Composite microcapsule wall material, microcapsules and preparation method of microcapsules

A technology of composite microcapsules and microcapsules, which is applied in the field of food processing, can solve the problems that the antioxidant properties of Ganoderma lucidum spore oil are not significantly improved, the product stability of Ganoderma lucidum spore oil is not high, and the scope of application of the product is limited, and good stability is achieved. and anti-oxidation, anti-oxidative effect enhancement, the effect of isolating the outside air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

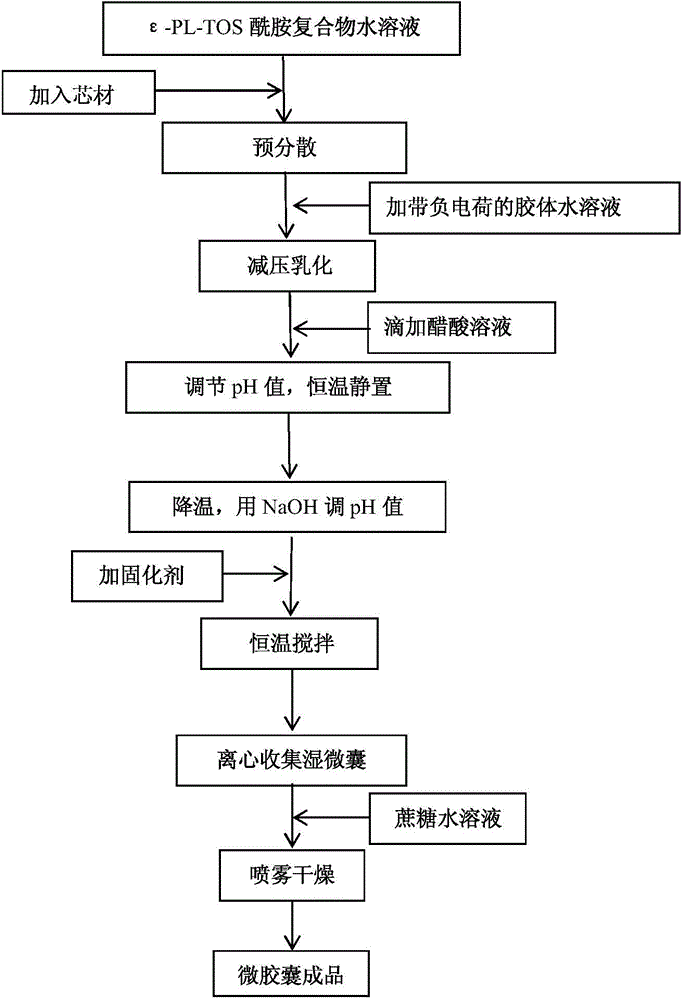

Method used

Image

Examples

Embodiment 1

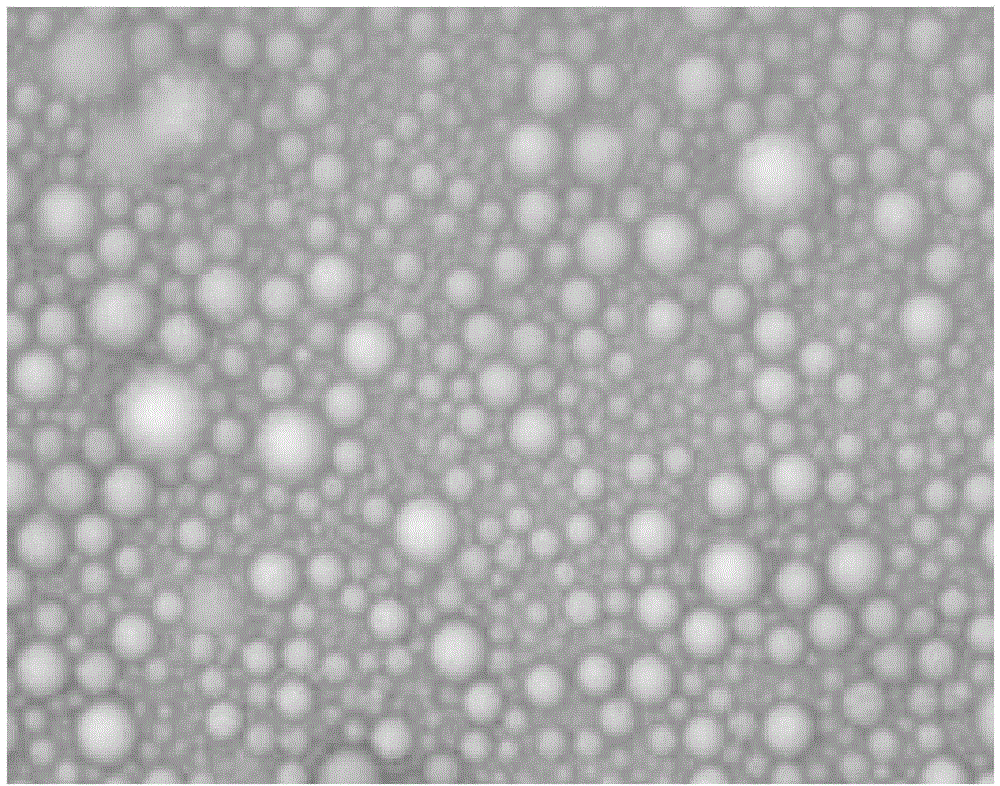

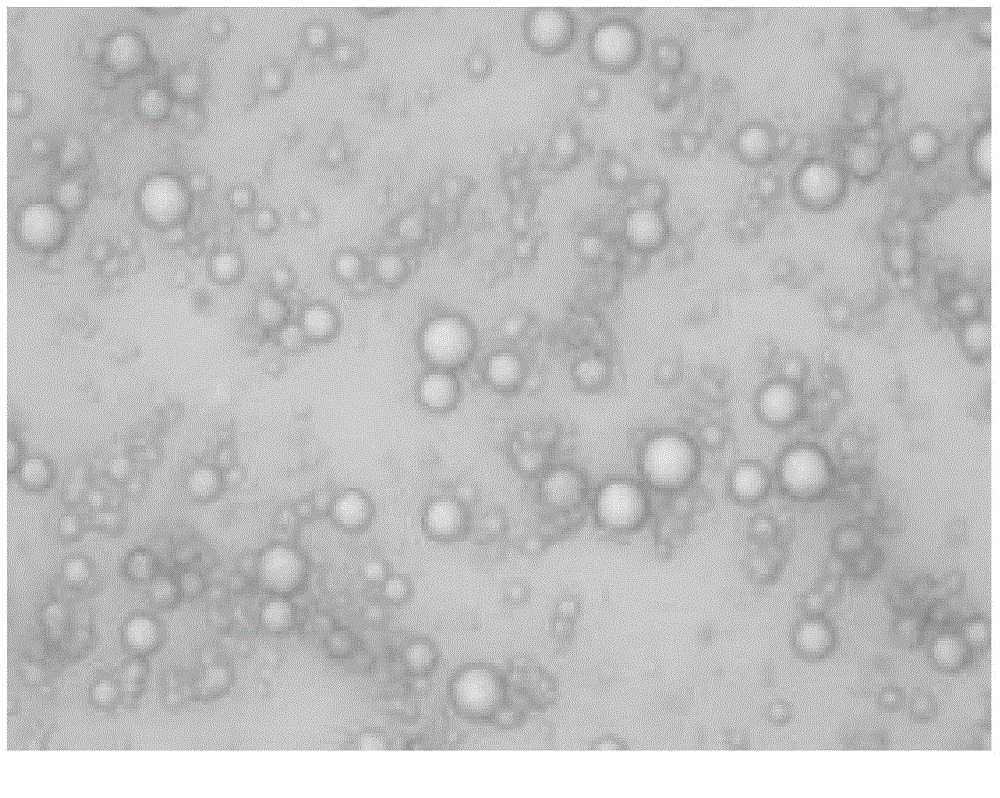

[0046] Dissolve 6g of ε-PL-TOS amide complex and 8g of gum arabic in 400mL of 50°C water respectively to prepare a solution of ε-PL-TOS amide complex and gum arabic, cool to 40°C for later use. At 40°C, add 9.0 mg of Ganoderma lucidum spore oil to the above 400 mL of 1.5% ε-PL-TOS amide complex solution by mass, and shear and emulsify at 10,000 rpm for 5 min; then add 400 mL of 2% gum arabic solution, Disperse at 22000rpm for 15min to obtain a stable emulsion. Vacuum the emulsion to a relative vacuum of 0.09Mpa, keep it for 10min, then add dropwise acetic acid with a mass fraction of 5% under stirring to adjust the pH value of the emulsion to 4.6, continue stirring for 10min, cool down to 4°C, and precipitate Microcapsules; add dropwise NaOH with a mass fraction of 10% to adjust the pH to 6.5, add 160 U of transglutaminase, and stir at 4°C for 10 hours to solidify the microcapsules to obtain a mixed system. The mixed system was refrigerated and centrifuged at 15,000 rpm at 4°...

Embodiment 2

[0049] Dissolve 7g of ε-PL-TOS amide complex and 8g of gum arabic in 400mL of 50°C water respectively to prepare a solution of ε-PL-TOS amide complex and gum arabic, cool to 40°C for later use. At 40°C, add 9.0 mg of Ganoderma lucidum spore oil to the above 400 mL of the ε-PL-TOS amide complex solution with a mass fraction of 1.75%, and shear and emulsify at 10,000 rpm for 5 min; then add 400 mL of 2% gum arabic solution, Disperse at 22000rpm for 15min to obtain a stable emulsion. Vacuum the emulsion to a relative vacuum of 0.09Mpa, keep it for 10min, then add dropwise acetic acid with a mass fraction of 5% under stirring to adjust the pH value of the emulsion to 4.6, continue stirring for 10min, cool down to 4°C, and precipitate Microcapsules; add dropwise NaOH with a mass fraction of 10% to adjust the pH to 6.5, add 320 U of transglutaminase, keep stirring at 4°C for 10 hours, solidify the microcapsules, and obtain a mixed system. The mixed system was refrigerated and centr...

Embodiment 3

[0052] Dissolve 8g of ε-PL-TOS amide complex and 8g of gum arabic in 400mL of 50°C water respectively to prepare a solution of ε-PL-TOS amide complex and gum arabic, and cool to 40°C for later use. At 40°C, add 9.0 mg of Ganoderma lucidum spore oil to the above 400 mL of 2% ε-PL-TOS amide complex solution by mass, and shear and emulsify at 10,000 rpm for 5 min; then add 400 mL of 2% gum arabic solution, Disperse at 22000rpm for 15min to obtain a stable emulsion. Vacuum the emulsion to a relative vacuum of 0.08Mpa, keep it for 10 minutes, then add dropwise acetic acid with a mass fraction of 5% under stirring to adjust the pH value of the emulsion to 4.6, continue stirring for 10 minutes, cool down to 4°C, and precipitate Microcapsules; add dropwise NaOH with a mass fraction of 10% to adjust the pH to 6.5, add 320 U of transglutaminase, keep stirring at 4°C for 10 hours, solidify the microcapsules, and obtain a mixed system. The mixed system was refrigerated and centrifuged at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com