VOCs treatment process and equipment using heterogeneous catalytic oxidation

A heterogeneous catalytic oxidation and process technology, which is applied in the field of VOCs treatment and volatile organic compounds, can solve the problems of unsuitable exhaust gas, slow degradation rate, and inability to meet the emission standards, and achieve synergistic effects, oxidation effects, and strong oxidation effects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

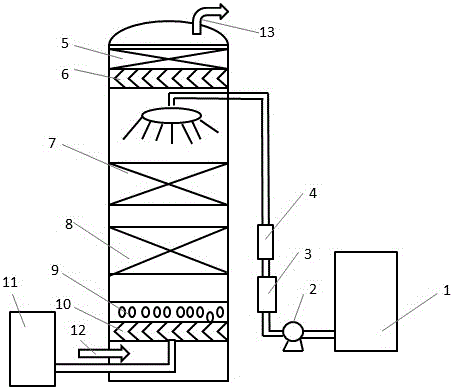

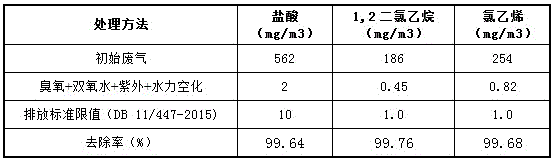

[0040] Such as figure 1 As shown, in order to verify the VOCs treatment effect of the patent of the present invention, a pilot test of the patented technology of the invention was carried out. In the pilot test, the bottom of the spray tower has a diameter of 0.8m and a height of 5m. The bottom of the spray tower is connected to the ozone generator 11 and the air inlet 12. The inner bottom of the spray tower is provided with a corrugated plate 10 and a Pall ring 9. The height of the corrugated plate 10 is 0.2m, and the height of the Pall ring 9 is 0.2m. An atomizing nozzle is arranged in the middle of the spray tower, and the atomizing nozzle is connected to the spray liquid storage tank 1 through the pipeline connected by the pump 2. The pipeline is equipped with a hydraulic cavitator 4 and a UV catalytic lamp 3 to perform ultraviolet catalysis and hydraulic cavitation on the spray liquid, and the H 2 o 2 Add it into the pipeline through the metering pump 2; install the cat...

Embodiment 2

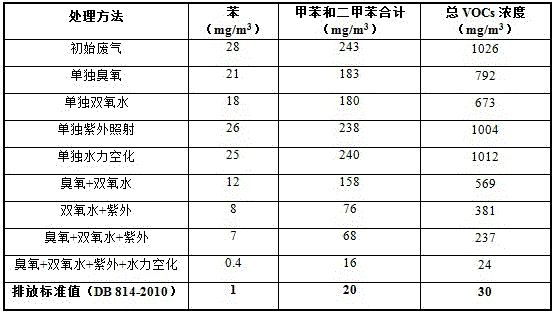

[0047] In order to verify the VOCs treatment effect of the patent of the present invention, a pilot test of the patented technology of the invention was carried out. In the pilot test, the bottom of the spray tower has a diameter of 0.8m and a height of 5m. The bottom of the spray tower is connected to the ozone generator 11 and the air inlet 12. The inner bottom of the spray tower is provided with a corrugated plate 10 and a Pall ring 9. The height of the corrugated plate 10 is 0.2m, and the height of the Pall ring 9 is 0.2m. An atomizing nozzle is arranged in the middle of the spray tower, and the atomizing nozzle is connected to the spray liquid storage tank 1 through the pipeline connected by the pump 2. The pipeline is equipped with a hydraulic cavitator 4 and a UV catalytic lamp 3 to perform ultraviolet catalysis and hydraulic cavitation on the spray liquid, and the H 2 o 2 Add it into the pipeline through the metering pump 2; install the catalytic filler 7 about 1m dow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com