Small cigarette packet side face shaping device

A technology for shaping devices and cigarette packs, applied in packaging and other directions, can solve problems such as negative impact on sales, and achieve the effect of continuing fully automated production, solving quality problems, and operating safely and reliably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

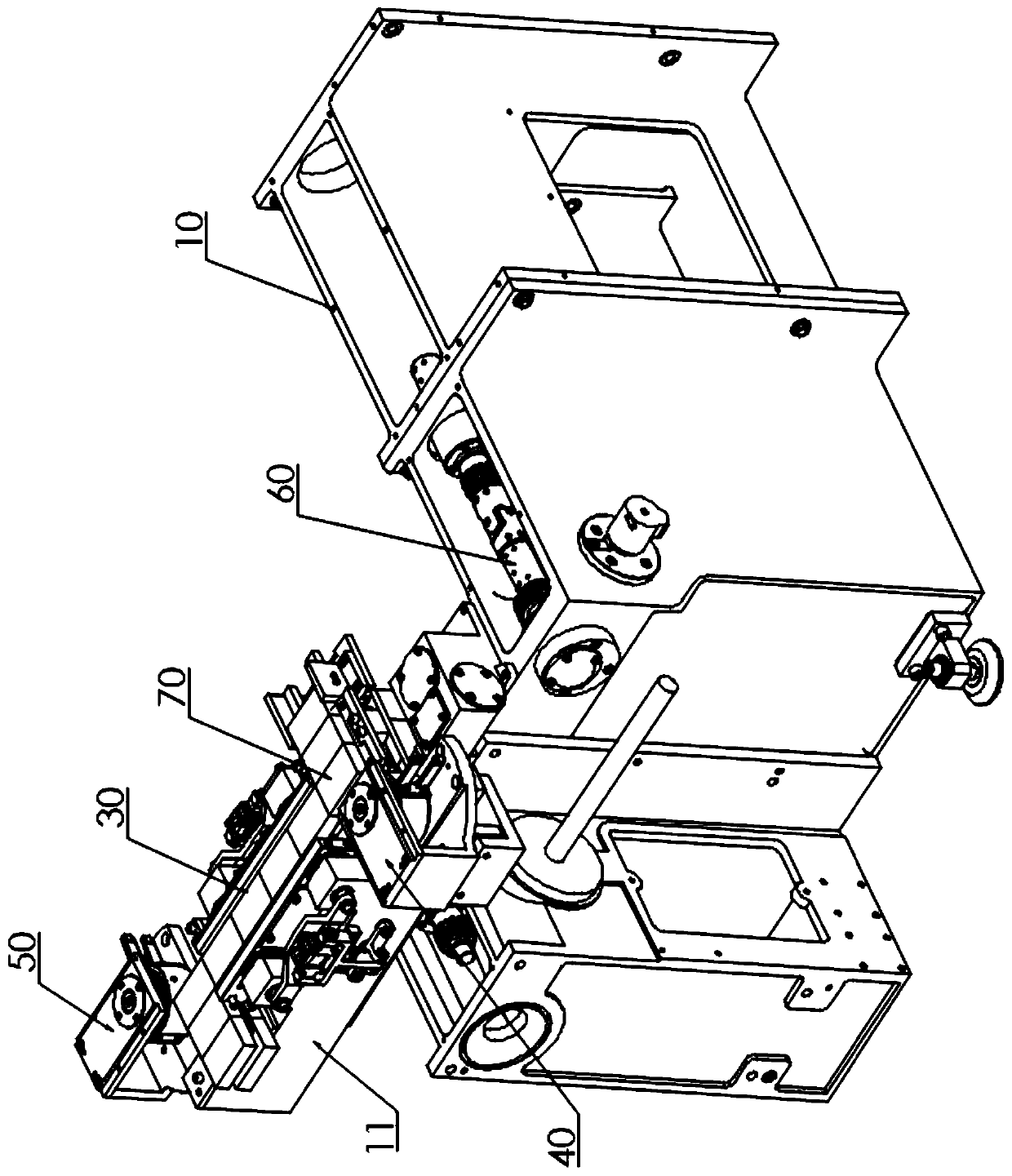

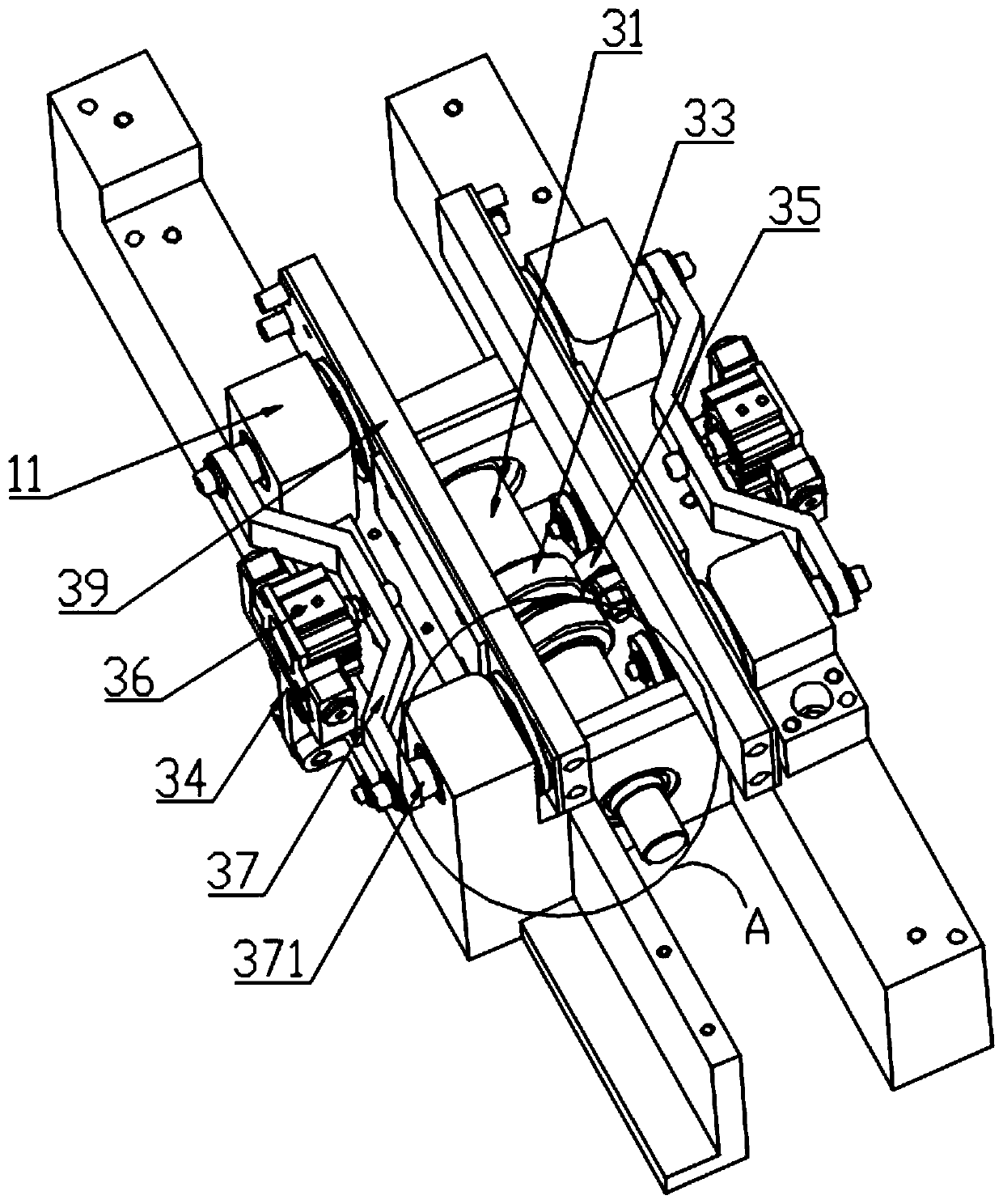

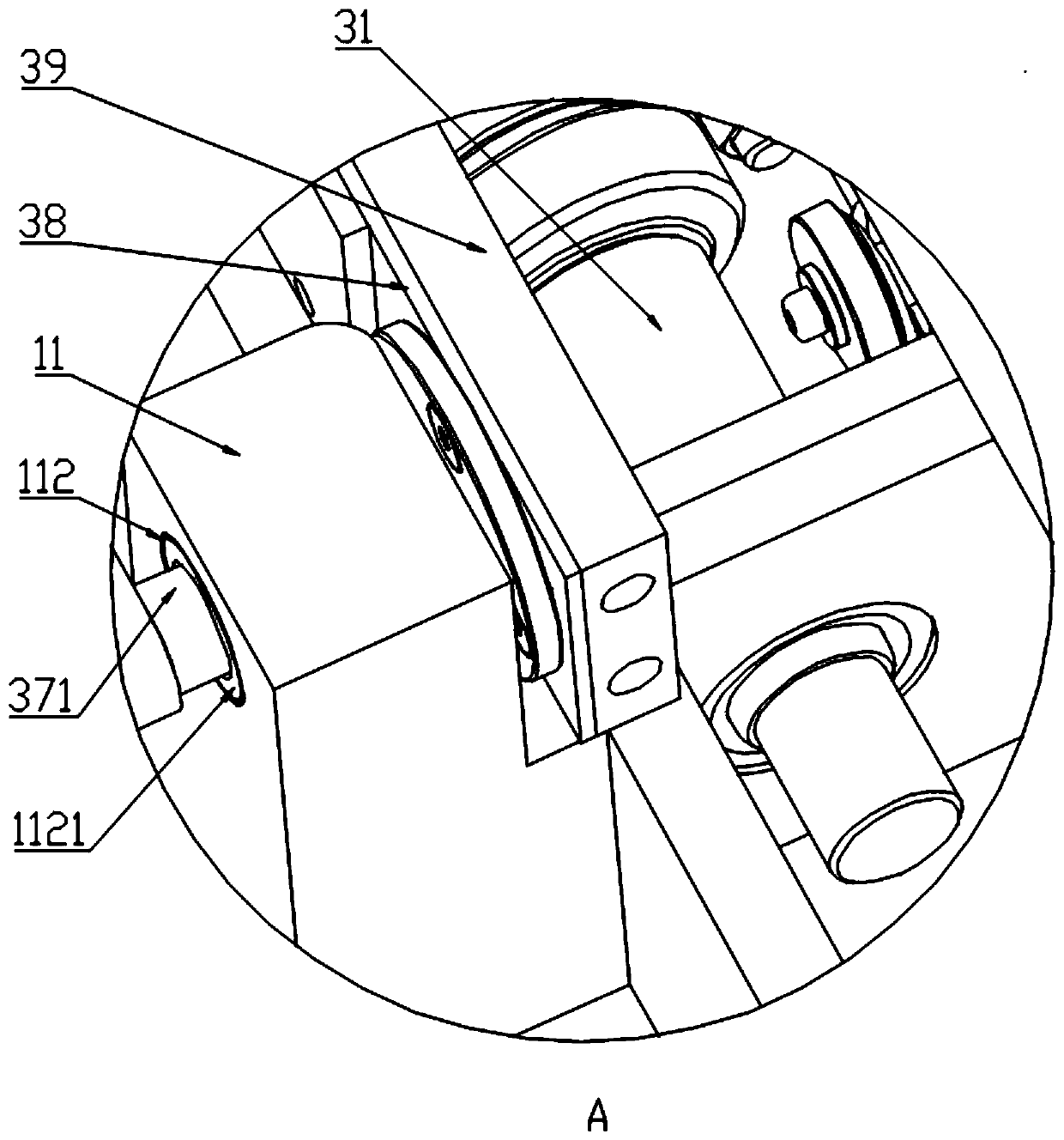

[0048] see Figure 1 to Figure 6 , a side shaping device for a small pack of cigarettes in the present embodiment, comprising a box body 10, a delivery channel, a soldering iron plate moving mechanism 30, a first toggle mechanism 40, a second toggle mechanism 50 and a transmission mechanism 60; the box Body 10 is respectively provided with side panel 11 on both sides corresponding to shaping channel 22; Described transmission mechanism 60 is arranged in the casing 10, and this transmission mechanism 60 is gear transmission mechanism 60, and the input end of this transmission mechanism 60 and power source (figure not shown), the transmission mechanism 60 has a first output end and a second output end;

[0049] Specifically, the delivery channel is arranged on the box body 10, and the delivery channel includes an input channel 21, a shaping channel 22 and an output channel 23; the input channel 21 and the output channel 23 are respectively vertically communicated with the two en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com