Device and method for preparing a recess in a bone

a technology for preparing bones and bones, applied in the field of bone preparation recesses or holes, can solve the problems of increasing pain for patients, affecting the healing process, and inconvenient use of single recess screws,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

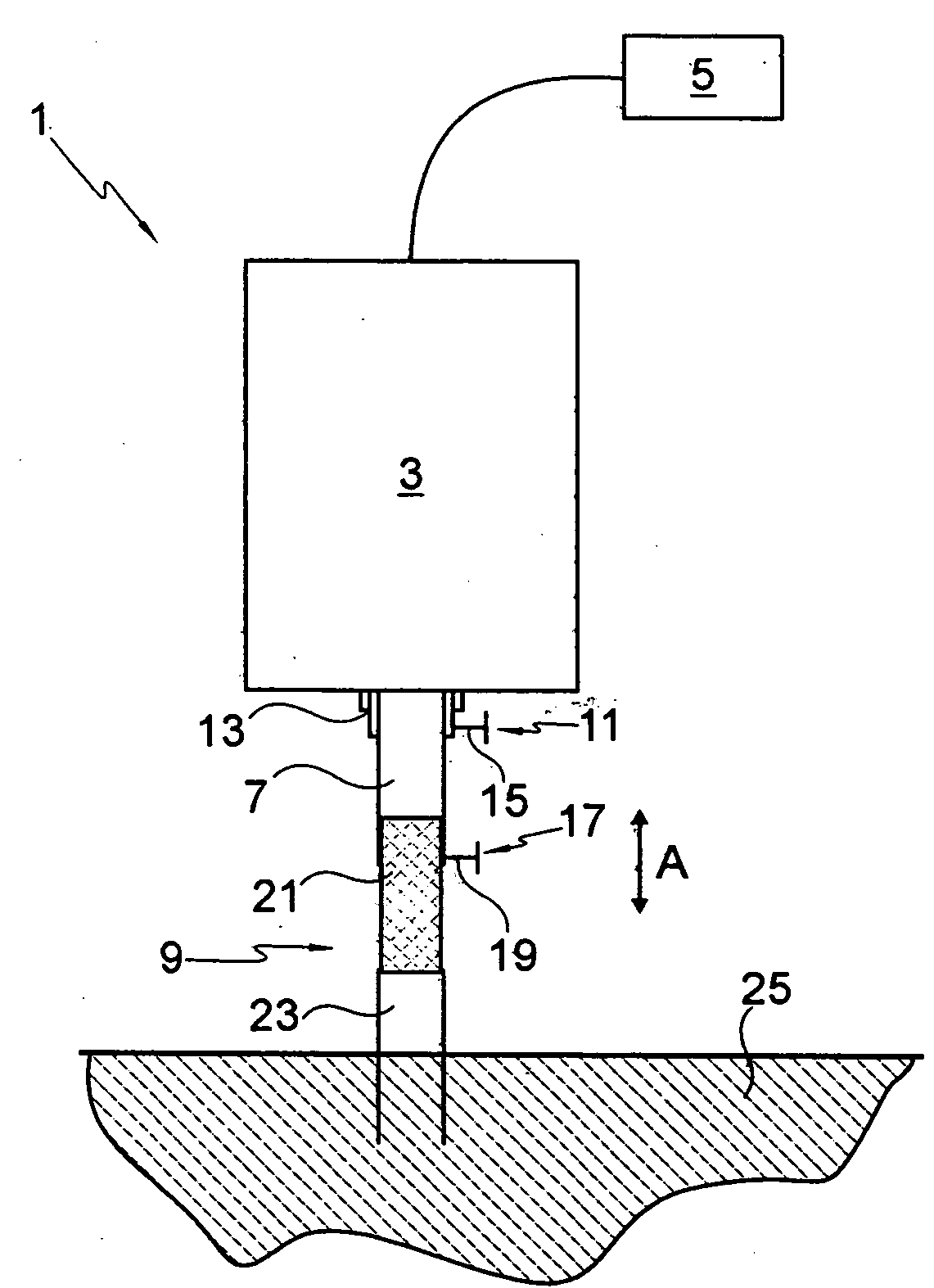

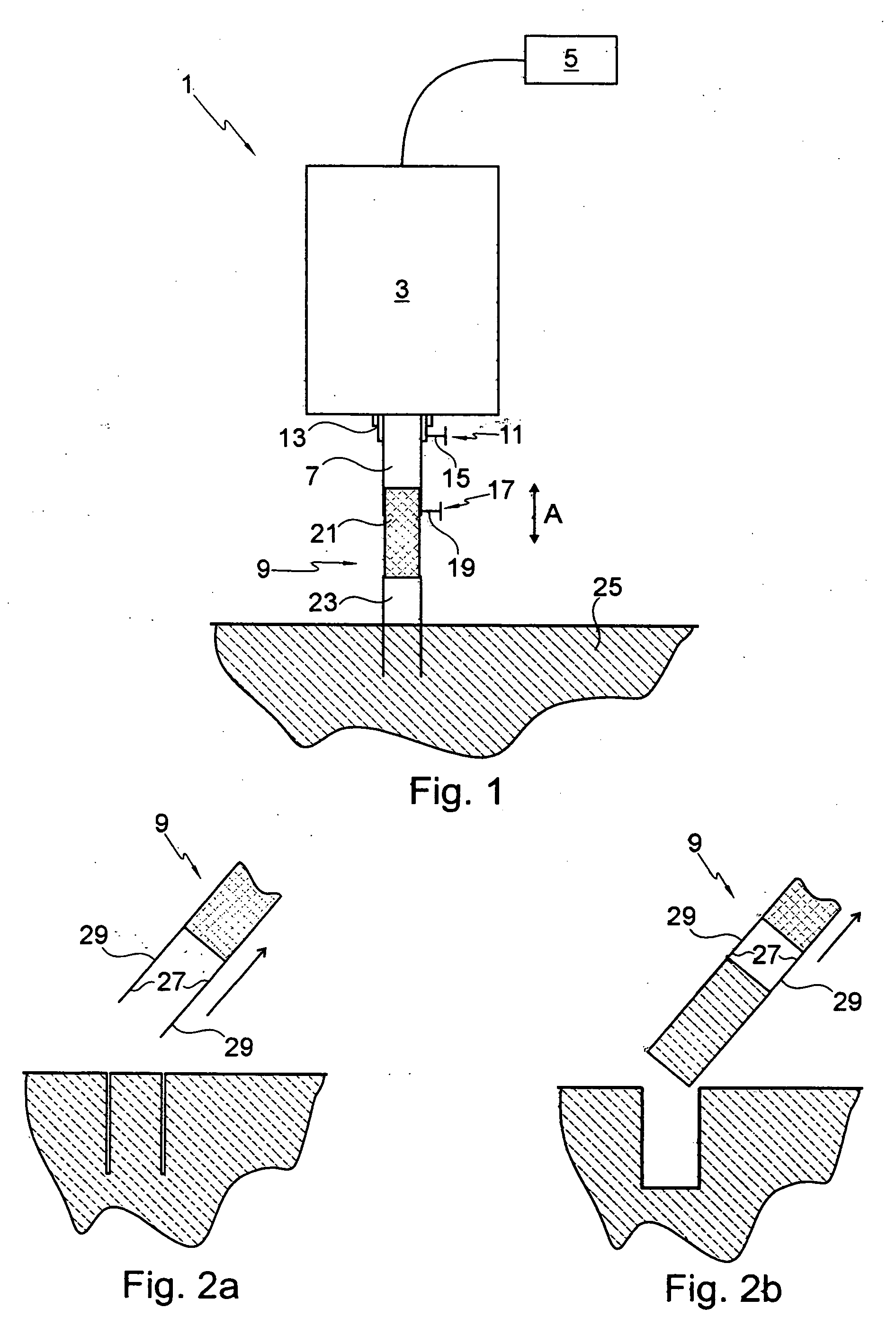

[0037]As schematically shown in FIG. 1, a punching device 1 according to an embodiment of the invention comprises an ultrasonic generator 3 controlled via a control 5, an ultrasonic sonotrode 7 and a punching tool 9.

[0038]The ultrasonic sonotrode 7 is coupled to the ultrasonic generator 3 via a fixation mechanism 11 which can comprise for example a frame 13 and a clamping screw 15. The ultrasonic generator 3 is adapted to emit ultrasonic vibrations with an adaptable frequency of e.g. 20 to 50 kHz which are transmitted to the sonotrode 7. The arrow A in FIG. 1 indicates a direction of these ultrasonic vibrations. Furthermore, the ultrasonic generator 3 may be adapted to produce ultrasonic vibrations with a selectable amplitude of between 5 and 100 μm along the direction A.

[0039]The punching tool 9 is coupled to the ultrasonic sonotrode 7 via a further fixation mechanism 17 which can comprise a clamping screw 19. Thereby, the ultrasonic vibrations can be transmitted from the sonotrode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com