Automatic feeding and discharging device

A technology of automatic loading and unloading, hopper, applied in the direction of feeding device, peeling device, positioning device, etc., can solve the problems of low efficiency of manual loading and unloading, complex structure of automatic loading and unloading, and achieve the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

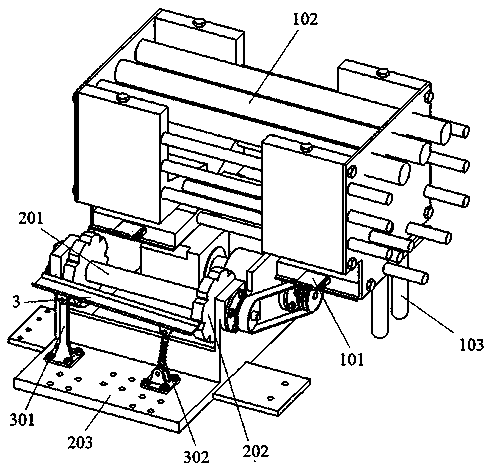

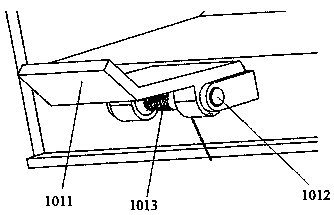

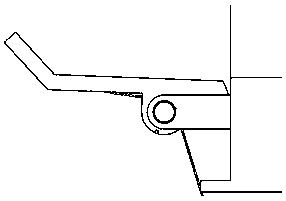

[0022] refer to figure 1 As shown, the automatic loading and unloading device includes a hopper 102. The inner bottom of the hopper 102 is provided with a slope surface, and the side wall of the hopper 102 is provided with a feed opening connected to the lower end of the slope surface. The front end of the paddle 101 is upturned to form a catch 1011, and the rear end of the paddle 101 is rotatably connected to the horizontal shaft 1012, and the horizontal shaft 1012 is connected to the paddle bracket fixed on the outer side of the bottom of the hopper 102; the bottom surface of the paddle is connected to the outer side of the bottom of the hopper An elastic reset mechanism is arranged between them, and the elastic reset mechanism makes the paddle 101 automatically flip up after being pressed downwards; a rotary table 2 is set under the paddle 101, and a turntable motor is arranged on the rotary table 2 and is parallel to the feeding port. The turntable shaft 201, the turntable...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com