Composite caramel-flavour aroma spice, baking preparation method and application

A spice and sweet aroma technology, which is applied to compound coke sweet aroma aroma spice and its application in cigarettes and tobacco-related products, can solve the problems of weak aroma, application limitation and the like, achieves natural coordination of tobacco aroma, wide application range, Low cost of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1 Preparation of Glucose Compound Burnt Sweet Fragrance Perfume

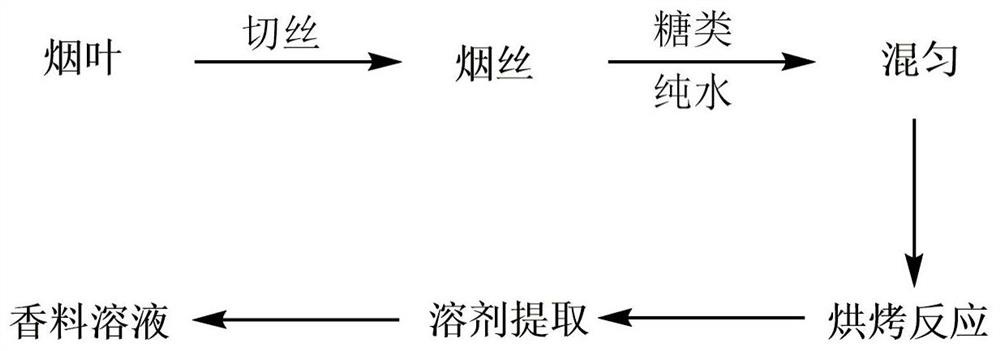

[0030] Such as figure 1 As shown, shred 10.0 parts of tobacco leaves (YQ1 grade, produced in Qujing, Yunnan, year 2014), add 3.0 parts of glucose and mix well, then spray 2.0 parts of pure water and mix well. Spread it out on a tray, then put it into an oven preheated to 140°C, and bake for 10.0min. The reaction product was cooled, then added to a round bottom flask, added 50.0 parts by mass of 50% ethanol-water solution, and extracted under reflux for 40.0 min. Filter to obtain the compound burnt sweet spice solution.

Embodiment 2

[0031] Example 2 Fragrance component analysis and sensory evaluation of glucose compound burnt-sweet fragrance

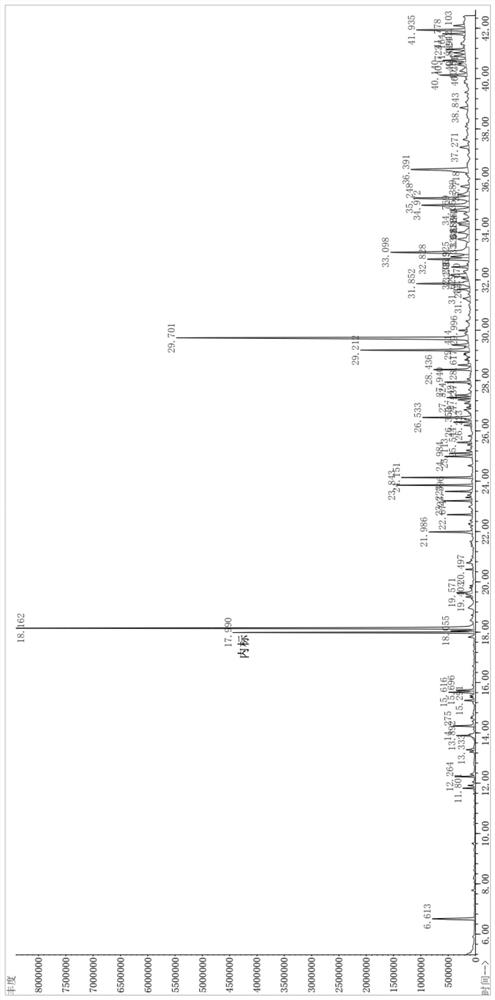

[0032] Take 15.0 mL of compound burnt-sweet aroma fragrance solution, add 15.0 mL of pure water, add 10.0 mL of dichloromethane, and extract. The dichloromethane layer was transferred, and 10.0 mL of dichloromethane was added, and the extraction was repeated once. The two dichloromethane layers were combined, concentrated to 0.9 mL, and 100 μL of internal standard phenylethyl propionate (1782 μg / mL) was added.

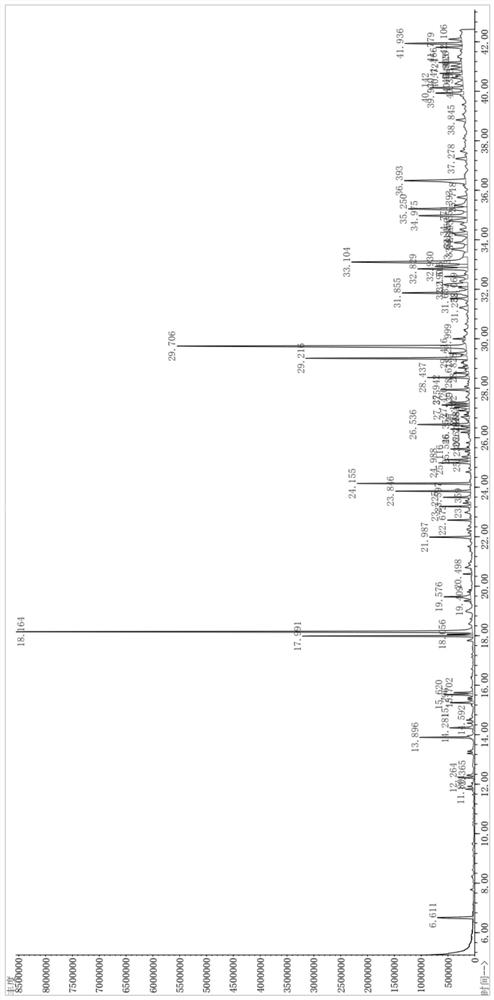

[0033] Preparation of control solutions. Tobacco leaves of the same grade were taken, the ratio of solid to liquid was 1:5, and 50% ethanol was added for extraction to obtain a control solution. The control solution was extracted by the same method as above and then analyzed by GC-MS.

[0034] Glucose caramelization blank solution preparation. Take 10.0 parts of filter paper, add 3.0 parts of glucose, spray into 2.0 parts of pure water and mix well. Spr...

Embodiment 3

[0046] Preparation and Application of Example 3 Fructose Compound Burnt Sweet Spice

[0047] Shred 10.0 parts of tobacco leaves (grade YQ1, produced in Qujing, Yunnan, year 2014), add 3.0 parts of fructose and mix well, then spray 2.0 parts of pure water and mix well. Spread it out on a tray, then put it into an oven preheated to 140°C, and bake for 10.0min. The reaction product was cooled, then added to a round bottom flask, added 50.0 parts by mass of 50% ethanol-water solution, and extracted under reflux for 40 min. Filtrate to obtain the fructose compound burnt sweet spice solution.

[0048] Add the fructose compound burnt sweet flavor solution to Sichuan Zhongyan 2 at an amount of 1 μL per cigarette. # Module blank cigarette stick. The sensory evaluation was carried out with the blank cigarette without adding the above product as a control. The sensory evaluation results showed that: compared with the control, the cigarettes added with fructose-combined burnt-sweet sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com