papain with a weight of 1‰ of the precipitate was added and placed in a water bath at 50°C for 2 hours, and the protein was removed by the Sevage method. Add 8g of activated carbon and place it in a 70°C water bath to heat for 3 hours, remove the activa...

Embodiment 2

[0021] A method for extracting and purifying Ganoderma lucidum polysaccharides, comprising the following steps: extract 300 g of dried Ganoderma lucidum with 2000 ml of ether Soxhlet for 4 hours to remove oil, and evaporate the residue to dryness. The residue after evaporating to dryness was extracted with 750ml of boiling water for 3 times, and the boiling water extracts obtained three times were combined, concentrated, centrifuged, and the supernatant was taken, and anhydrous ethanol with 3 times the volume of the clear liquid was added for alcohol precipitation, and stood for 12 hours , and centrifuge again to collect the precipitate. The precipitate was washed three times with 300ml of ethanol and 300ml of acetone in turn, then dissolved in distilled water, and then papain with a weight of 2‰ of the precipitate was added, placed in a water bath at 50°C for 4 hours, and the protein was removed by Sevage method. Add 8g of activated carbon and place it in a 70°C water bath to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com