Method for preparing nitrogen-phosphorus-magnesium compound fire retardant

A composite flame retardant, nitrogen and phosphorus technology, applied in the direction of fire-resistant coatings, can solve the problems of poor compatibility and high filling amount of magnesium-based flame retardants, achieve stable performance, significant product performance and environmental friendliness, and reduce the filling amount. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

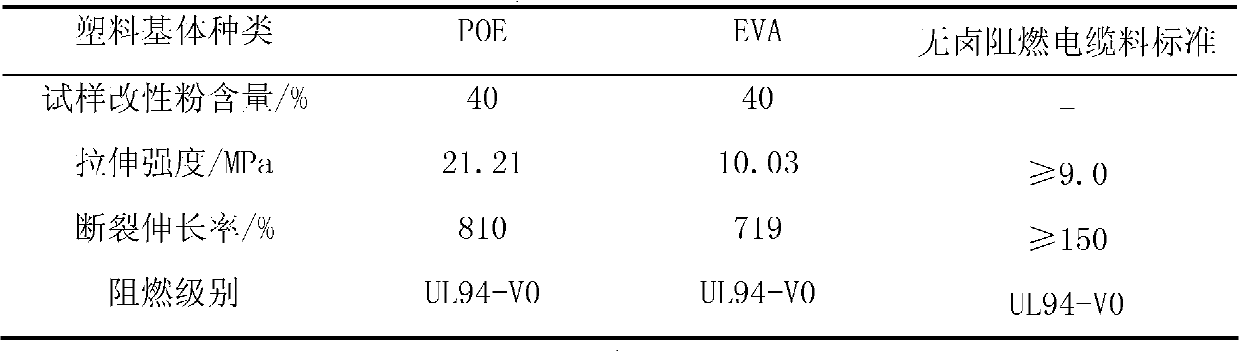

[0013] Take 10kg of 1000-8000 mesh magnesium hydroxide powder, 30g of sodium hexametaphosphate, and take 40L of a mixture of two-carbon alcohol and water at a ratio of 1:1 to 1:5 as a solvent, and add it to the reactor, keeping 150r / min stirring speed, heated to 60°C and kept warm for 1h; filtered, put the filter cake in the reactor, added 9kg of phosphoric acid alcohol solution with a mass ratio of 1:2, mixed and stirred for 15min, and then added the twelve-carbon-containing Nitrogen compound 1.5kg, continue to stir and react for 20 minutes, after the reaction is completed, dry the product to obtain a fluffy composite flame retardant product. The prepared composite flame retardant is used in EVA and POE plastics. The measured basic parameters and the comparison data of halogen-free flame-retardant cable materials are shown in Table 1, which shows that the composite flame retardant meets the corresponding national standard requirements.

[0014] Table 1 Application performanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com