Flame-retarding polyvinyl alcohol-based composite crosslinked aerogel-coating rigid polyurethane foam material and preparation method thereof

A polyvinyl alcohol-based, rigid polyurethane technology, applied in the direction of fireproof coatings, alginic acid coatings, coatings, etc., can solve the problems of reducing the mechanical properties of foam materials, high cost, complicated preparation process, etc., and achieve excellent smoke suppression, Reduces the effect of smoke and toxic gases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

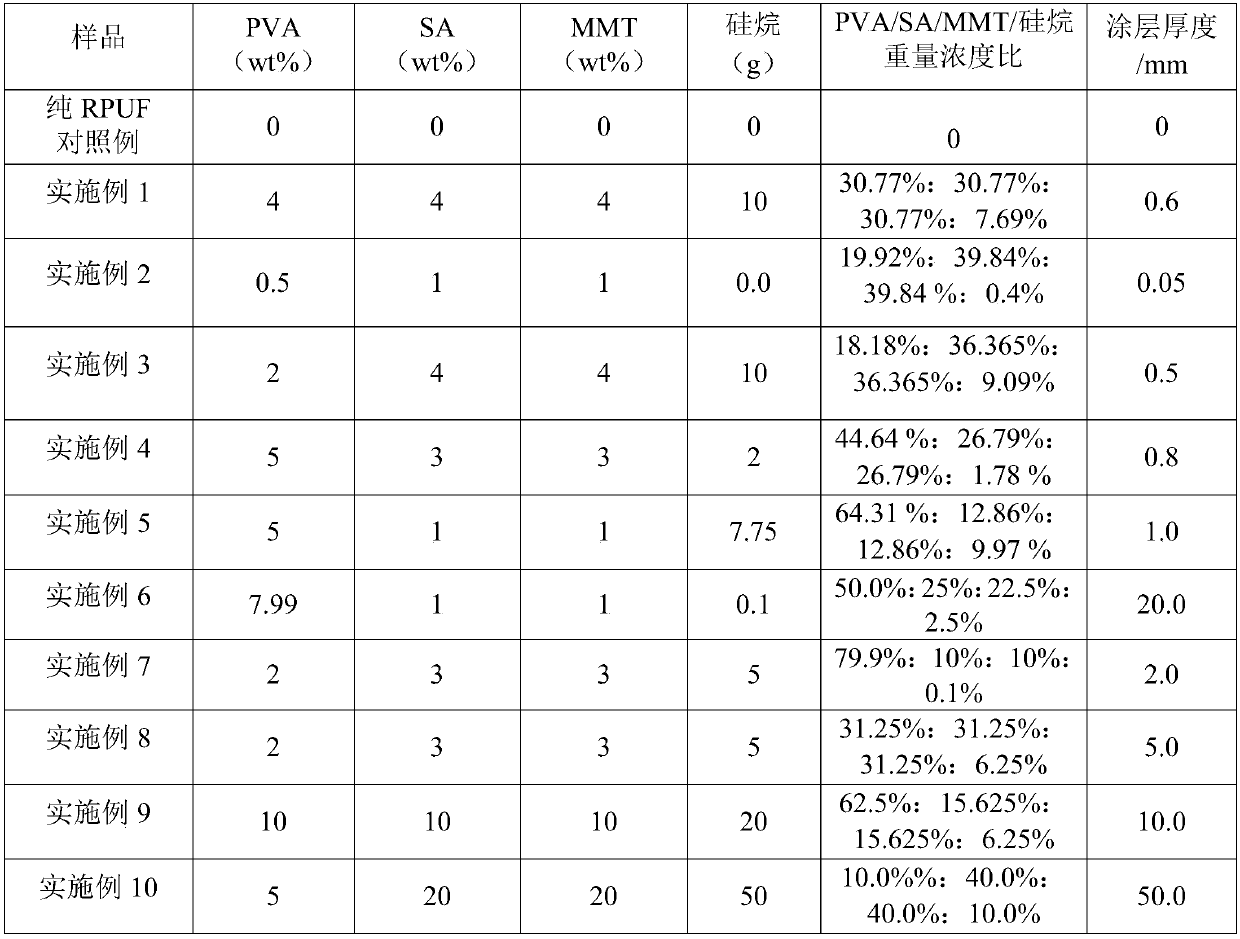

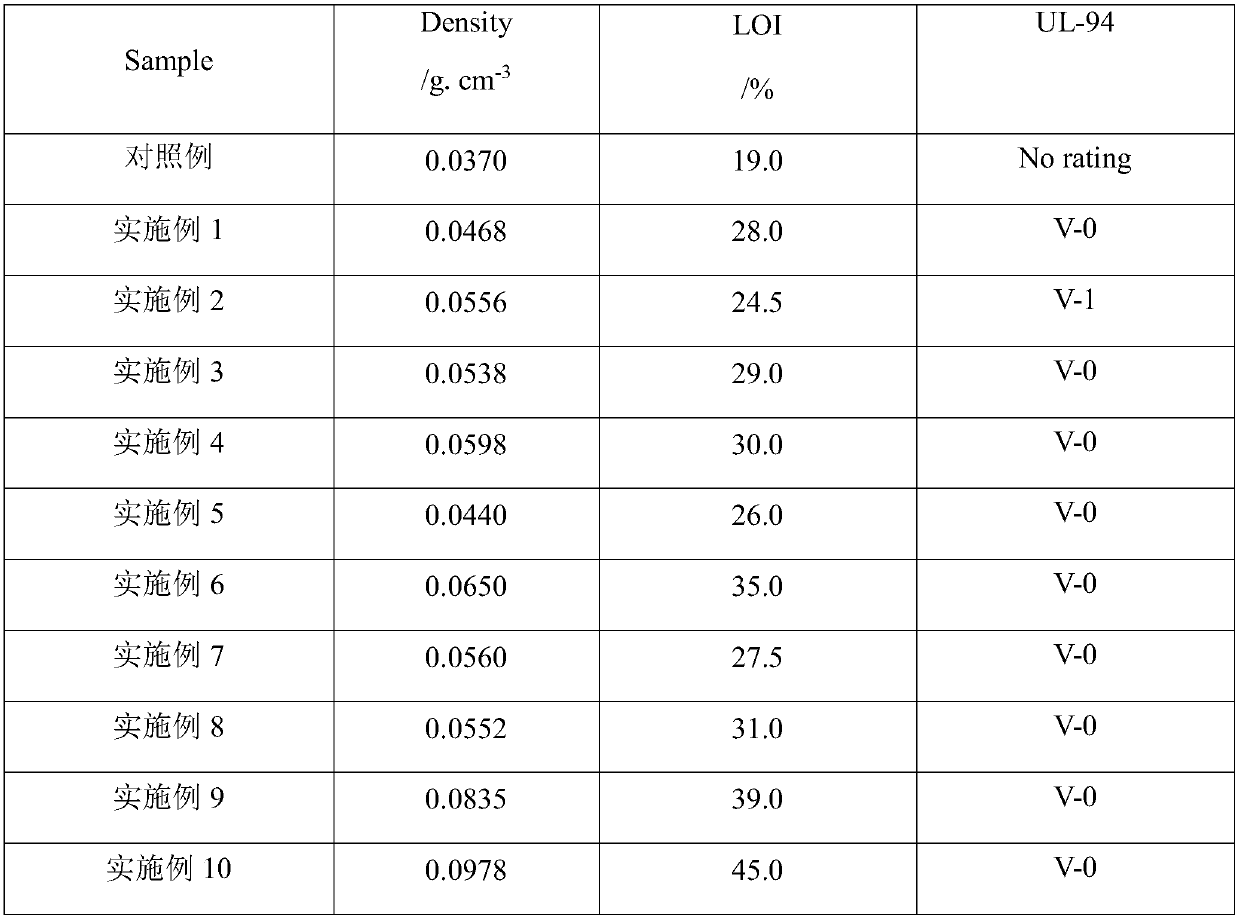

Embodiment 1

[0016] Prepare the RPUF sample by one-step free foaming method, weigh a certain amount of polyether polyol (4110), foaming agent and put it in a paper cup, stir at 2000rpm for 30s and mix well, then add a certain amount of isocyanate (MDI) and stir for 20s Finally, the mixture was quickly poured into a mold to obtain a freely foaming RPUF, and the RPUF material was aged at 80°C for 12 hours to prepare a rigid polyurethane foam sample.

[0017] Add 40g of polyvinyl alcohol into deionized water with a weight of 1000g of polyvinyl alcohol and heat to dissolve at 80°C, then add 40g of sodium alginate and 40g of montmorillonite and stir at high speed for 1 hour to make it fully gelled. solution, sodium alginate solution, and montmorillonite aqueous dispersion are 4wt%, 4wt%, and 4wt%, respectively, and the pH of the polyvinyl alcohol composite hydrogel is adjusted to 10 with ammonia water, and then compounded in polyvinyl alcohol Add 10 g of methyltrimethoxysilane dropwise to the h...

Embodiment 2

[0019] Firstly, RPUF samples were prepared by one-step free foaming. Weigh a certain amount of polyether polyol (4110), foaming agent and put it in a paper cup, stir at 2000rpm for 30s and mix well, then add a certain amount of isocyanate (MDI) and stir for 20s, then quickly pour the mixture into the mold, The freely foaming RPUF can be obtained, and the RPUF material is aged at 80° C. for 12 hours to prepare a rigid polyurethane foam sample.

[0020]Add 5g of polyvinyl alcohol into deionized water with a weight of 1000g of polyvinyl alcohol and heat to dissolve at 80°C, then add 10g of sodium alginate and 10g of montmorillonite and stir at high speed for 0.5 hours to make it fully gelled. solution, sodium alginate solution, and montmorillonite water dispersion by weight are 0.5wt%, 1wt% and 1wt%, respectively, using ammonia to adjust the pH of the polyvinyl alcohol composite hydrogel to be 9, and then Add 0.1g of methyltriethoxysilane dropwise to the composite hydrogel syste...

Embodiment 3

[0022] Firstly, RPUF samples were prepared by one-step free foaming. Weigh a certain amount of polyether polyol (4110), foaming agent and put it in a paper cup, stir at 2000rpm for 30s and mix well, then add a certain amount of isocyanate (MDI) and stir for 20s, then quickly pour the mixture into the mold, The freely foaming RPUF can be obtained, and the RPUF material is aged at 80° C. for 12 hours to prepare a rigid polyurethane foam sample.

[0023] Add 20g of polyvinyl alcohol into deionized water with a weight of 1000g of polyvinyl alcohol and heat to dissolve at 80°C, then add 40g of sodium alginate and 40g of montmorillonite and stir at high speed for 0.5 hours to make it fully gelled. solution, sodium alginate solution, and montmorillonite aqueous dispersion were 2wt%, 4wt%, and 4wt%, respectively, using ammonia to adjust the pH of the polyvinyl alcohol composite hydrogel to be 9, and then compounding the polyvinyl alcohol Add 10g of aminopropyl-aminoethyl-methyltrimet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com