Application of 3-(2-hydroxyphenyl) propionic acid in cigarettes

A technology of hydroxyphenyl and propionic acid, which is applied in the application field of 3-propionic acid in cigarettes, can solve the problems of intolerance to baking, fast aroma release, uneven release, etc., and achieve favorable storage, uniform aroma release, The effect of good moisturizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

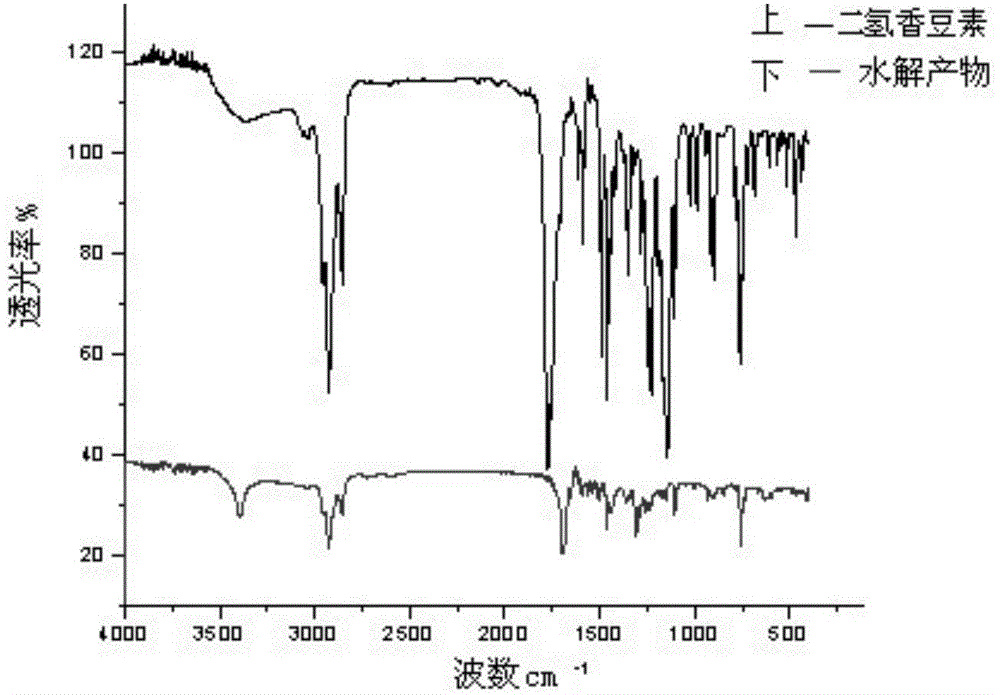

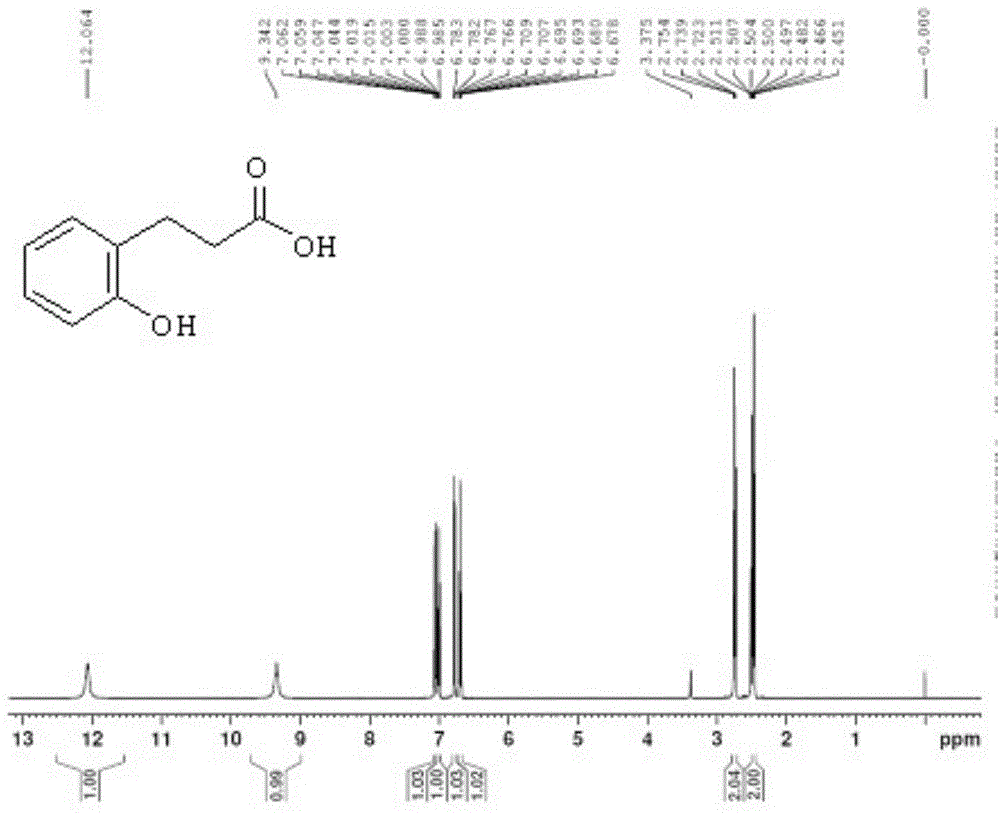

[0026] Add 0.2 mol of dihydrocoumarin into a three-necked flask, and continue to add 0.3 mol of absolute ethanol, heat and stir in an oil bath to dissolve, then add 0.6 mol of 10 mol / L NaOH solution, react at 80°C, and detect by chromatography , stop heating after conversion of raw materials and cool to room temperature to obtain saponified liquid.

[0027] Under the condition of reduced pressure of 76mmHg, evaporate ethanol and a part of water to the saponified liquid, and add 30mL of saturated salt solution or water-absorbing agent sodium sulfate to it to obtain the concentrated saponified liquid;

[0028] Measure 300mL of 2.0mol / L HCl solution, add 70.0g of NaCl solid particles to it, stir quickly to dissolve it, add it to the concentrated saponification solution at room temperature for acidification, precipitate the product, and refrigerate overnight at 0°C Let it age. Finally, the product was obtained by suction filtration under reduced pressure.

[0029] The results of...

Embodiment 2

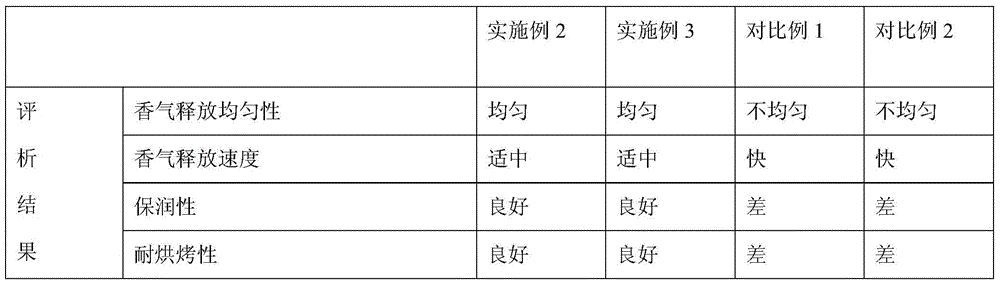

[0031] Flavoring experiment 1

[0032] Take the 3-(2-hydroxyphenyl)propionic acid prepared in Example 1 and dilute it with Daqu wine at 52° C. to a solution with a concentration of 2.0 g / L. Take 5mL of the above solution, add flavor by spraying, so that the above solution is evenly sprayed on 1000g cut tobacco, equilibrate at 22°C and relative humidity of 60% for 48h, bake, take out and make cigarettes, smoke for evaluation, and compare with the control sample Comparison (addition of dihydrocoumarin) for evaluation.

Embodiment 3

[0034] Flavoring experiment 2

[0035] Take the 3-(2-hydroxyphenyl)propionic acid prepared in Example 1 and dilute it with Daqu wine at 52° C. to a solution with a concentration of 2.0 g / L. Take 5mL of the above-mentioned solution, add flavor by spraying, spray the above-mentioned solution evenly on 1000g of thin slices, equilibrate at 22°C and relative humidity of 60% for 48h, bake, take out and make cigarettes, and smoke them for evaluation, compare with the control sample Comparison (addition of dihydrocoumarin) for evaluation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com