High-purity sio extracted from a rice husk 2 Methods

A rice husk, high-purity technology, applied in silica, bulk chemical production, nanotechnology and other directions, can solve the problems of high cost, long process flow, low quality of SiO2 products, etc., to improve the purity, the process is simple, the elimination of The effect of mass transfer resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

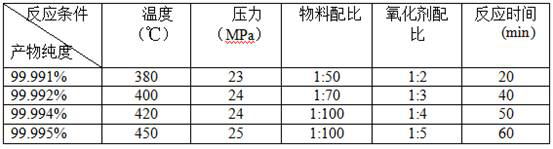

[0015] Embodiment 1: extract high-purity SiO in a kind of rice husk 2 method, the specific steps are:

[0016] Rice husk, compound oxidant (HNO 3 -H 2 SO 4 mixed oxidant) into the high-temperature and high-pressure reactor, and under airtight conditions, use inert gas (nitrogen) to replace the air in the reactor, and then add distilled water to obtain a reaction system. The system reaches the supercritical state, and react for 20 minutes to obtain the reaction product system, cool to room temperature, separate the solid and liquid phases, wash the solid with deionized water, and dry to obtain high-purity SiO 2 ; The temperature of the supercritical state is 380 ° C, the pressure is 23Mpa; rice husk and HNO 3 The mass ratio is 1:50, HNO 3 with H 2 SO 4 The volume ratio is 1:2;

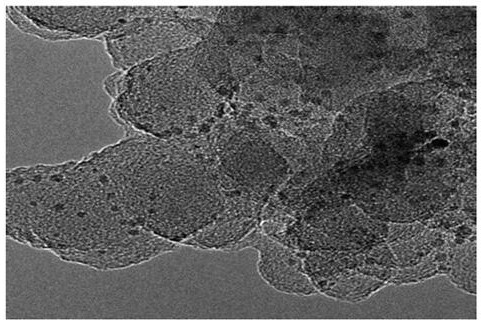

[0017] The present embodiment high-purity SiO 2 The scanning electron microscope image of figure 1 shown, from figure 1 It can be seen that high-purity SiO 2 The average particle size of cry...

Embodiment 2

[0019] Embodiment 2: extract high-purity SiO in a kind of rice husk 2 method, the specific steps are:

[0020] Rice husk, compound oxidant (HNO 3 -H 2 SO 4 mixed oxidant) into the high-temperature and high-pressure reactor, and under airtight conditions, use inert gas to replace the air in the reactor, and then add distilled water to obtain a reaction system. Critical state, and react for 40 minutes to obtain the reaction product system, cool to room temperature, separate the solid and liquid phases, wash the solid with deionized water, and dry to obtain high-purity SiO 2 ; The temperature of the supercritical state is 400°C and the pressure is 24Mpa; rice husk and HNO 3 The mass ratio is 1:70, HNO 3 with H 2 SO 4 The volume ratio is 1:3;

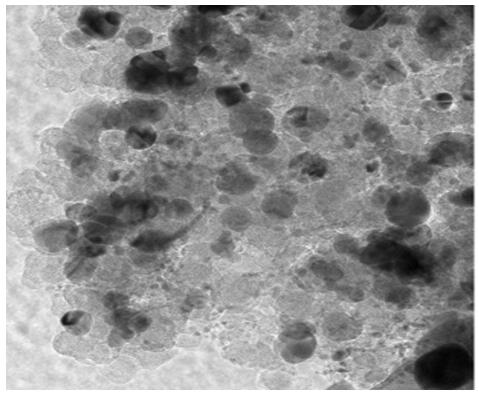

[0021] The present embodiment high-purity SiO 2 The scanning electron microscope image of figure 2 shown, from figure 2 It can be seen that high-purity SiO 2 The average particle size of crystals is 3.0 nm;

[0022] The prese...

Embodiment 3

[0023] Embodiment 3: extract high-purity SiO in a kind of rice husk 2 method, the specific steps are:

[0024] Rice husk, compound oxidant (HNO 3 -H 2 SO 4 mixed oxidant) into the high-temperature and high-pressure reactor, and under airtight conditions, use inert gas to replace the air in the reactor, and then add distilled water to obtain a reaction system. Critical state, and react for 50 minutes to obtain the reaction product system, cool to room temperature, separate the solid and liquid phases, wash the solid with deionized water, and dry to obtain high-purity SiO 2 ; The temperature of the supercritical state is 420 ℃, the pressure is 24Mpa; rice husk and HNO 3 The mass ratio is 1:100, HNO 3 with H 2 SO 4 The volume ratio is 1:4;

[0025] From this embodiment high-purity SiO 2 The scanning electron microscope picture shows that high-purity SiO 2 The average particle size of crystals is 1.5 nm;

[0026] The present embodiment high-purity SiO 2 The purity is 9...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com