Method for preparing titanium-silicalite molecular sieve from natural zeolite through supercritical replacement and modification

A titanium-silicon molecular sieve and supercritical replacement technology, which is applied in the production of crystalline aluminosilicate zeolites and bulk chemicals, can solve the problems of difficult preparation of titanium-silicon molecular sieves with high titanium content, high gas-solid phase mass transfer resistance, and natural zeolites. Low purity and other problems, to achieve the effect of low production cost, eliminate mass transfer resistance, and increase added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Put 30g of natural mordenite in a 500ml three-path bottle, add 150ml, 0.8M NH 4 The Cl solution was stirred at 80°C for 2 hours, washed with water, dried, and repeated twice;

[0024] (2) Take 10g of natural mordenite treated by (1) in a 500ml three-path bottle, add 200ml6MH 2 SO 4 The solution was stirred at 70°C for 0.5h, washed with water, and baked at 105°C for 10 hours;

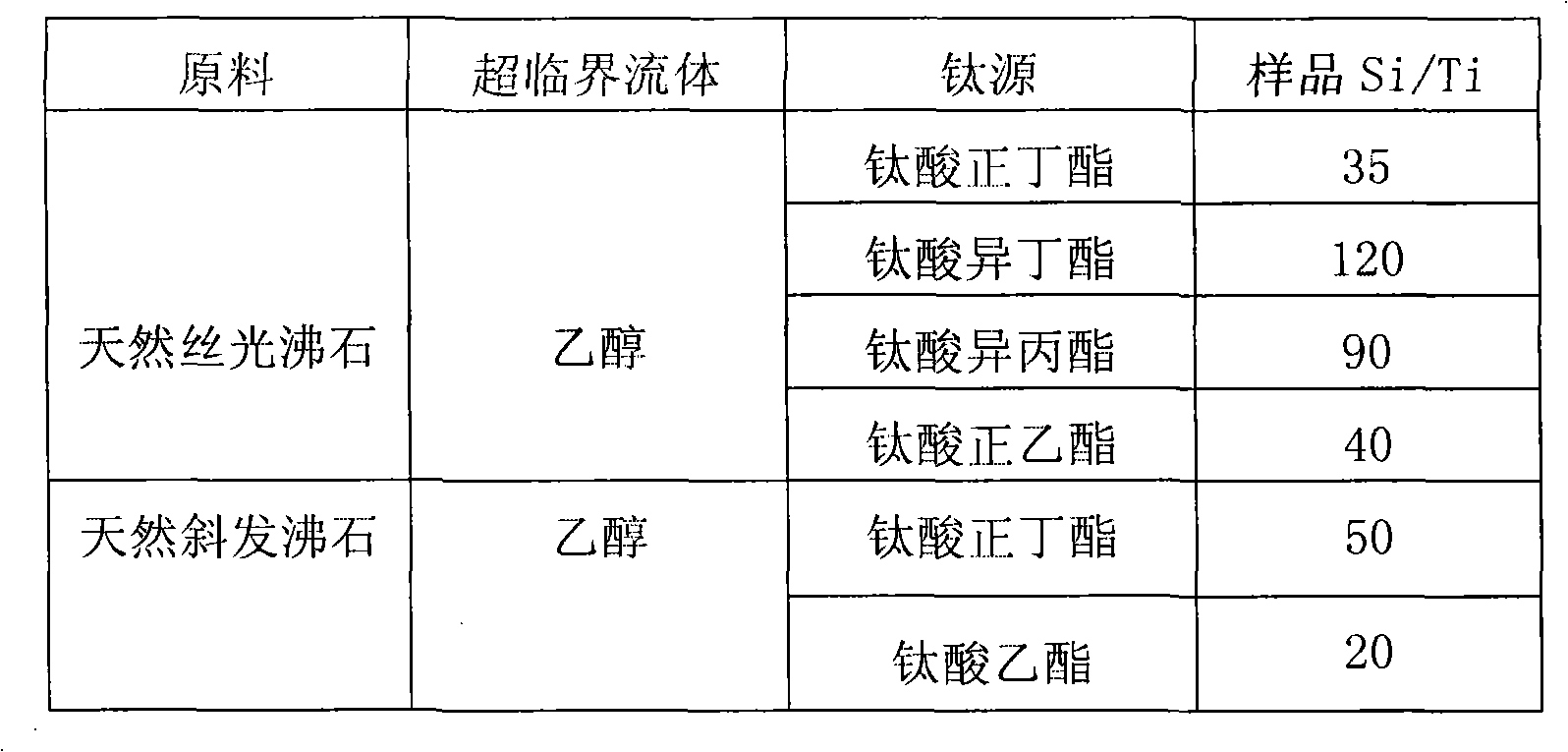

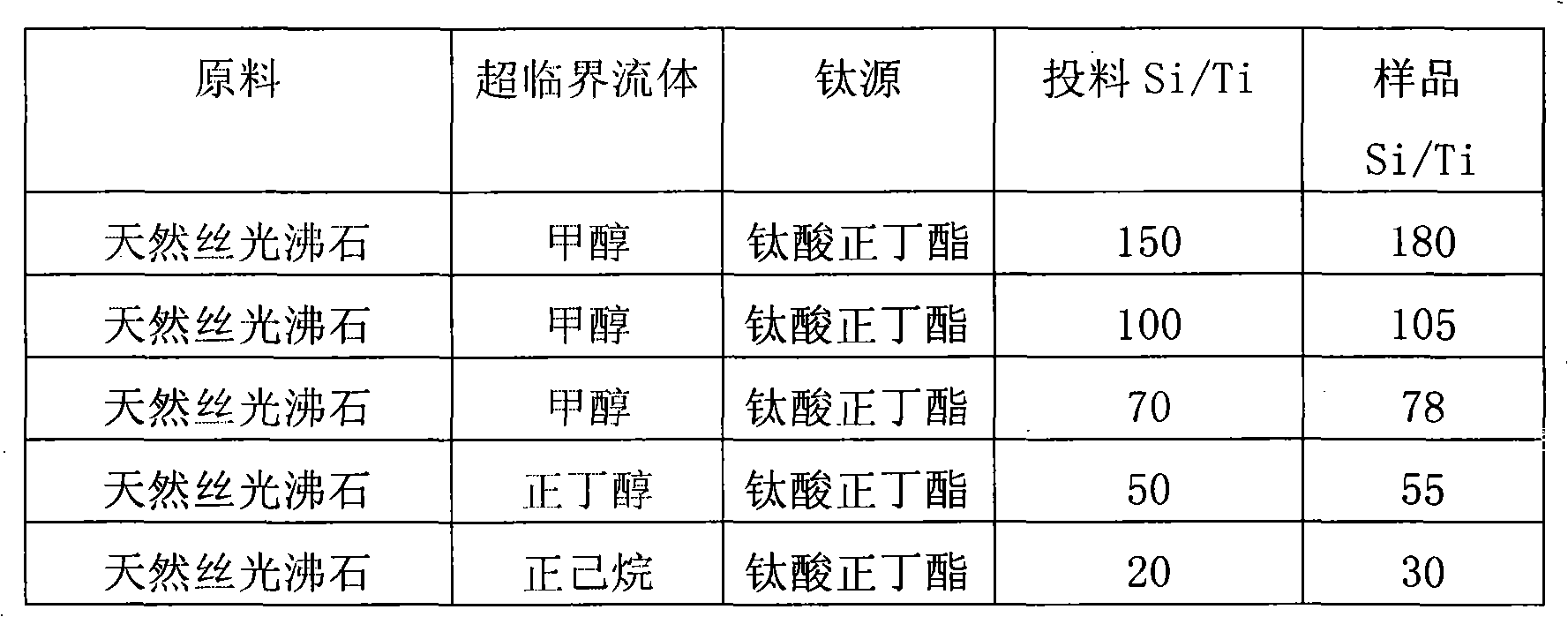

[0025] (3) In a 100ml autoclave, add 2g of the dealuminated zeolite treated in (2) into a stainless steel tray placed on the upper part of the autoclave, add n-butyl titanate with a Si / Ti of 120, and heat to 35°C. Pump titanium dioxide into the autoclave to a pressure of 7.5Mpa, react under this condition for 3 hours, slowly exhaust to room temperature, take out the sample, wash with absolute ethanol, dry at 105°C for 10 hours, and dry at 300°C in an air atmosphere Roast for 5 hours to obtain a titanium-containing molecular sieve sample; the sample is characterized by powder X-ray diffracti...

Embodiment 2

[0027] (1) Put 30g of natural mordenite in a 1000ml three-path bottle, add 600ml, 0.1M NH 4 NO 3 The solution was stirred at 70°C for 5 hours, washed with water, dried, and repeated 4 times;

[0028] (2) Take 20g of natural mordenite treated by (1) in a 500ml three-path bottle, add 100ml1MHNO 3 The solution was stirred at 85°C for 8h, washed with water, and baked at 105°C for 10 hours;

[0029] (3) In a 100ml stainless steel autoclave, add 60ml of absolute ethanol, place 2g of the sample treated in (2) in the stainless steel tray on the upper part of the autoclave, add isobutyl titanate with a Si / Ti of 10, The temperature was programmed to rise to 250°C, and the pressure of the autoclave was 10Mpa. Under these conditions, the reaction was carried out for 0.5 hours, and the heating was stopped. The temperature and pressure were slowly reduced to room temperature and normal pressure. The samples were taken out, washed with absolute ethanol, and dried at 105°C for 10 hours. Ca...

Embodiment 3

[0031] (1) Place 30g of natural mordenite in a 500ml three-path bottle, add 300ml, 1.0M (NH 4 ) 2 SO 4 The solution was stirred at 100°C for 1 hour, washed with water, dried, and repeated once;

[0032] (2) Take 20 g of natural clinoptilolite treated in (1) in a 500 ml three-path bottle, add 300 ml of 12M HCl solution, stir at 100° C. for 5 hours, wash with water, and bake at 105° C. for 10 hours;

[0033] (3) In a 100ml stainless steel autoclave, place 2g of the sample treated in (1) in the stainless steel tray on the upper part of the autoclave, add 60ml of n-hexane, add isopropyl titanate with a Si / Ti of 150, and program the temperature To 220°C, the pressure of the autoclave is 8Mpa. Under this condition, react for 6 hours, stop heating, and the temperature and pressure will slowly return to room temperature and normal pressure. Take out the sample, wash it with absolute ethanol, and dry it at 105°C for 10 hours. Calcined at 700°C for 5 hours in an air atmosphere to obt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com