Anticorrosive steel strand and its production method

A technology for steel strands and a manufacturing method, applied in the field of anti-corrosion prestressed bars and their production, can solve the problems of short service life of steel strands, easy cracking of epoxy coatings, easy generation of pinholes, etc. Good anchoring effect and not easy to crack

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

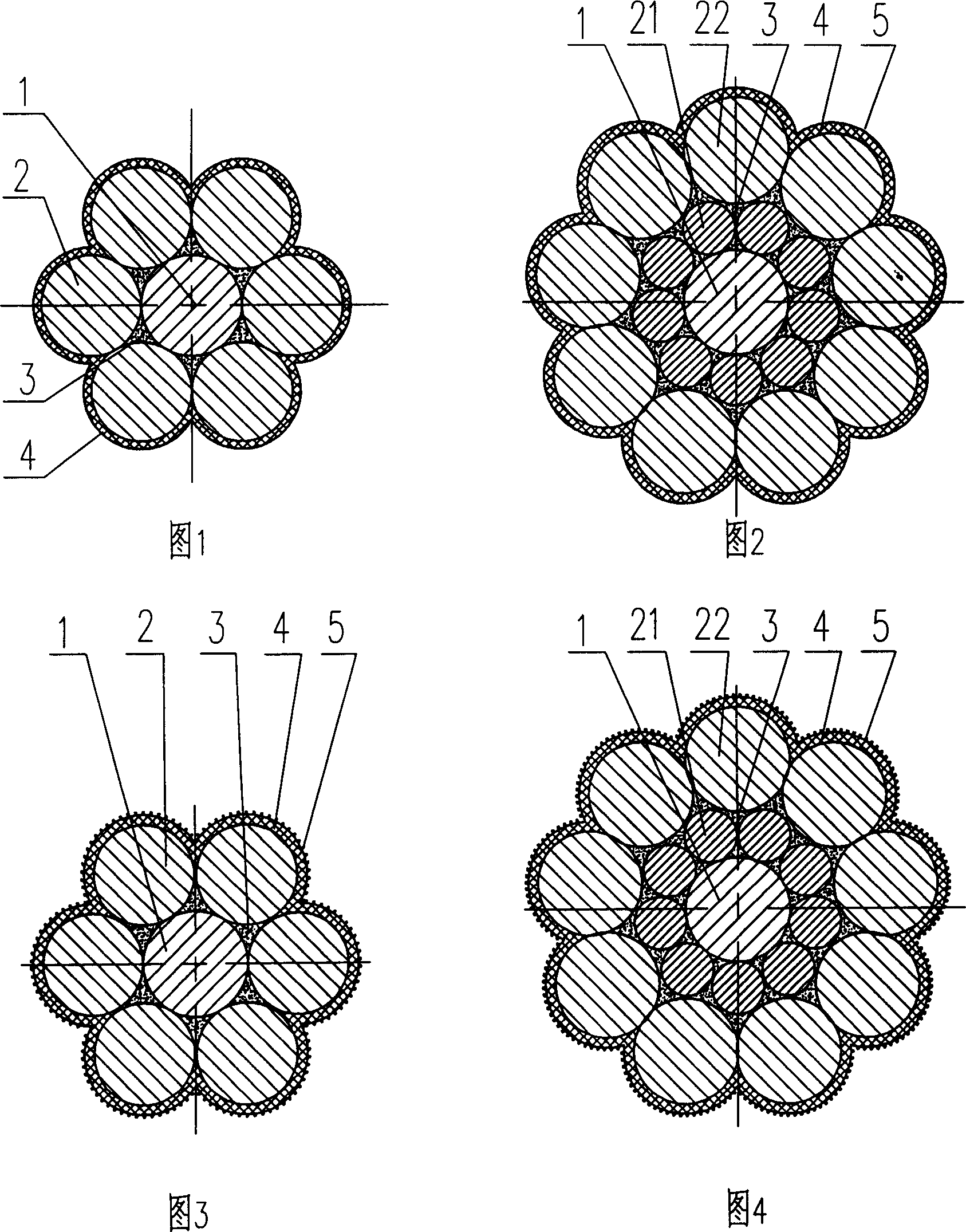

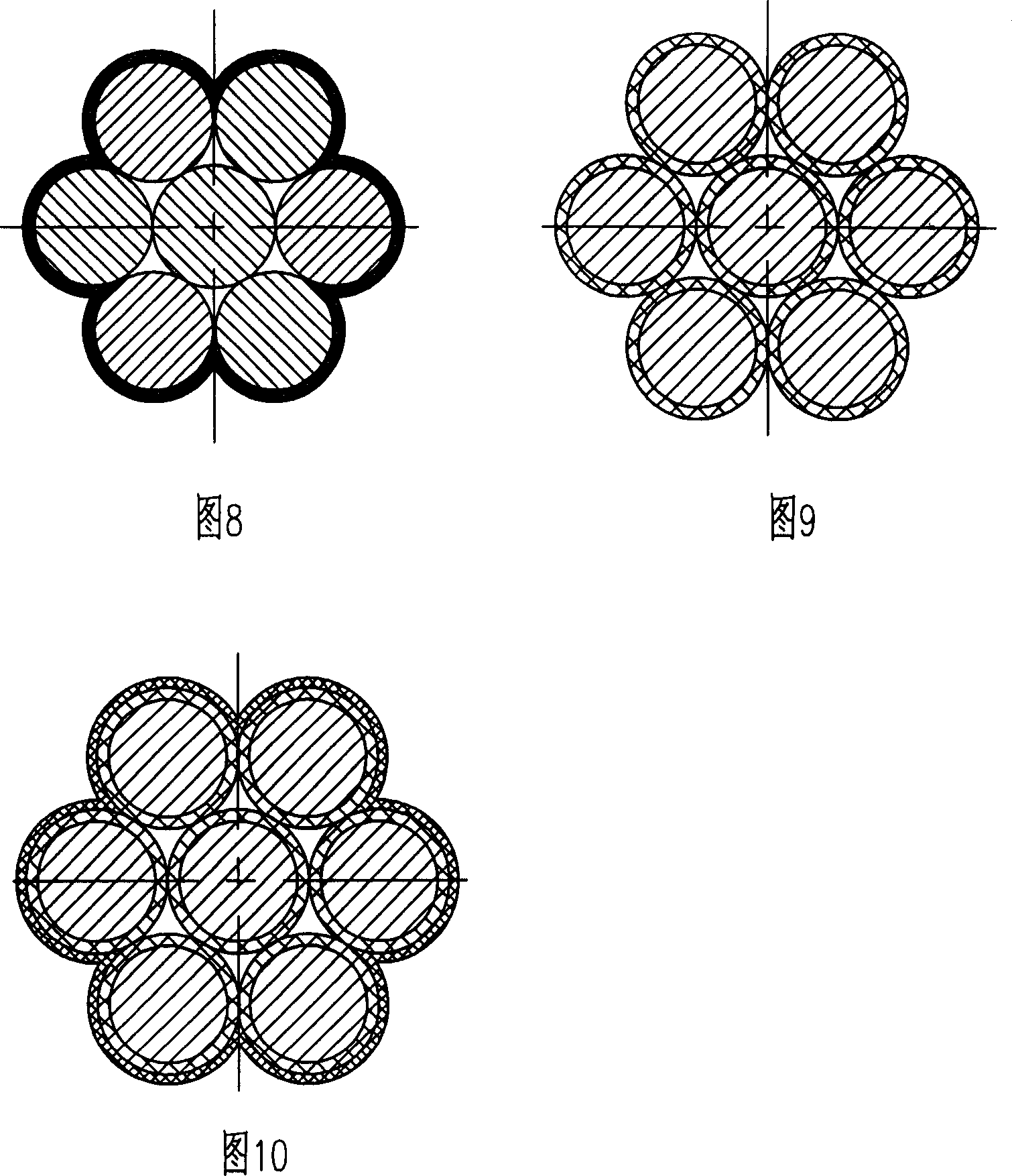

[0035] An anti-corrosion steel strand, which is formed by twisting a central wire 1 and a side wire 2, and is filled with an anti-corrosion material 3 around the center wire 1 and the side wire 2 and the interstices between the twists, and the outermost layer of the wire Coated with an anti-corrosion layer 4, the anti-corrosion material filled around the center wire and the side wires and the intertwined gaps and the anti-corrosion material coated on the outer periphery of the outermost side wires to form the anti-corrosion layer are all the same thermoplastic polymer material— — Polyethylene or polyolefin (see Figure 1, Figure 2), Figure 1 is 7 steel strands, Figure 2 is 19 steel strands, in Figure 2: 21 is the inner layer edge wire, 22 is the outer layer edge wire , the inner side wire 21 and the outer layer side wire 22 are collectively referred to as the side wire 2.

[0036] As a modification of this embodiment, the anti-corrosion material filled around the center wire an...

Embodiment 2

[0038] A kind of anti-corrosion steel strand with anti-slip structure, its basic structure is the same as that of Embodiment 1, and it is still formed by twisting the central wire 1 and the side wire 2, and it is filled in the surroundings of the center wire 1 and the side wire 2 and the twisted gap There is an anti-corrosion material 3, coated with an anti-corrosion layer 4 on the outer periphery of the side wire, the anti-corrosion material filled in the center wire and the side wire and the interstices between them and the anti-corrosion material coated on the outer circumference of the side wire. It is a thermoplastic polymer material—polyethylene or polyolefin, the difference is that: the outside of the anti-corrosion layer 4 of the steel strand is an anti-corrosion layer with a non-slip structure.

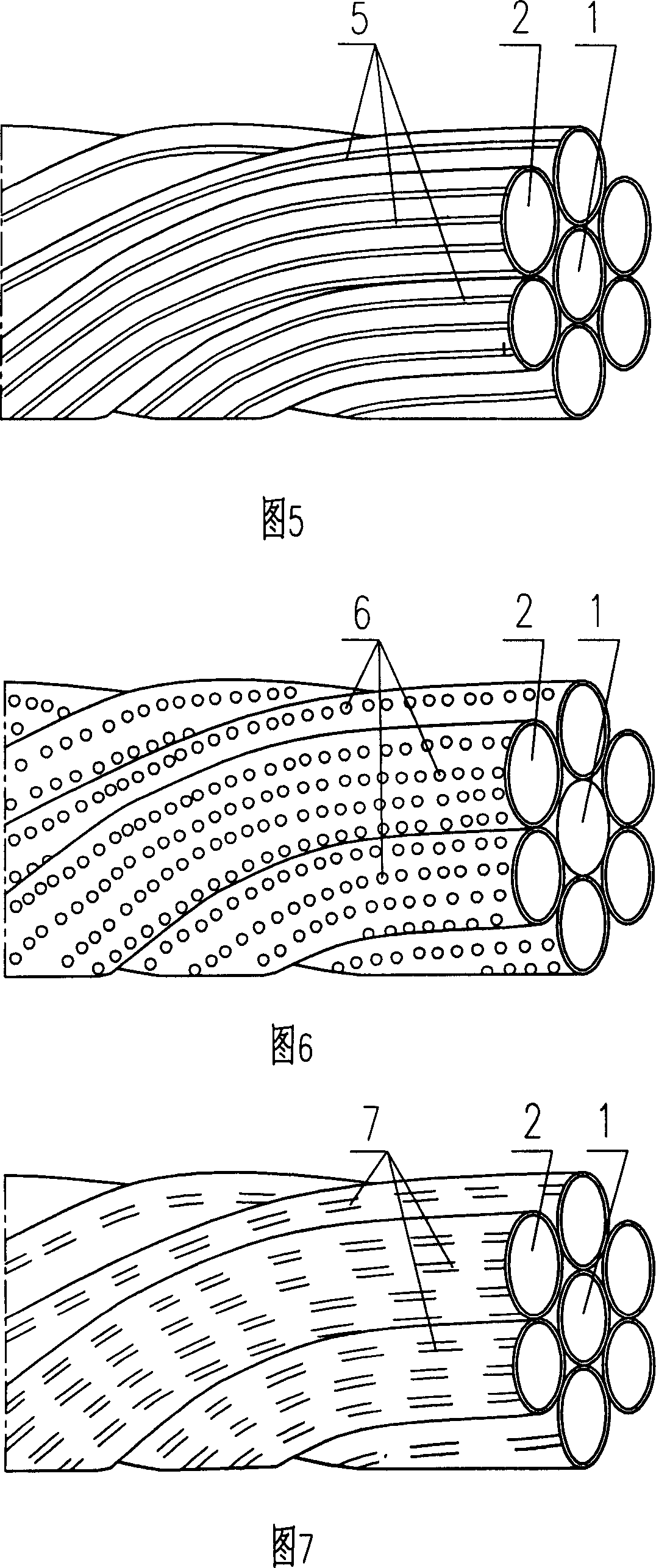

[0039] The anti-slip structure on the outside of the anti-corrosion layer 4 of the steel strand can be N protruding thin helixes 5, that is: N protruding thin helixes 5 are di...

Embodiment 3

[0043]The manufacturing method of the anti-corrosion steel strand described in the first embodiment is that the steel strand is first disassembled, and then the center wire and the edge wire are coated with a layer of thermoplastic polymer material around the center wire and the side wire through a pressurized extrusion process, and then twisted, and then the Extrusion molding process, so that the outside of the outermost edge wire of the steel strand is coated with a layer of thermoplastic polymer material to form an inner filling layer and an outer coating layer that are integrated with each other. The specific steps are as follows:

[0044] A. Pre-treatment of steel strands:

[0045] ①Clean the steel strand and dry it,

[0046] ② Split the steel strands: Open the prestressed steel strands according to the predetermined length in turn,

[0047] ③ Preheat the center wire and side wire in the open state of the steel strand;

[0048] B. Pretreatment of thermoplastic polymer m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com