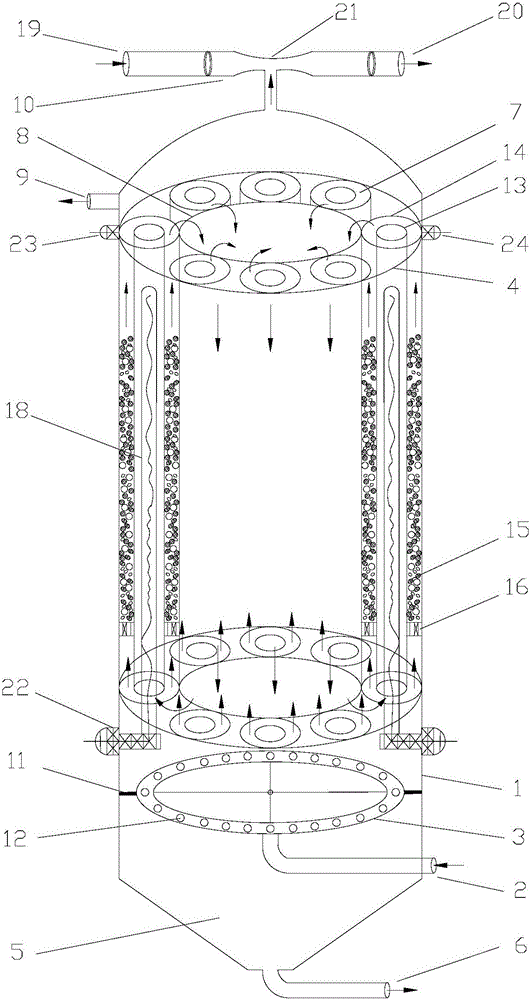

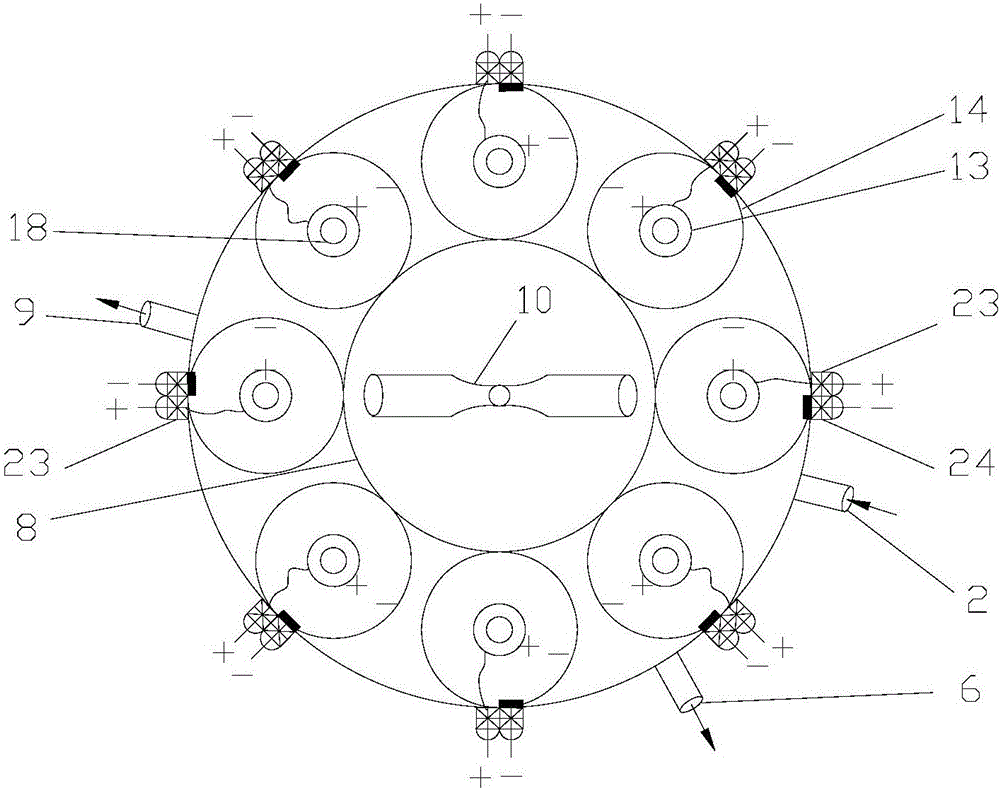

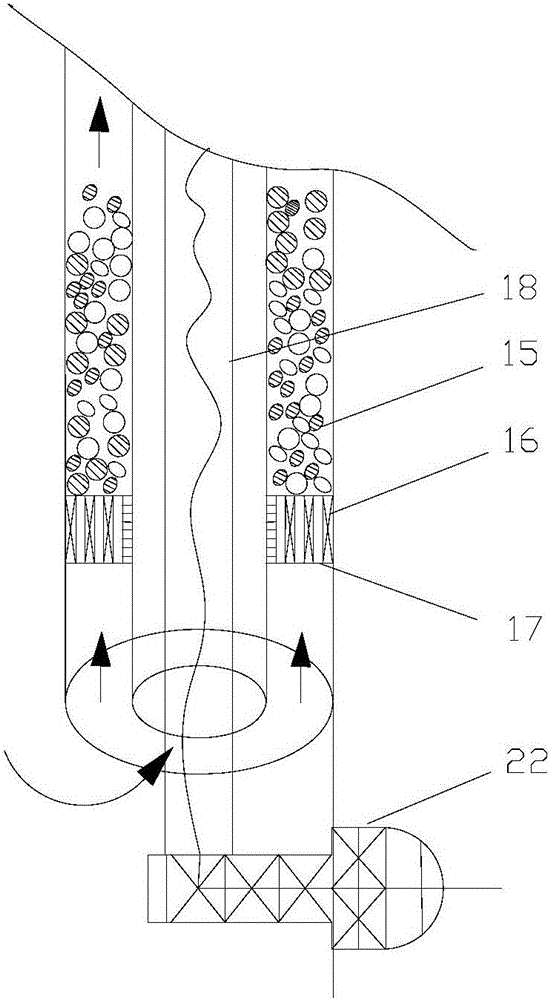

Internal recycle photoelectron-catalytic oxidation combined treatment device

A technology of photoelectric catalysis and treatment device, which is applied in special compound water treatment, oxidized water/sewage treatment, illumination water/sewage treatment, etc. Reduction and other problems, to achieve the effect of reducing the recombination rate of photogenerated electrons and holes, improving the photocatalytic activity, and enhancing the removal ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A petrochemical company in Heilong Province used biochemical methods to treat petroleum refining wastewater, and the volume of wastewater was about 20m 3 / h, wastewater contains a large amount of refractory and toxic and harmful substances, such as benzene, acrylonitrile and other substances. With the improvement of environmental protection standards, the existing sewage treatment process is facing upgrading and transformation.

[0029] The company's biochemical effluent was carried out for 3m by using the internal circulation photoelectric catalytic oxidation combined treatment device of the present invention 3 / d pilot deep treatment test, the COD of the water entering the device is between 159-331mg / L, with an average of 272mg / L, the device is loaded with a DC power supply output current of 500A, and a medium-pressure mercury lamp is used as the ultraviolet light source. 310-365nm, the power of a single cylindrical ultraviolet light source is 200w, and the residence ...

Embodiment 2

[0031] An oil production company in Liaoning Province used oil separation + biochemical process to treat the waste water containing polymer in the land terminal oil production, and the water volume was about 180m 3 / h, the wastewater contains a large amount of refractory cyclic substances and polymers, resulting in poor biodegradability of the wastewater, and poor treatment effect of the existing process. It is difficult to meet the technical requirements with traditional oxidation technology and biotechnology.

[0032] Using the internal circulation photoelectric catalytic oxidation combined treatment device of the present invention to carry out 24m to the wastewater containing poly 3 / d pilot test, the influent COD of poly-containing wastewater is between 272-378mg / L, the average is 343mg / L, the output current of the DC power supply is 600A, and the low-pressure mercury lamp is used as the ultraviolet light source, and the ultraviolet light wavelength is 220-250nm , the pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com