Curve chain type conveying mechanism

A technology of chain conveying and curve, applied in the direction of conveyor, conveyor objects, transportation and packaging, etc., can solve the problem that a single set of mechanism cannot change the direction of material conveying.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

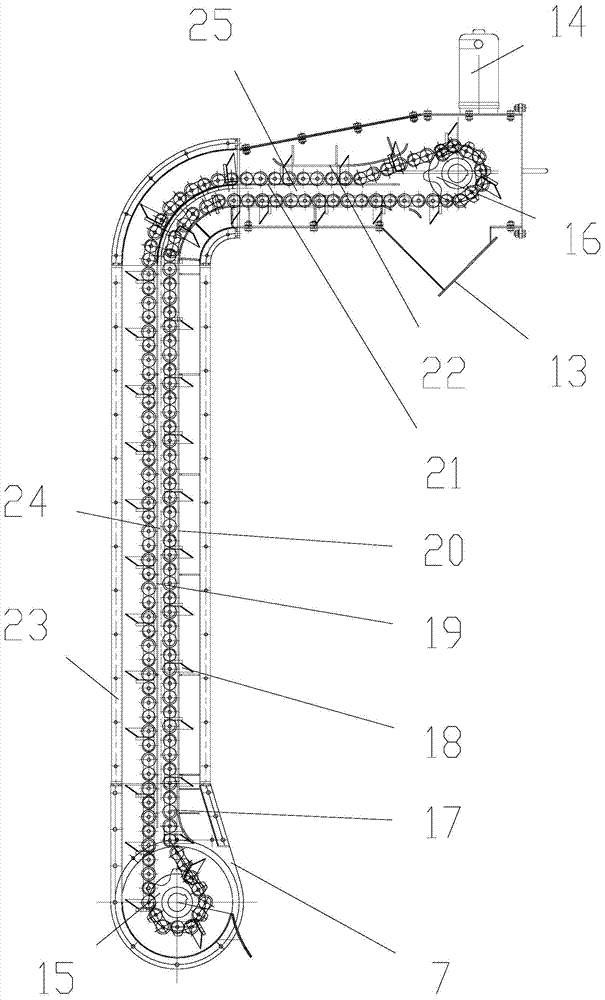

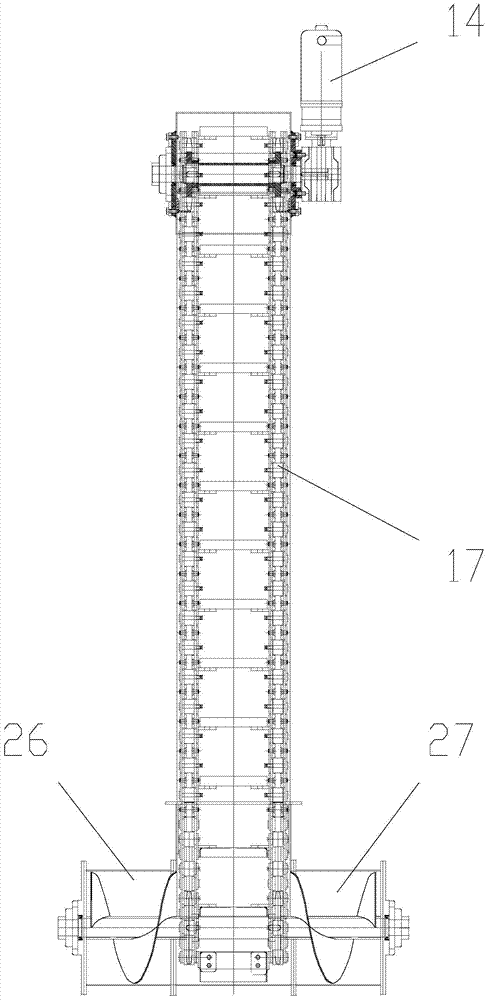

[0017] Below in conjunction with accompanying drawing, this technology is further described:

[0018] see figure 1 , figure 2 The curved chain conveying mechanism shown includes a box body 23 with a feed port 7 and a discharge port 13 at both ends, and sprockets 15 and 16 that are rotated in the feed port 7 and the discharge port 13. , the chain 17 that is arranged on the sprockets 15 and 16, the scraper bucket 18 that is rigidly connected to the outside of the chain 17, the power source (motor) 14 that is arranged on the box body 23 to provide power for the curved chain conveyor mechanism; One section of the body 23 is vertically arranged to form the vertical lifting section 24 of the material conveying device 5, and the other section extends backward after smooth bending to form the direction-changing transport section 25 of the material conveying device 5; in the box body 23, the lower sprocket 15 is also provided with left and right feed screw 26 and 27 coaxial with low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com