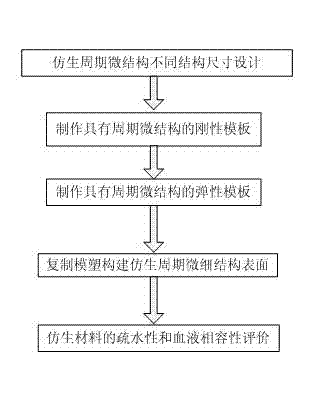

Method for constructing hemocompatible material surface with bionic periodic structure

A blood compatibility and construction method technology, applied in the design and manufacture of bionic micro-nano structures, can solve problems such as blood coagulation, achieve the effects of improving material surface friction, reducing side effects, and safe and reliable use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

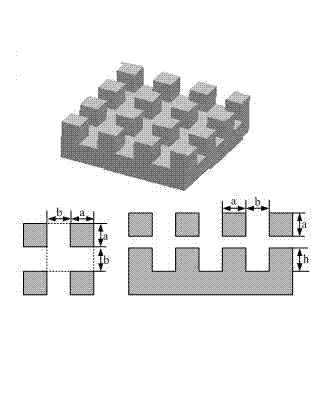

[0034] 1. Periodic surface structure design. According to the designed geometric model, the apparent contact angle calculation formula of the periodic structure surface is deduced based on the classical wetting theory, and the appropriate geometric structure size is determined according to the formula to meet the ideal superhydrophobic surface requirements. take side length a 10 mm, square column spacing b 20 mm, height h The apparent contact angle of the lower surface of the structure of this size is greater than 150°, which is superhydrophobic.

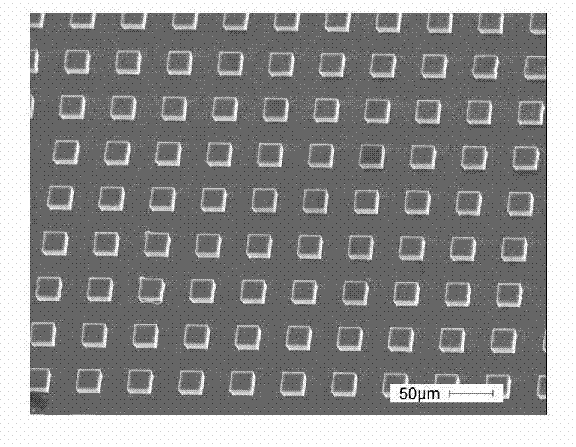

[0035] 2. Production of silicon-based hard (rigid) templates. Use photolithography to carve a periodic array of square pillars on the silicon substrate according to a pre-designed periodic microstructure pattern, and the side length of the micropillars a 10 mm, square column spacing b 20 mm, height his 5mm. First, clean the silicon wafer sample, and treat it at 180°C for more than 4 hours to remove surface water molecules, an...

Embodiment 2

[0041] 1. Periodic surface structure design. take side length a 20 mm, square column spacing b 50 mm, height h The apparent contact angle of the lower surface of this size structure is greater than 150°, which is superhydrophobic.

[0042] 2. Production of K9 glass hard template. Use photolithography to carve a periodic array of square pillars on the silicon substrate according to a pre-designed periodic microstructure pattern, and the side length of the micropillars a 20 mm, square column spacing b 50 mm, height h is 20mm. First, clean the K9 glass sample, and treat it at 180°C for more than 4 hours to remove surface water molecules, and use a thick glue spinner (Karl Suss, Germany, RC8) to spin-coat SU with the required thickness on the surface of K9 glass. -8 photosensitive resin, the thickness of the SU-8 layer can be controlled by adjusting the speed and time of glue rejection. Then, pre-baking the SU-8 glue was performed in a programmed oven, and a photoresist mo...

Embodiment 3

[0048] 1. Periodic surface structure design. take side length a 50 mm, square column spacing b 100 mm, height h The apparent contact angle of the lower surface of this size structure is greater than 150°, which is superhydrophobic.

[0049] 2. Production of titanium dioxide hard template. Use photolithography to carve a periodic array of square pillars on the silicon substrate according to a pre-designed periodic microstructure pattern, and the side length of the micropillars a 50 mm, square column spacing b 100 mm, height h is 25 mm. Firstly, the titanium dioxide sample was cleaned and treated at 180°C for more than 4 hours to remove surface water molecules, and the surface of the silicon wafer was spin-coated with SU- 8 Photosensitive resin, the thickness of the SU-8 layer can be controlled by adjusting the speed and time of glue rejection. Then, pre-baking the SU-8 glue was performed in a programmed oven, and a photoresist model was obtained by contact exposure on a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com