A kind of tubular membrane preparation method for membrane distillation

A tubular membrane and membrane distillation technology, which is applied in the fields of nanofiber tubular membrane preparation, tubular membrane preparation, and electrospinning tubular membrane preparation, can solve the problems of high operating cost, difficult control, and difficult control of membrane preparation conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

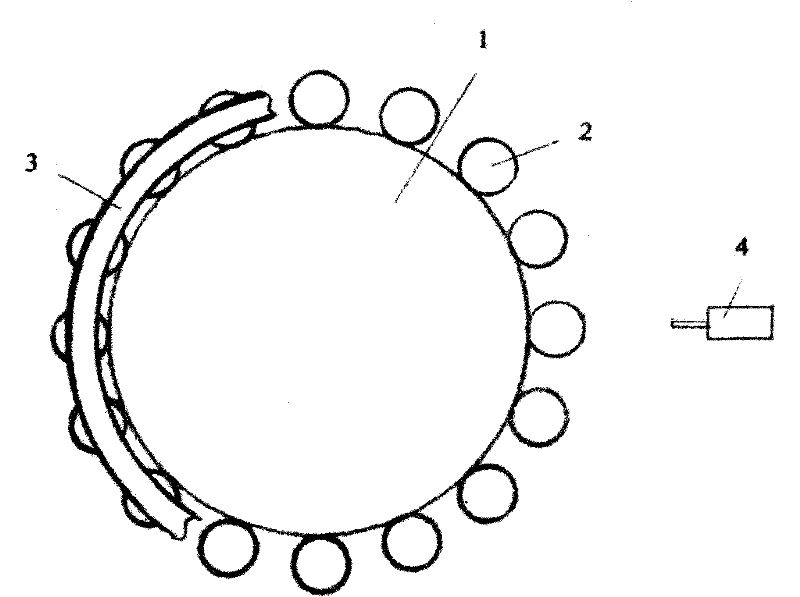

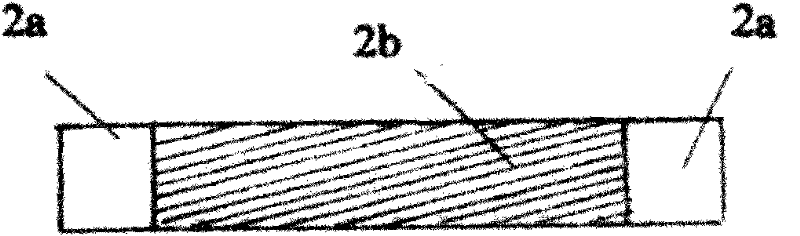

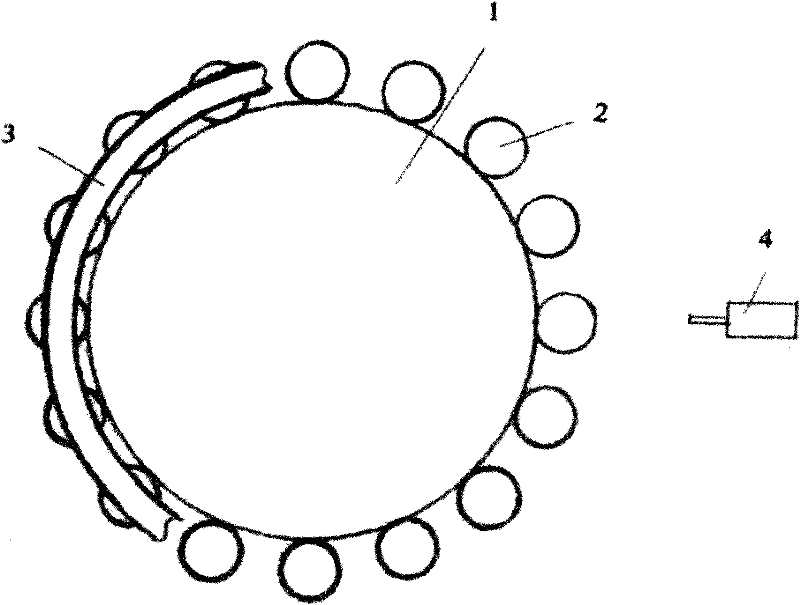

[0009] Dissolve PVDF with a molecular weight of 600,000 in a mixed solvent of DMF and acetone, and the concentration is 10 g of PVDF in every 100 ml of mixed solvent. In order to obtain a membrane with high porosity, the volume ratio of the mixed solvent to DMF is 60%. Stir at a constant temperature of 40°C to best extend the PVDF molecules in the mixed solvent. The viscosity of the solution was measured with a rotational viscometer. When the viscosity reached the maximum, it indicated that the macromolecular PVDF molecules were stretched optimally in the mixed solvent. At this point the solution is ready for use and enters the electrospinning operation. Electrospinning was performed when the operating room temperature reached 30°C and the humidity was below 40%. Adjust the rotation speed of the central round roller 1 to make the film deposited on the support tube uniform. Adjust the rotational speed of the circular support 3 so that the film thickness deposited on each sup...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com