Filter material for self-antibacterial and self-disinfecting mask and manufacturing method thereof

A manufacturing method and mask technology, applied in separation methods, chemical instruments and methods, applications, etc., can solve the problems of non-antibacterial and disinfecting mask filter material manufacturing methods, low sterilization efficiency, etc., to achieve high safety and avoid secondary pollution , the effect of reducing the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

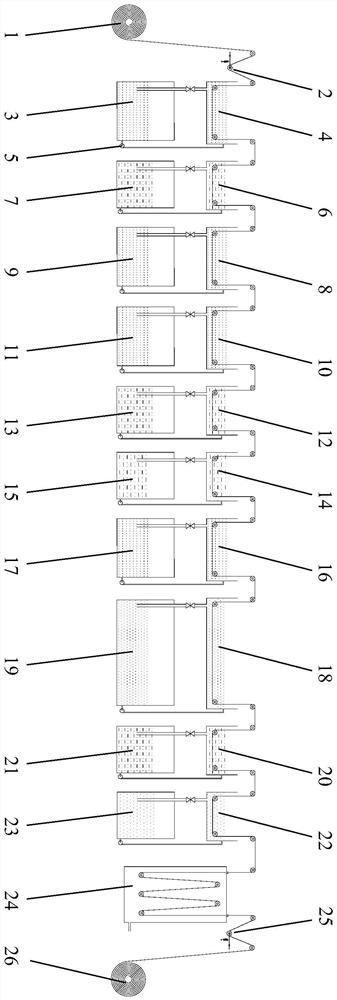

[0044] Embodiment one: as shown in Figure 1, the manufacture method of a kind of novel self-antibacterial disinfection mask filter material of the present invention comprises the following major steps:

[0045] (1) Power discharge, according to the tension information detected by the discharge tension adjustment roller, the speed of the discharge motor is controlled to achieve constant tension discharge and stable and constant speed production;

[0046] (2) Degreasing: use alkaline degreasing agent for cleaning, a preferred formula contains NaOH 150±100 g / L, NaOH 2 CO 3 30±20 g / L, Na 3 PO 4 30±20 g / L, alkylphenol polyoxyethylene ether 0.5±0.5 g / L, sodium lauryl sulfate or sodium lauryl sulfate 0.5±0.5 g / L, appropriate amount of defoamer, temperature controlled at 60±20℃;

[0047] (3) After degreasing, wash with water until the washing water is neutral, and multi-stage countercurrent washing can be used to improve efficiency;

Embodiment 2

[0058] Embodiment 2: The difference from Embodiment 1 is that the activation process uses PdCl 2 The acidic solution is activated, and then add pure water washing process and clean the filter material until it is neutral, and then enter the pre-silver process as well. Other steps are all with embodiment one, wherein a kind of preferred palladium activation solution formula is: PdCl 2 0.15±0.1 g / L, concentrated HCl (37±3%) 25±10mL / L, control temperature at 30±20°C.

Embodiment 3

[0059] Embodiment 3: The difference from Embodiment 2 is that after the activation and washing process, the degumming process is added, and then the pre-silvering process is also entered, and other steps are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com