Intelligent dynamic metering production system

An intelligent dynamic and automatic feeding technology, applied in loading/unloading, container, packaging and other directions, can solve the problems such as the huge difference in the height of the mold cavity between the tonnage model and the size, the vibration source cannot be completely solved, and the weighing error of the vibration source, etc. The effect of convenient and fast discharging, simple structure and controllable speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

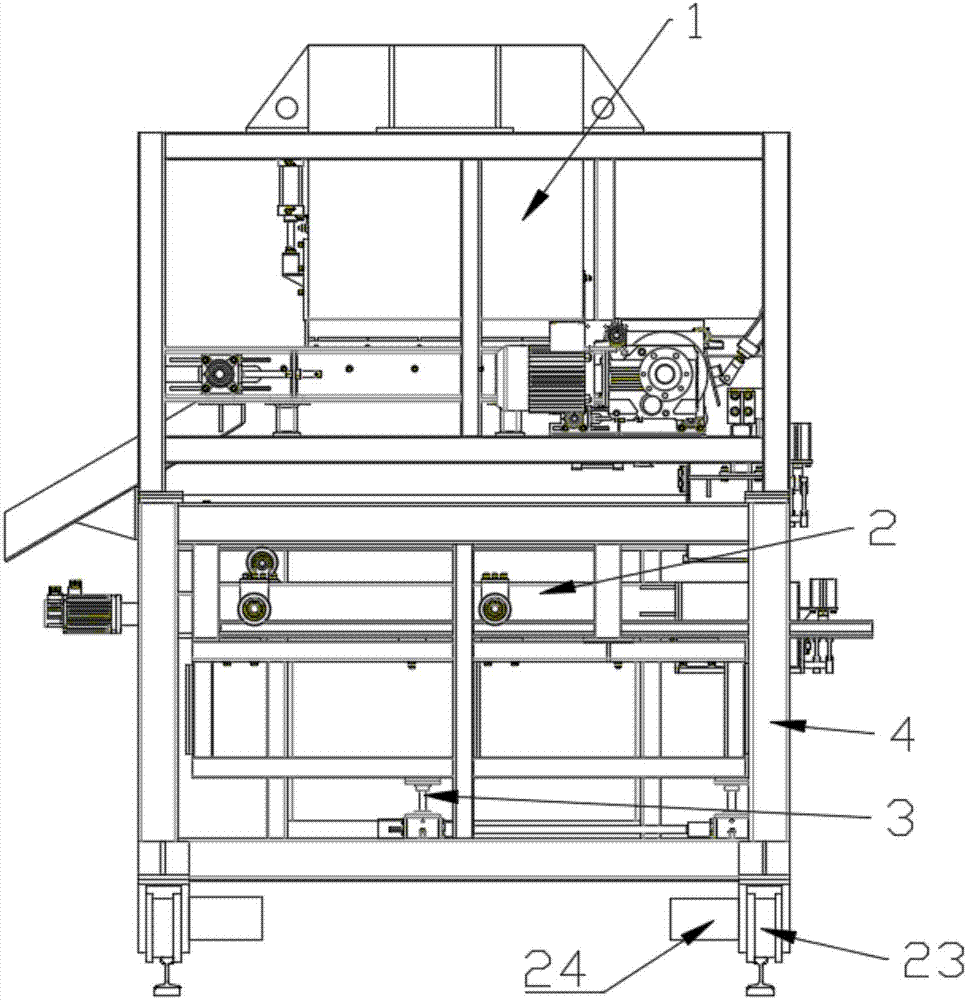

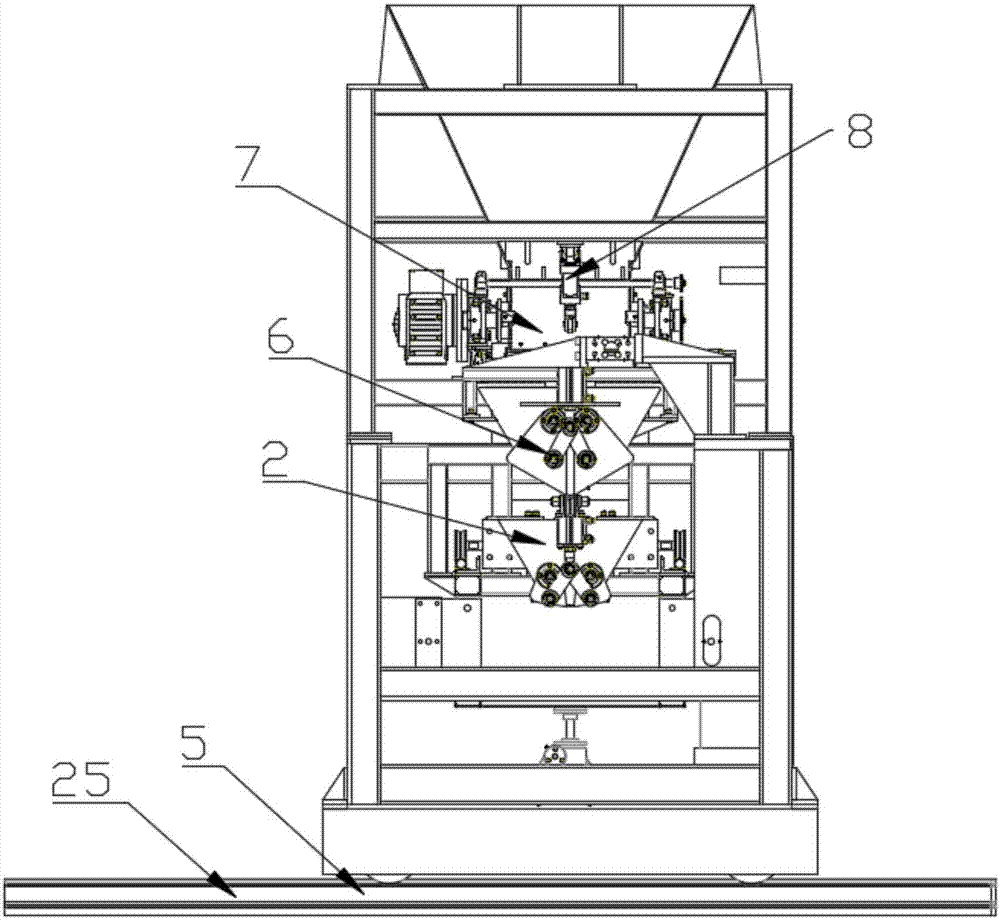

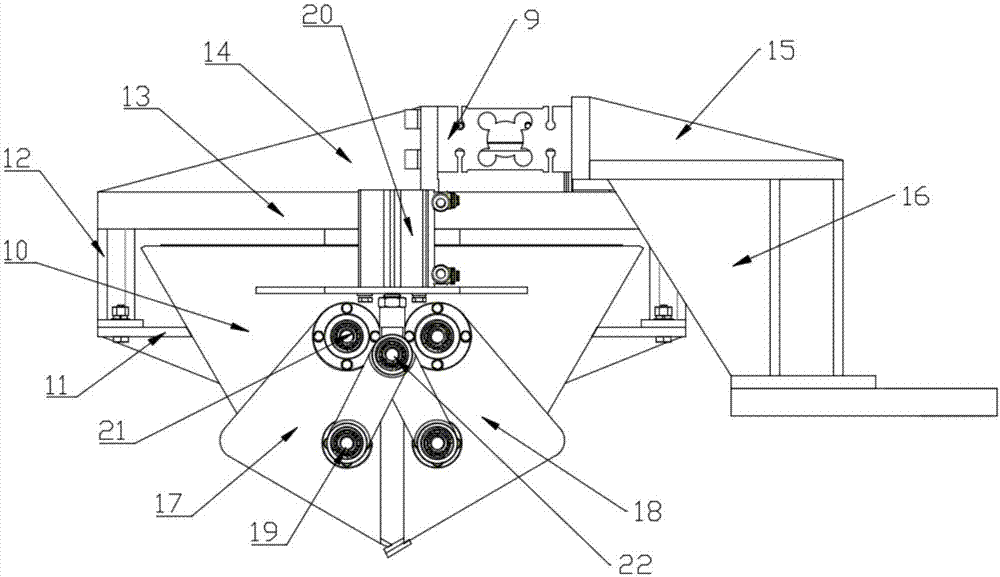

[0025] see Figure 1-2 , an intelligent dynamic measurement and prediction system, mainly composed of a silo prediction device 1, an accurate weighing device 6, an automatic feeding device 2, an automatic double lifting mechanism 3, a track translation device 5, and a body fixing mechanism 4. The lower part of the device 1 is connected to the precise weighing device 6, and the lower part of the precise weighing device 6 is connected to the automatic feeding device 2. The automatic feeding device 2 is fixed on the body fixing mechanism 4 through the automatic double lifting mechanism 3, and the body fixing mechanism 4 is provided with rails through the bottom. Translating device 5 performs lateral movement.

[0026] The silo anticipating device 1 includes a pretreatment silo, the interior of the pretreatment silo is provided wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com