A kind of normal temperature scenting method and application

A scenting and flavoring technology, applied in the application and preparation of tobacco, tobacco, etc., can solve the problems of the loss of natural aroma and sweetness of cigarettes, and achieve the effects of enriching cigarette aroma, good cigarette application effect, and increasing cigarette aroma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

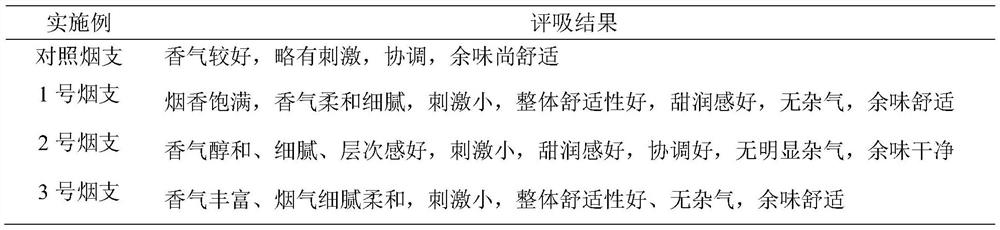

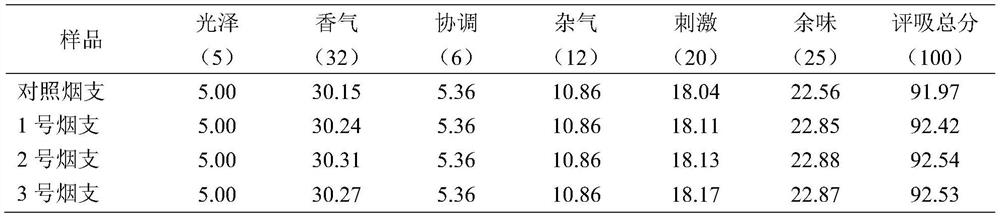

Examples

Embodiment 1

[0022] Take 7 parts of hyaluronic acid, 9 parts of potassium lactate and 8 parts of proline, dissolve potassium lactate in ultrapure water, heat and stir evenly at 60°C, add propylene glycol according to the mass ratio of 1:1, and then add transparent acid and proline, and continue to heat and stir for 0.5h at 70°C to obtain the desired functional excipients. The functional excipients were added to the tobacco leaves at a mass ratio of 1% for use.

[0023] The prepared oak tank (1m 3 ) closed with hot steam for 12h, applied with an automatic spray device to apply Maotai-flavor liquor, the usage amount was 0.1kg, closed for 24h, and carried out secondary application under the same application conditions, and then put the tobacco leaves added with functional accessories into the treated Closed in an oak storage box for 48 years, take it out for later use.

[0024] The scented tobacco leaves are added to the formula of the leaf group at a mass ratio of 2%, and then rolled into ...

Embodiment 2

[0026] Take 3 parts of aloe vera gel, 5 parts of potassium and sodium citrate, and 3 parts of aspartic acid, dissolve potassium and sodium citrate in ultrapure water, heat and stir evenly at 50°C, and add propylene glycol according to the mass ratio of 1:1 , and then sequentially add aloe vera gel and aspartic acid, and continue to heat and stir for 0.5 h at 50° C. to obtain the desired functional accessories. Functional excipients were added to tobacco leaves at a mass ratio of 3% for use.

[0027] The prepared camphor wood storage box (1m 3 ) closed with hot steam for 6h, used automatic spraying device to apply red wine, the usage amount was 0.2kg, closed for 36h, and carried out secondary application with the same application conditions, and then put the tobacco leaves into the treated camphor wood storage box After 72 hours of closed scenting system, it was taken out for use.

[0028] The scented tobacco leaves are added to the formula of the leaf group at a mass ratio o...

Embodiment 3

[0030] Take 3 parts of aloe vera gel, 5 parts of potassium and sodium citrate, and 3 parts of aspartic acid, dissolve potassium and sodium citrate in ultrapure water, heat and stir evenly at 50°C, and add propylene glycol according to the mass ratio of 1:1 , and then sequentially add aloe vera gel and aspartic acid, and continue to heat and stir for 0.5 h at 50° C. to obtain the desired functional accessories. Functional excipients were added to tobacco leaves at a mass ratio of 3% for use.

[0031] The prepared sandalwood storage box (1m 3 ) with hot steam for sealing treatment for 20h, using automatic spraying device to apply balsamic vinegar, the usage amount is 0.02kg, sealing treatment for 12h, carrying out secondary application with the same application conditions, and then putting the tobacco leaves into the treated sandalwood storage box and sealing After 48 hours of scenting, take it out for use.

[0032] The scented tobacco leaves are added to the formula of the le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com