High-speed four-way input and output hoister

A hoist, high-speed technology, used in conveyors, conveyor objects, rollers, etc., can solve the problems of high use cost, inflexible use, low lifting capacity, etc., and achieve the effect of saving time, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

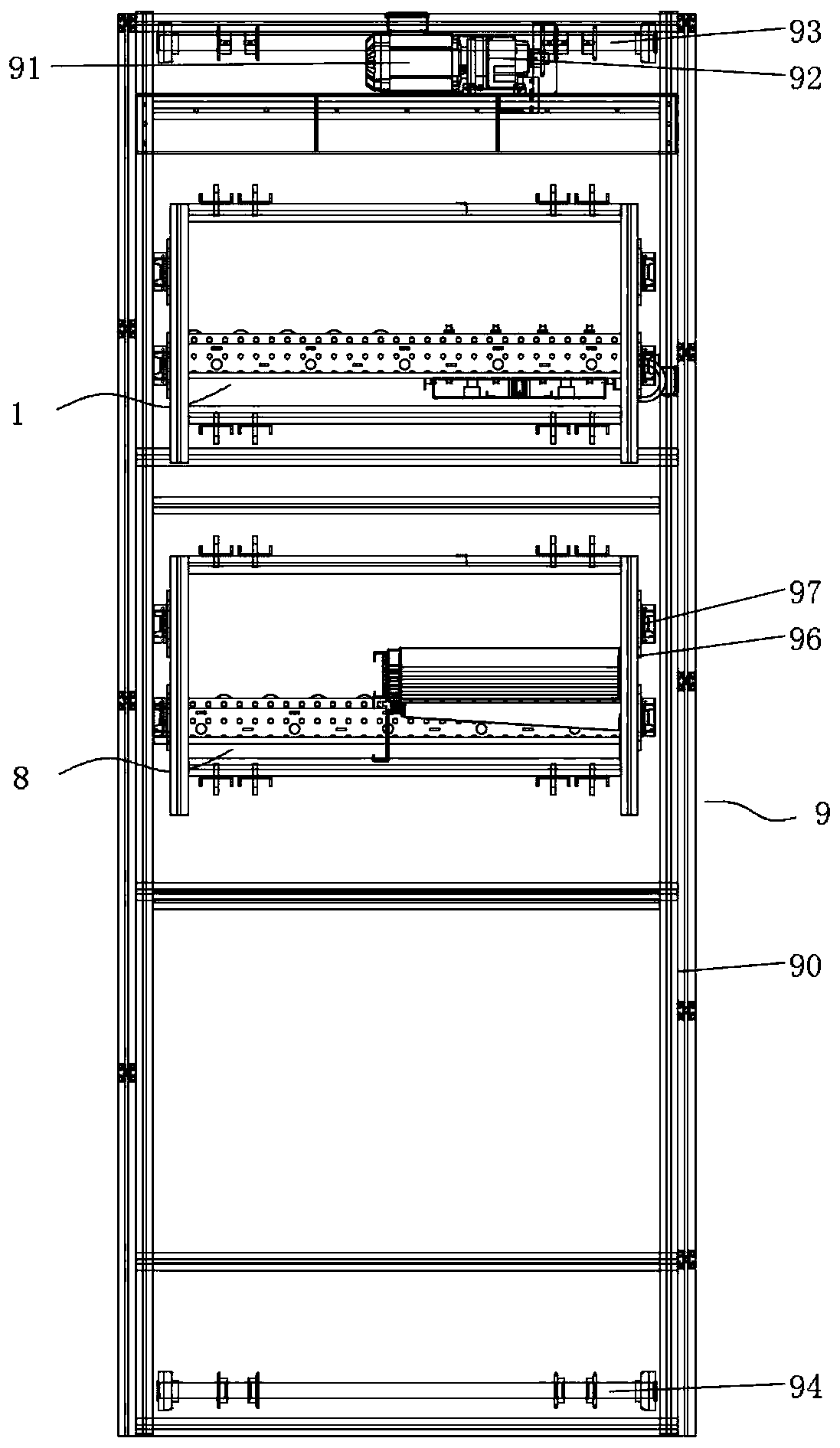

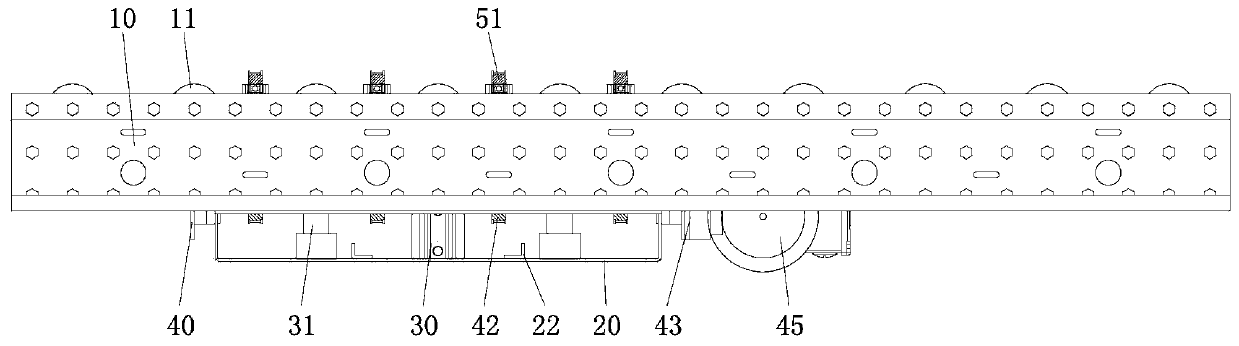

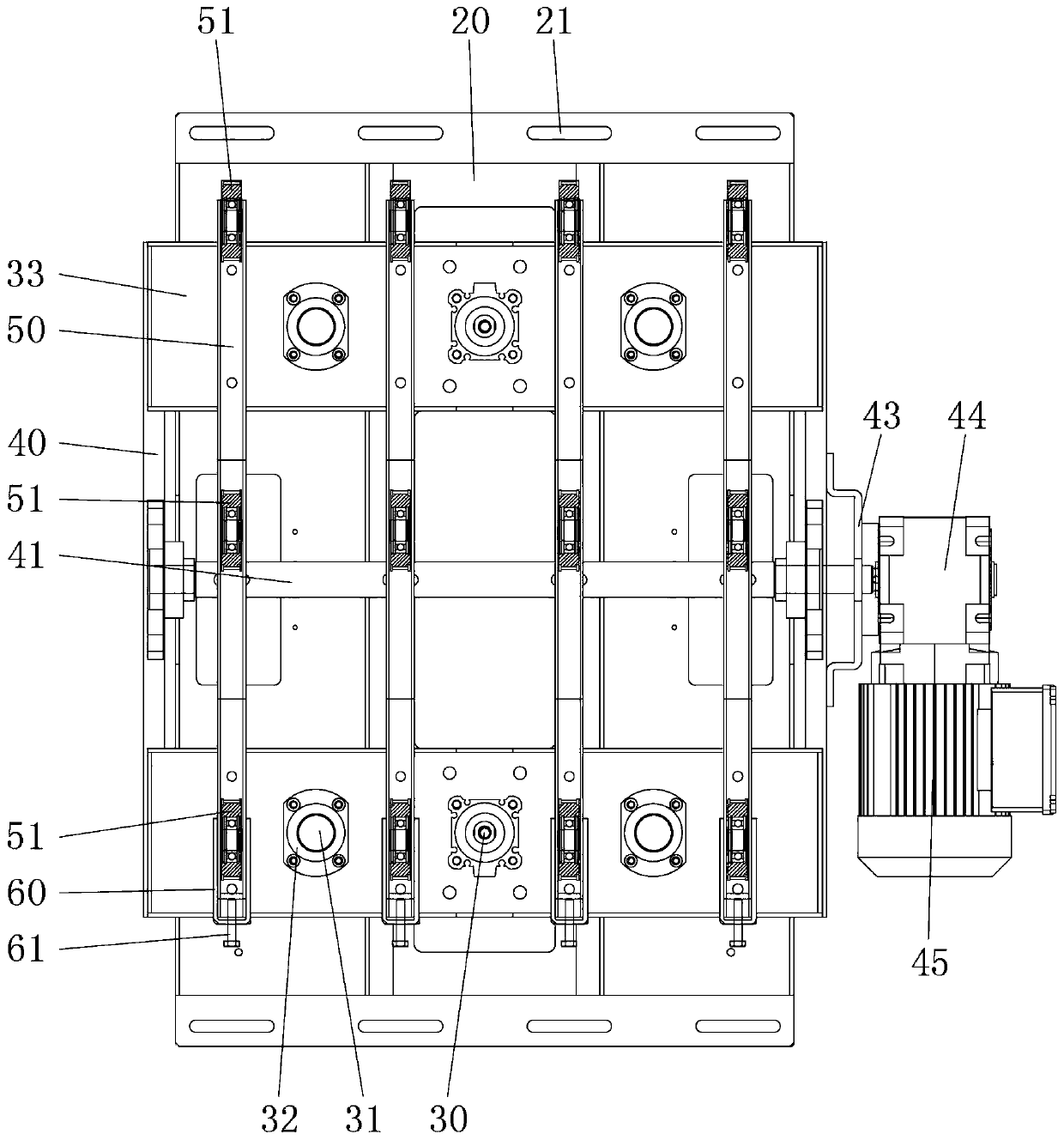

[0042] refer to figure 1 As shown, the present invention discloses a high-speed four-way entry and exit hoist, including a hoisting module 9 , a synchronous belt transfer module 1 and a turning conveying module 8 .

[0043] The lifting module 9 includes a lifting frame 90 , a lifting drive source 91 , a lifting drive shaft 93 , a lifting driven shaft 94 and a hanger 96 .

[0044] The lifting driving source 91 , lifting driving shaft 93 and lifting driven shaft 94 are all arranged on the lifting frame 90 . The free end of the lifting drive source 91 is connected to the lifting drive shaft 93 . The lifting drive shaft 93 and the lifting driven shaft 94 are respectively located at the upper and lower ends of the lifting frame 90 . A transmission chain (not shown in the figure) is arranged between the lifting driving shaft 93 and the lifting driven shaft 94 . The lifting drive source 91 can drive the lifting drive shaft 93 to rotate, thereby driving the transmission chain to ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com