Patents

Literature

41results about How to "Change the conveying direction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

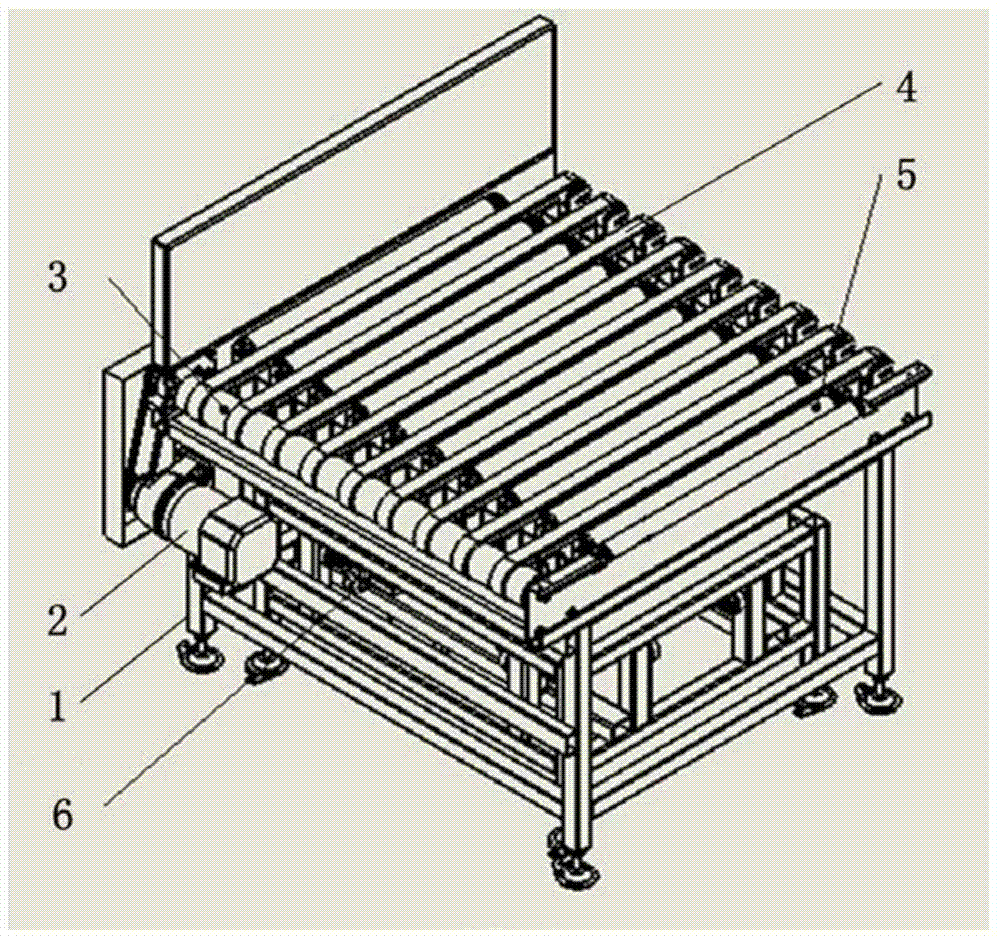

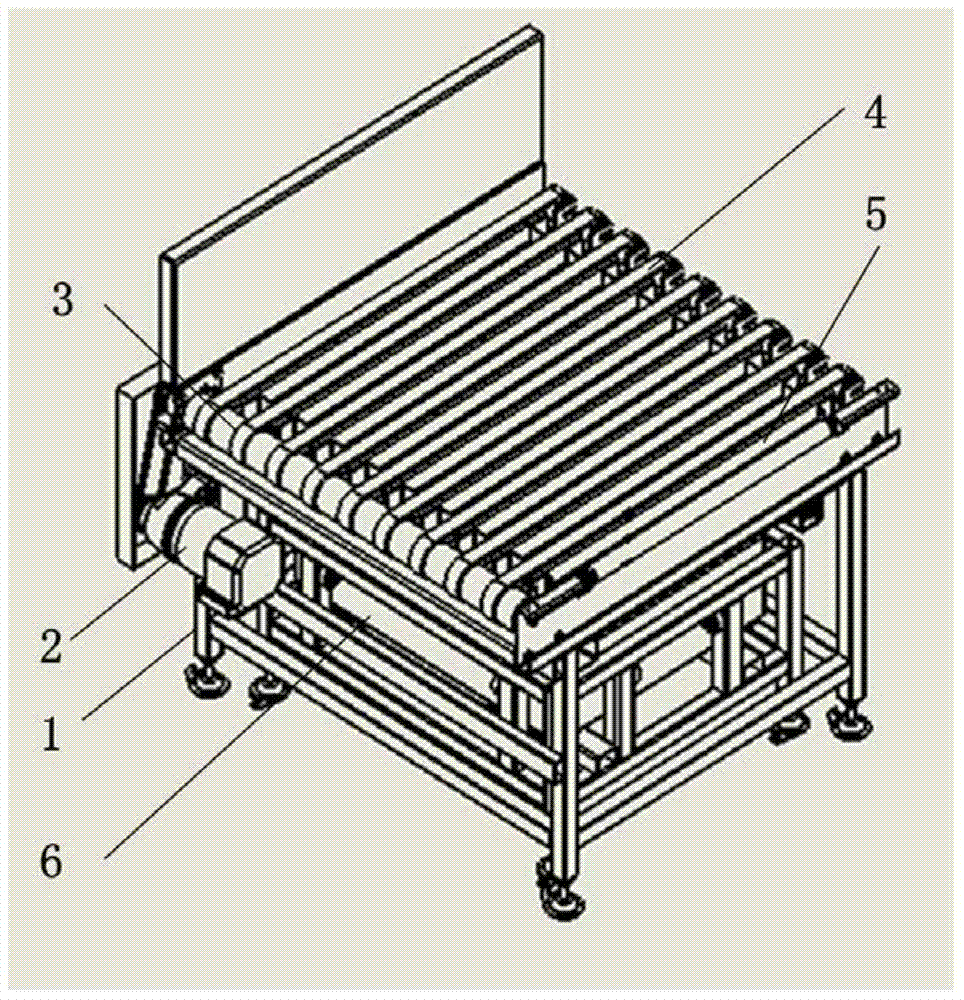

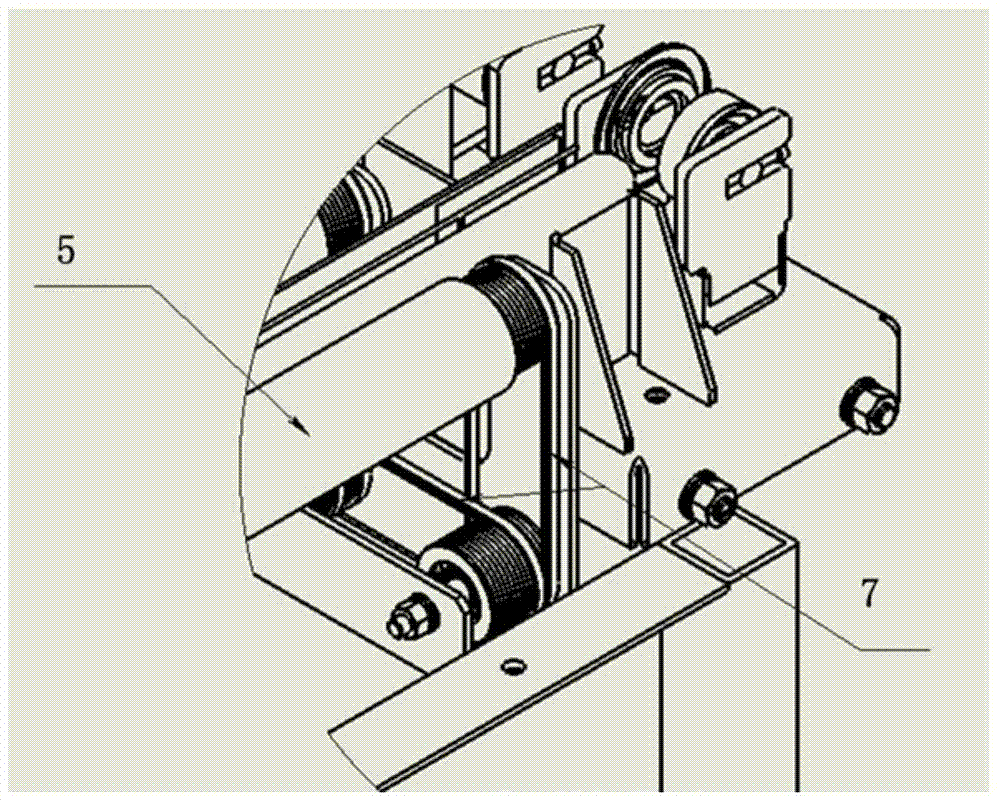

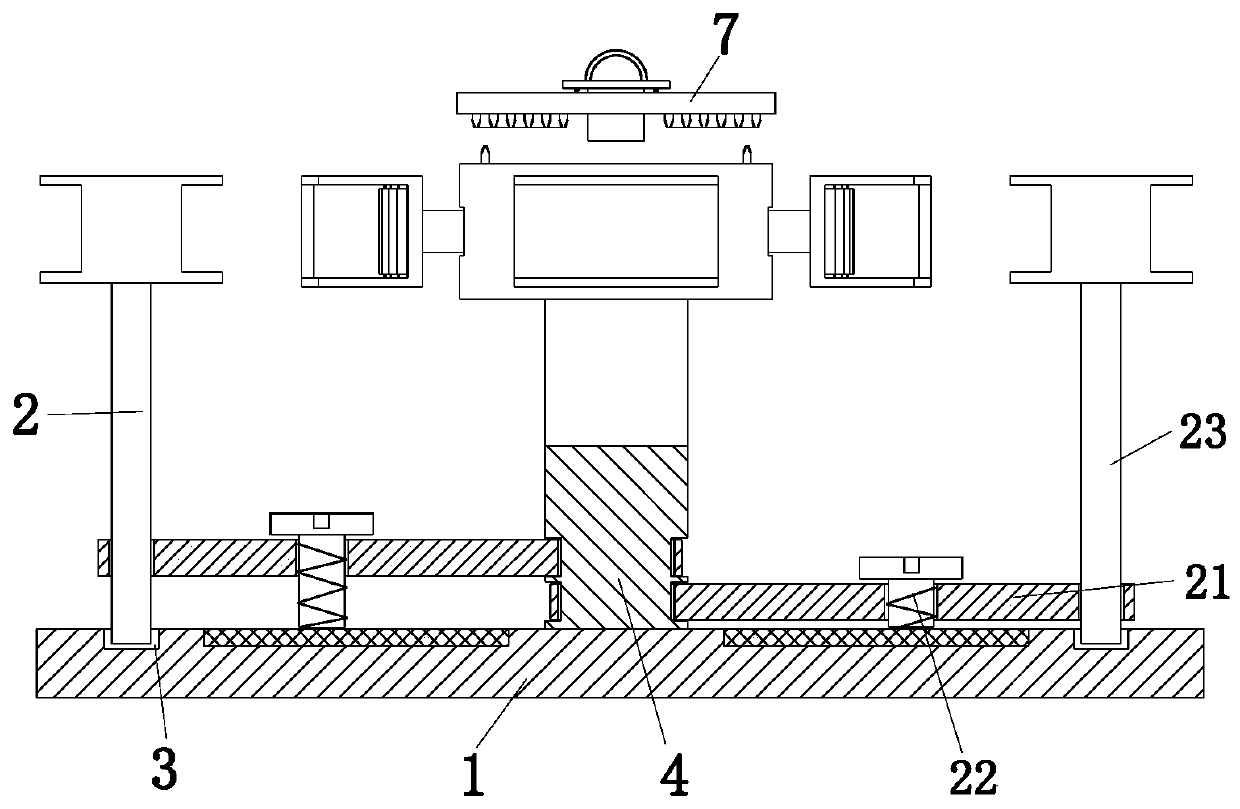

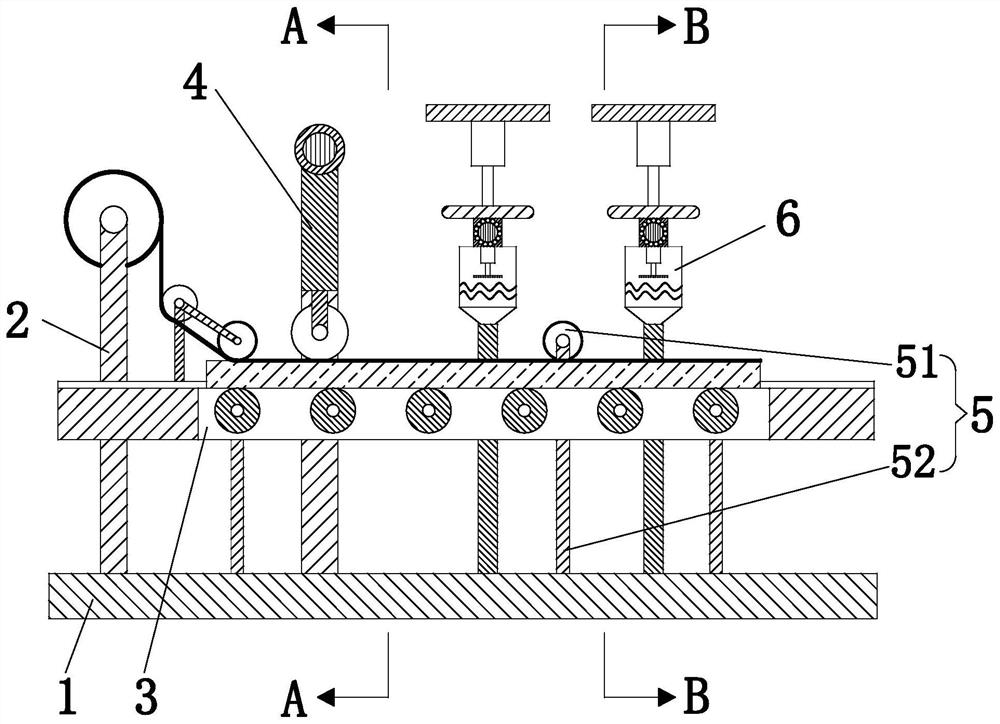

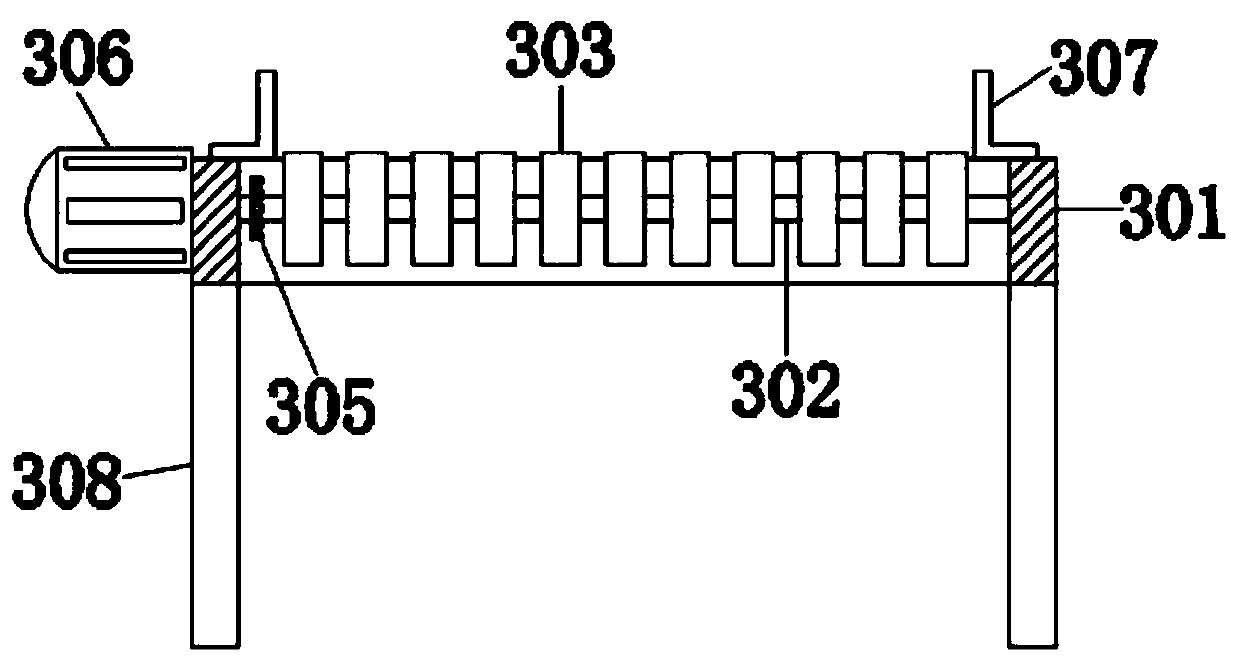

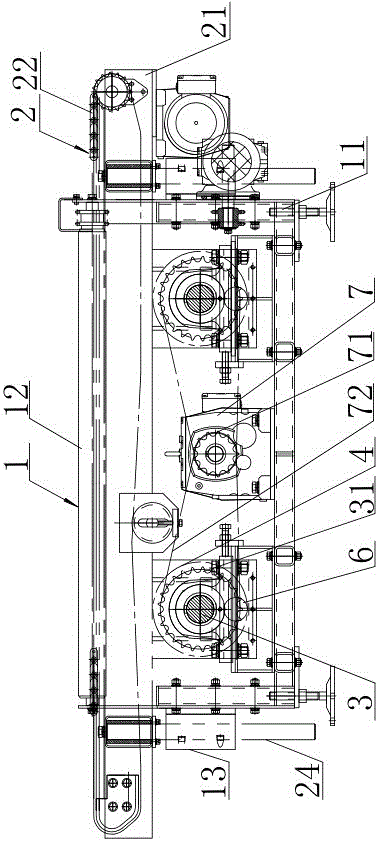

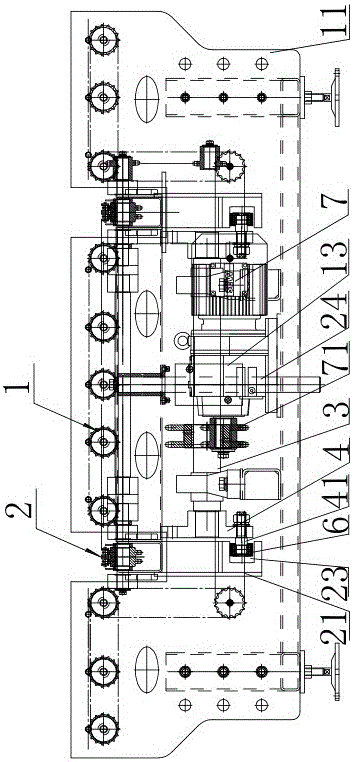

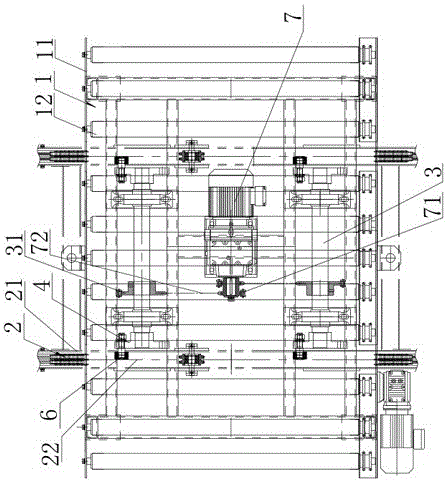

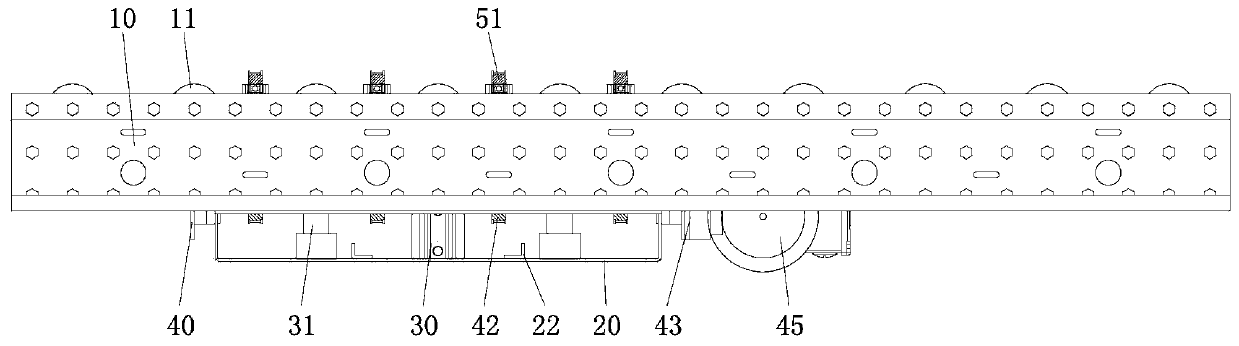

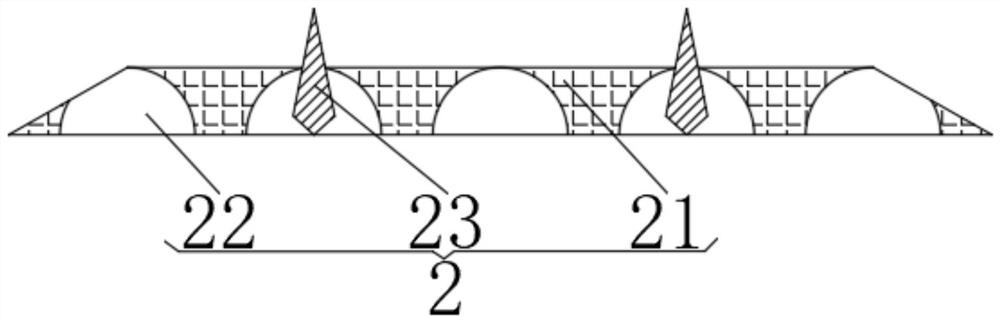

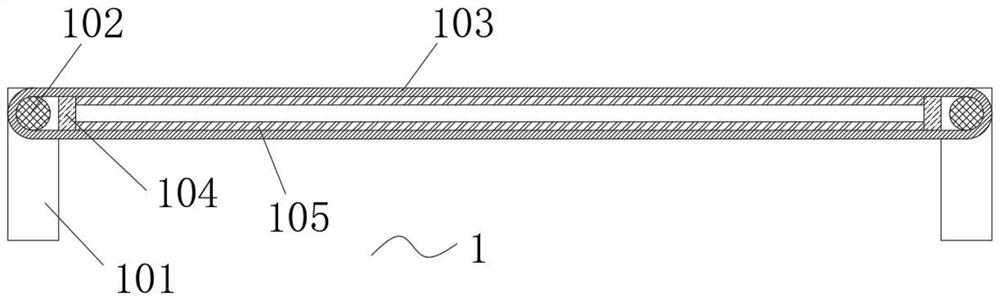

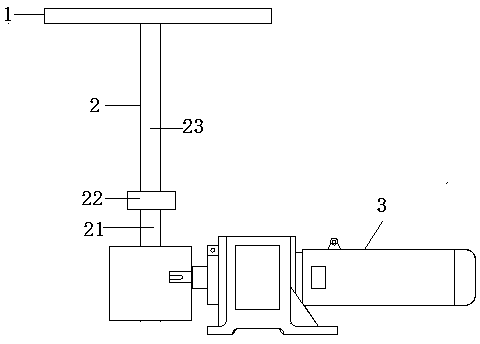

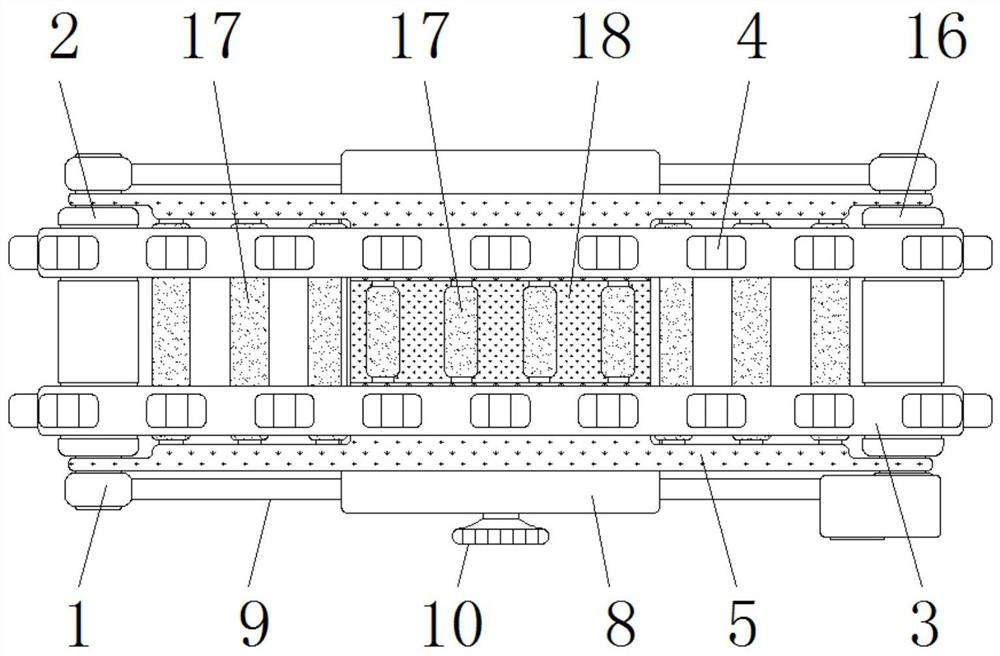

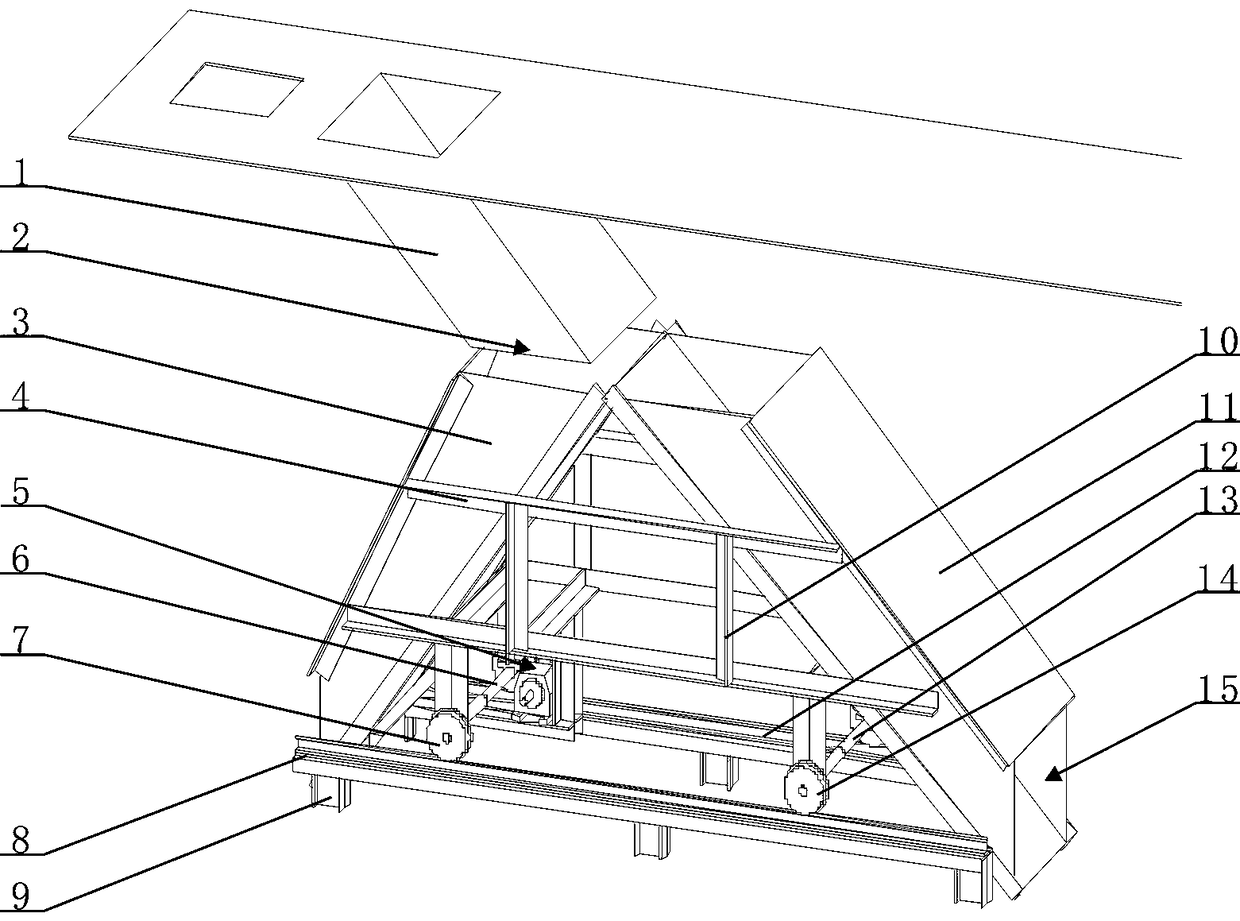

Belt type heavy transport machine

InactiveCN104261109AIncrease surface frictionNo slippageConveyor partsEngineeringMechanical engineering

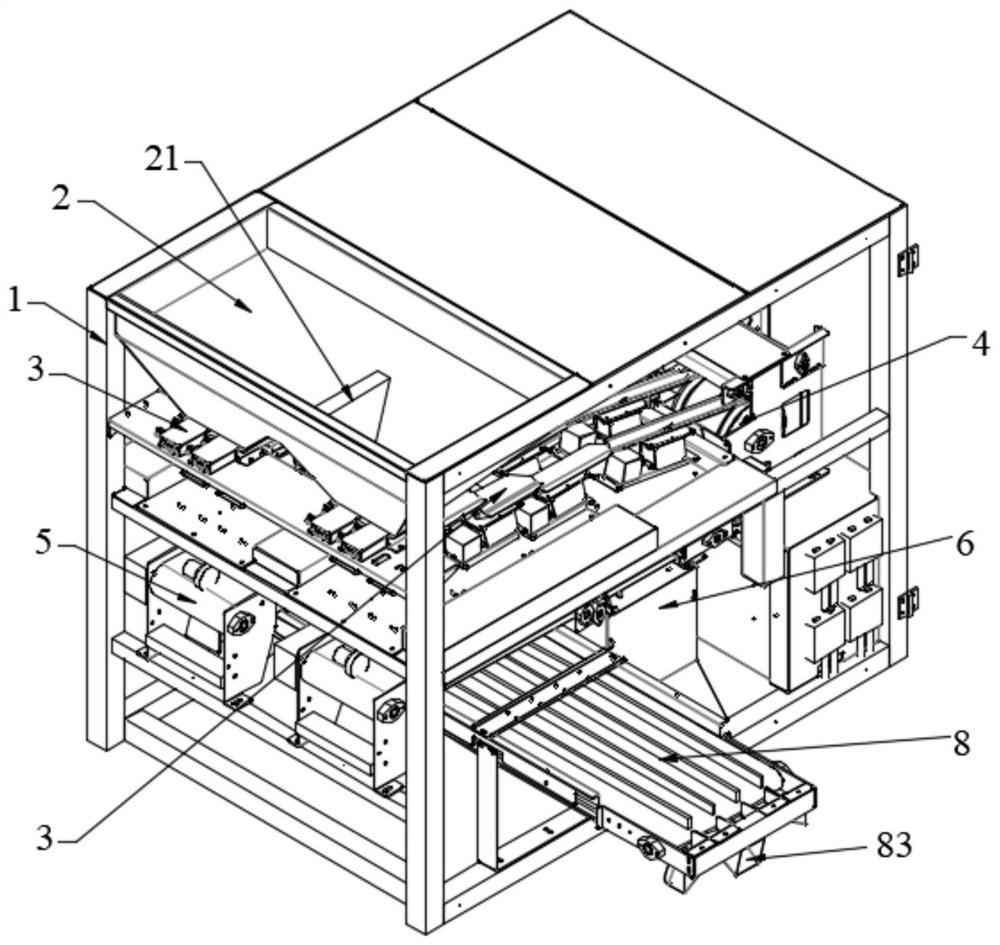

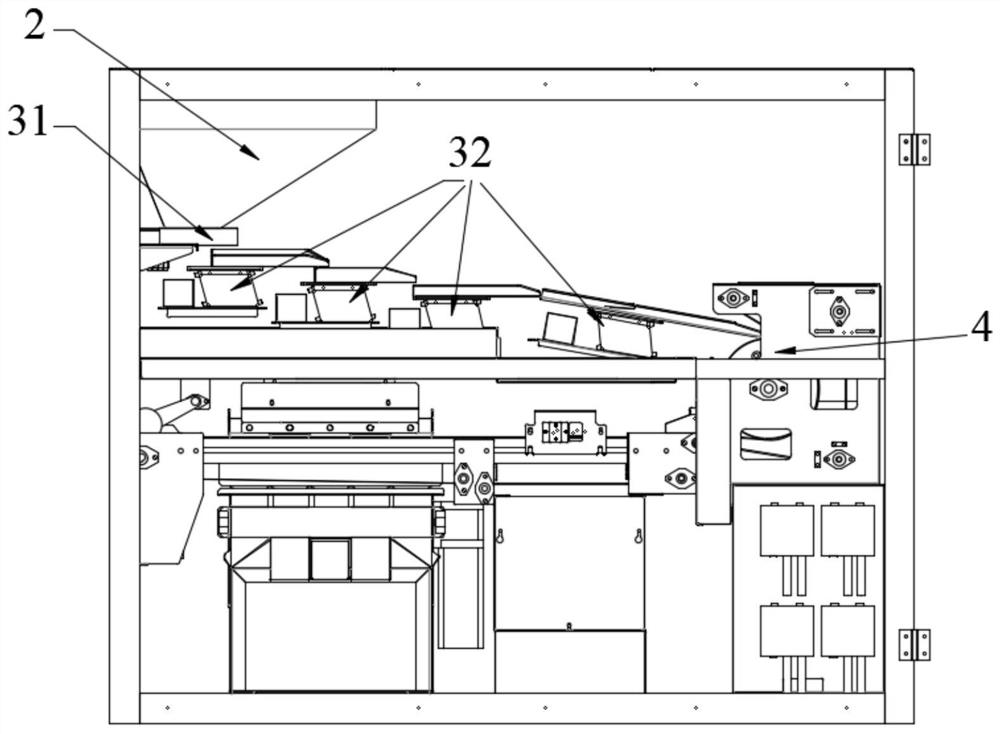

The invention discloses a belt type heavy transport machine, comprising a main frame, a belt type transport module, a conveying module and a jacking module, wherein the belt type transport module is arranged at the top of the main frame, the conveying module is arranged under the belt type transport module, the jacking module is arranged under the conveying module for lifting the same, and the conveying module moves in the space between the jacking module and the belt type transport module. The belt type heavy transport machine is applicable to transporting heavy objects, has the advantages of being low in noise, high in stability and easy to maintain, and is applicable to the field of industrial and logistic transport.

Owner:SHANGHAI REFINE AUTOMATION SYST

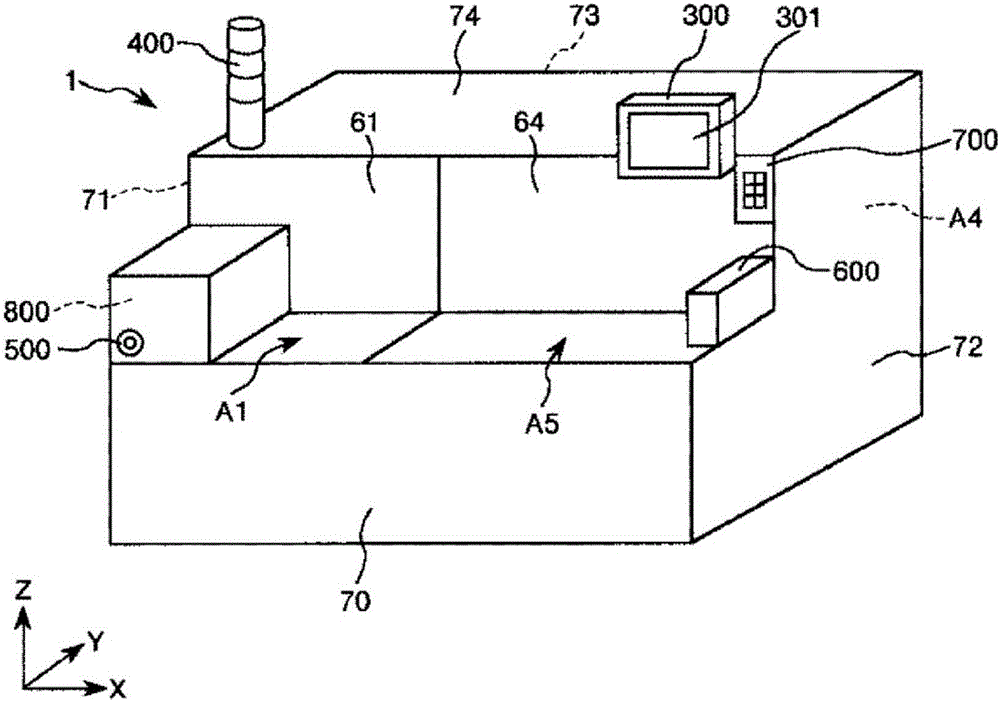

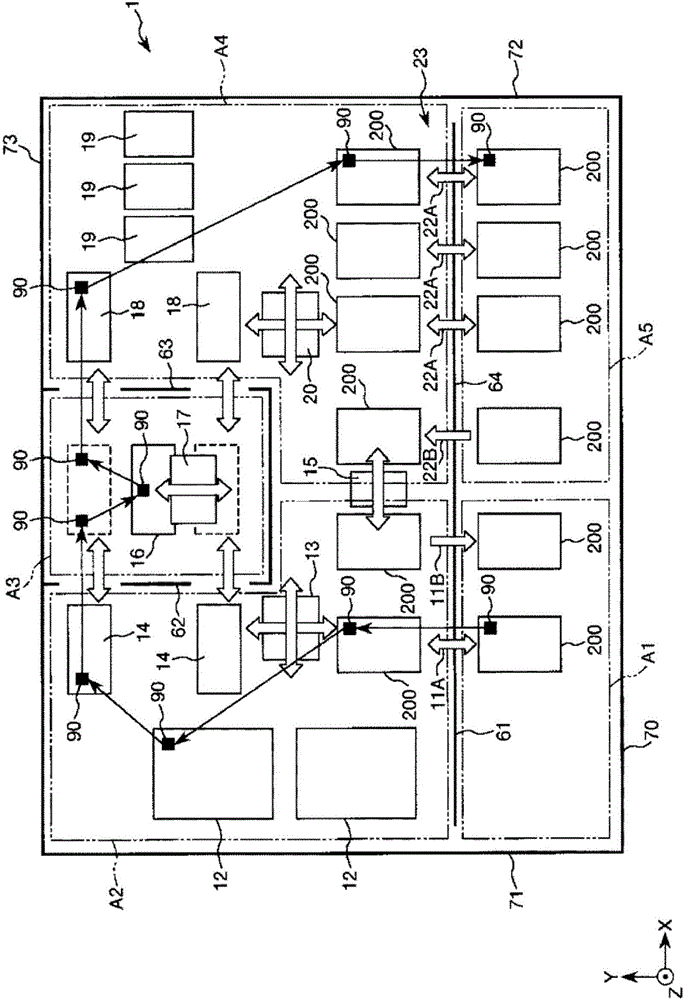

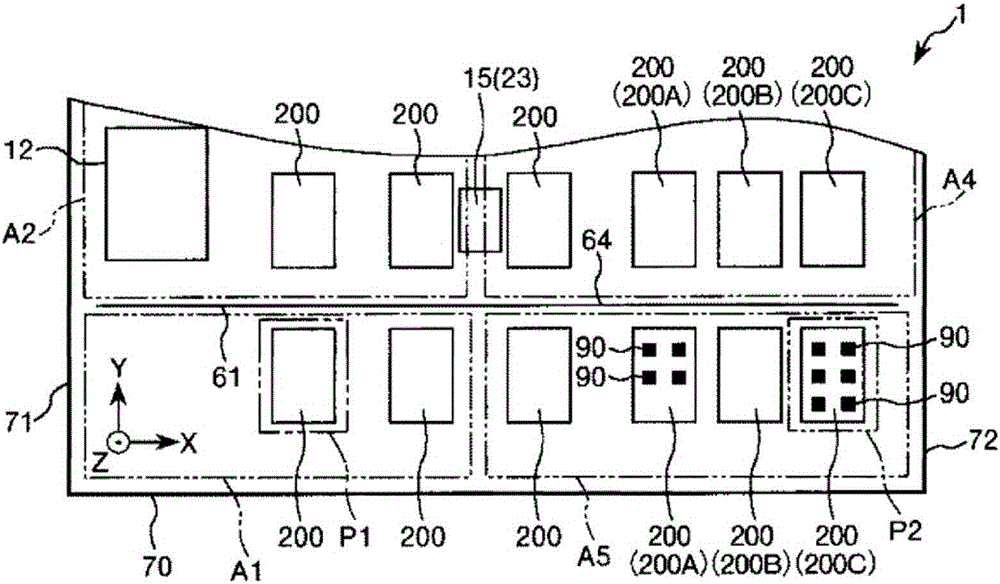

Electronic component conveying apparatus and electronic component inspection apparatus

InactiveCN106829359AChange the conveying directionMechanical conveyorsIndividual semiconductor device testingEngineeringElectronic component

An object of the present invention is to provide an electronic component conveying apparatus and an electronic component inspection apparatus, which can efficiently convey, for example, an electronic component to be re-inspected. The electronic component conveying apparatus of the present invention includes a conveyance unit (23) which can be used to convey a tray (200) that serves as a carrying member that carries an electronic component, which is an IC device (90). The conveyance unit (23) conveys the tray (200), which carries the IC device (90), to a first position where the IC device (90) is arranged before the first inspection, and to a second position for performing the second inspection of the IC device (90) after the first inspection, wherein the first position is different from the second position.

Owner:SEIKO EPSON CORP

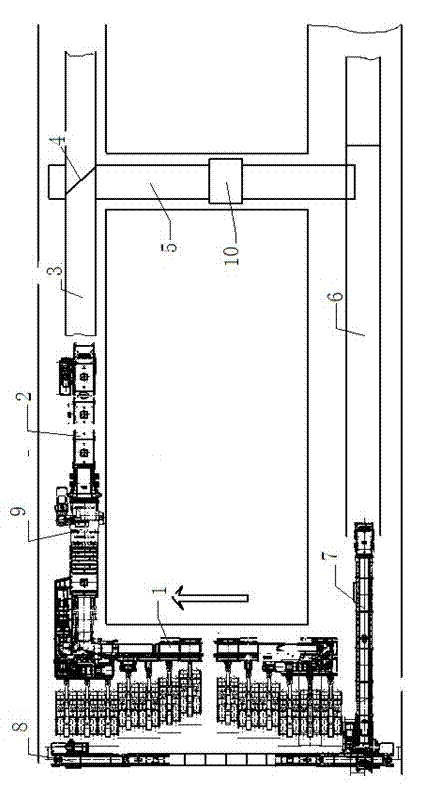

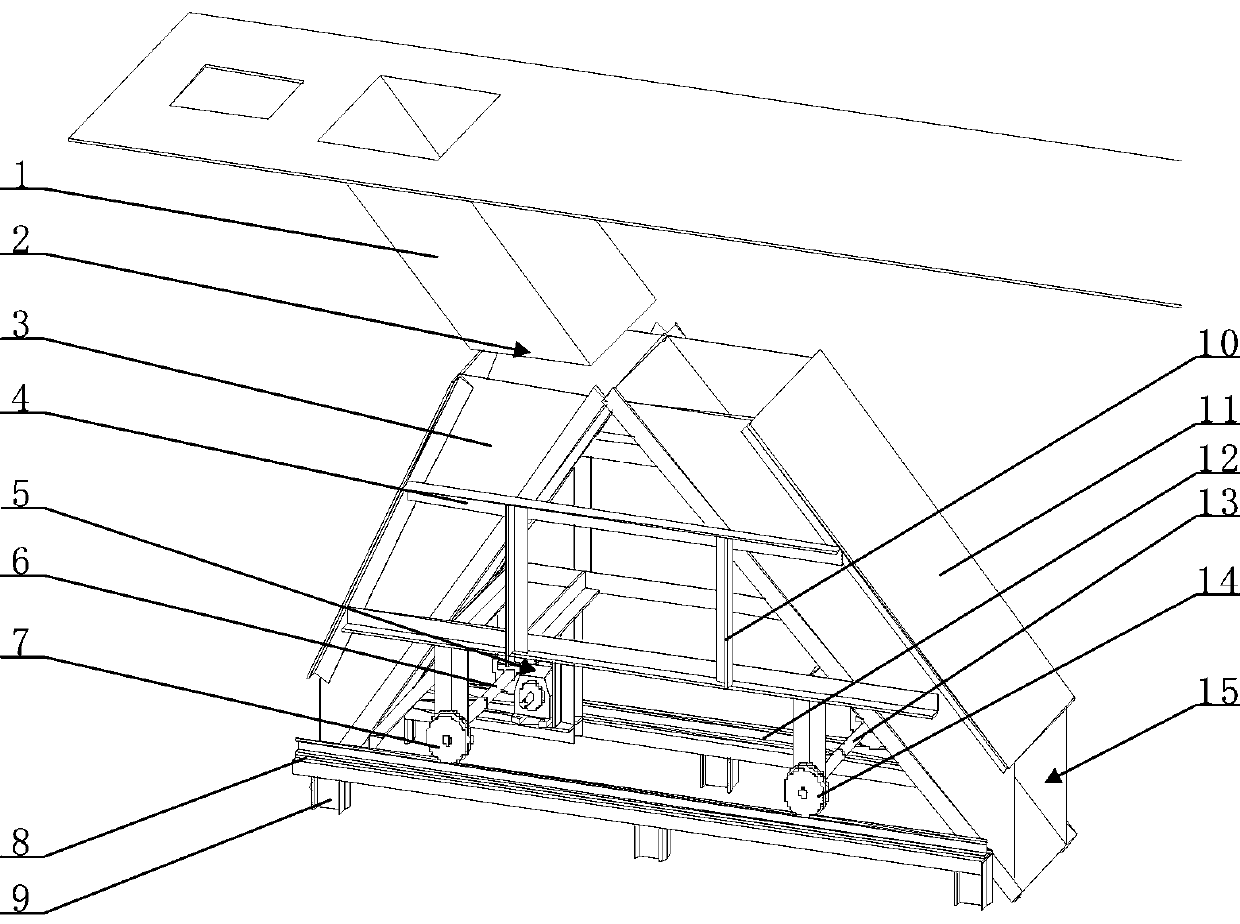

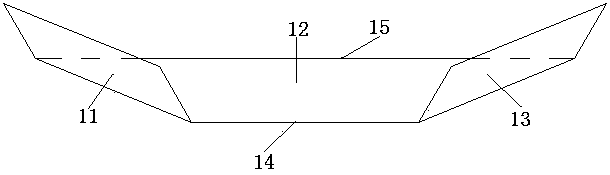

Method for backfilling separately-recovered and sub-transported gangues of underground dirt band coal layer and complete equipment

InactiveCN103114853AChange the conveying directionMitigation Assisted LiftingUnderground miningSurface miningEngineeringCoal

The invention discloses a method for backfilling separately-recovered and sub-transported gangues of an underground dirt band coal layer and complete equipment. The device comprises a front part scraper plate conveyor, wherein an output end of the front part scraper plate conveyor is provided with an external transportation reversed loader and a transportation belt; the transportation belt is provided with a reversing door; a far end reversed loader is arranged relatively to the reversing door of the transportation belt in a loading manner; a backhaul belt machine is arranged at an output end of the far end reversed loader; an output tail end of the backhaul belt machine is correspondingly provided with a backhaul reversed loader and a rear part conveyor for backfilling; an upper-layer coal layer, middle gangues and a lower-layer coal layer are adopted in sequence and the coal layers are transported to a well by a reversing device; the gangues are backhauled to a goaf, so that the mining rate of the coal layers is improved and the phenomenon of washing is avoided; and meanwhile, the upper and lower coal layers are transported to the well and the middle gangues are transported into an underground goaf so as to effectively avoid the pollution to an environment.

Owner:SHANDONG XINMEI MASCH EQUIP CO LTD

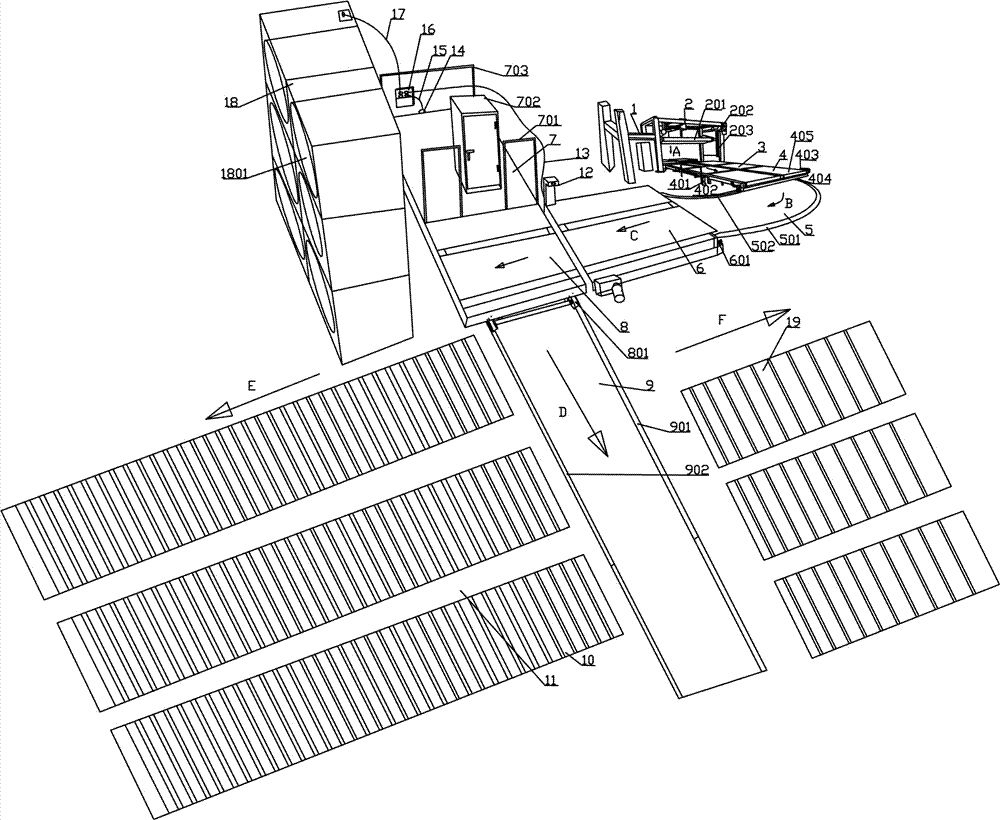

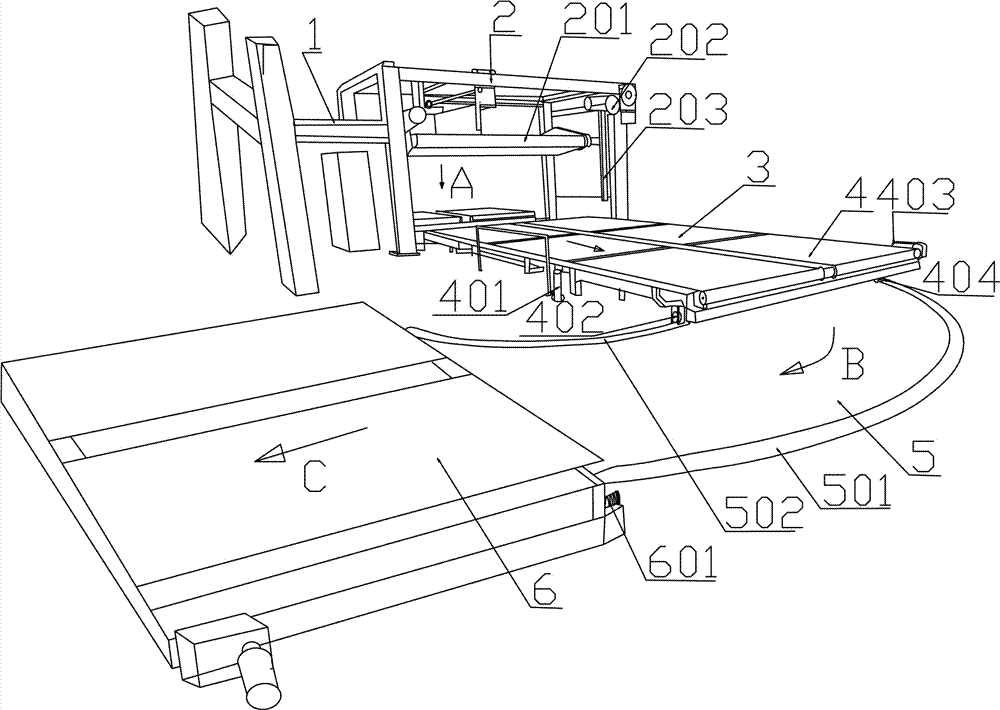

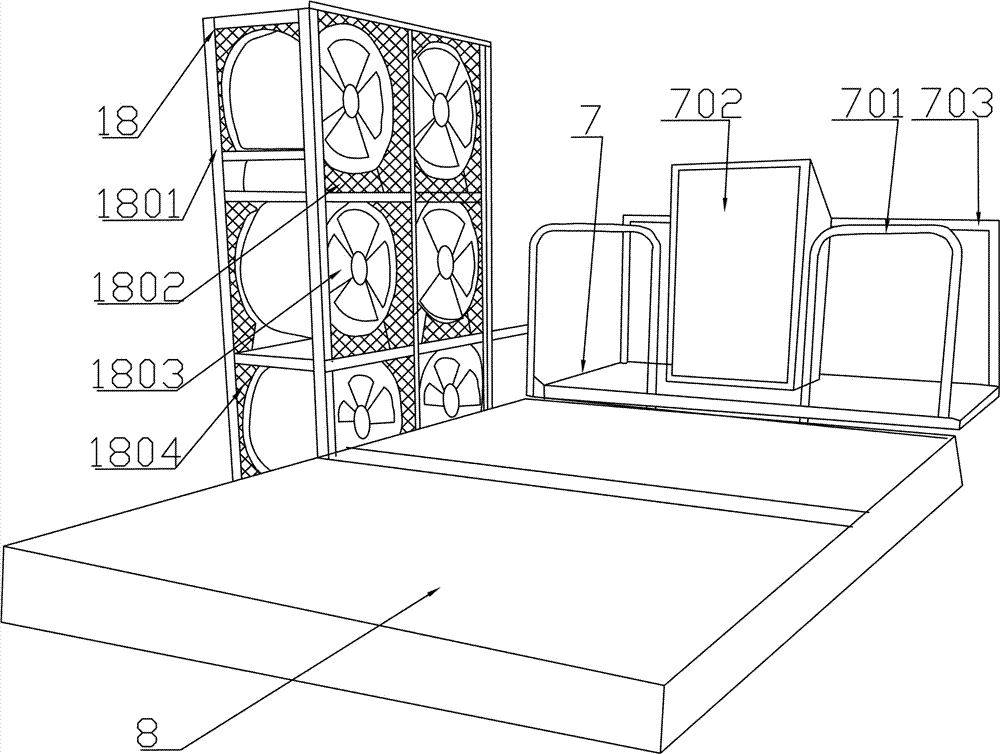

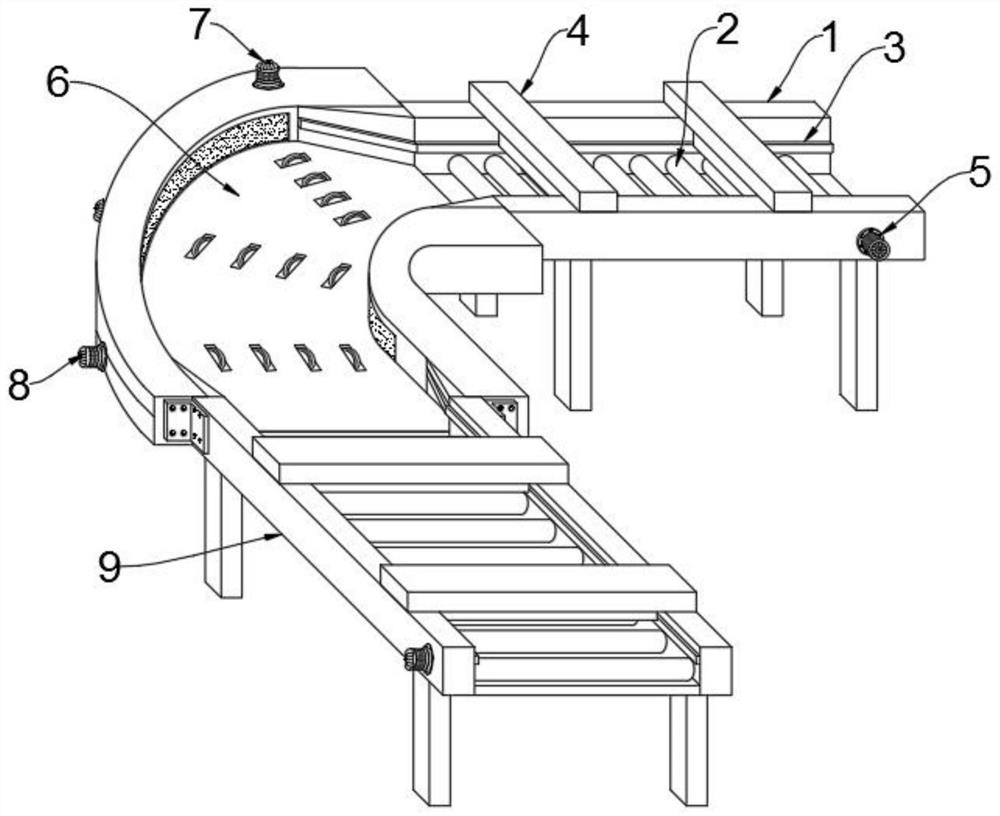

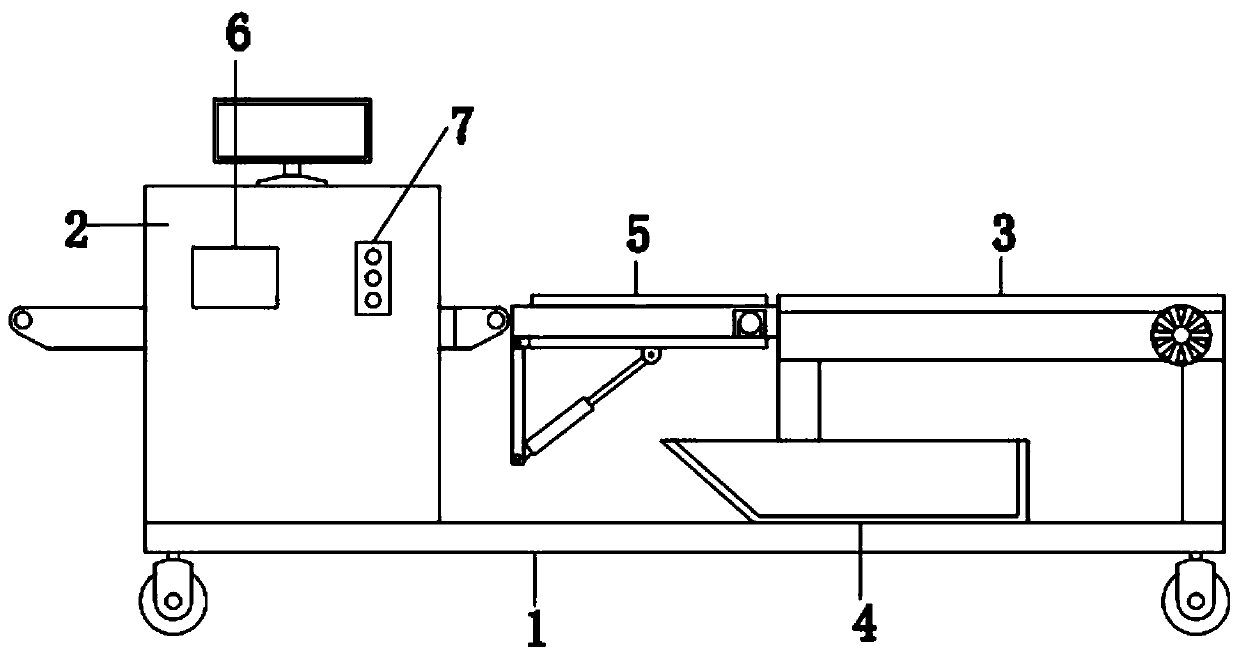

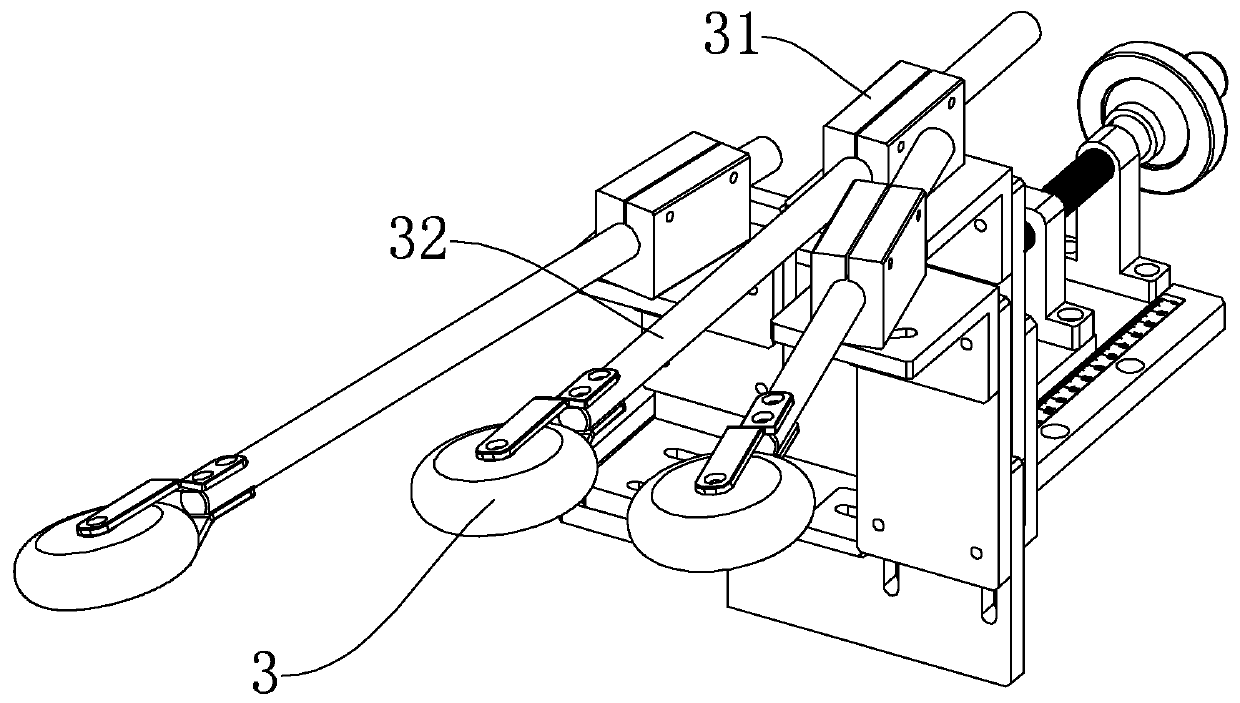

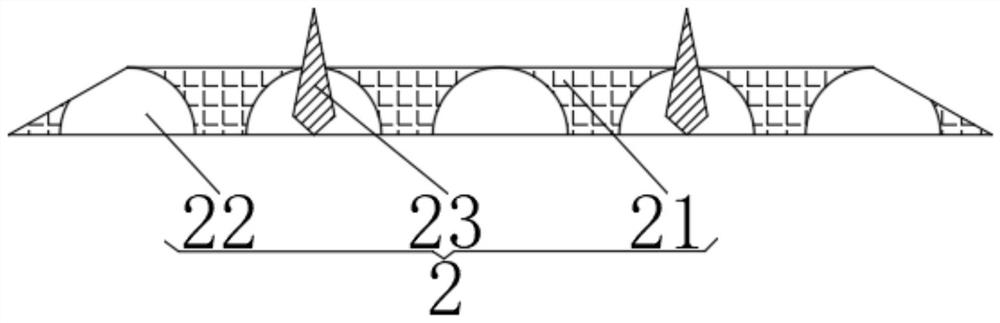

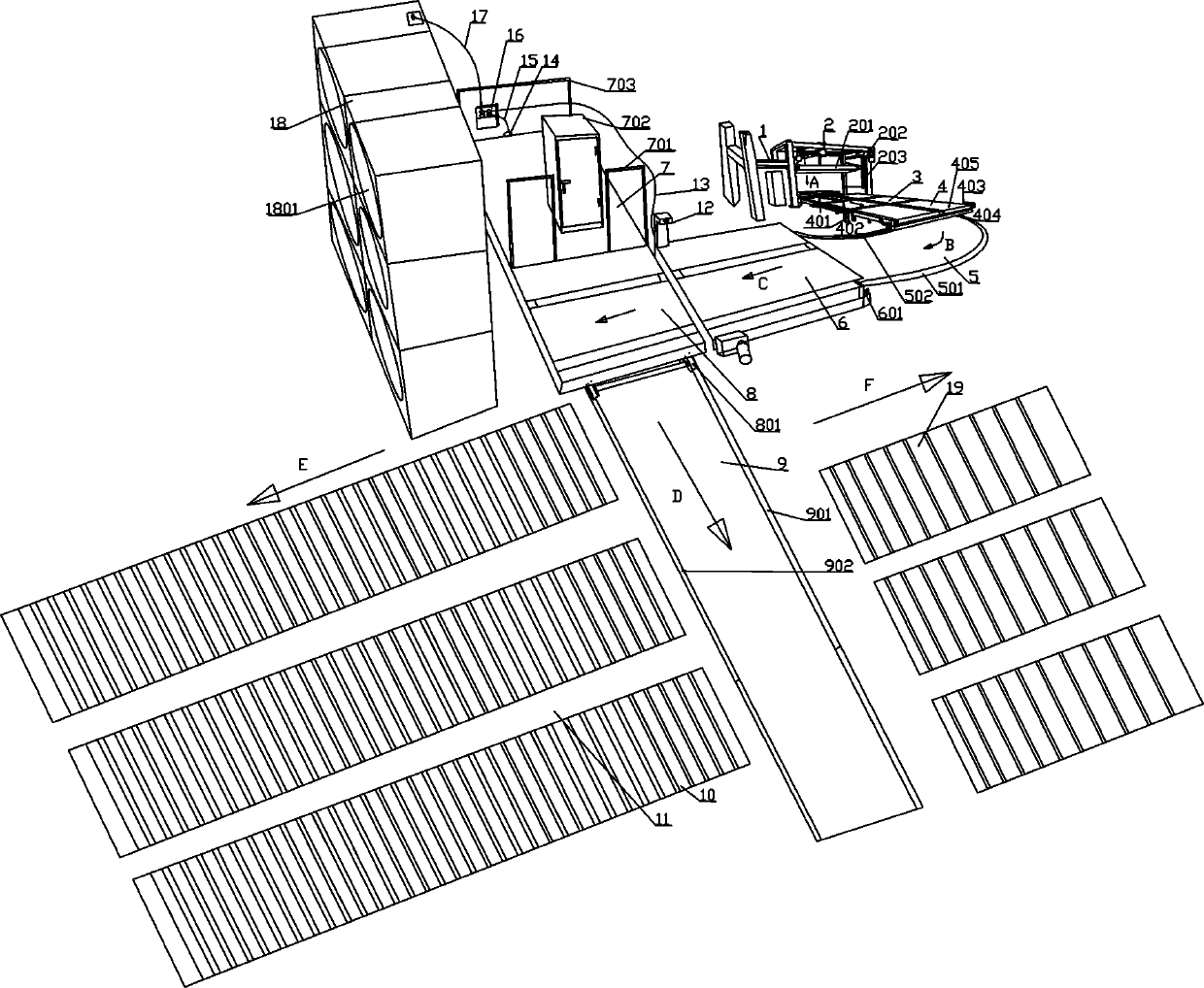

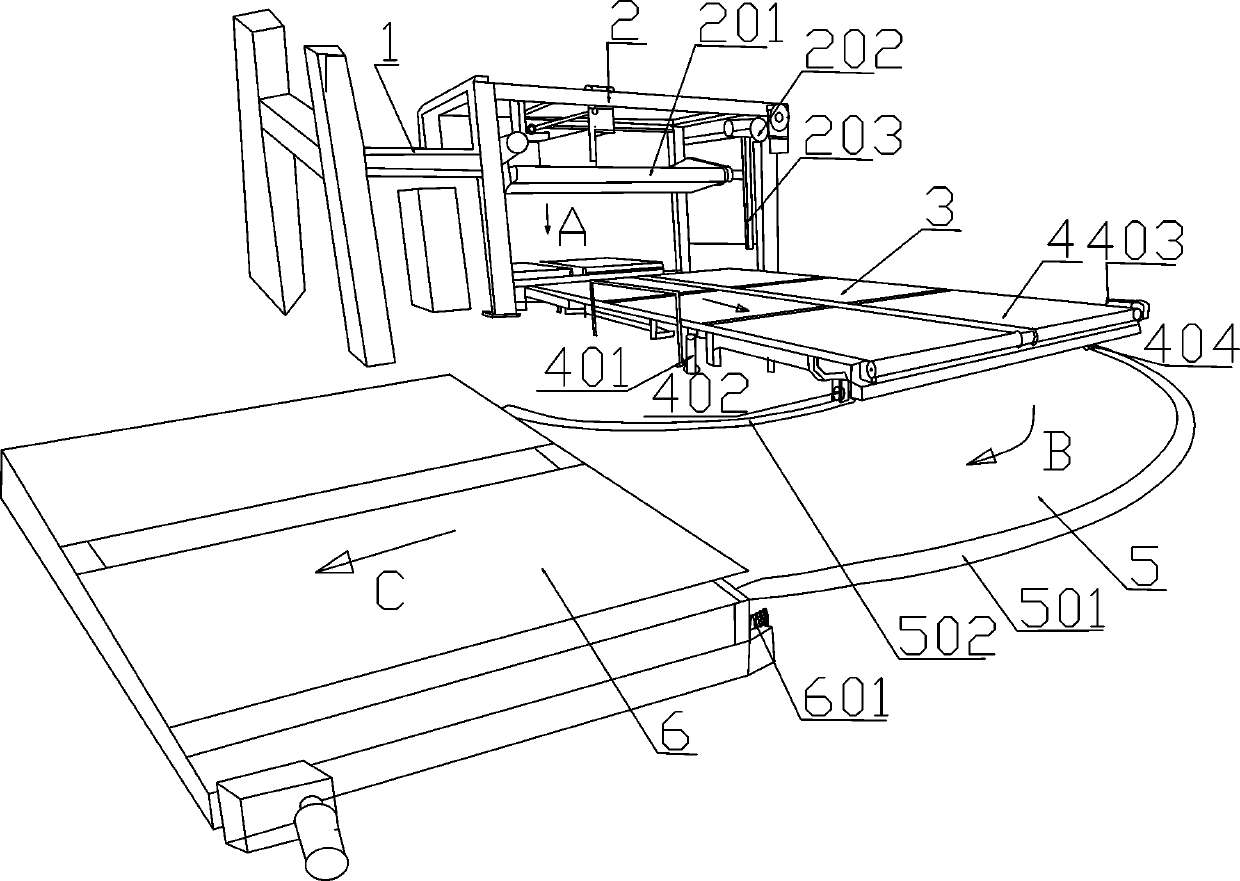

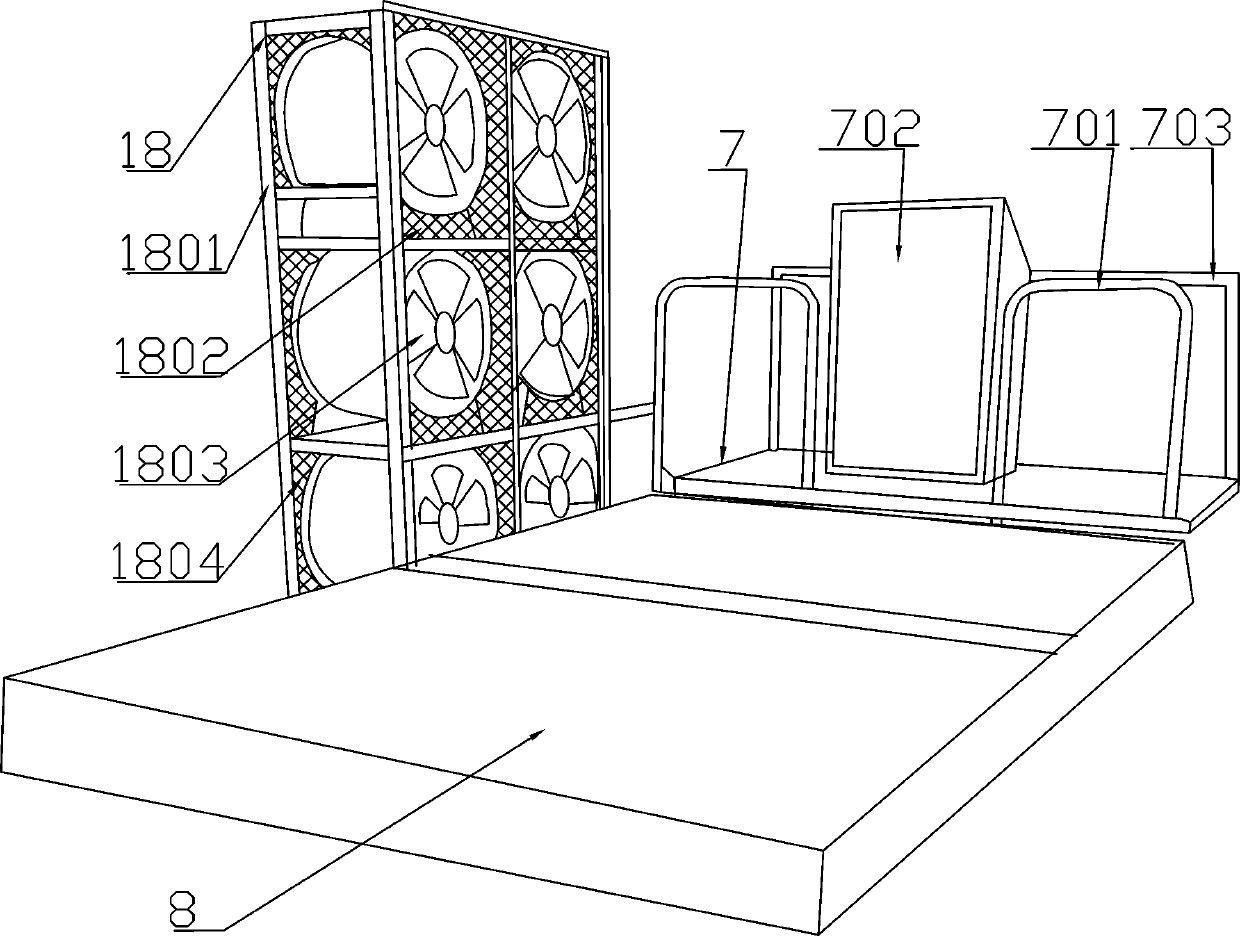

Paperboard high-speed transferring and negative-pressure dehumidifying production line

InactiveCN105438807AEasy to processRealize photoelectric automatic openingConveyor partsProduction lineDrive wheel

The invention relates to a paperboard high-speed transferring and negative-pressure dehumidifying production line. A lifting platform device is connected with a paperboard production line in a butt joint mode. A lifting platform is installed on the lifting platform device. The lifting platform is maintained at the same height with a first conveying device and connected with the first conveying device in a butt joint mode after falling to the ground. A transferring conveying device is connected with the first conveying device in a butt joint mode. A driving wheel is installed at the bottom of the transferring conveying device. The driving wheel is matched with an inner side arc-shaped track and an outer side arc-shaped track which are installed on an arc-shaped transferring area. A second conveying device is connected with the arc-shaped transferring area in a butt joint mode. A third conveying device is connected with the second conveying device in a butt joint mode. A negative-pressure dehumidifying device is installed on the ground of an extension section of the third conveying device. The paperboard high-speed transferring and negative-pressure dehumidifying production line can be connected with a high-speed board cutting machine in a butt joint mode, transfer small cut paperboards, remove glue moisture of gaps of corrugated paper through negative pressure and convey the cut paperboards to multiple later-stage work procedures to complete the high-speed transferring conveying of the whole paperboards.

Owner:YICHANG JINHAI COLAR PRINT CO LTD

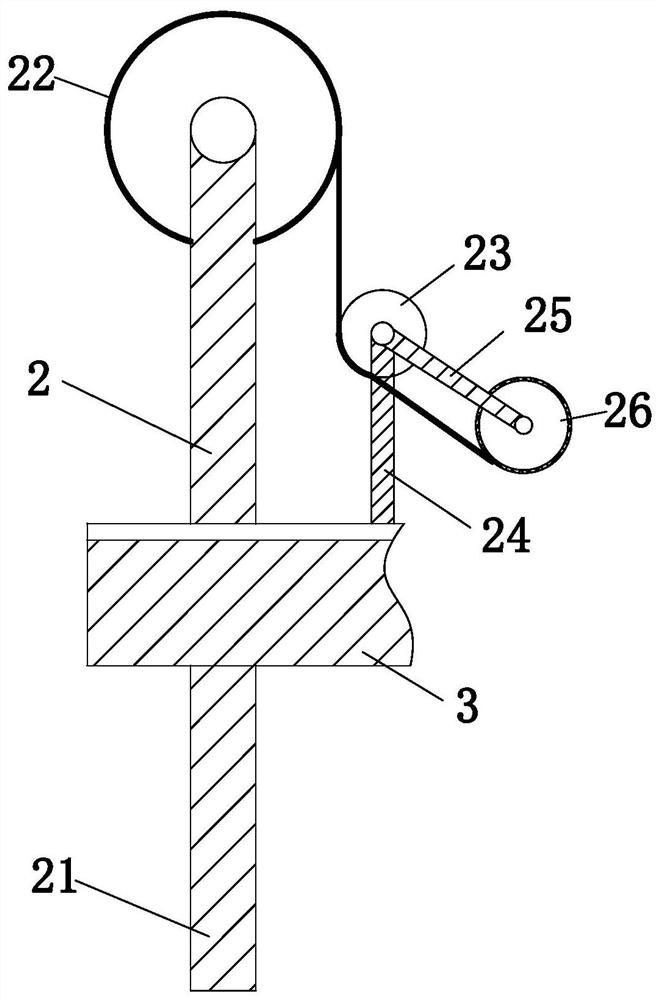

Direction changing type yarn textile working guide tensioning device and method

The invention relates to a direction changing type yarn textile working guide tensioning device and method. A bottom plate, direction changing pulley rods, an annular sliding groove, a connecting column, a connecting disc, anti-loosening devices and a rotating disc are included; the bottom plate is provided with the annular sliding groove, the annular sliding groove is connected with the directionchanging pulley rods in a sliding fit manner, the connecting column is installed in the middle portion of the bottom plate, the connecting column is located between the two direction changing pulleyrods, the upper end of the connecting column is provided with the connecting disc, the anti-loosening devices are evenly formed in the connecting disc in the circumferential direction, and the upper end of the connecting disc is provided with the rotating disc. According to the direction changing type yarn textile working guide tensioning device and method, yarns are synchronously supported to beopen through the anti-loosening devices, the winding length of the yarns is changed, and the yarns are wholly in the tightening state; and the conveying direction of the yarns is changed by position adjustment of the two direction changing pulley rods, friction generated when the yarns are subjected to direction-changing conveying, and the abrasion degree of the yarns is reduced.

Owner:福建石狮晨光化纤染织有限公司

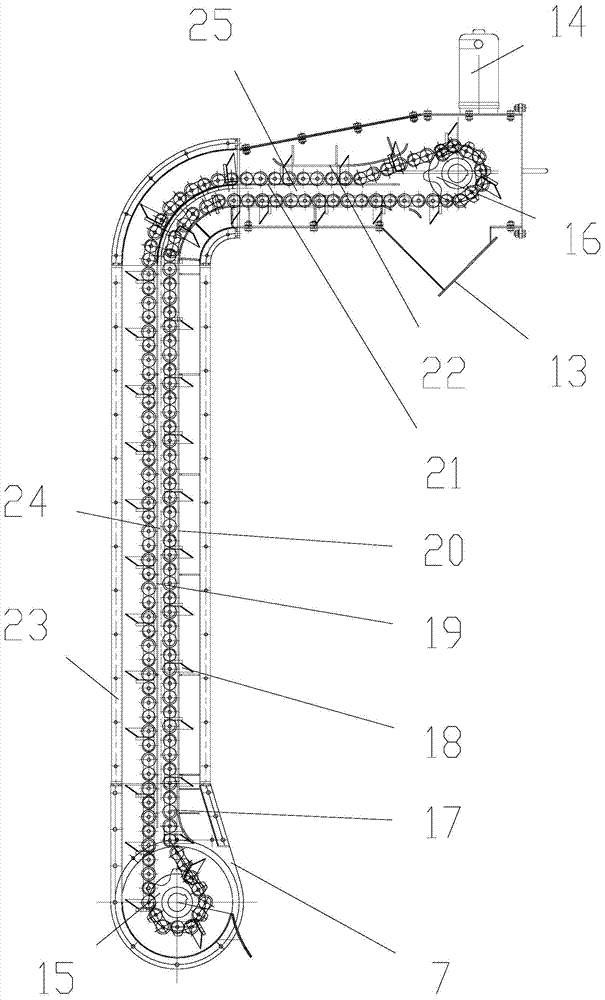

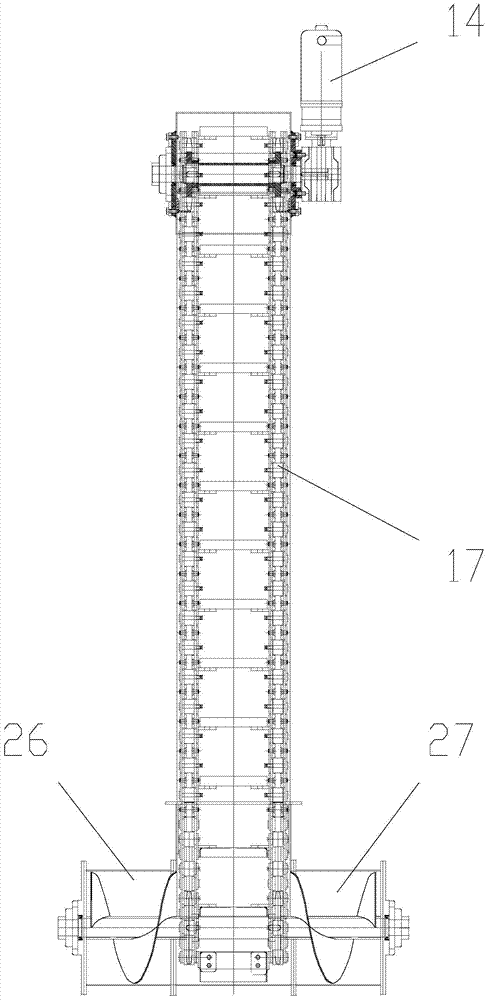

Curve chain type conveying mechanism

InactiveCN104495224AChange the conveying directionChange directionConveyorsConveyor partsSide chainSprocket

The invention provides a curve chain type conveying mechanism, which is applied to granular material transportation needing to change the conveying direction. The curve chain type conveying mechanism comprises a box, at least one pair of chain wheels, a chain, a scraper bucket and a power source, wherein a feeding hole and a discharging hole are only formed in the two ends of the box; the chain wheels are rotationally arranged in the feeding hole and the discharging hole of the box; the chain is arranged on the chain wheels; the scraper bucket is rigidly connected to the outer side of the chain; the power source is arranged on the box, and is used for supplying power to the curve chain type conveying mechanism; a segment of the box is arranged vertically, thereby forming a vertical lifting segment of the curve chain type conveying mechanism; the other segment of the box extends backwards after being bent smoothly, thereby forming a reversing transportation segment of the curve chain type conveying mechanism; in the vertical lifting segment and the reversing transportation segment, a return guide plate which is bent smoothly is arranged on the inner side of the inner side chain and is fixedly connected with the box; the inner side of the outer side chain is provided with a separating plate which is bent smoothly and is fixedly connected with the box; a part, which is positioned on the horizontal transportation segment, of the separating plate is a horizontal scraper; in the horizontal transportation segment, the outer side chain is further provided with a chain pressure plate of which the two ends tilt upwards and which is fixedly connected with the box.

Owner:LIYANG CITY ZHENGXIANG PRECISION MACHINERY

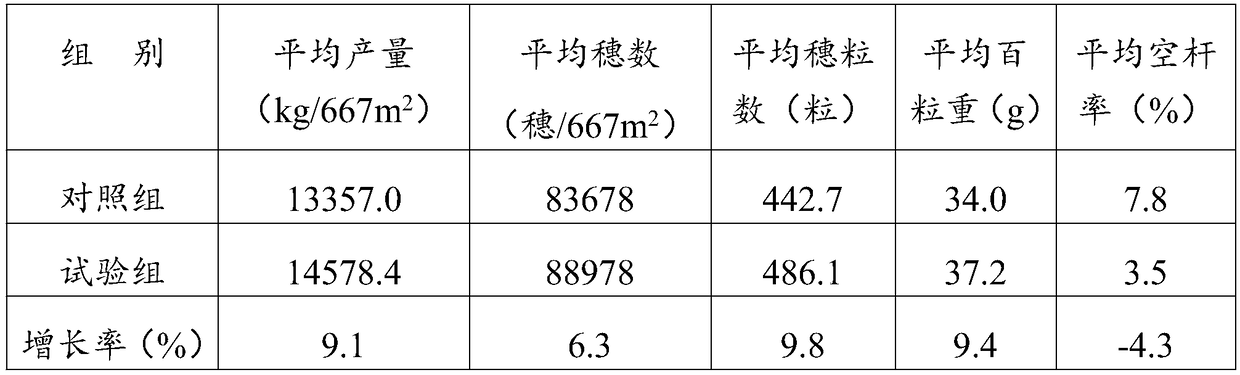

Corn cross pollination method

InactiveCN109380110AChange the conveying directionPromote early maturationPlant genotype modificationGrain weightEconomic benefits

The invention discloses a corn cross pollination method. The method comprises the following steps: detasseling a corn female parent, and cutting 2-7cm of top ends of female spikes before silks reel off from the female spikes; correspondingly bagging the female spikes of the female parent and the male spikes of a male parent; cutting the male spikes of the male parent of the corn 12-24h before pollen dispersing of the male spikes of the male parent of the corn, collecting pollen from the male spikes after pollen dispersing, drying and freezing the pollen; unfreezing the frozen pollen before pollination, and then performing the first and second hand corn cross pollination based on different silk reeling off degrees of the male parent of the corn. With the adoption of the pollination method,the problem that the flowering time is not met due to the weather can be prevented; the pollination demand of the female parent of the corn can be met; a pollen increasing agent and pure corn pollen are mixed and sprayed for pollination, so that the quantity of used pure pollen is decreased, and as a result, the quantity of planted cross corn male parents can be decreased; the corn product obtained with the pollination method is high in maturing rate; the corn seeds are high in hundred-grain weight; the stem empty rate is low; and the improvements on economic benefits of corn planting are facilitated.

Owner:GUANGXI ZHUANG AUTONOMOUS REGION ACAD OF AGRI SCI

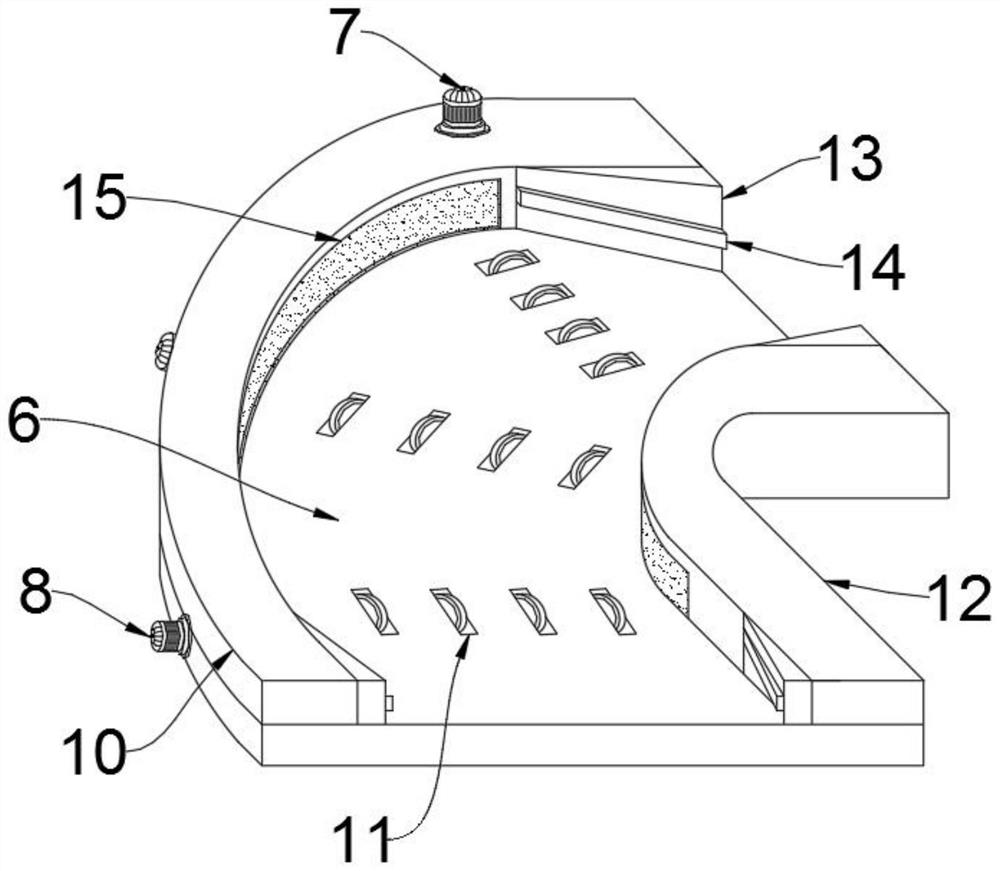

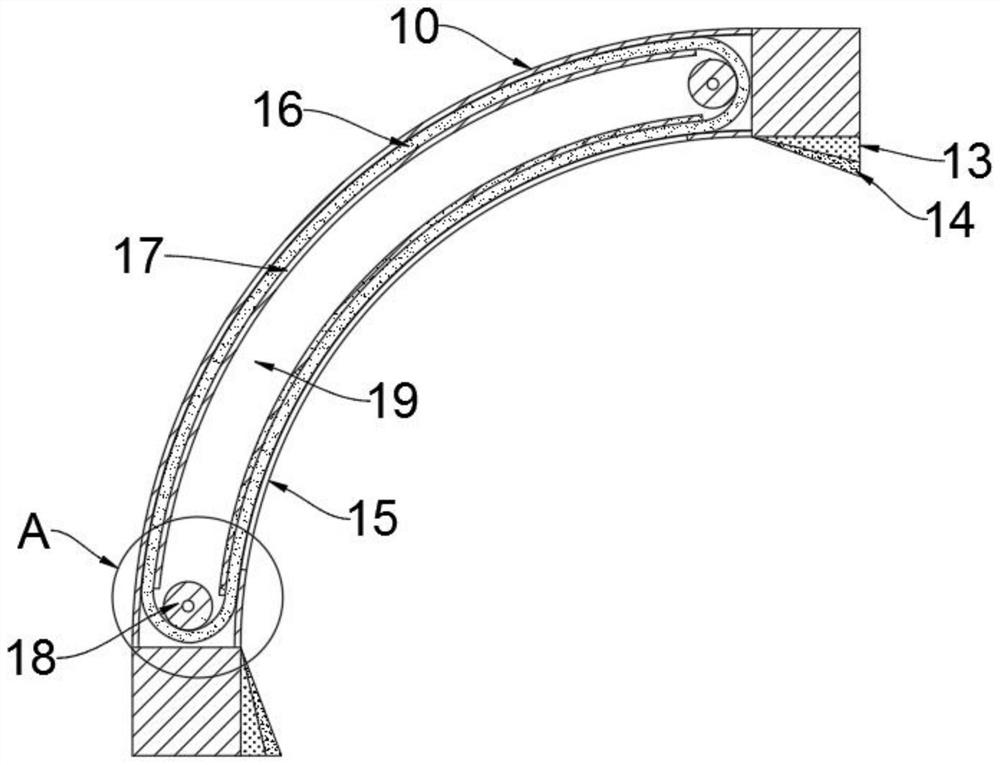

Conveying device for glass production and working method of conveying device

PendingCN113443353AImprove steering abilityImprove stabilityConveyorsCharge manipulationEngineeringMechanical engineering

The invention discloses a conveying device for glass production and a working method of the conveying device, relates to the technical field of conveying devices, and aims to solve the problems that in the prior art, when glass is turned and conveyed, the glass often collides with a side frame, so that corners of the glass are damaged, and the quality of the glass is influenced. A steering table is installed on one side of a first conveying frame, the first conveying frame is fixedly connected with a steering table through bolts, a second conveying frame is installed in front of the steering table, the steering table is fixedly connected with the second conveying frame through bolts, a protection box is installed above the steering table, and the steering table is fixedly connected with the protection box through bolts. An arc-shaped box is arranged on one side of the protection box along the upper portion of the steering table, the arc-shaped box is fixedly connected with the steering table through bolts, a guide inner cavity is formed in the protection box, and a guide opening is formed in the protection box along one side of the guide inner cavity.

Owner:江苏佳成特种玻璃制造有限公司

Printing and dyeing temperature adjusting device and method for dope-dyed copper ion fabric

InactiveCN111778669AAvoid damageAchieve temperatureTextile treatment machine arrangementsFilter paperChemistry

The invention provides a printing and dyeing temperature adjusting device and a printing and dyeing temperature adjusting method for dope-dyed copper ion fabric, and relates to the field of printing and dyeing, and the printing and dyeing temperature adjusting device for dope-dyed copper ion fabric is connected with a box body. The device comprises a spray head, a tank body and a conveying pipe, and the tank body is transversely arranged at the top of a box. According to the printing and dyeing temperature adjusting device for the dope-dyed copper ion fabric, a filter paper cylinder makes contact with dye fluid according to the heat transfer effect, the temperature of the dye fluid is transferred to water in the cylinder, and the water encounters heat to generate water vapor. A baffle is controlled to ascend or descend according to the amount of water vapor, so that a first channel and a second channel are controlled to be unblocked or blocked, and the conveying direction of cooling liquid is changed. Cooling can be conveyed into the water pipe or the spiral pipe under different conditions. And the water pipe and the spiral pipe are matched with each other to cool the dye fluid under two temperature conditions. The temperature adjusting effect on the dye is achieved, so that damage to the fabric due to the fact that dye fluid is sprayed on the fabric at too high temperature isavoided.

Owner:ZHEJIANG GANGLONG WEAVING TECH

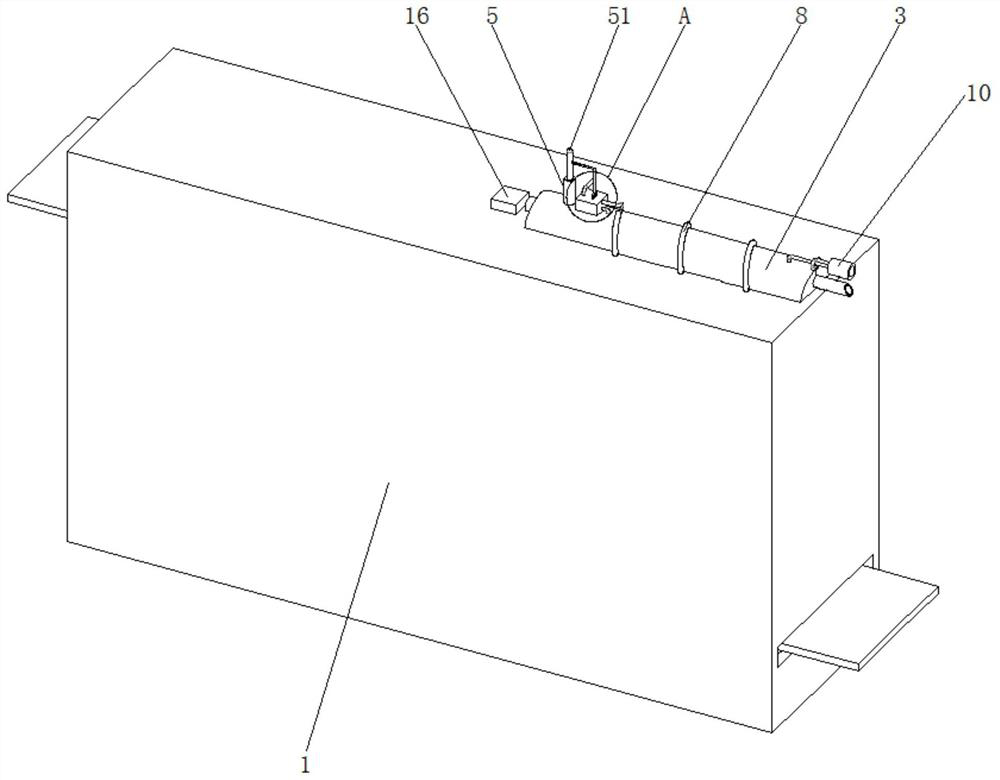

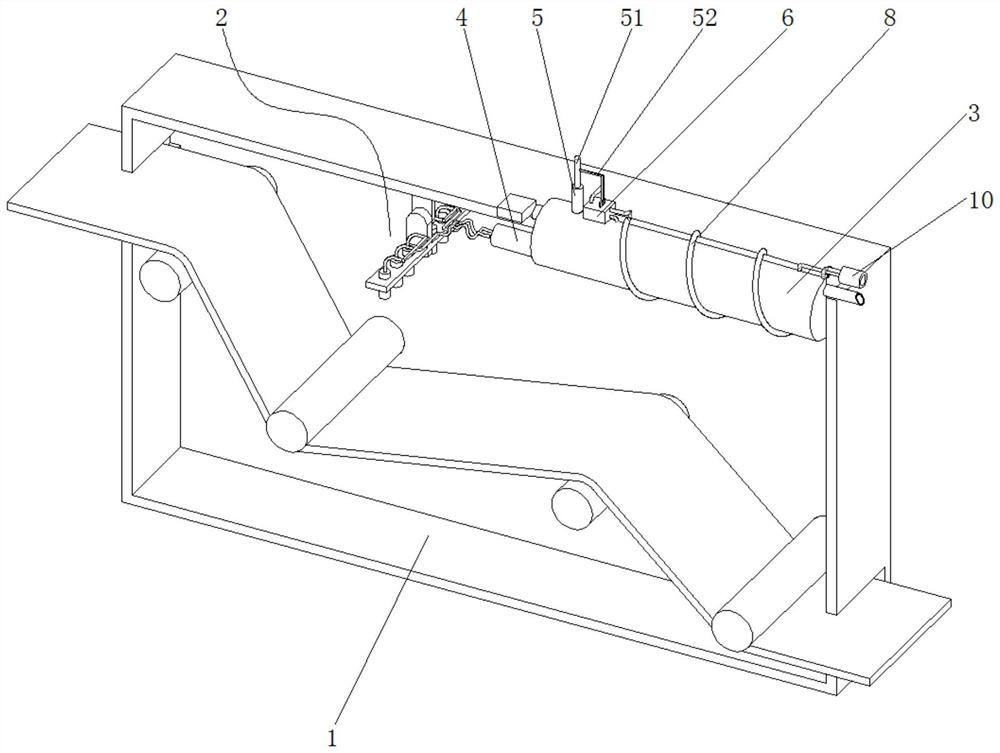

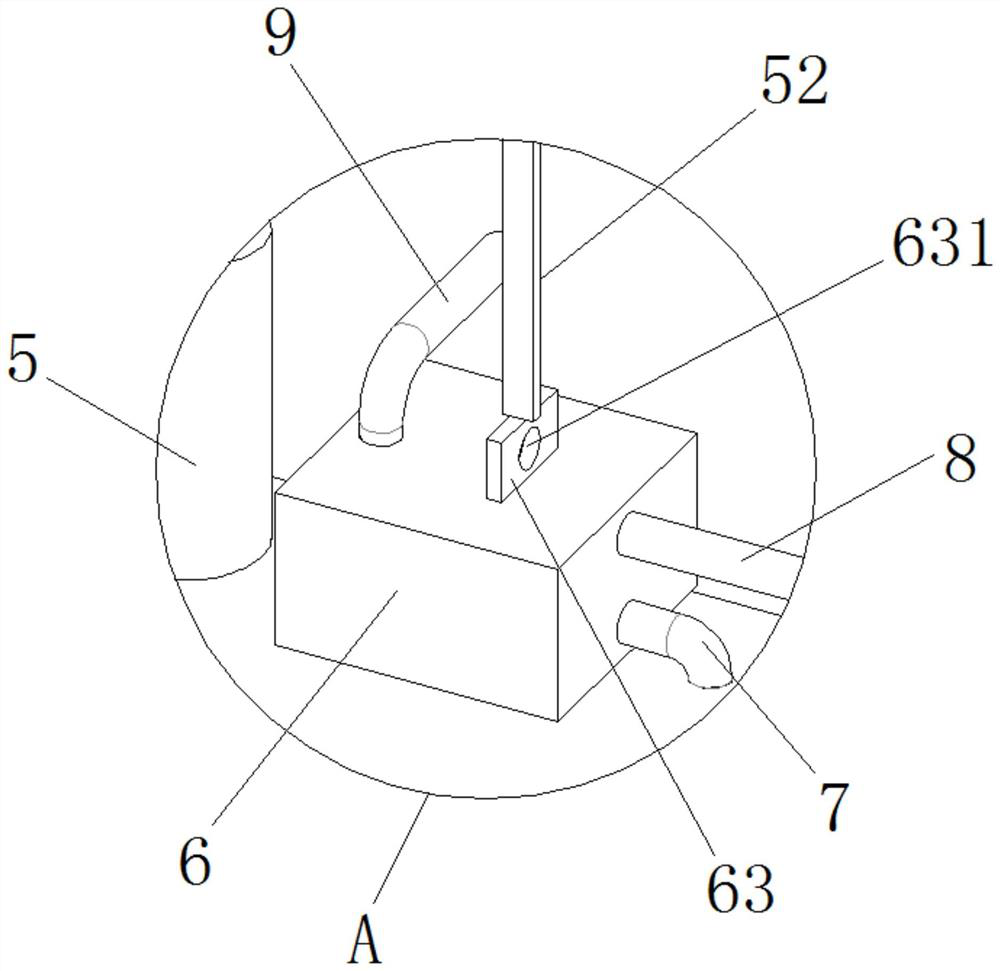

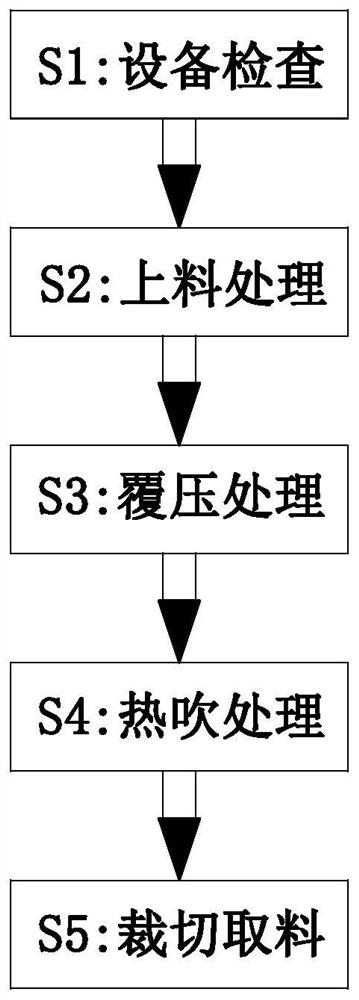

Manufacturing and processing method of heat-preservation, energy-saving and decoration integrated plates

InactiveCN112318865AChange the conveying directionImprove efficiencyCovering/liningsFlat articlesHeat conservationPlastic film

The invention relates to a manufacturing and processing method of heat-preservation, energy-saving and decoration integrated plates. Manufacturing and processing equipment of the heat-preservation, energy-saving and decoration integrated plates comprises a bottom plate, an unwinding device, a conveying device, a film covering device, a smoothing mechanism and hot blowing devices, wherein the unwinding device is arranged at the left end of the bottom plate, the conveying device is placed on the right side of the unwinding device, the film covering device is installed at the position, close to the left end, of the conveying device, the smoothing mechanism is arranged on the right side of the film covering device, and the hot blowing devices are symmetrically arranged on the left side and theright side of the smoothing mechanism. The method can solve the following defects possibly existing in an existing film covering mode of the heat-preservation, energy-saving and decoration integratedplates: a, plastic films are manually laid on the heat-preservation, energy-saving and decoration integrated plates and are manually flattened, the flattening effect is difficult to judge, and the required time is long, so that the film covering efficiency is low, and the film covering effect is poor; and b, when the number of the heat preservation, energy-saving and decoration integrated platesis large, much labor force is input in the film covering process, consumed time is long, efficiency is reduced, and benefits of enterprises are affected.

Owner:深圳正宇机电科技有限公司

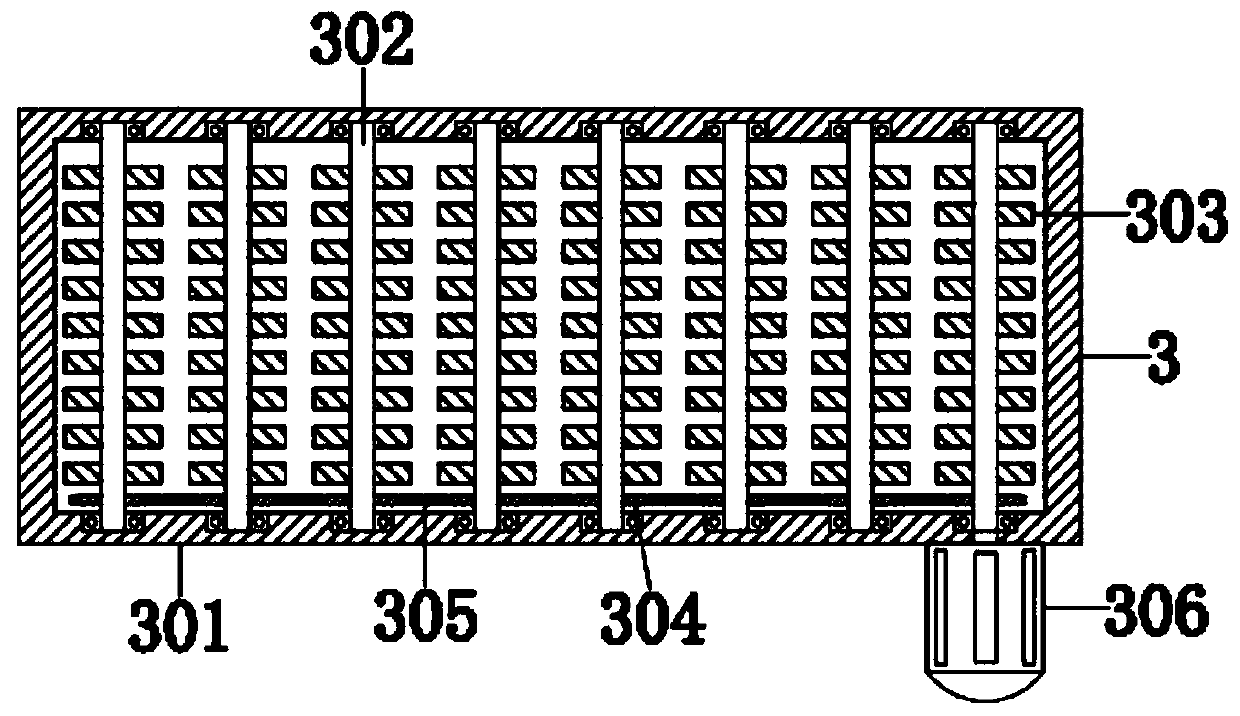

Logistics conveying belt with cargo security check function

InactiveCN110902256AChange the conveying directionHigh degree of automationConveyorsControl devices for conveyorsLogistics managementSwitch box

The invention discloses a logistics conveying belt with a cargo security check function. The logistics conveying belt with the cargo security check function comprises a base, a security check machineand a conveying mechanism are mounted on the left side and the right side of the top end of the base respectively, the top end of the left side and the top end of the right side of the front face of the security check machine are connected with a PLC and a switch box through screws respectively, moreover, the PLC is electrically connected with the switch box, the position, below the conveying mechanism, of the right side of the top end of the base is provided with a material box, the top end of the left side of the conveying mechanism is connected with a turnover mechanism through a screw, theconveying mechanism comprises a frame, the front side and the rear side of an inner cavity of the frame are rotatably connected with first rotating shafts through bearings from left to right, the outer walls of the first rotating shafts are provided with first rollers from front to back, and the front sides of the outer walls of the first rotating shafts are in key connection with first sprocketwheels. According to the logistics conveying belt with the cargo security check function, automatic screening and extraction can be achieved for unqualified cargoes, the automation degree is high, time and labor are saved, and the storage or carrying efficiency is improved.

Owner:CIXI TAIPINGNIAO LOGISTICS

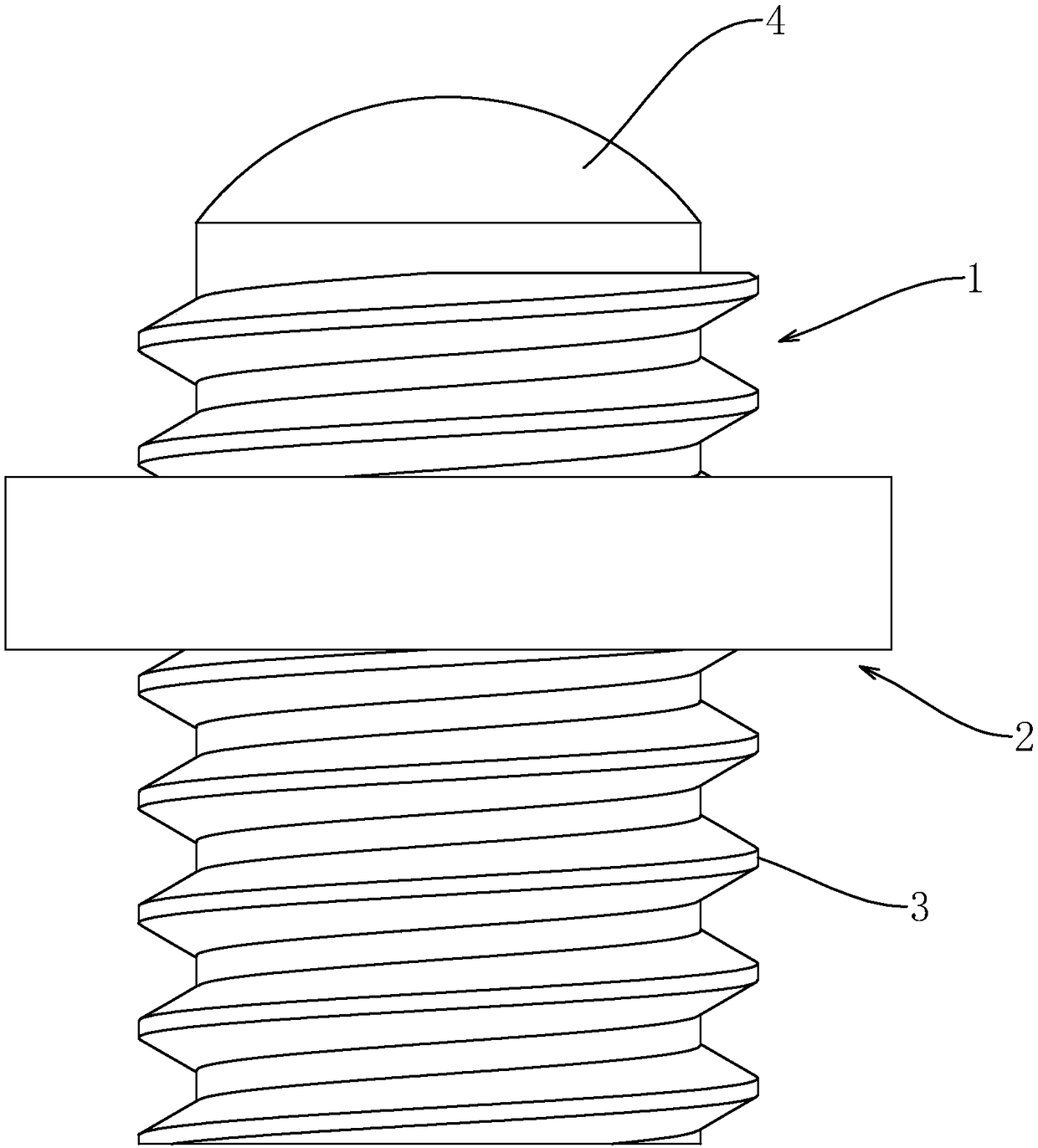

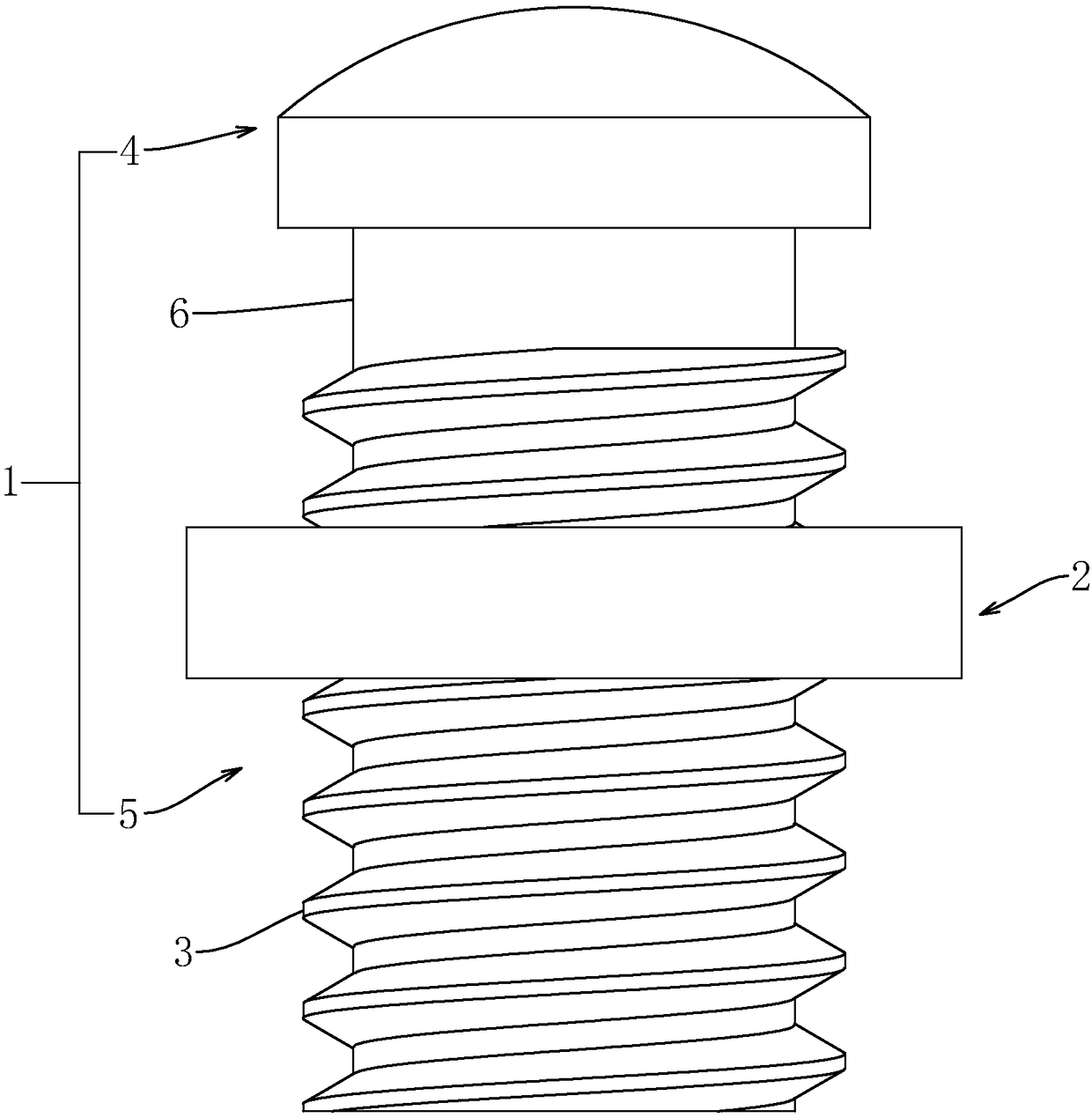

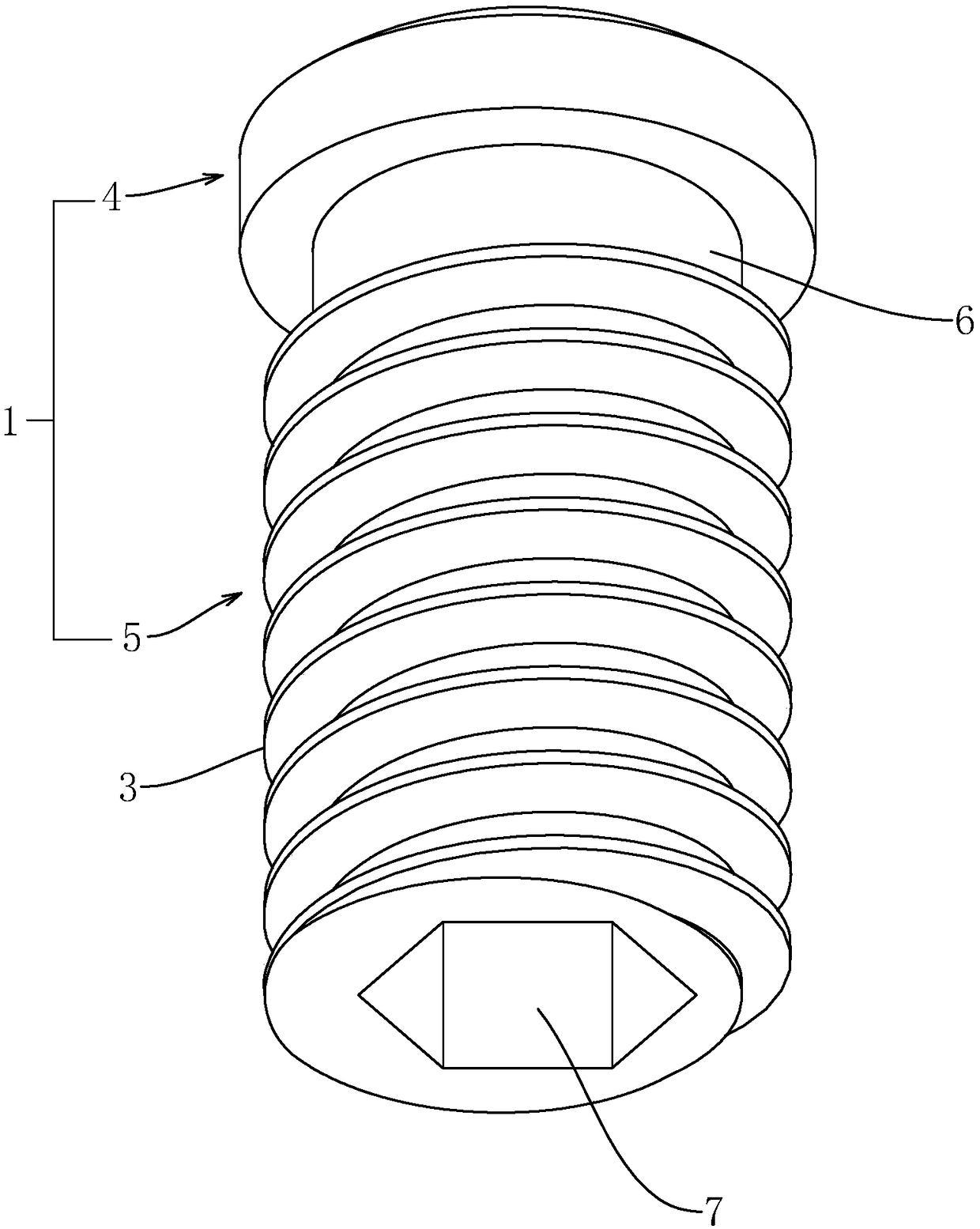

Adjusting screw assembly and manufacturing process thereof

ActiveCN108506312ANot easy to break awaySmall curvature bendingPinsMetal-working feeding devicesMaximum diameterEngineering

The invention discloses an adjusting screw assembly. The adjusting screw assembly has the advantages that a screw part and a nut are not easy to separate. The adjusting screw assembly comprises the screw part and the nut which are in threaded connection; and the screw part comprises a rod part and an arc surface end head connected to one end of the rod part, the outer surface of the rod part is provided with external threads, and the maximum diameter, perpendicular to the shaft axis of the rod part, of the arc surface end head is larger than the large diameter size of the external threads. Themaximum diameter, perpendicular to the shaft axis of the rod part, of the arc surface end head is arranged to be larger than the large diameter size of the external threads so that the position of the nut can be limited by the arc surface end head when the nut rotates to the end, provided with the arc surface end head, of the screw part, then the nut cannot be separated from the screw part from the end provided with the arc surface end head, therefore, when the screw part and the nut are assembled, only by installing the nut at the position, attaching to the arc surface end head, on the screwpart, the nut cannot be easily separated from the screw part.

Owner:浙江吉达金属有限公司

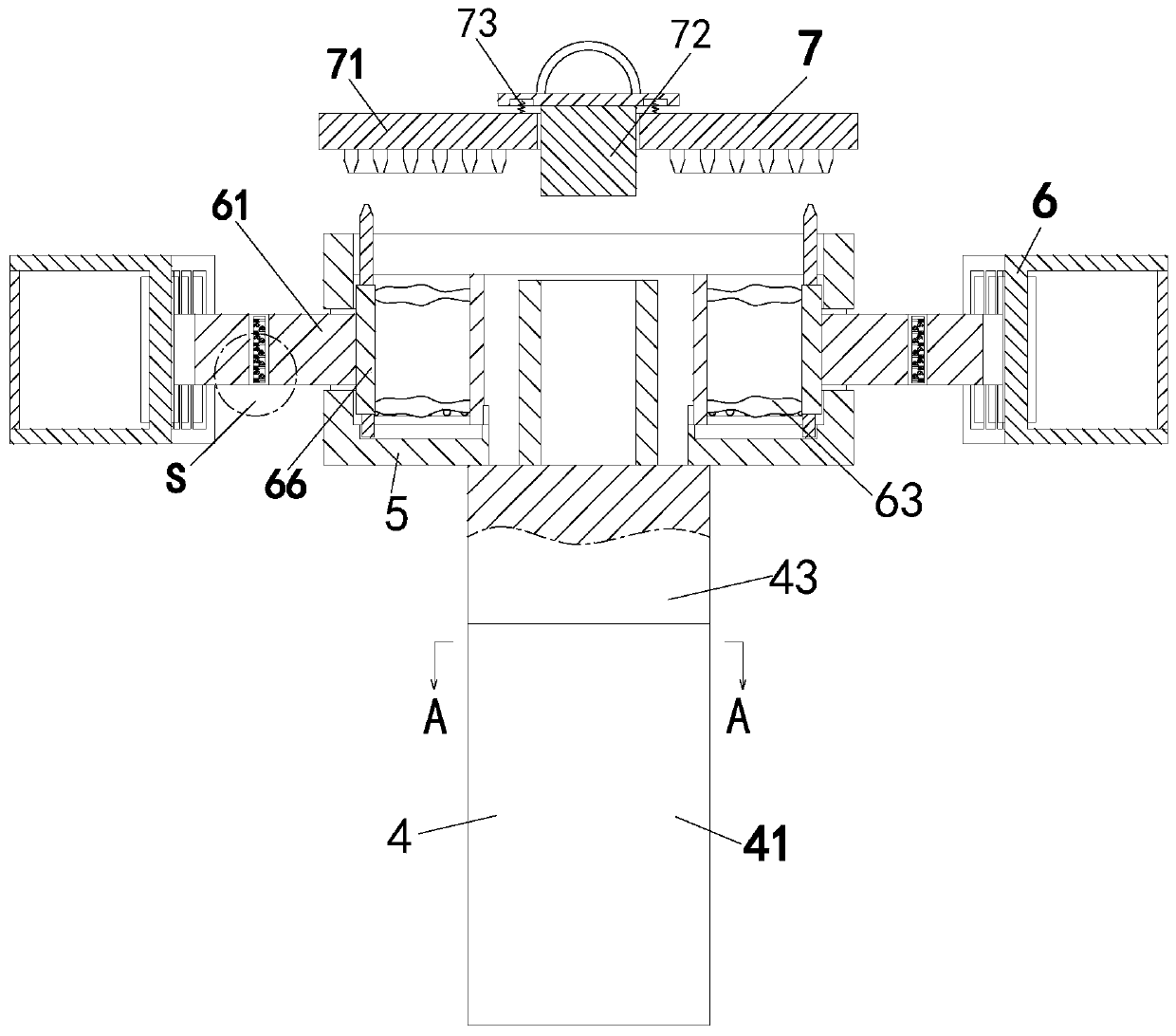

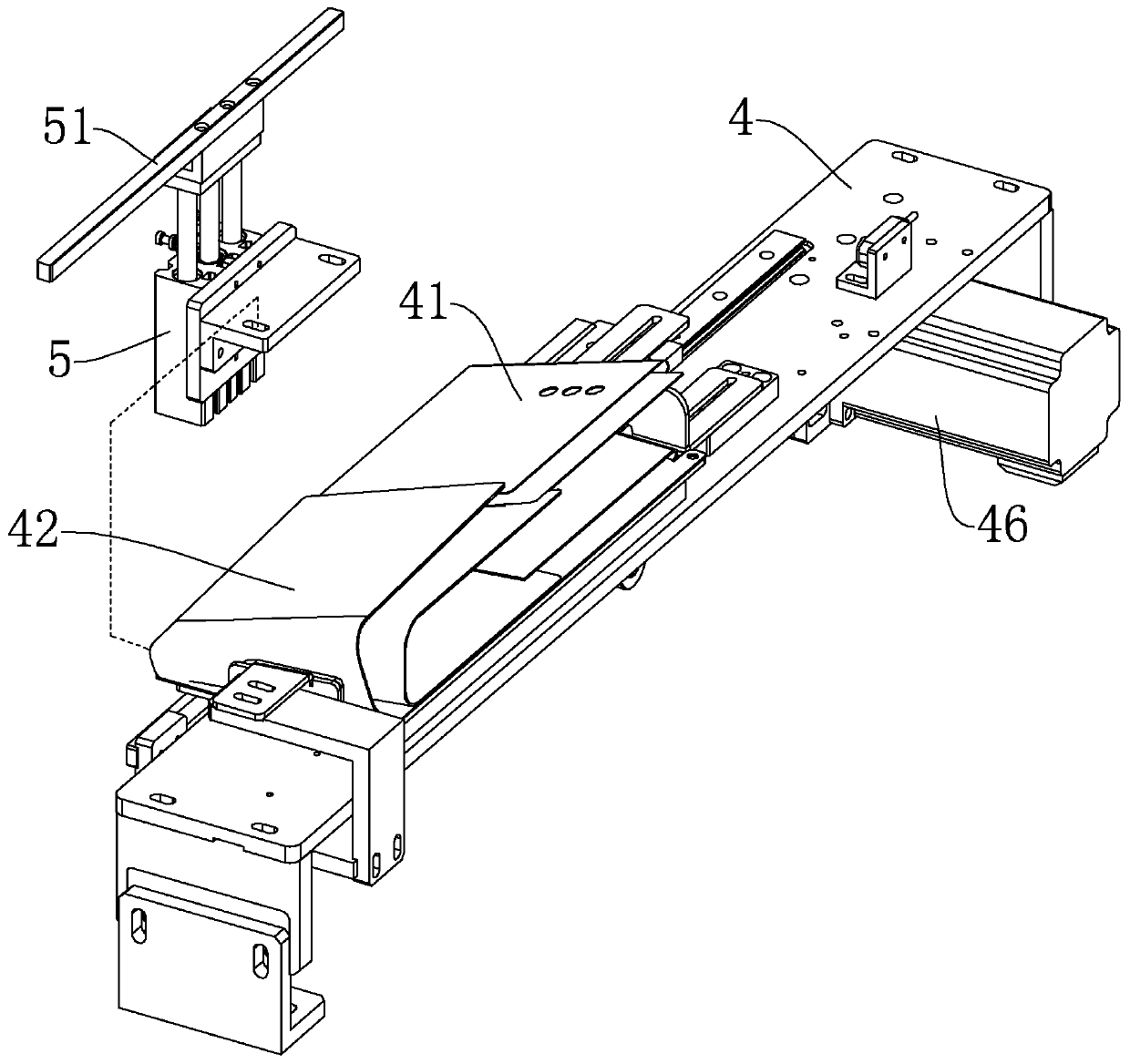

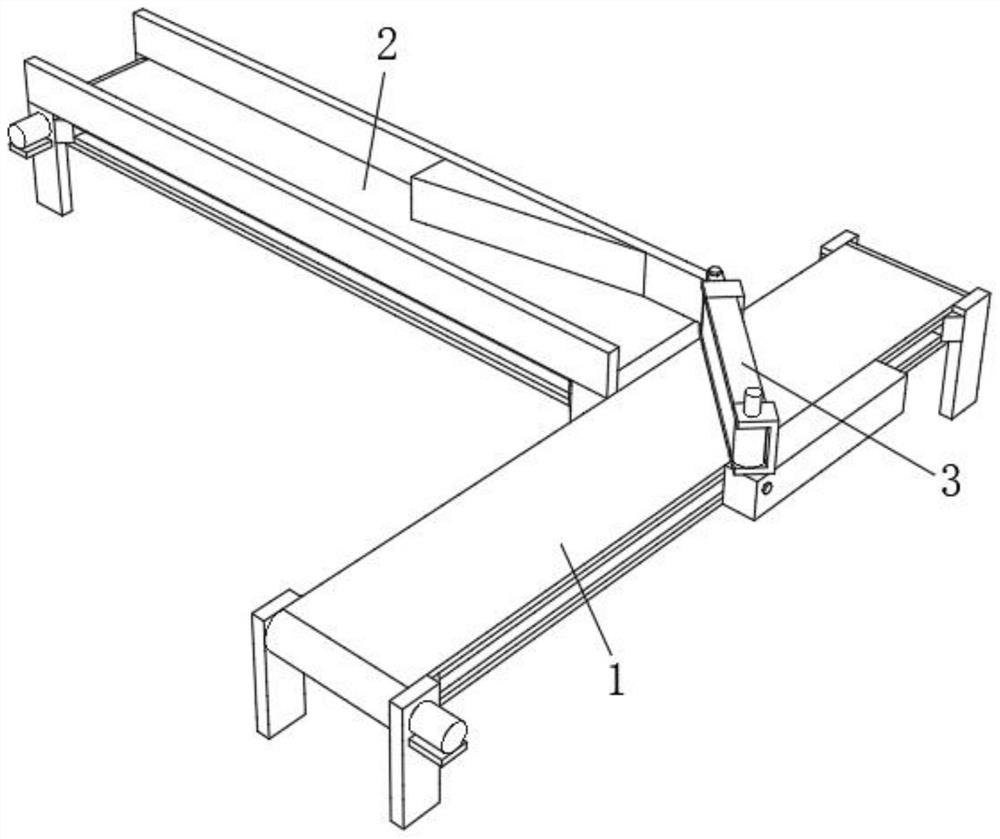

Reversing device of stack conveying mechanism

InactiveCN105059946AChange the conveying directionIncrease productivityStacking articlesConveyor partsEngineeringMechanical engineering

Owner:JIANGSU NEWAMSTAR PACKAGING MACHINERY

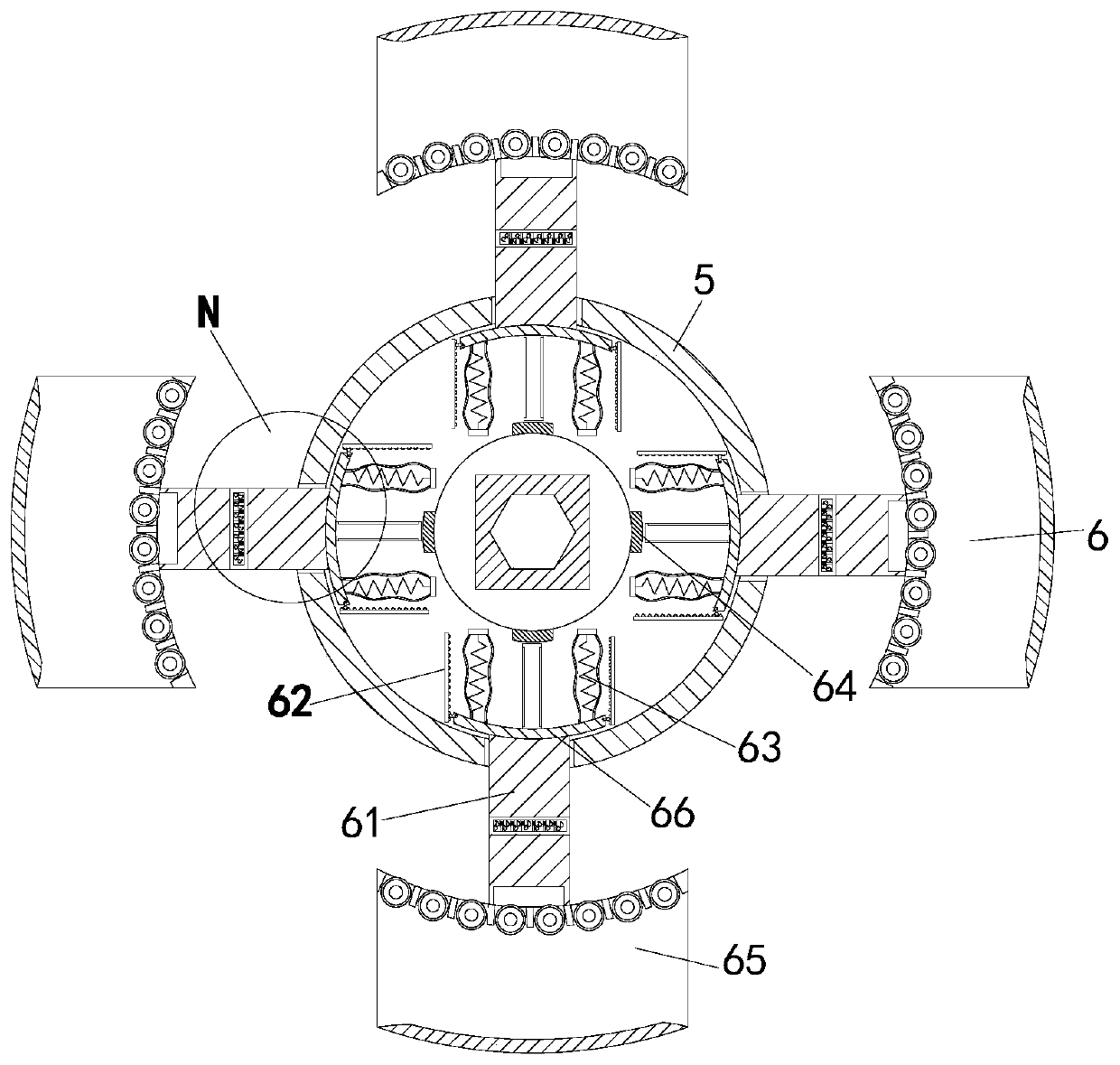

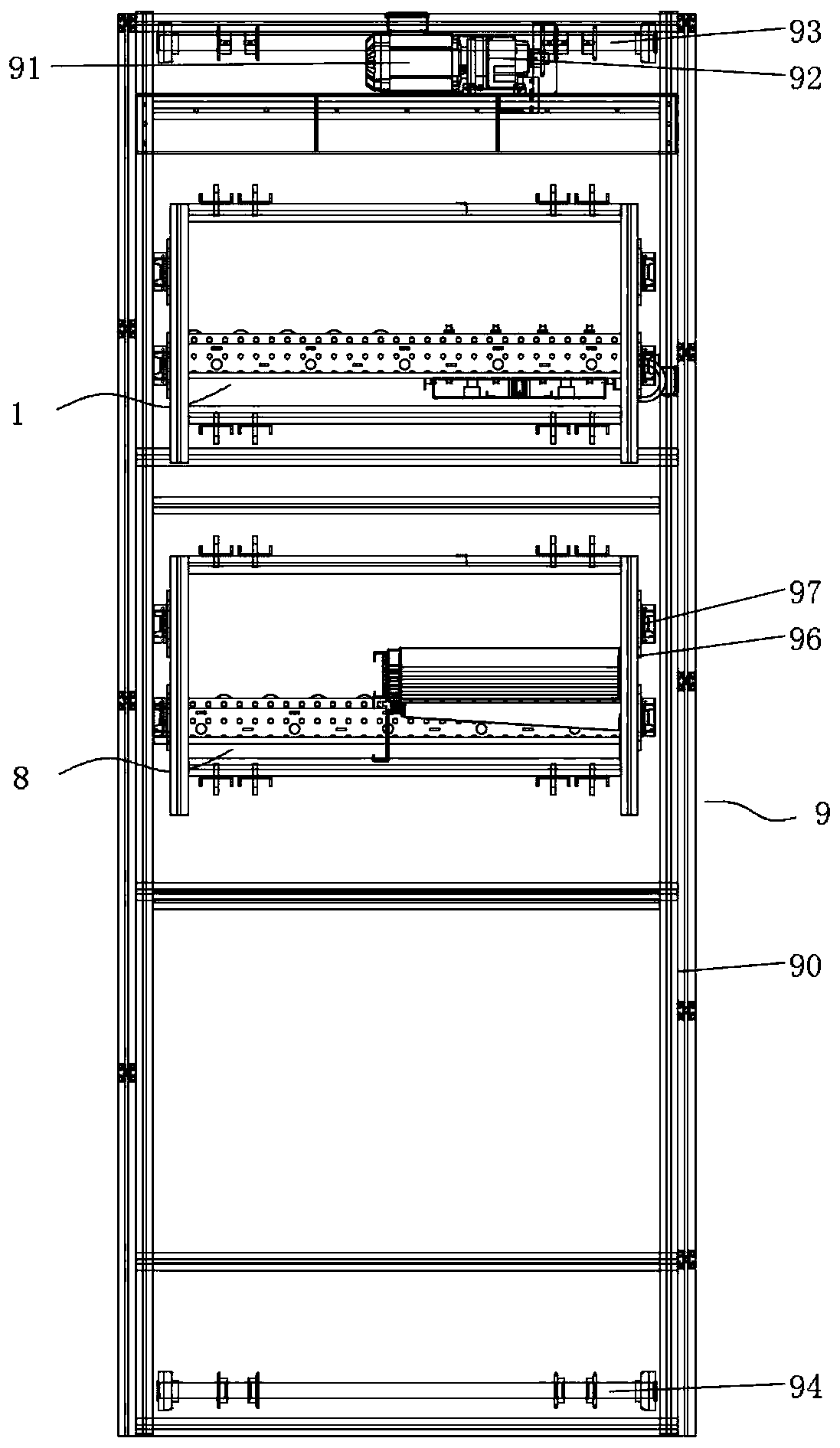

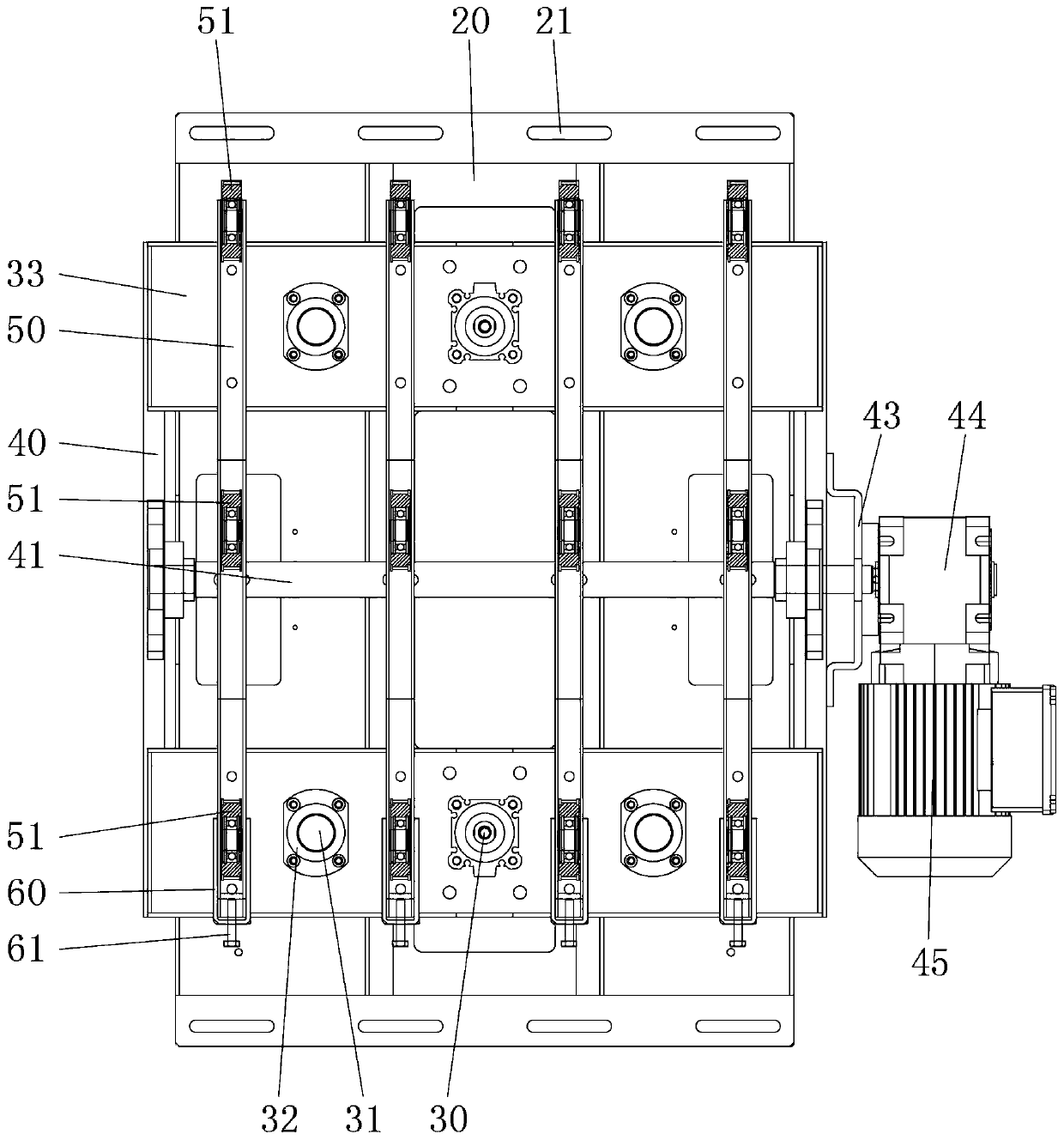

High-speed four-way input and output hoister

PendingCN110116879AFlexible and convenient deliveryChange the conveying directionConveyorsConveyor partsEngineeringTransfer mechanism

The invention discloses a high-speed four-way input and output hoister which comprises a hoisting module, a synchronous belt transferring module and a turning conveying module, wherein the above hoisting module comprises a hoisting rack, a hoisting driving source and at least two hanging frames; the hanging frames are sequentially and slidably arranged on the hoisting rack in the hoisting direction; the hoisting driving source is arranged on the hoisting rack; a transmission chain is arranged between the free end of the hoisting driving source and the hanging frames; the synchronous belt transferring module comprises a conveying mechanism and an original transferring mechanism; the conveying mechanism is used for conveying an object in the original conveying direction; the original transferring mechanism is used for conveying the object in the direction perpendicular to the original conveying direction; the conveying mechanism is arranged on one hanging frame; the transferring mechanism is arranged on the conveying mechanism; the turning conveying module comprises a turning frame; the turning frame is smoothly bent, rises gradually, and is arranged on the other hanging frame; and conveying rollers are arranged on the turning frame. The high-speed four-way input and output hoister combines the flexibility and the rapidity; the structure is simple and the use is convenient; and the time and the cost are reduced.

Owner:苏州中舰智能装备科技有限公司

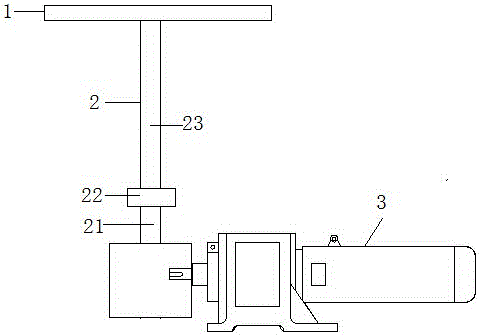

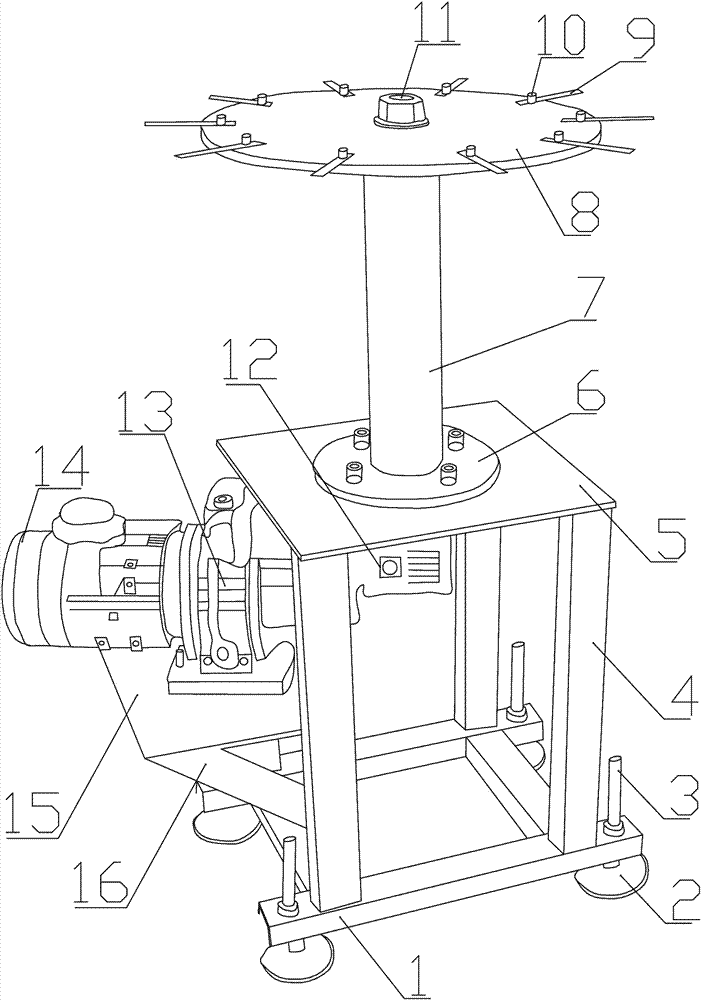

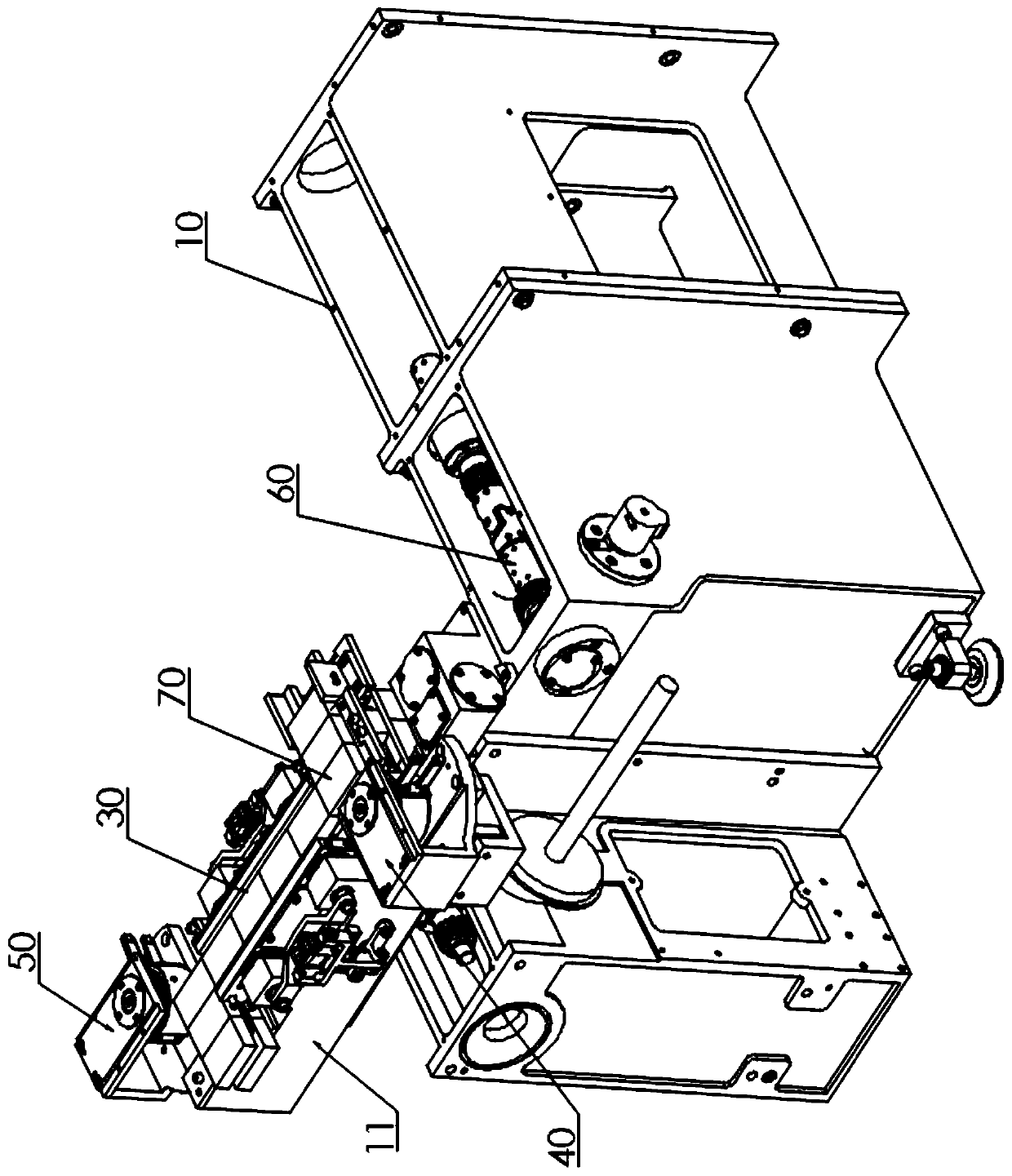

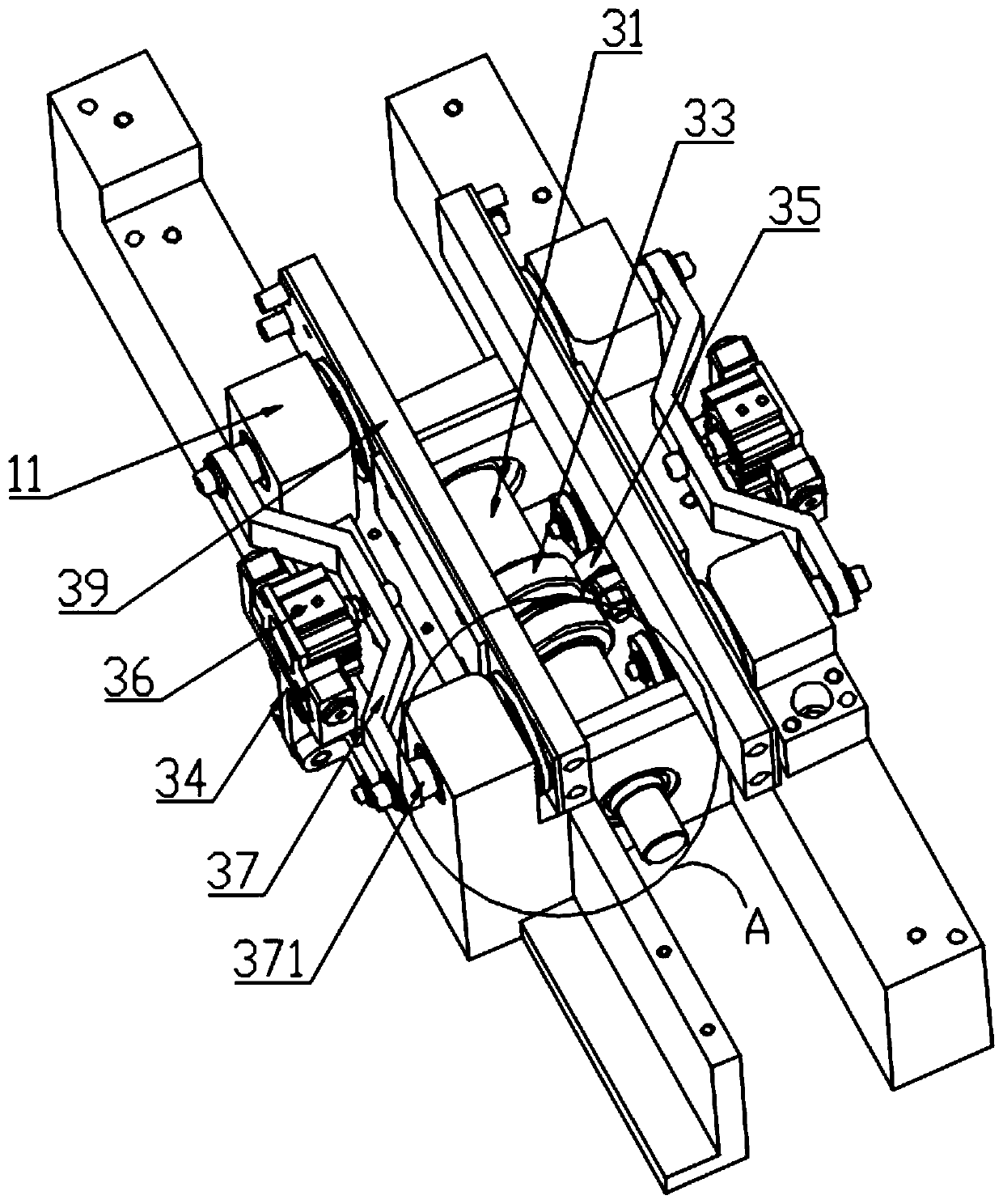

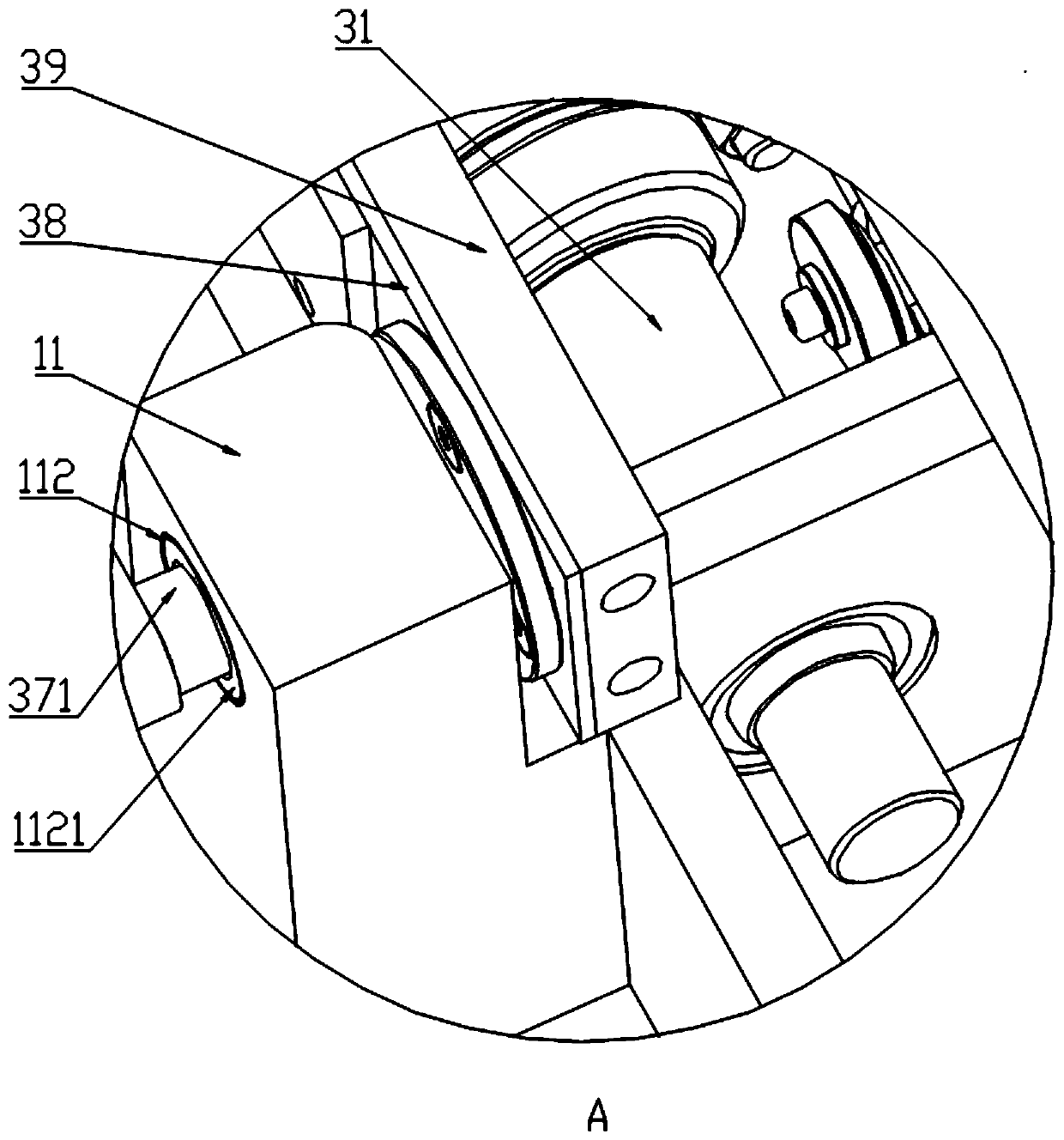

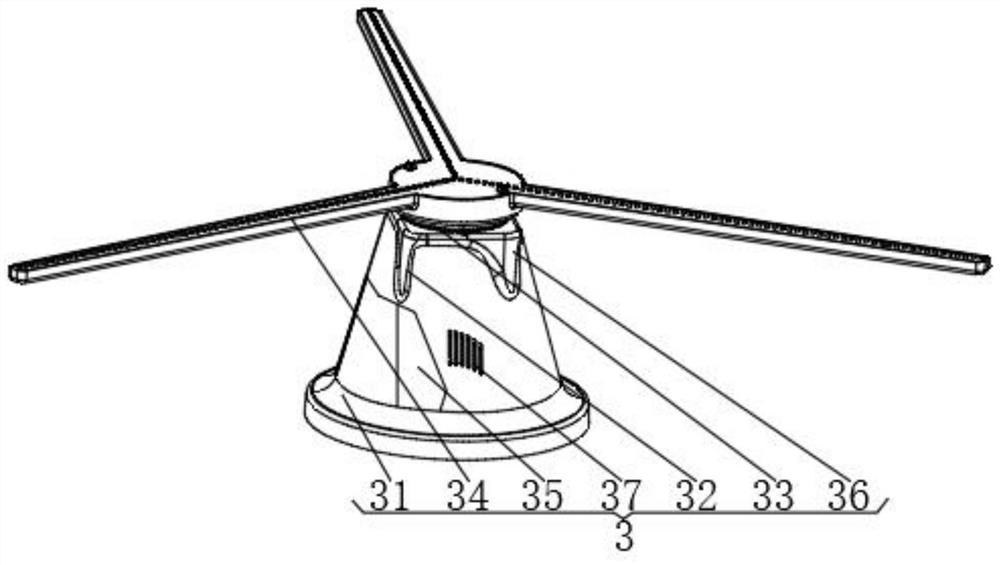

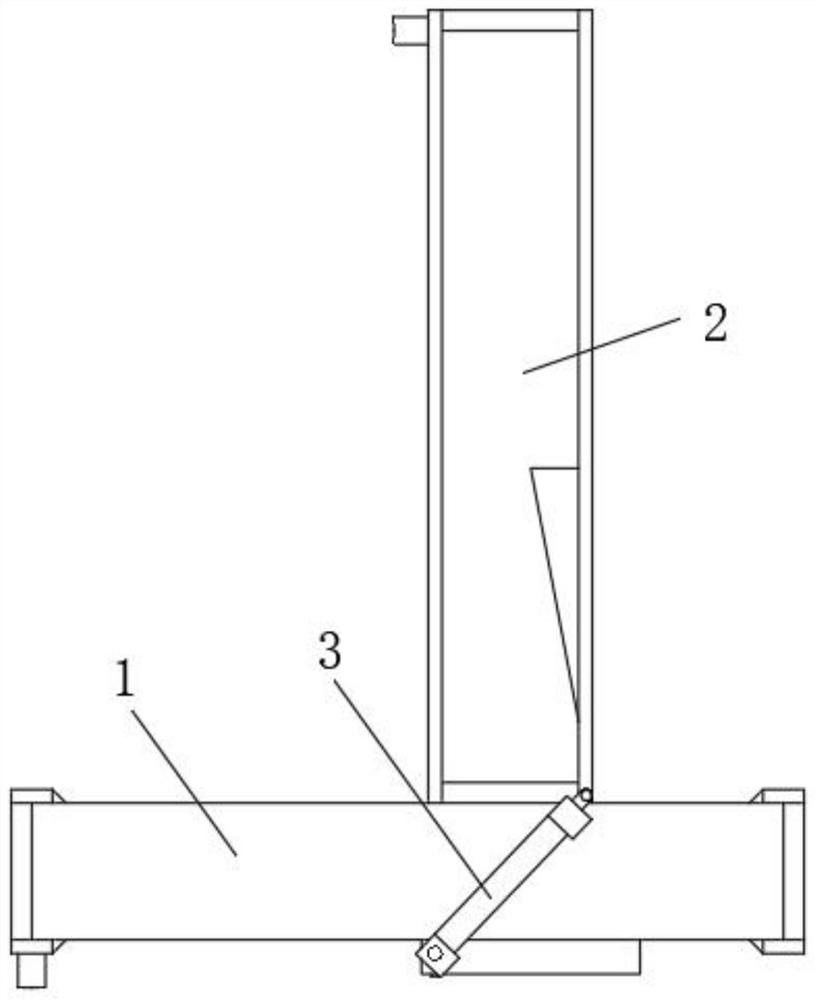

A valve spring heat treatment furnace swing device

ActiveCN104071596BNo accumulationChange the conveying directionLoading/unloadingMechanical engineeringHeat treated

The invention relates to an oscillating device for a valve spring heat treatment furnace, which comprises an oscillating head for changing the delivery direction of the valve spring, a transmission mechanism for changing the oscillating direction of the oscillating head, and a deceleration motor. The input end of the swing head for changing the delivery direction of the valve spring is connected with the output end of the conveyor, and the output end is connected with the input end of the heat treatment furnace. The height of the input of the swing head for changing the delivery direction of the valve spring is higher than the height of its output. The output end of the transmission mechanism for changing the swinging direction of the swinging head is fixedly installed under the swinging head. The output shaft of the reduction motor is fixedly connected with the input end of the transmission mechanism for changing the swing direction of the swing head. The invention can quickly and continuously change the conveying direction of the valve spring, avoiding its accumulation at the entrance of the heat treatment furnace, thereby saving manpower and material resources and improving the quality of the valve spring.

Owner:安庆谢德尔汽车零部件有限公司

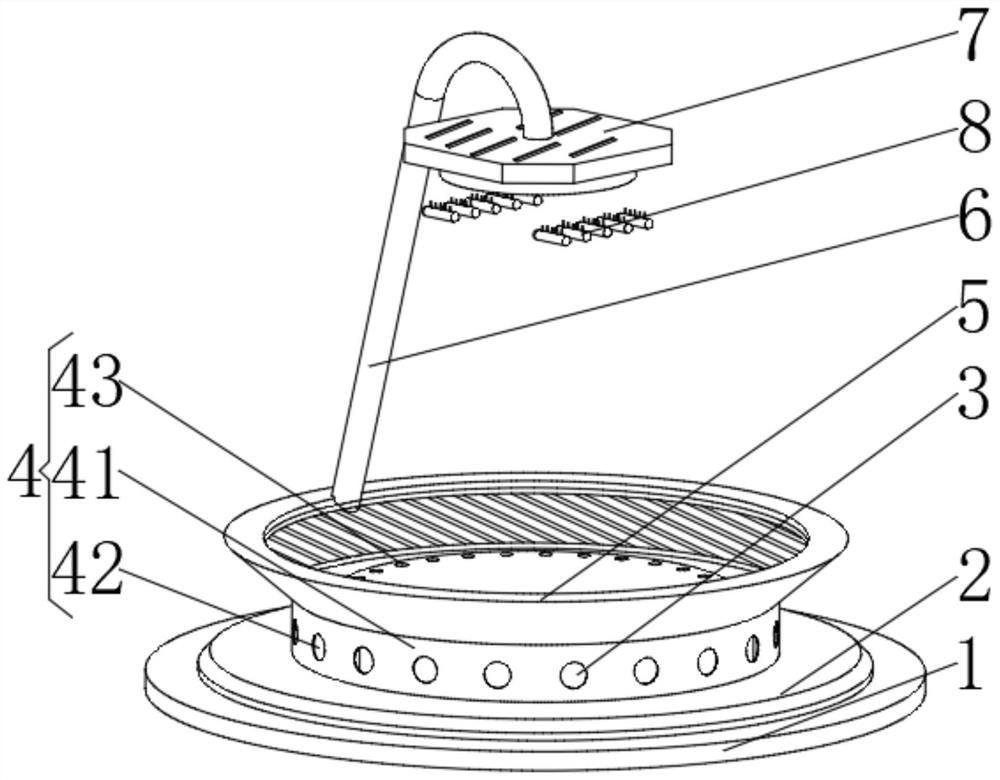

Transfer mechanism for glass bottle making conveyor line

InactiveCN107303999AEasy to adjustChange the conveying directionConveyorsConveyor partsEngineeringTransfer mechanism

The invention provides a transfer mechanism for a glass bottle making conveyor line. The transfer mechanism comprises a bottom frame. A plurality of columns are mounted on the top of the bottom frame; a worktable is mounted on the tops of the columns; a chassis is fixedly mounted in the center of the worktable through bolts; a column is mounted on the chassis; a rotary shaft is mounted in the column; a rotary disc is fixedly mounted on the top end of the rotary shaft through bolts; a glass bottle stirring device is mounted on the top of the rotary disc; and a power device is connected to the bottom of the rotary shaft. The transfer mechanism can be mounted between two crossed glass bottle conveyor lines. The conveying direction of the glass bottles can be changed by means of the structure, so that transfer mechanism transfers.

Owner:宜昌晶品玻璃制品有限公司

A magnetic levitation wind force dustproof rotating display hanger

ActiveCN111685552BAvoid deformationImprove cleanlinessPump componentsHousehold cleanersEngineeringEnergy supply

Owner:江洪燕

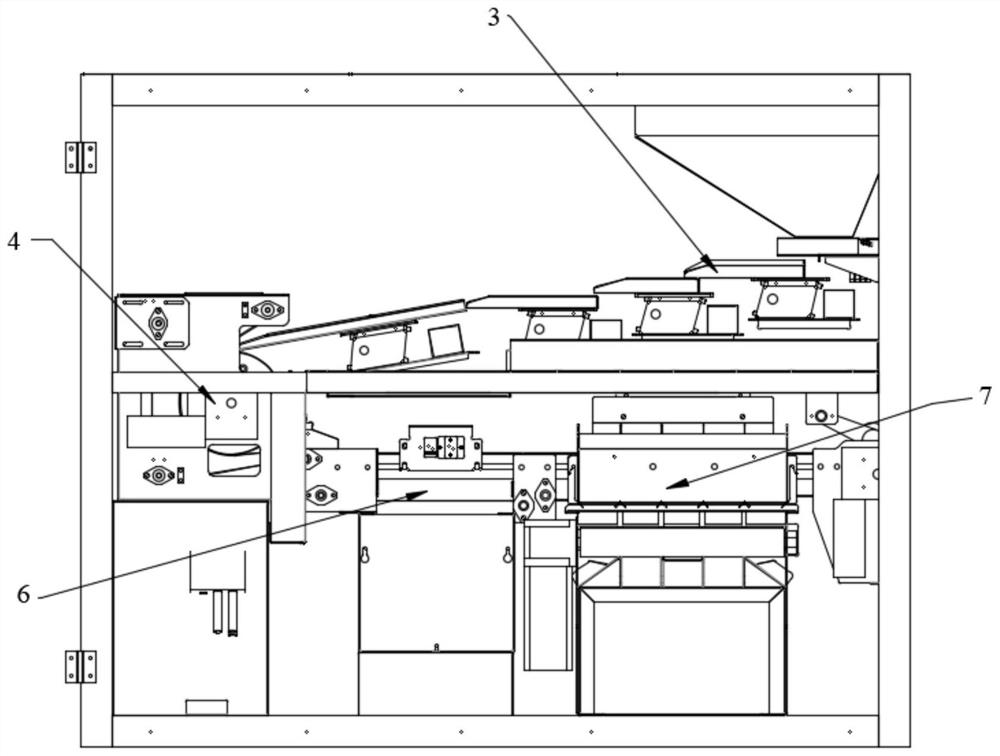

Intelligent manufacturing teaching training platform with material block conveying device

InactiveCN110033666AChange the conveying directionChange delivery timeCosmonautic condition simulationsEducational modelsDrive wheelDrive shaft

The invention provides an intelligent manufacturing teaching training platform with a material block conveying device, and relates to the technical field of ore mining. Support columns, driving wheelsand driven wheels are separately arranged on a first track and a second track, and a driving shaft and a driven shaft are respectively arranged on each driving wheel and the corresponding driven wheel; each driving shaft is connected with a driving system, and the upper part of the driving system is provided with a left chute and a right chute; and the lower parts of the left chute and the rightchute are respectively provided with discharge ports, and the left chute and the right chute are connected through a transverse support and a vertical support; the upper parts of the left chute and the right chute are provided with fixing chutes, and the fixing chutes are provided with feeding ports. The intelligent manufacturing teaching training platform is high in practicability and simple to use, the ore conveying time can be rapidly changed, many complex steps are omitted, the working intensity of workers is greatly reduced, and the smooth operation of ore conveying is guaranteed.

Owner:JIANGSU JIAOTONG COLLEGE

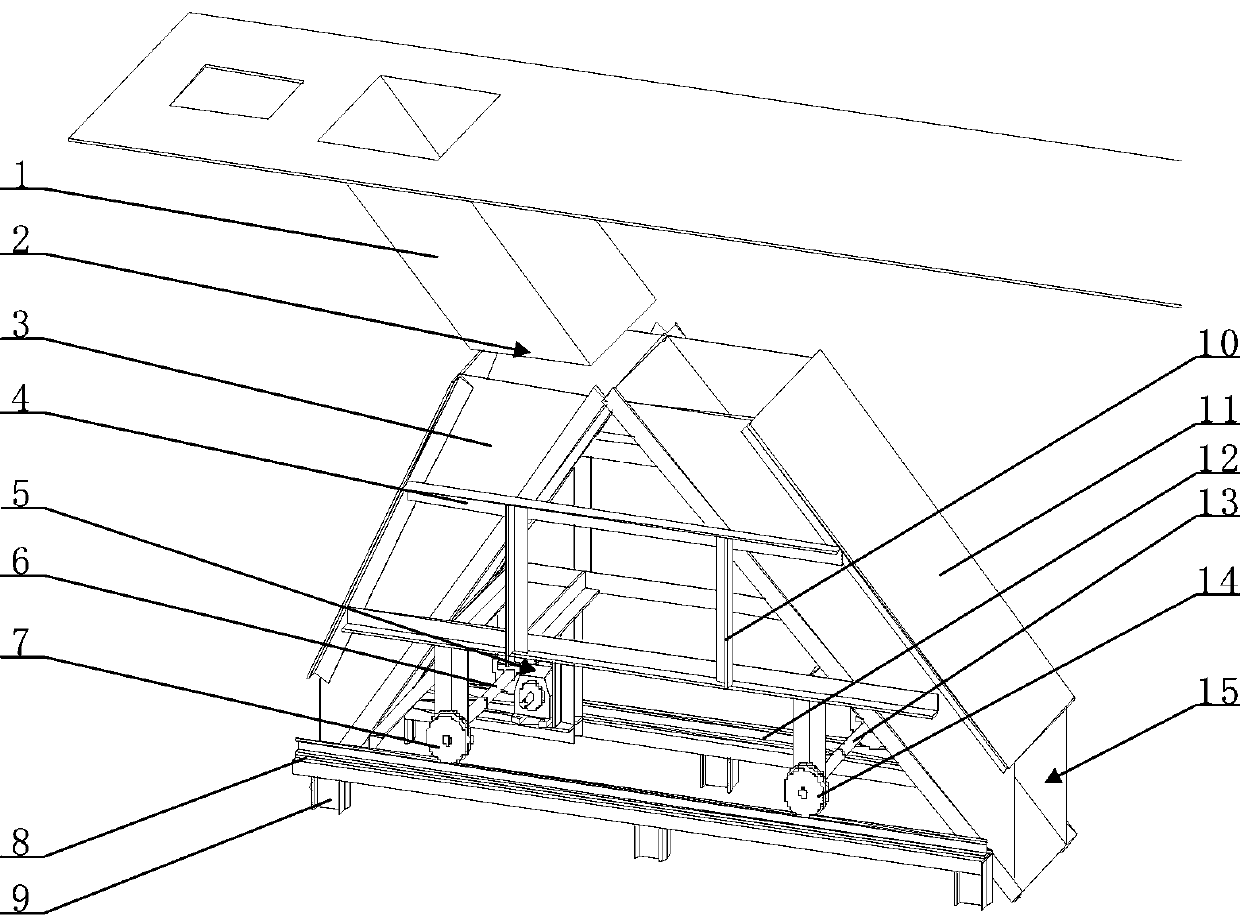

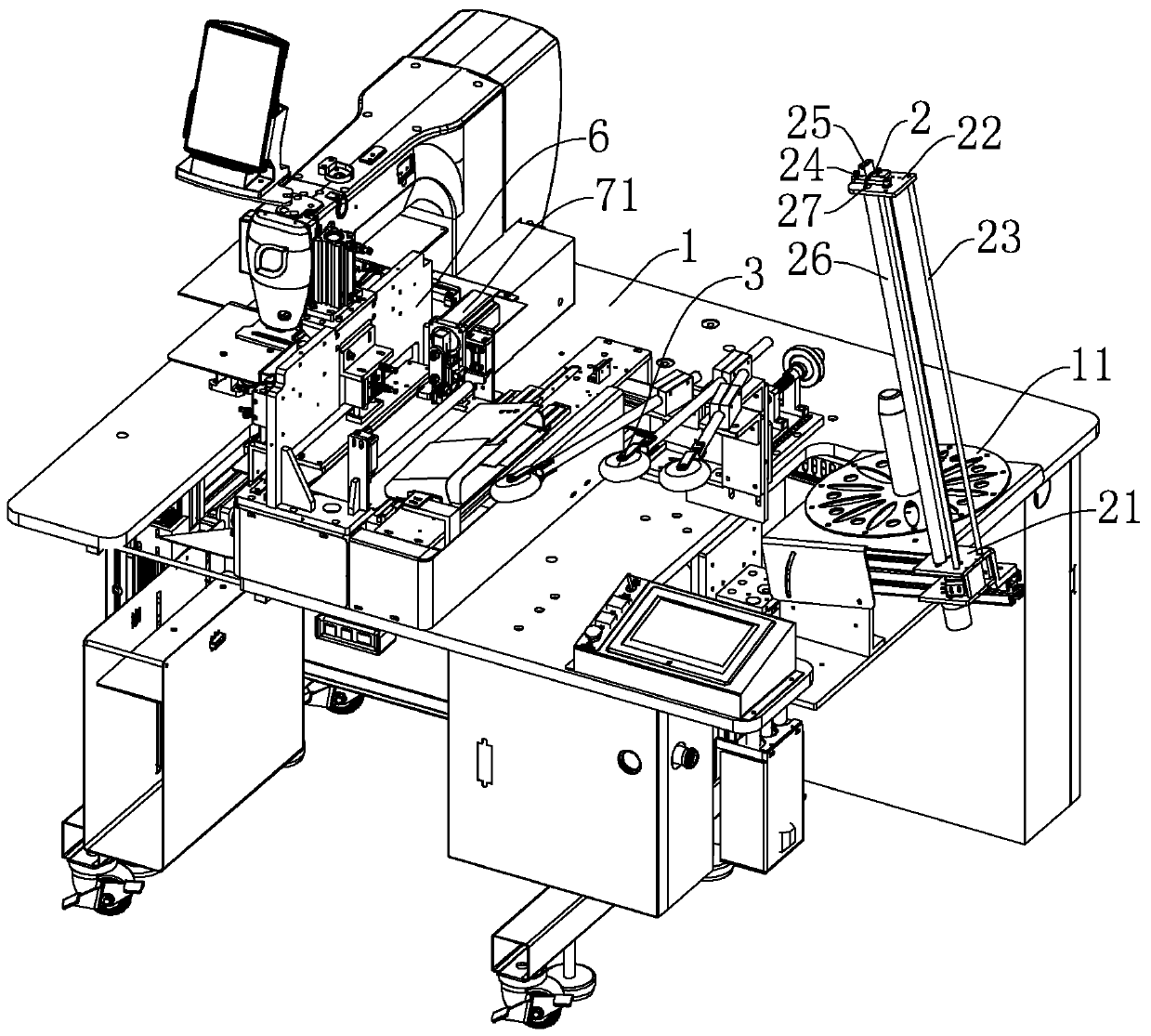

Feeding mechanism of rib collar automatic sewing machine

PendingCN110541251AChange the conveying directionEasy to foldWorkpiece carriersWork-feeding meansEngineeringSewing machine

The invention discloses a feeding mechanism of a rib collar automatic sewing machine. The feeding mechanism comprises a machine frame, a material roll plate for placing a rib cloth roll, a vertical cloth pulling guide rod in the conveying direction of rib cloth, a cloth ejecting wheel assembly acting on the central line position of the pulled-out rib cloth, and a pulling cylinder assembly foldingthe edges of the two sides of the pulled-out rib cloth along the central position.

Owner:NINGBO SUPREME ELECTRONIC MASCH INC

Small cigarette packet side face shaping device

InactiveCN111252311AAvoid quality problemsContinuation of fully automated productionPackagingComputer sciencePackaging machine

The invention relates to a small cigarette packet side face shaping device. By adjusting the position relationship between an original CH cigarette packet beautifier device machine and a barrel packing machine, an input channel is in butt joint with an output port of the cigarette packet beautifier device machine, the electromechanically-combined small cigarette packet side face shaping device isadditionally arranged, an output channel is in butt joint with an input port of the barrel packing machine, then side face shaping can be conducted on a cigarette packet before barrel packing of the cigarette packet, and thus quality problems of folds, swirl marks and unevenness of transparent paper on the side face of the cigarette packet are solved; and the transparent paper wrapped in appearance of the cigarette packet is flat and beautiful, meanwhile, the situation that the quality of the cigarette packet in the product production process is guaranteed is continued, and the set of shapingdevice can ensure synchronous butt-joint of a transmission mechanism, the original CH cigarette packet beautifier device machine and a host of the barrel packing machine.

Owner:广东省韶关烟草机械配件厂有限公司

Sorting and conveying unit with improved outlet

Owner:SYNTEGON TECHNOLOGY GMBH

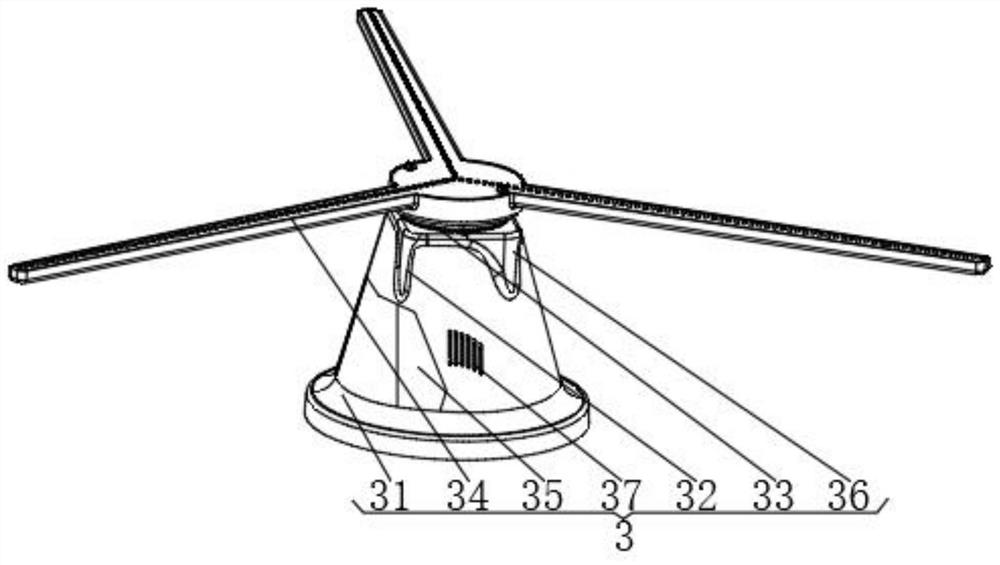

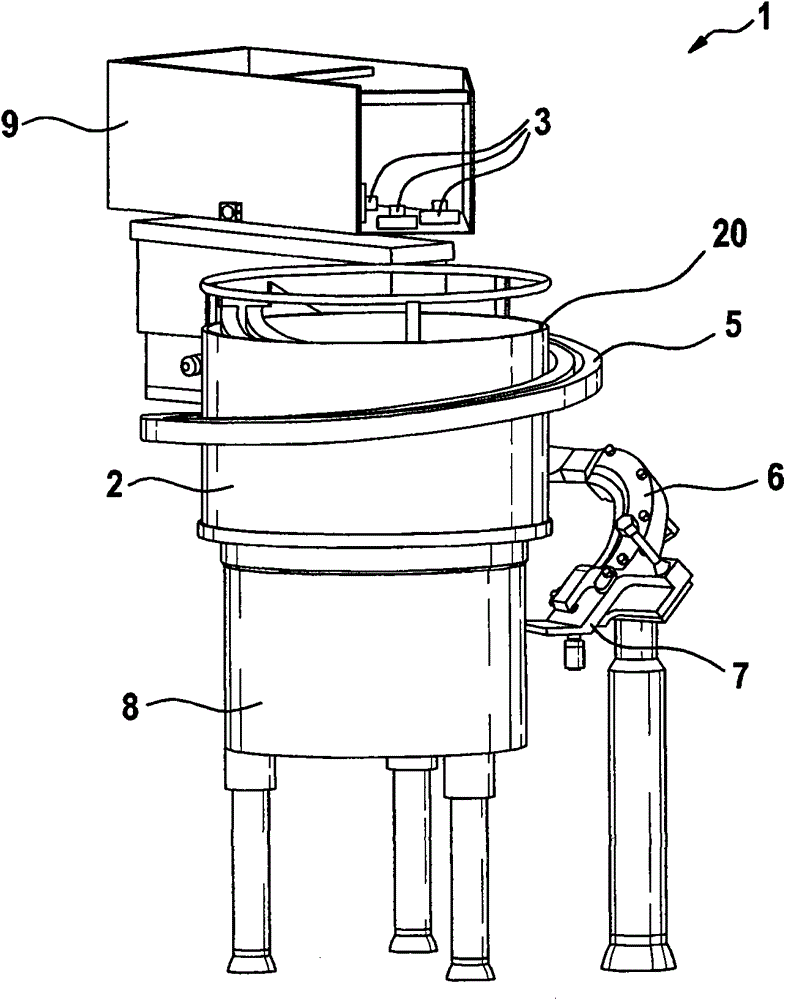

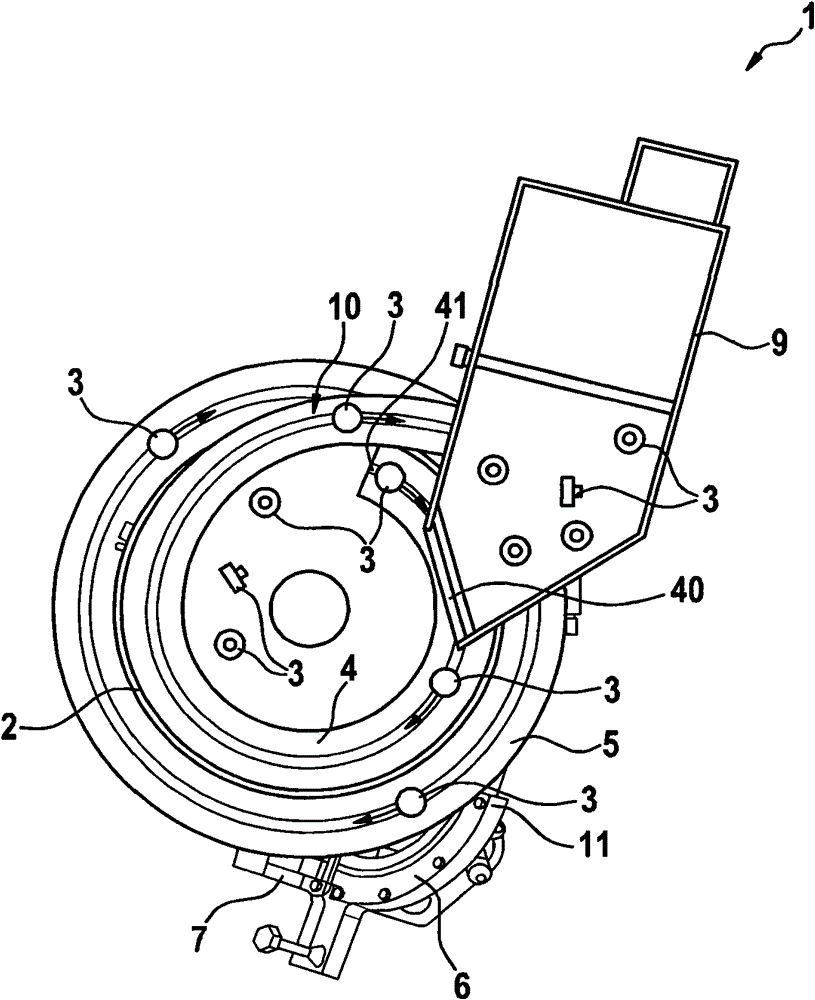

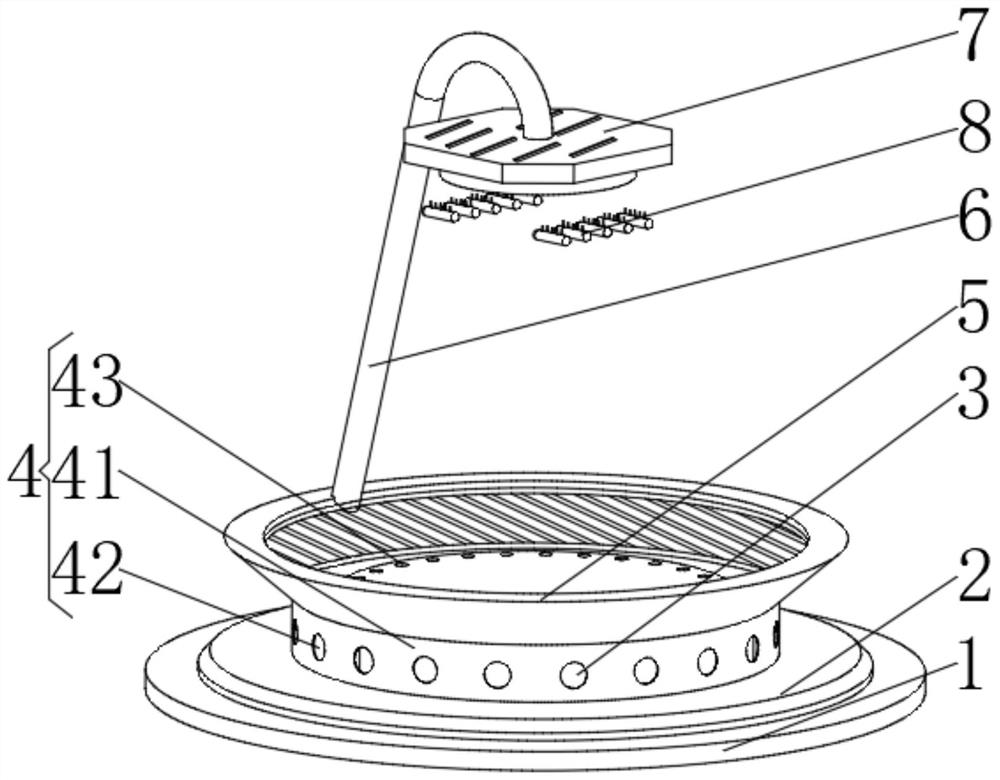

A sorter for chewable palm fruits

The invention provides a sorting machine for chewable palm plant fruit, comprising a frame, a controller, a camera device installed on the frame, and a hopper, a seed feeding component, a flanging device, and a conveying device connected in sequence. device, sorting device and discharging assembly. The seed feeding assembly includes a vibrating unit that conveys the fruits falling from the hopper one by one through vibration. The sorting device includes an air blowing device and a plurality of air blowing ports. The discharge channel, a plurality of air blowing ports are connected to a plurality of discharge passages respectively, and the plurality of air blowing ports are respectively opened or closed through the solenoid valve. The camera device captures the fruit on the conveying device and sends it to the controller. The information determines that it belongs to a certain category, controls the solenoid valve of the blowing port corresponding to this category to open, and blows the fruit onto a discharge channel. The invention can automatically sort the chewable palm plant fruits one by one according to the parameters such as shape and size.

Owner:HUNAN WANYING TECH

Magnetic suspension wind power dust-proof rotary display clothes hanger

ActiveCN111685552AAvoid deformationImprove cleanlinessPump componentsHousehold cleanersMechanical engineeringClothes hanger

The invention discloses a magnetic suspension wind power dust-proof rotary display clothes hanger comprising a protective base; a buffer mechanism is fixedly connected to the middle position of the top of the protective base; a multi-directional air blowing mechanism is arranged in the middle of the top of the buffer mechanism; the outer surface of the top of the protective mechanism is fixedly connected with a rotary air guide mechanism; an energy supply supporting rod is fixedly connected to the middle of the back face of the top of the protective base, an electromagnetic attraction mechanism is fixedly connected to the end, away from the protective base, of the energy supply supporting rod, and a clothes fixing suspension mechanism is movably connected to the side, away from the energysupply supporting rod, of the electromagnetic attraction mechanism. The invention relates to the technical field of display clothes hangers. Suspension hanging is carried out through magnetic force, the hanging distance can be adjusted according to the gravity of clothes, deformation of the clothes is avoided, effective surrounding protective is carried out through spiral airflow, the clothes areblown to naturally float and rotate, multi-directional display is completed, cleanliness and brightness of the clothes are guaranteed, and the quality of the clothes is guaranteed.

Owner:江洪燕

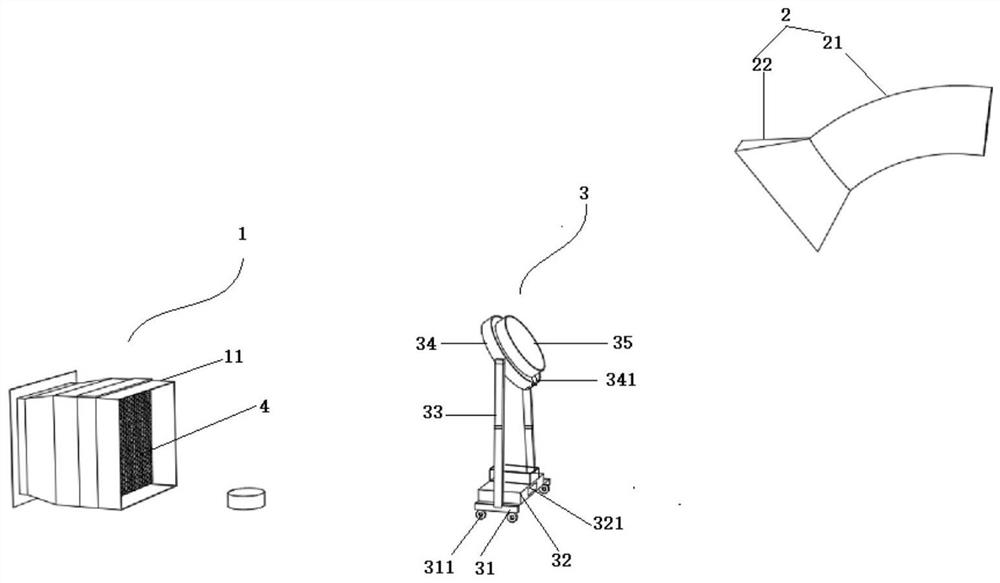

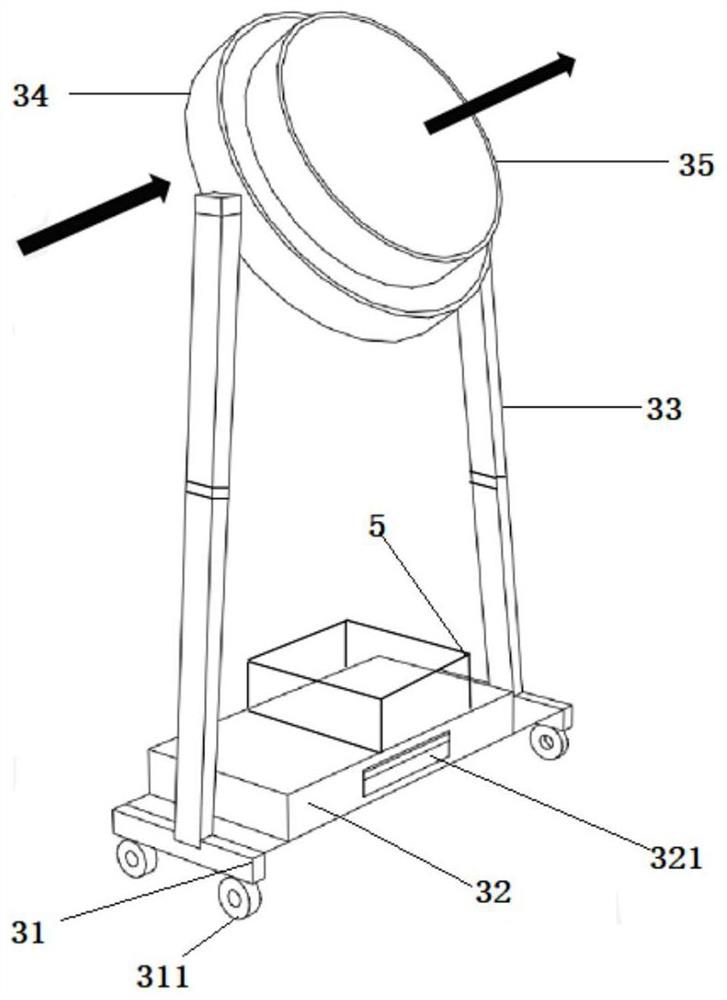

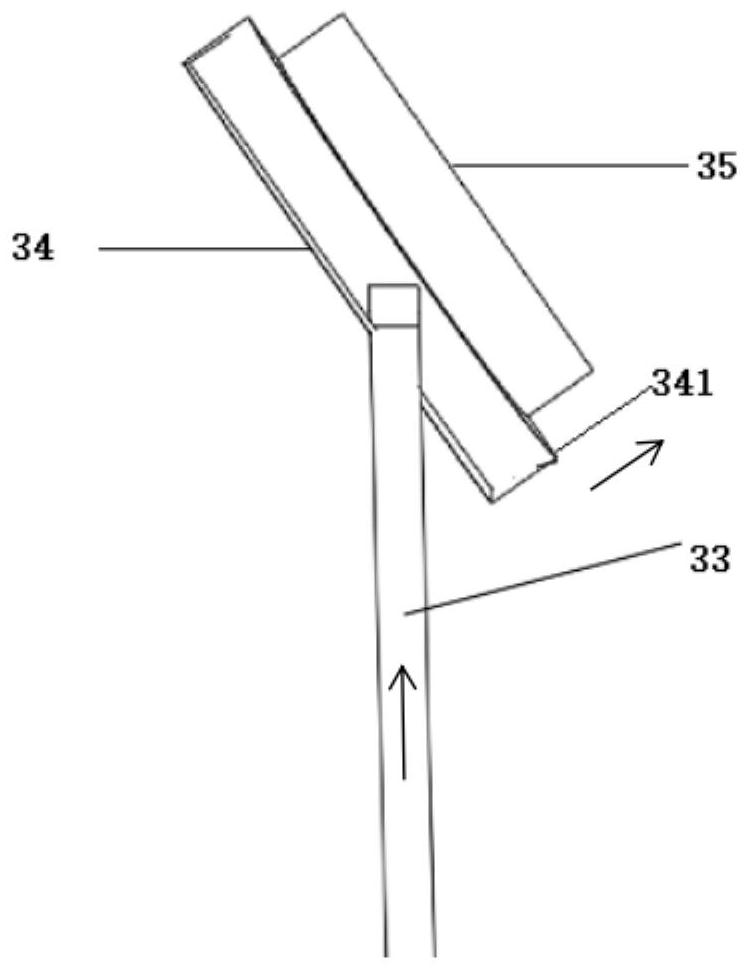

Airflow-direction-adjustable pollutant targeted long-distance multi-stage transport system and method

PendingCN114877454ALow decay ratePrevent escapeMechanical apparatusLighting and heating apparatusTransport systemEnvironmental engineering

The invention discloses an airflow-direction-adjustable pollutant targeted long-distance multi-stage transport system which comprises a long-distance air supply device and an air exhaust device which are arranged in a building, and further comprises a movable relay air supply device. The long-distance air supply device is used for conveying air flow into the building; the movable relay air supply device is used for conveying the captured polluted airflow to the air exhaust device; and the exhaust device is used for exhausting the captured polluted airflow out of the building. The invention further discloses a pollutant targeted long-distance multi-stage transportation method with the adjustable airflow direction, and the method is achieved through the pollutant targeted long-distance multi-stage transportation system with the adjustable airflow direction. Particularly, a single or a plurality of movable relay air supply devices with adjustable angles are arranged in the building, so that the conveying direction of the air flow in the building is changed, and the effect of inducing the polluted air flow to diffuse towards a discharge port is achieved.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Multi-angle conveying device for machinery production

InactiveCN111792353AChange the conveying directionSolve the waste of resourcesConveyor partsElectric machineryConveyor belt

The invention discloses a multi-angle conveying device for machinery production, and relates to the technical field of machining. The multi-angle conveying device for machinery production comprises afirst conveying assembly and a second conveying assembly, wherein the first conveying assembly is connected with the second conveying assembly through a transferring assembly; the first conveying assembly comprises two groups of support legs; a rotary roller is rotatably connected between each group of support legs and is driven through an external motor; a first conveyor belt is connected to theouter sides of the two rotary rollers in a sleeving way; a first fixed plate is fixedly arranged on the inner sides of each group of support legs and is located in the first conveyor belt; and two second fixed plates are fixedly arranged between the two first fixed plates. According to the multi-angle conveying device for machinery production provided by the invention, through adjusting the transferring assembly, the accessory conveying direction can be changed, so that accessories can be conveyed to different production processes, and the problem that the resources are wasted since an existing conveying device is difficult to change a conveying direction and more conveyor belts need to be used is solved.

Owner:安徽华中机械配套工程有限公司

Cardboard high-speed transfer and negative pressure dehumidification production line

InactiveCN105438807BEasy to processRealize photoelectric automatic openingConveyor partsProduction lineDrive wheel

The invention relates to a paperboard high-speed transferring and negative-pressure dehumidifying production line. A lifting platform device is connected with a paperboard production line in a butt joint mode. A lifting platform is installed on the lifting platform device. The lifting platform is maintained at the same height with a first conveying device and connected with the first conveying device in a butt joint mode after falling to the ground. A transferring conveying device is connected with the first conveying device in a butt joint mode. A driving wheel is installed at the bottom of the transferring conveying device. The driving wheel is matched with an inner side arc-shaped track and an outer side arc-shaped track which are installed on an arc-shaped transferring area. A second conveying device is connected with the arc-shaped transferring area in a butt joint mode. A third conveying device is connected with the second conveying device in a butt joint mode. A negative-pressure dehumidifying device is installed on the ground of an extension section of the third conveying device. The paperboard high-speed transferring and negative-pressure dehumidifying production line can be connected with a high-speed board cutting machine in a butt joint mode, transfer small cut paperboards, remove glue moisture of gaps of corrugated paper through negative pressure and convey the cut paperboards to multiple later-stage work procedures to complete the high-speed transferring conveying of the whole paperboards.

Owner:YICHANG JINHAI COLAR PRINT CO LTD

Valve spring heat treatment furnace swinging device

ActiveCN104071596ANo accumulationChange the conveying directionLoading/unloadingMaterial resourcesIndustrial engineering

The invention relates to a valve spring heat treatment furnace swinging device. The valve spring heat treatment furnace swinging device comprises a swinging head used to change the conveying direction of a valve spring, a transmission mechanism used to change the swinging direction of the swinging head and a deceleration motor. An input end of the swinging head used to change the conveying direction of the valve spring is connected with an output end of a conveying machine, and an output end of the swinging head used to change the conveying direction of the valve spring is connected with an input end of a heat treatment furnace. The height of the input end of the swinging head used to change the conveying direction of the valve spring is higher than the height of the output end of swinging head used to change the conveying direction of the valve spring. An output end of the transmission mechanism used to change the swinging direction of the swinging head is fixedly installed below the swinging head. An output shaft of the deceleration motor is fixedly connected with an input end of the transmission mechanism used to change the swinging direction of the swinging head. The valve spring heat treatment furnace swinging device can rapidly and continuously change the conveying direction of the valve spring, prevents a stacking phenomenon from occurring on an entrance of the heat treatment furnace, and thereby saves manpower and material resources, and improves quality of the valve spring.

Owner:安庆谢德尔汽车零部件有限公司

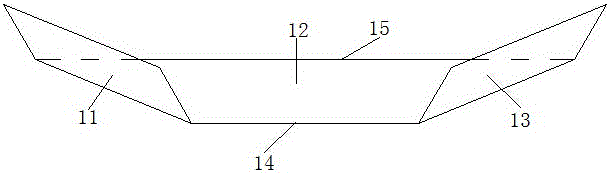

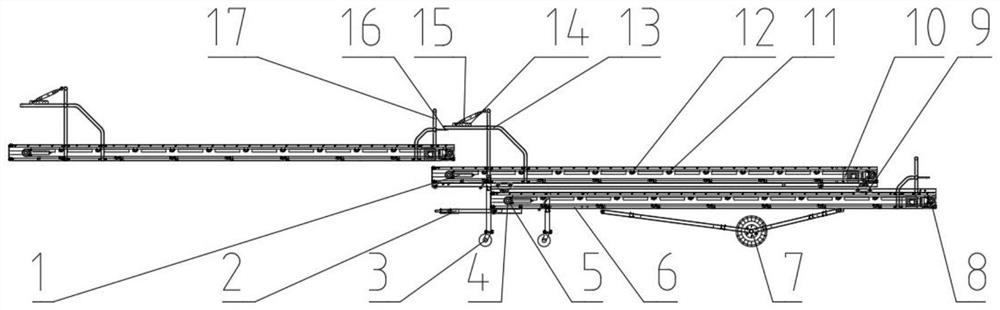

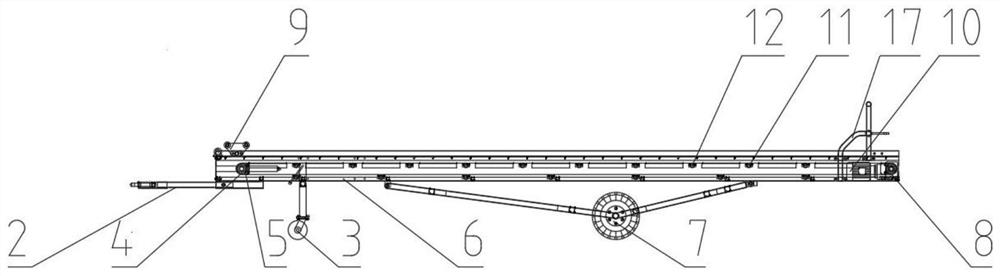

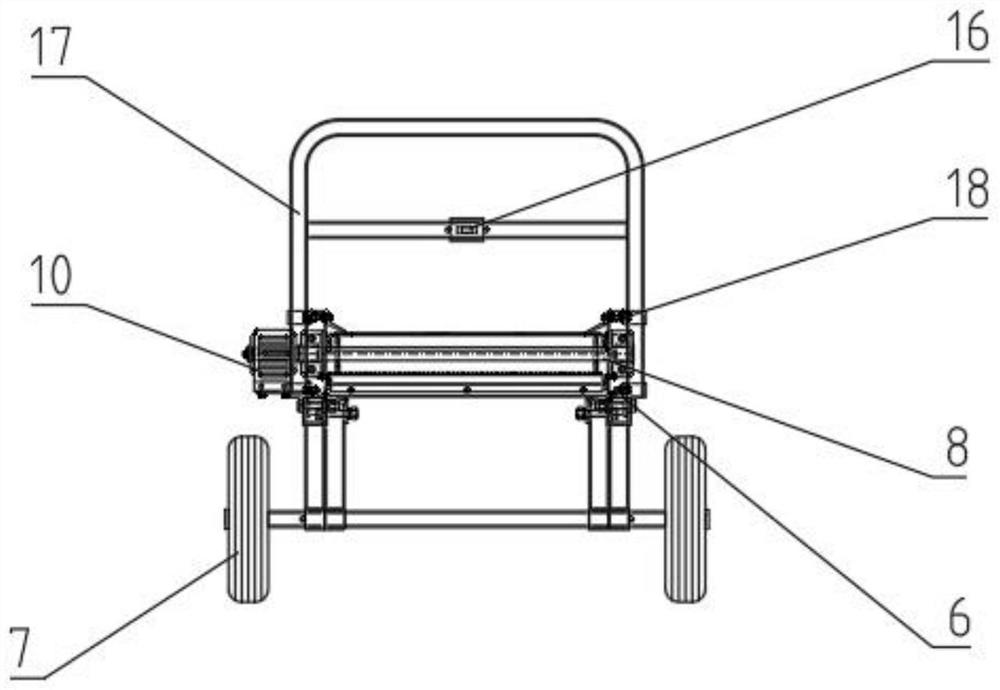

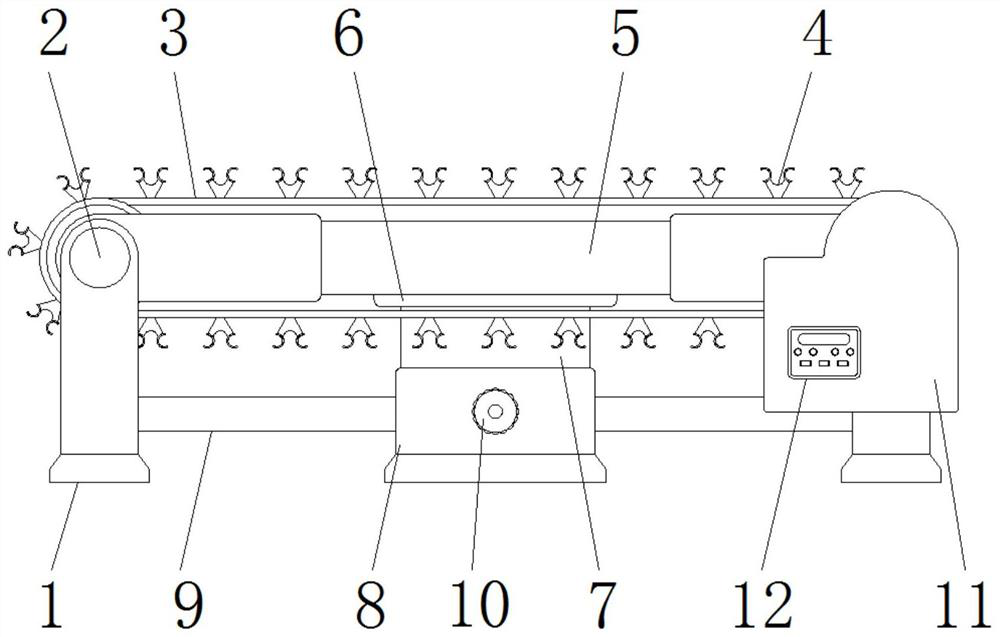

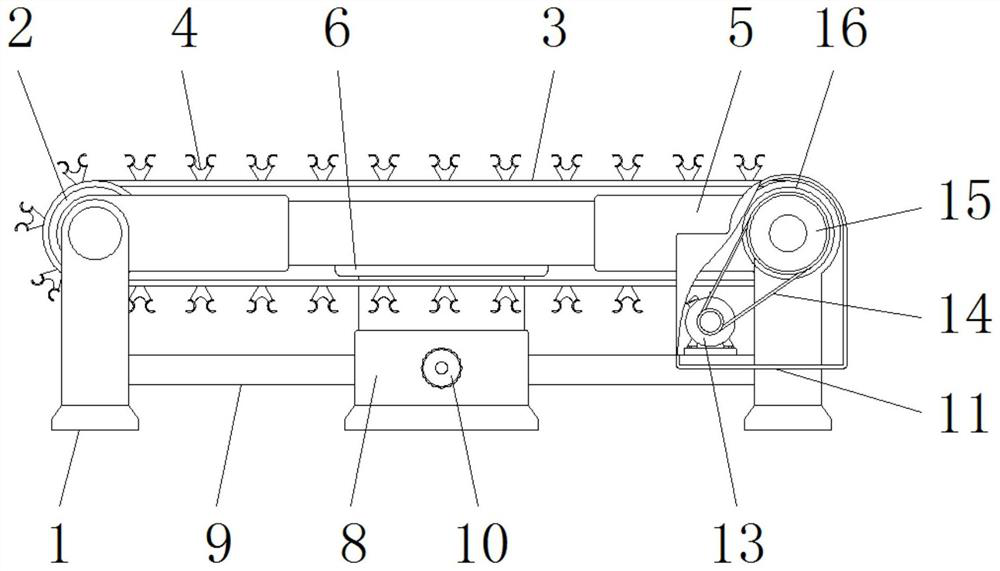

Novel potato conveying warehousing machine

PendingCN112340340AEasy to adjustChange the conveying directionStorage devicesAgricultural engineeringElectric machinery

The invention discloses a novel potato conveying warehousing machine. The novel potato conveying warehousing machine is in traction connection with a tractor, and a conveying device is mainly composedof a main frame, an installation plate, a tensioning device, a turnabout drum, a transmission drum, a motor speed reducer, a conveying belt and parallel carrier rollers. A middle-layer conveying device is connected with a lower-layer conveying device through rail wheels, and the middle-layer conveying device can be pushed to change the conveying distance. The upper-layer conveying device can be inclined and the conveying height can be changed by changing different hole positions of a pull rod on a porous adjusting plate, the upper-layer conveying device is connected with the middle-layer conveying device through a pin shaft, and the upper-layer conveying device can be transversely pushed to change the conveying direction. The structure is novel and reasonable, adjustment is easy and convenient, and operation reliability is high.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

A conveying device for textile cloth production that can change the conveying direction

ActiveCN109665276BEasy to transportChange the conveying directionMechanical conveyorsRoller-waysIndustrial engineeringCotton material

The invention discloses a conveying direction changeable conveying device for textile fabric production. The conveying device comprises a driven roller, a driving roller, a main shaft rod set and a transmission rod; the outer side of the driven roller and the outer side of the driving roller are connected through a conveying belt, the conveying belt is connected with a conveying clamping piece, each of the outer end of the driven roller and the outer end of the driving roller is connected with a supporting column, the front end of the driven roller and the front end of the driving roller are connected through a supporting frame, and the rear end of the driven roller and the rear end of the driving roller are connected through a supporting frame; and a groove is formed in each supporting frame, conveying rotating rollers are connected between the supporting frames, conveying rotating rollers are connected in the grooves, the lower ends of the supporting frames are connected with supporting blocks through reinforcing plates, and supporting tubes are arranged at the lower ends of the supporting blocks. According to the conveying direction changeable conveying device for textile fabric production, textile fabric can be conveniently conveyed in a dragging mode, so that energy consumption can be reduced; and meanwhile, the conveying direction can be changed conveniently, so that different conveying requirements can be met conveniently.

Owner:浦江海工机械有限公司

Intelligent bothway chute

InactiveCN108438719AChange the conveying directionChange delivery timeConveyorsConveyor partsDrive wheelDrive shaft

The invention relates to an intelligent bothway chute, and relates to the technical field of ore extraction. A first rail and a second rail are each provided with a supporting column, a driving wheeland a driven wheel, the driving wheels and the driven wheels are provided with driving shafts and driven shafts correspondingly, the driving shafts are connected with a driving system, the upper portion of the driving system is provided with a left chute and a right chute, outlet openings are formed in the lower portions of the left chute and the right chute, the left chute and the right chute areconnected through a transverse support and a vertical support, fixed chutes are arranged at the upper portions of the left chute and the right chute, and discharging openings are formed in the fixedchutes. The intelligent bothway chute is high in practicability and relatively simple in use, the ore conveying time can be quickly changed, many complex steps are omitted, the working strength of workers is greatly reduced, and the ore conveying work is guaranteed to be smoothly done.

Owner:HENAN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com