Belt type heavy transport machine

A transfer machine and transfer technology, applied in the direction of conveyor objects, transportation and packaging, etc., can solve the problems of high noise, achieve the effect of convenient maintenance, convenient maintenance, and guaranteed stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

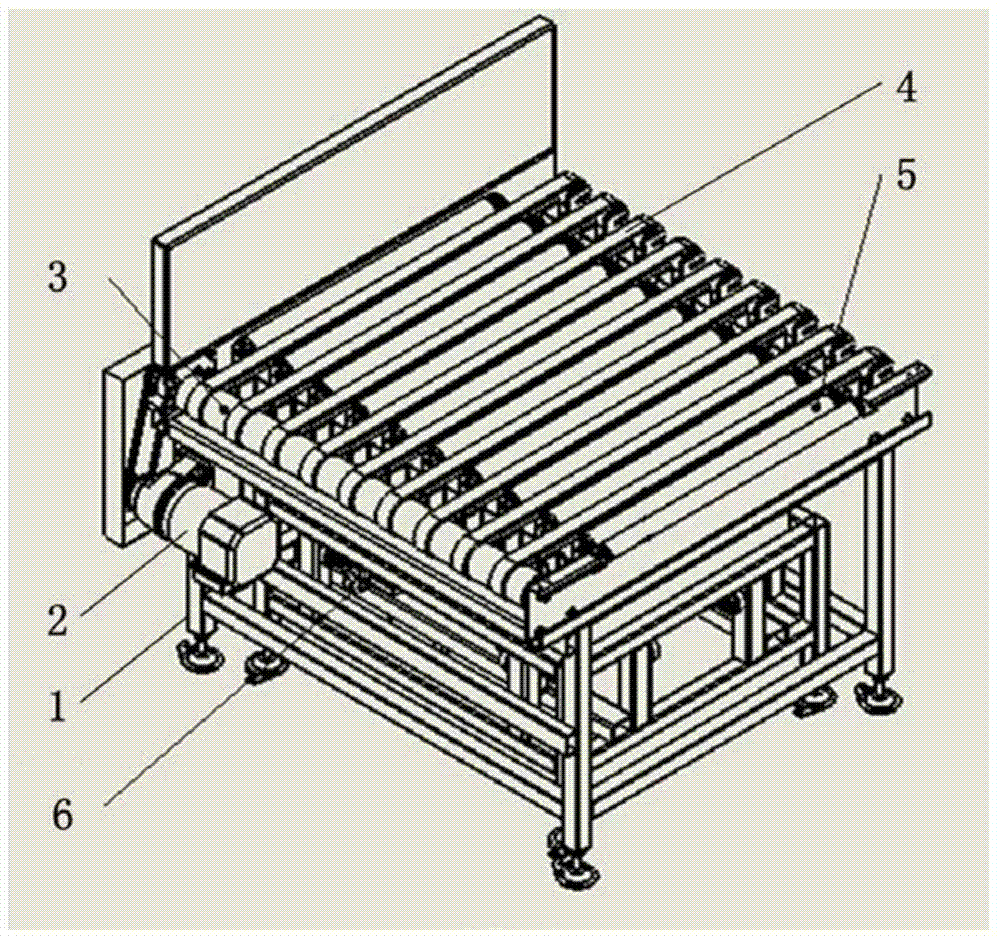

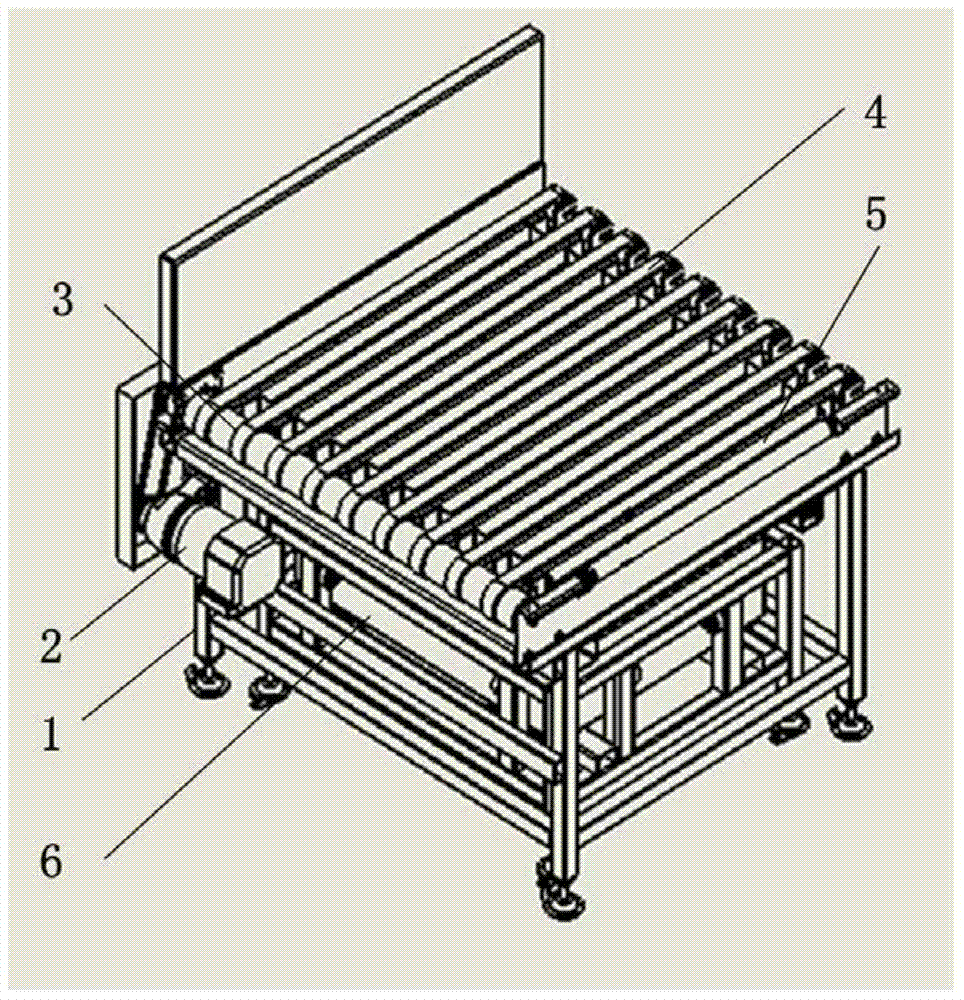

[0028] Such as figure 1 As shown, there is a belt-type transmission module on the top of the main support 1, which mainly includes a drive motor 2, a conveying roller 3 and a belt 4. A plurality of belts 4 are evenly spaced in parallel in a row, and one end of the belt 4 is vertically connected to the conveying roller 3. When working, the drive motor 2 drives the conveyor roller 3 to rotate, and the conveyor roller 3 drives the belt 4 to run, so that the objects placed on the belt 4 are linearly transmitted along the belt's running direction.

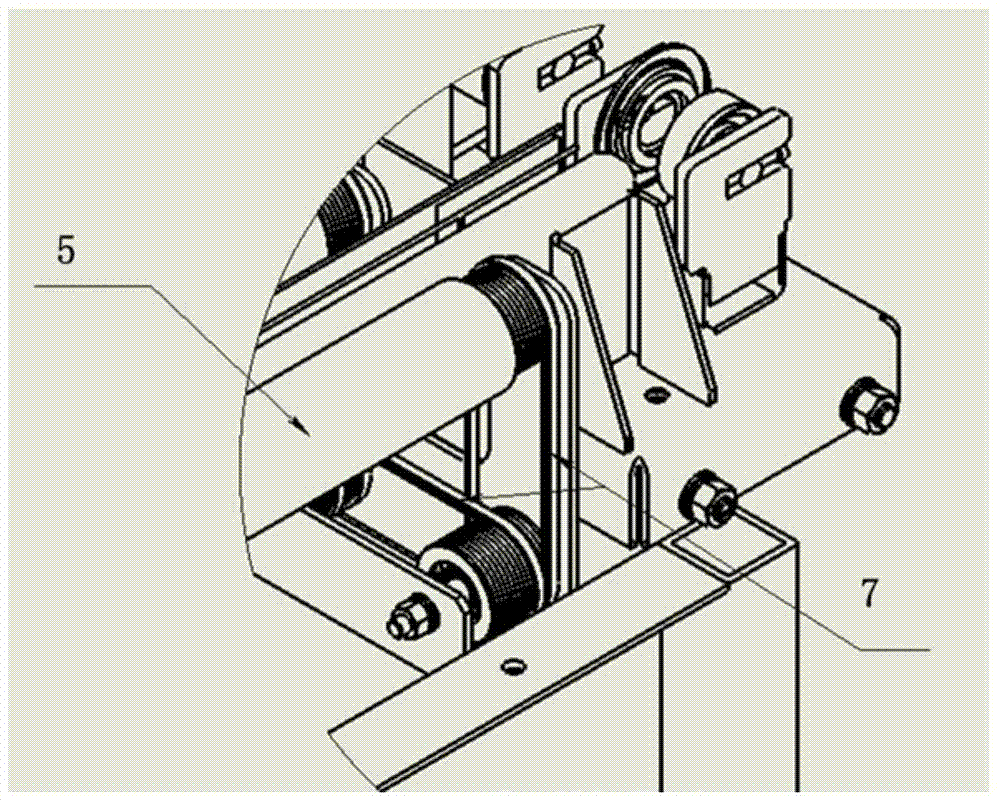

[0029] Preferably, a device for adjusting the distance between the driving rollers is provided in the belt transmission module, so that the belt can be tensioned to an appropriate degree during operation. Furthermore, in the belt transmission module, one end of the belt is connected to the driving roller, and the other end is connected to the pulley, so that each belt can be finely adjusted through an independent pulley.

[0030] It should b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com