Adjusting screw assembly and manufacturing process thereof

A technology for adjusting screws and manufacturing processes, applied in the direction of manufacturing tools, screws, threaded fasteners, etc., can solve the problems of separation of screws and nuts, high assembly costs, and difficult separation of screws and nuts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

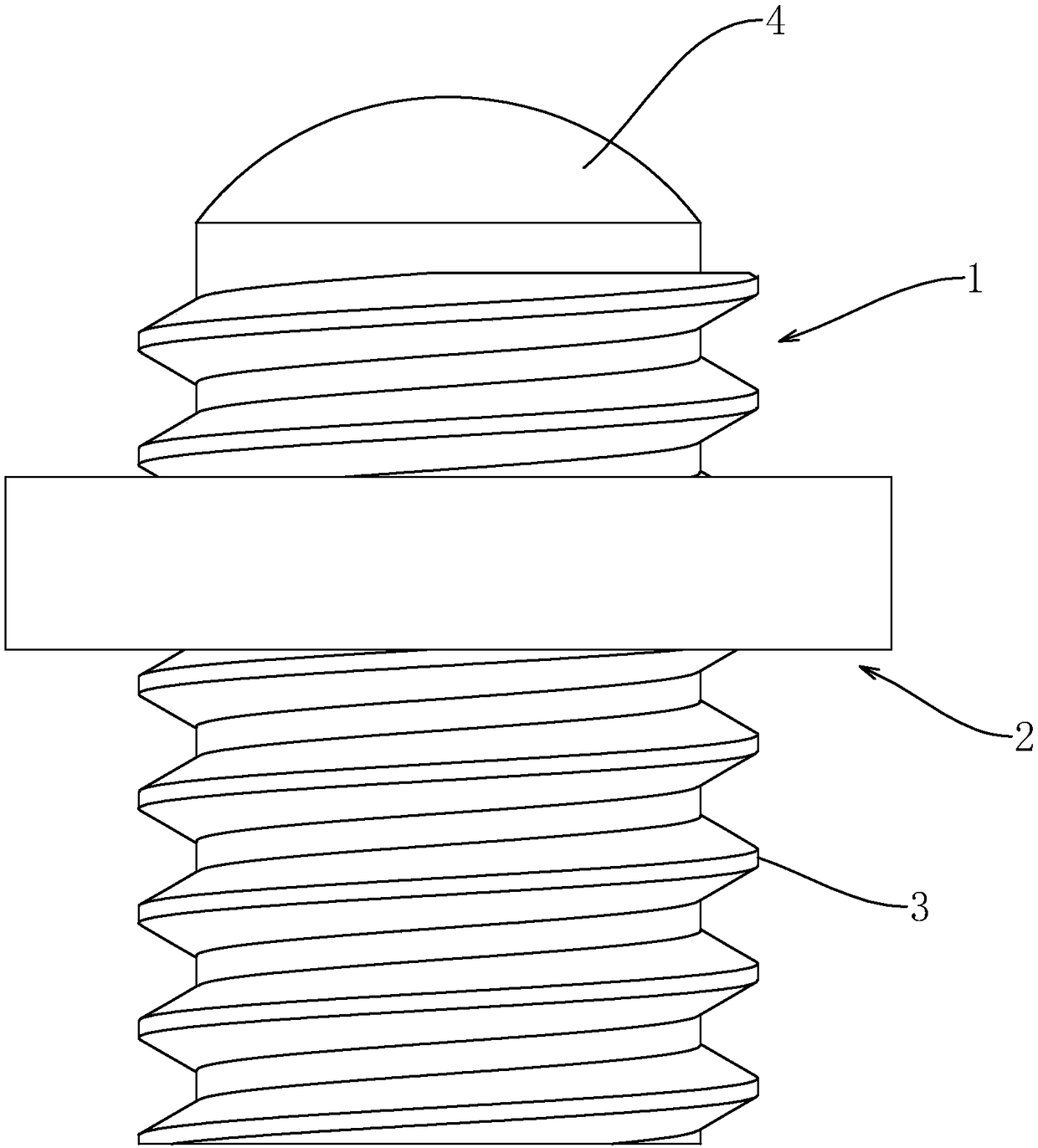

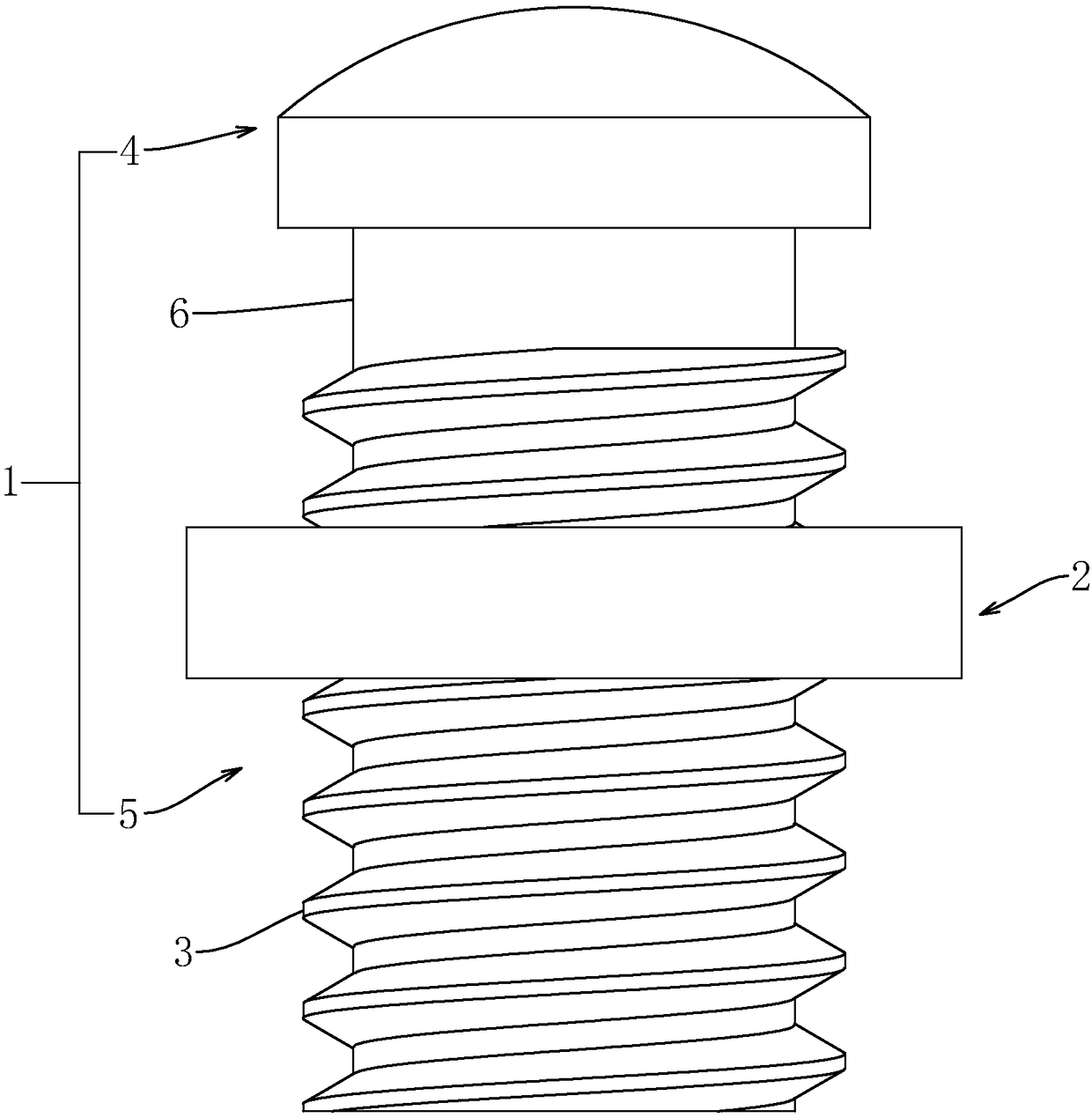

[0045] like figure 2 As shown, an adjusting screw assembly includes a screw member 1 and a nut 2 that are threaded.

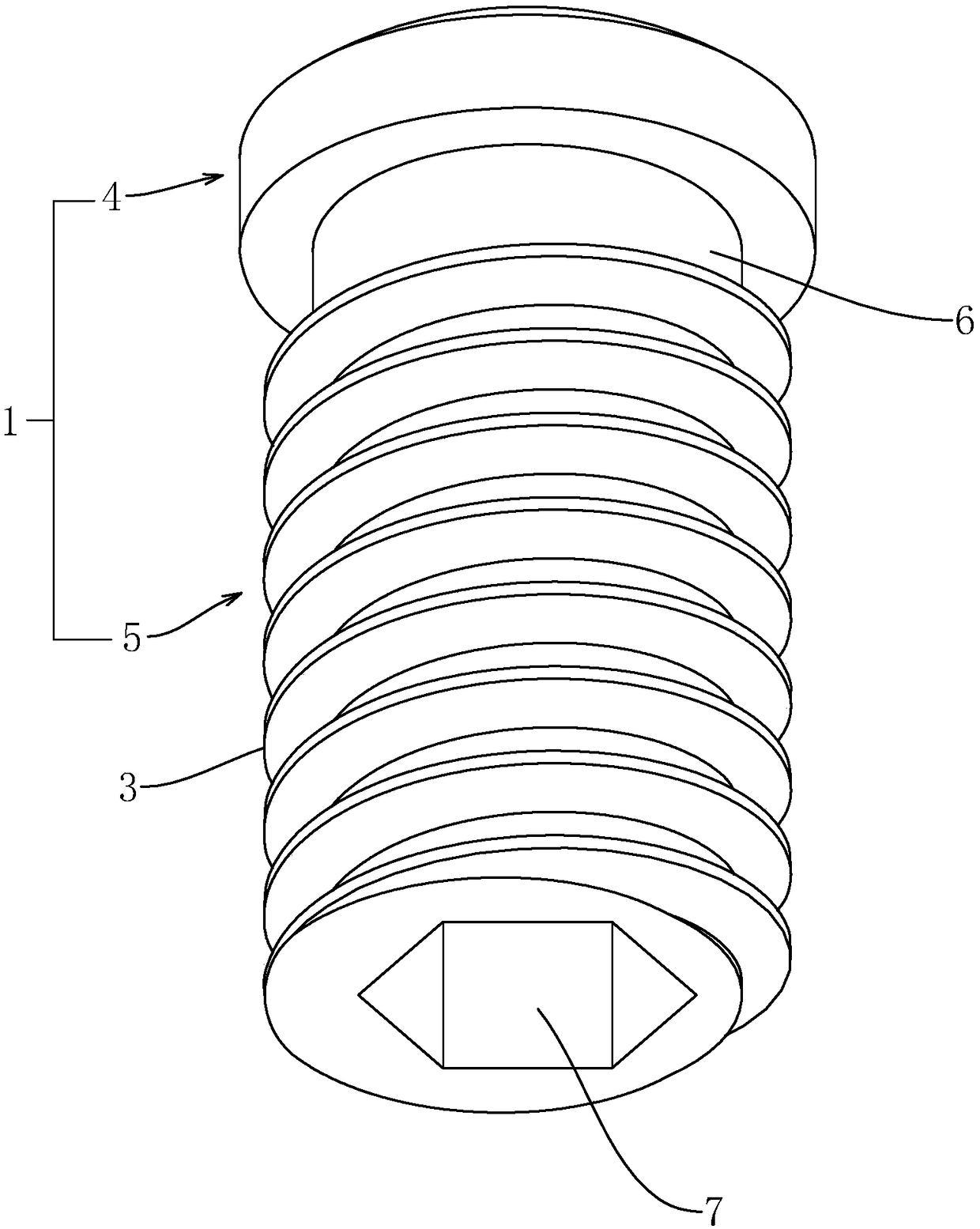

[0046] like figure 2 and image 3 As shown, the screw 1 includes a rod 5 and an arc-shaped end 4 connected to one end of the rod 5. The outer surface of the rod 5 is formed with an external thread 3, and the major diameter of the external thread 3 is A±a. The maximum diameter of the arc surface end 4 perpendicular to the shaft center line of the rod portion 5 is B, B=A+a+b, which is larger than the maximum diameter of the external thread 3 . A connection section 6 with a diameter C is formed at the joint between the rod portion 5 and the arc-shaped end 4, and C is equal to the minor diameter of the external thread 3 . The end of the rod part 5 facing away from the arc surface end 4 is formed with an inner hexagonal groove 7, and the inner hexagonal groove 7 is used as a force receiving part to drive it to rotate.

[0047] like figure 2 and image 3 As ...

Embodiment 2

[0049] A manufacturing process for an adjusting screw assembly, comprising:

[0050] Step a: cold heading

[0051] like Figure 4 As shown, the blank 12 is cold-forged by a cold heading machine. The blank 12 includes a rod 5 and an arc-shaped end 4. The diameter of the arc-shaped end 4 is B, and the diameter of the rod 5 is A±a. An inner hexagonal groove 7 is formed on the end of the rod portion 5 facing away from the arc surface end 4 .

[0052] Step b: Cleaning

[0053] Use a washing machine to remove surface oil stains.

[0054] Step c: Rub teeth

[0055] like image 3 and Figure 5 As shown, the surface of the blank 12 is rubbed by the thread rubbing machine 8 to form the screw 1 . The tooth rubbing machine 8 includes a conveying device 9, a screening device 10 and a tooth rubbing device 11. The conveying device 9 conveys the blanks 12, and the screening device 10 screens the blanks 12 with a fixed orientation to ensure that the processing effect of each blank 12 is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com