Superspeed fiber reinforced resin abrasive cut-off wheel

A fiber-reinforced resin, cutting grinding wheel technology, applied in the direction of bonding grinding wheels, abrasives, metal processing equipment, etc., can solve the problems of damaging the mechanical strength of grinding wheel cutting sheets, shortening the service life of grinding wheel cutting sheets, and blocking the surface of grinding wheel by chip removal. Enhanced strength, surface friction and chip removal, easy heat dissipation, and improved grinding speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

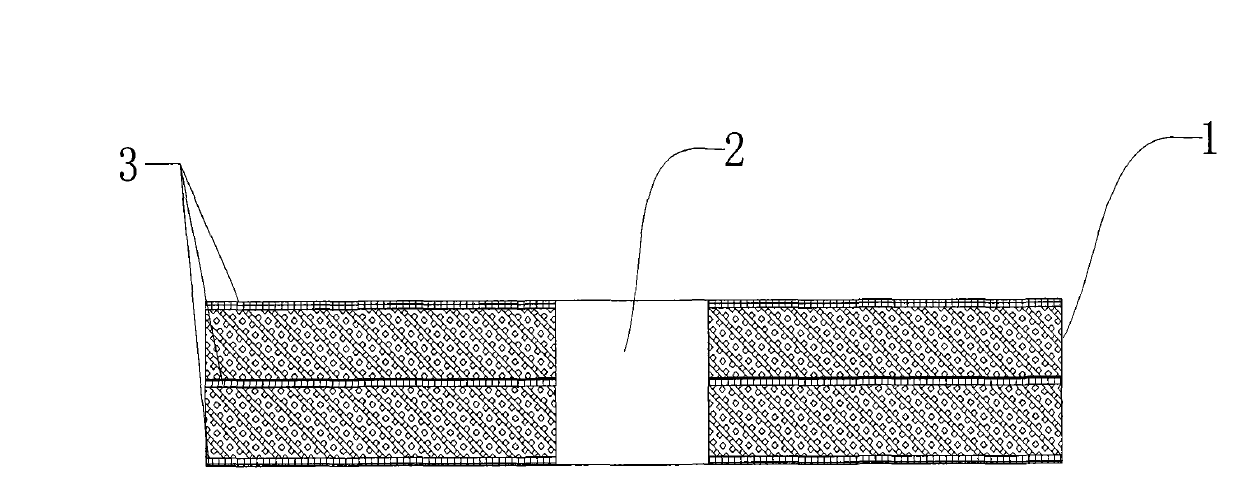

[0020] Such as figure 1 As shown, an ultra-high-speed fiber-reinforced resin cutting grinding wheel provided by the embodiment of the present invention includes a grinding wheel main body 1, a central hole 2 is provided in the middle of the grinding wheel main body 1, and three layers of glass fiber mesh cloth 3 are arranged on the grinding wheel main body 1. A layer of glass fiber mesh cloth 3 is respectively located on the top surface, middle part and bottom surface of the grinding wheel main body 1, and is combined with the grinding wheel main body 1. The grinding wheel main body 1 is made of 70%-86% abrasive, 7%-19% bonding agent and 5%-12% filler is compounded togeth...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com