Method for improving comfort of heated cigarettes

A comfort and cigarette technology, applied in the field of improving the comfort of heated cigarettes, can solve the problems of cigarettes affecting the amount of smoke, aroma, and undesired odor, and achieve the effects of increasing richness and improving smoking comfort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Take 37% of water, 22% of ethanol, 1% of ascorbic acid and 40% of menthol by weight to prepare the surface fragrance essence, and control the pH value of the surface fragrance to be no more than 6. Then add the prepared top fragrance to the cooling section of the heated cigarette, the addition amount is 5% of the weight of the cigarette core material, and the addition method is coating. Measure the moisture and water activity of the cigarette core material after adding the surface flavor, and then add 2% calcium stearoyl lactylate by weight of the cigarette core material as a water-holding agent to adjust the moisture content and water activity of the cigarette core material. Carry out sensory evaluation, and measure the water loss rate and rehydration rate of cigarettes to judge the stability of moisture (see Table 2).

Embodiment 2-4

[0037] 1 material liquid preparation

[0038] 1.1 Material liquid preparation

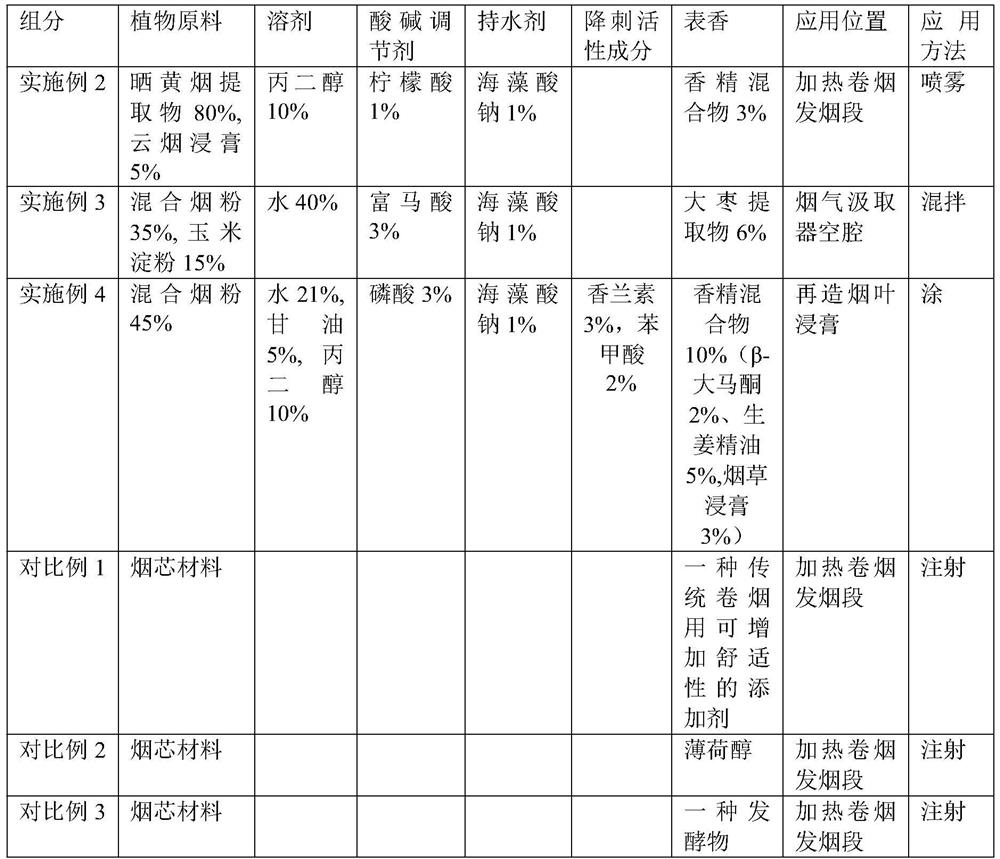

[0039] Screen the target components, mix the plant material, solvent, active agent (ester), and stabilizer in the ratio in Table 1 to form a water-containing feed liquid, and its moisture content is not less than 50% (in order to ensure the fluidity of the feed liquid, It is convenient for processing and use in the later stage of the process), the pH is controlled not to be higher than 6.0, the viscosity is not higher than 1500mPa·s, and at least it can pass through the 80-mesh sieve smoothly.

[0040] 1.2 Controlling the PH value of feed liquid

[0041] Use a pH meter to detect the pH value of the aqueous feed solution prepared in 1.1. When the pH is greater than 6, select phosphoric acid and glacial acetic acid to adjust to below 6; pH value in.

[0042] 2 Preparation of cigarette core material

[0043]Prepare the material liquid in 1 into a fuming sheet, and dry it to a moisture content of 1...

Embodiment 2

[0057] Example 2 includes the whole process of the preparation of cigarette core materials; Example 3 is the preparation of particle samples; in Example 4, there are more thorn-reducing active ingredients in the components; Comparative Examples 1-3 are all directly added on the basis of the existing cigarette core Currently commonly used surface fragrance substances.

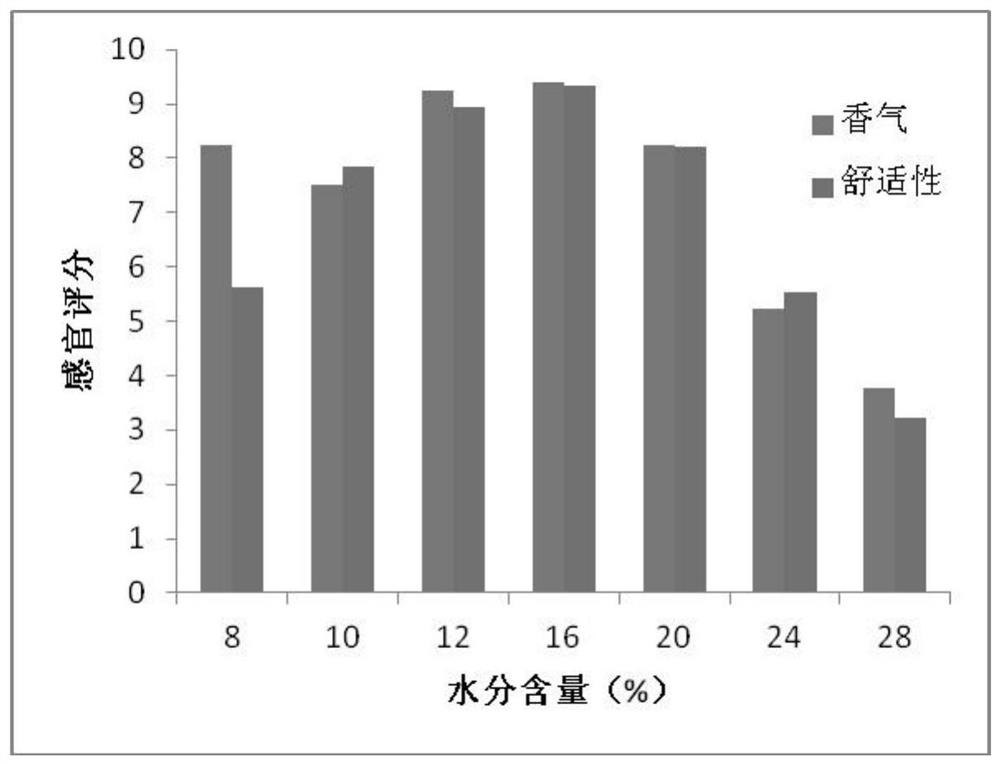

[0058] Table 2 Parameters and comfort evaluation of feed liquid, surface aroma, core material and cigarette sticks

[0059]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com