Preparation method of anti-skid elastic spandex core-spun yarn suitable for jean fabric

A technology of spandex core-spun yarn and denim fabric, which is applied in the preparation of anti-slip elastic spandex core-spun yarn and the field of preparation of anti-slip elastic spandex core-spun yarn. Effect of Hysteresis Area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

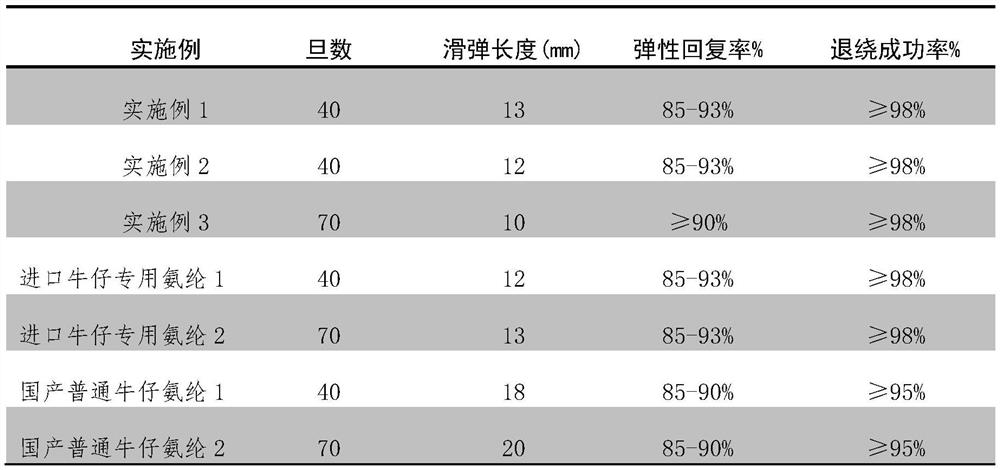

Examples

Embodiment 1

[0033] Step 1: Prepolymer Preparation

[0034] 1) Mix the raw materials polytetramethylene ether glycol PTMG 2000 and 4,4'-diphenylmethane diisocyanate, and react at 80°C for 100 minutes to prepare an isocyanate group-terminated prepolymer, in which 4,4'- The mol ratio of diphenylmethane diisocyanate and polytetramethylene ether glycol 2000 is 1.70:1;

[0035] 2) After the prepolymer is cooled to 45° C., N,N-dimethylacetamide solution is added and mixed evenly by sufficient stirring to prepare a solution with a concentration of 35% by mass.

[0036] The second step: the preparation of polyurethane urea

[0037] 2) Dissolving ethylenediamine and diethylamine into the solvent N,N-dimethylacetamide to form a mixed amine solution with a concentration of 7.00% by mass;

[0038] 3) Add the prepared mixed amine solution to the N,N-dimethylacetamide solution of the prepolymer and stir rapidly to react to form a polyurethane solution with a concentration of 35% by mass, wherein the a...

Embodiment 2

[0047] Step 1: Prepolymer Preparation

[0048] 1) Mix the raw material polytetramethylene ether glycol PTMG 1800 with 4,4'-diphenylmethane diisocyanate and 2,4'-diphenylmethane diisocyanate, and react at 90°C for 120 minutes to prepare the isocyanate group Blocked prepolymer in which the mass ratio of 2,4'-diphenylmethane diisocyanate to 4,4'-diphenylmethane diisocyanate is 1:9 and the molar ratio of isocyanate groups to hydroxyl groups is 2.00:1 ;

[0049] 2) After cooling the prepolymer to 45° C., add N,N-dimethylacetamide solution, stir and mix evenly to prepare a solution with a concentration of 40% by mass.

[0050] The second step: the preparation of polyurethane urea

[0051] 2) dissolving ethylenediamine, butylenediamine, and diethylamine into the solvent N,N-dimethylacetamide to form a mixed amine solution with a concentration of 7.00% by mass;

[0052] 3) Add the prepared mixed amine solution to the N,N-dimethylacetamide solution of the prepolymer and stir rapidly...

Embodiment 3

[0061] Step 1: Prepolymer Preparation

[0062] 1) Mix the raw materials polytetramethylene ether glycol PTMG 2000 and 4,4'-diphenylmethane diisocyanate, and react at 90°C for 100 minutes to prepare an isocyanate group-terminated prepolymer, in which 4,4'- The mol ratio of diphenylmethane diisocyanate and polytetramethylene ether glycol 2000 is 1.50:1;

[0063] 2) After cooling the prepolymer to 45° C., add N,N-dimethylacetamide solution, stir and mix evenly to prepare a solution with a concentration of 40% by mass.

[0064] The second step: the preparation of polyurethane urea

[0065] 2) dissolving ethylenediamine, butylenediamine, diethylamine, and 1,4-butanolamine into the solvent N,N-dimethylacetamide to form a mixed amine solution with a concentration of 7.00% by mass;

[0066] 3) Add the prepared mixed amine solution to the N,N-dimethylacetamide solution of the prepolymer and stir rapidly to react to form a polyurethane solution with a mass percentage concentration of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com