Cardboard high-speed transfer and negative pressure dehumidification production line

A production line and cardboard technology, applied in the field of cardboard high-speed transfer and negative pressure dehumidification production line, can solve the problems of low work efficiency, impossible transfer, cumbersome operation process, etc., and achieve the effect of saving electric energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

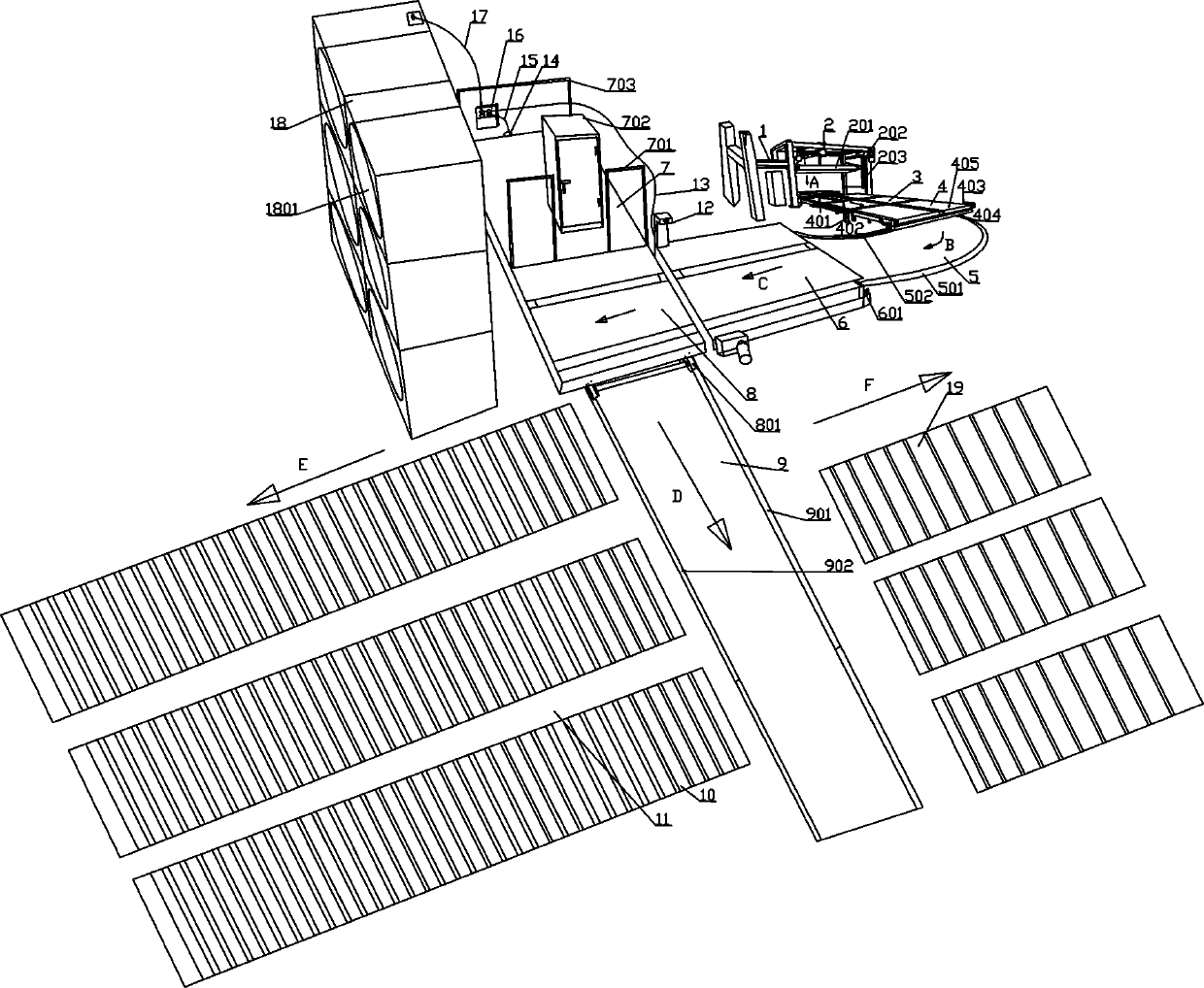

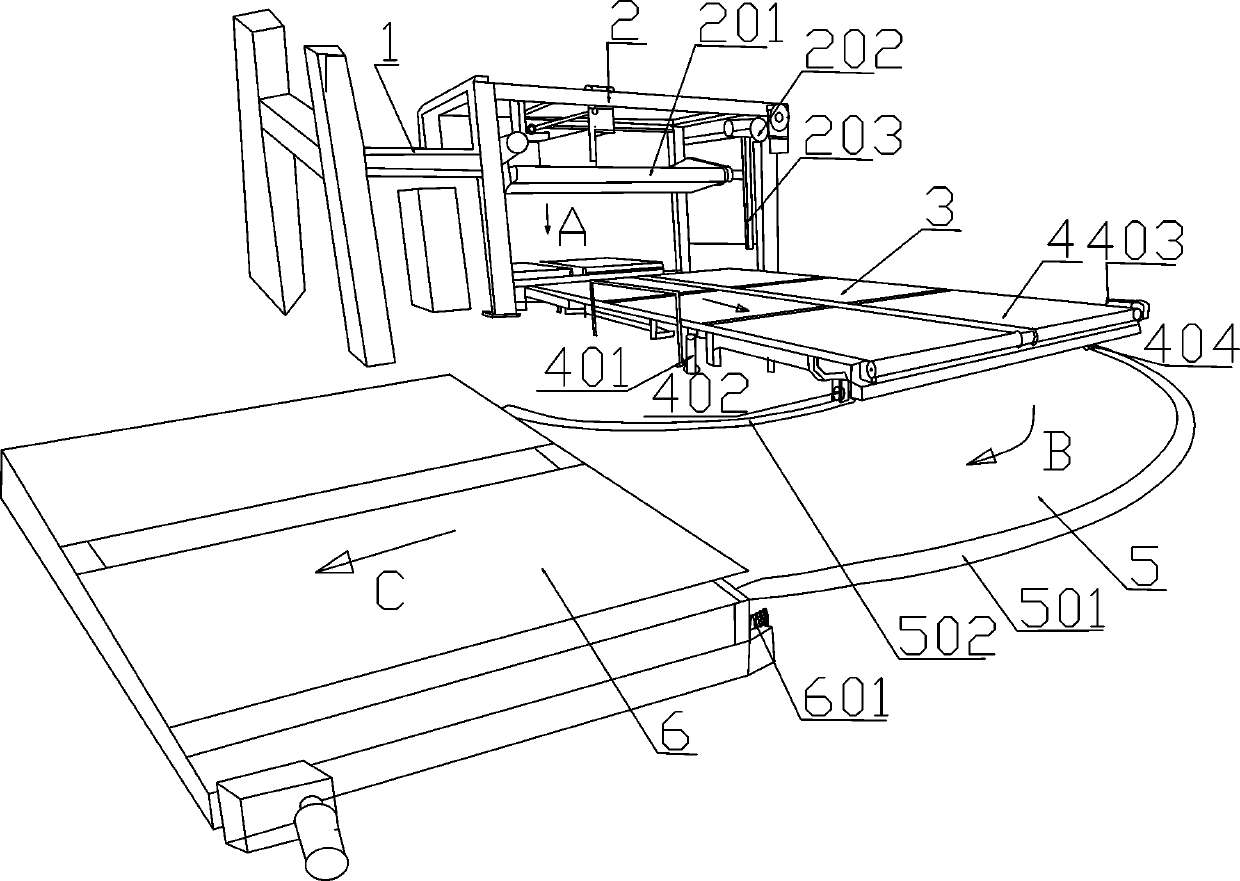

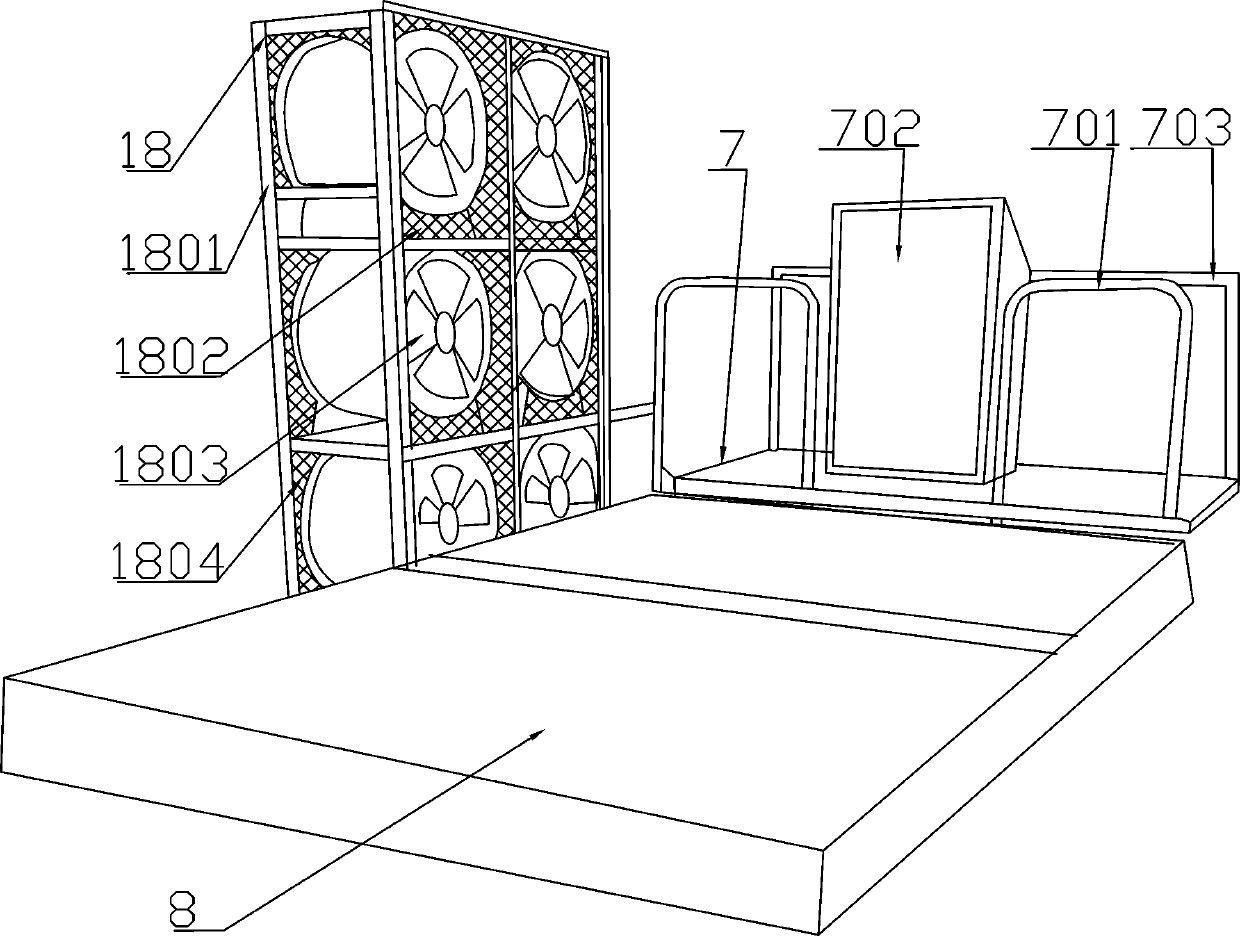

[0036] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0037] join Figure 1-3, a cardboard high-speed transfer and negative pressure dehumidification production line, which includes a cardboard production line 1 for cutting cardboard, a lifting platform device 2 docked with the cardboard production line 1, and a lifting platform 201 is installed on the lifting platform device 2, and the lifting platform 201 carries the cardboard on the roll Driven by the lifting motor 202, it slides up and down along the track 203 to realize the lifting of the cardboard. After the lifting platform 201 lands, it maintains the same height with the No. 1 conveying device 3 and docks with each other. The transfer conveying device 4 docks with the No. 1 conveying device 3. The transmission device 4 can rotate around the rotating shaft 401, and the bottom of the transfer transmission device 4 is equipped with a drive wheel 404. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com