Patents

Literature

122results about How to "Increase the overlapping area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

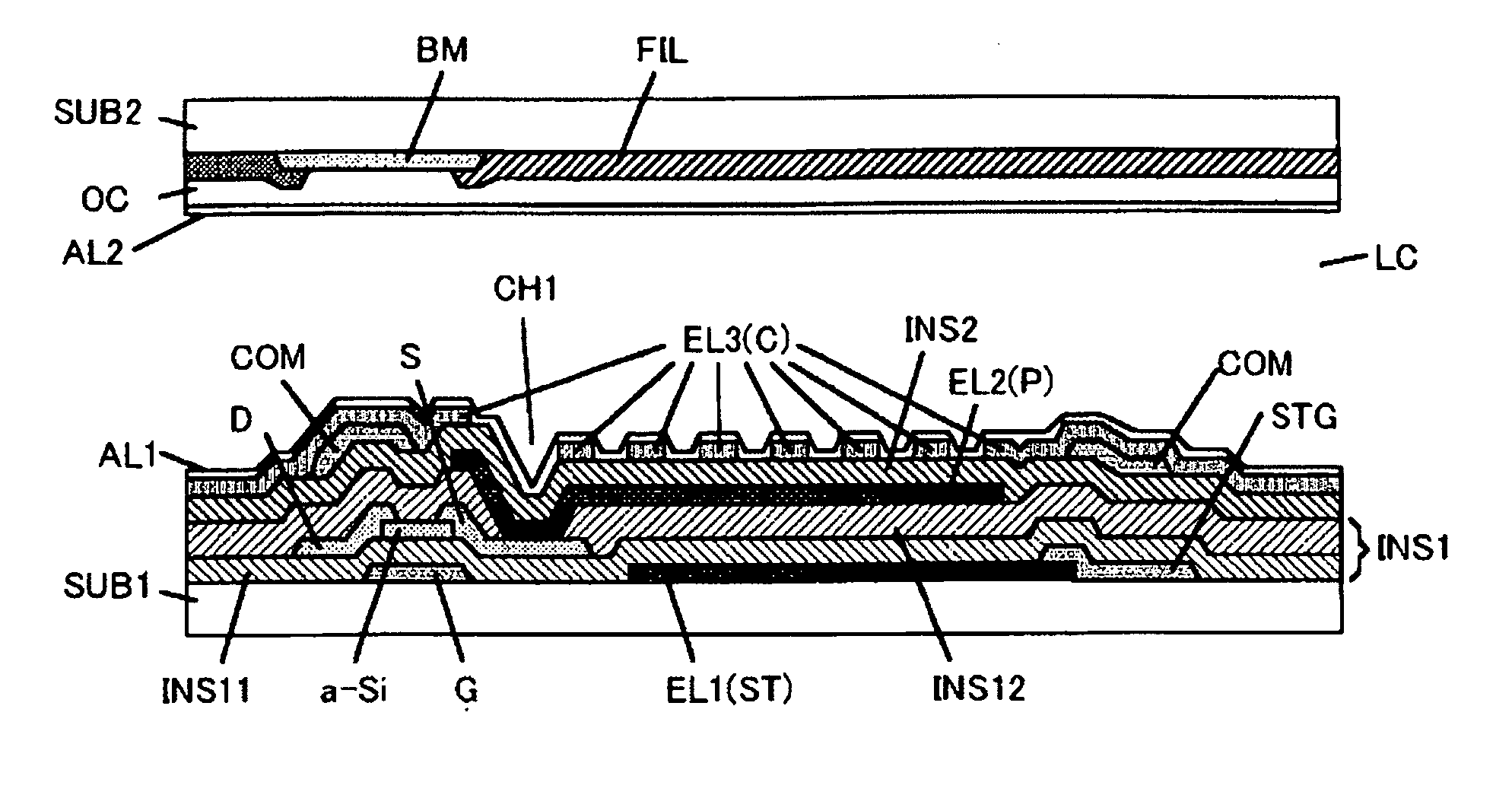

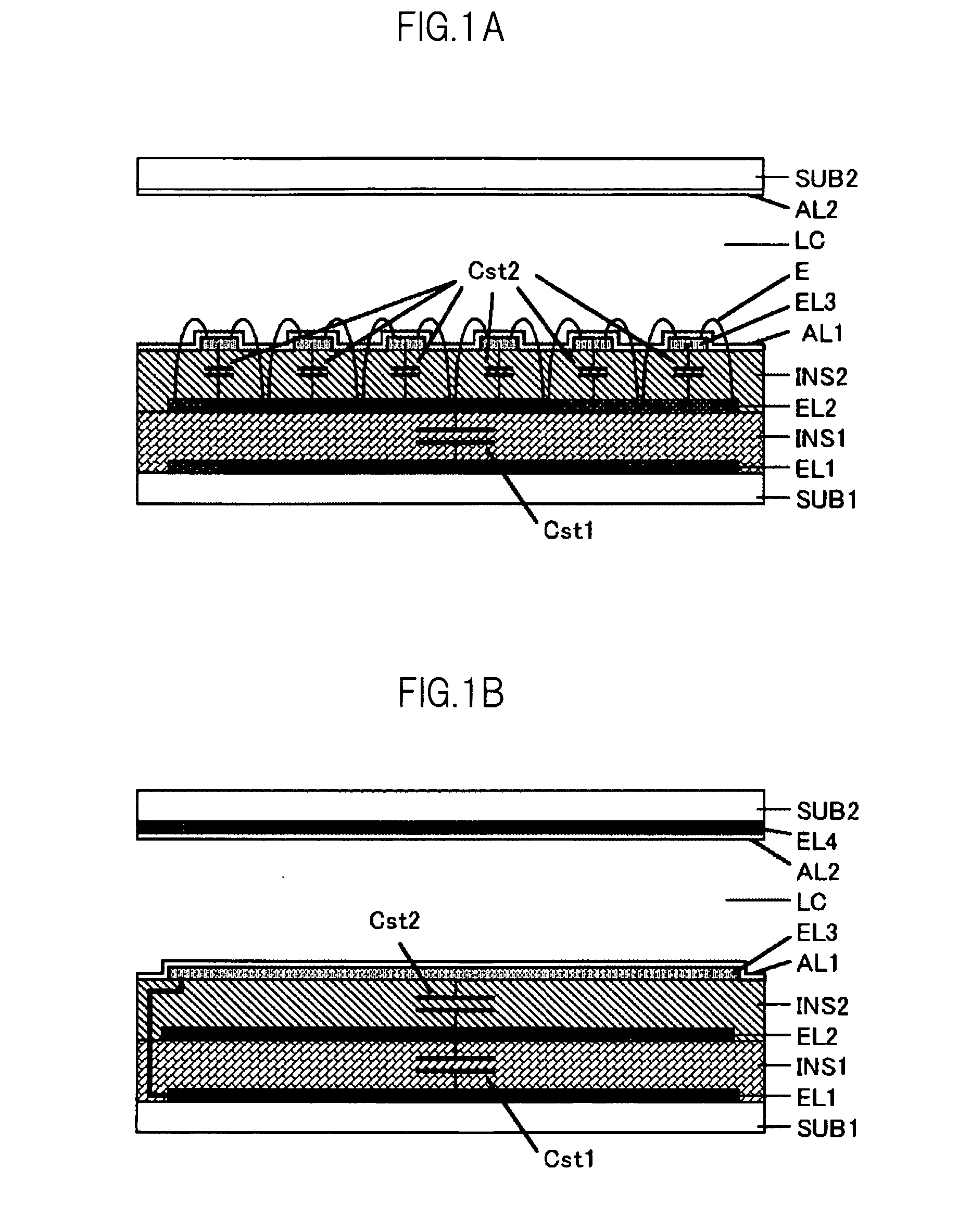

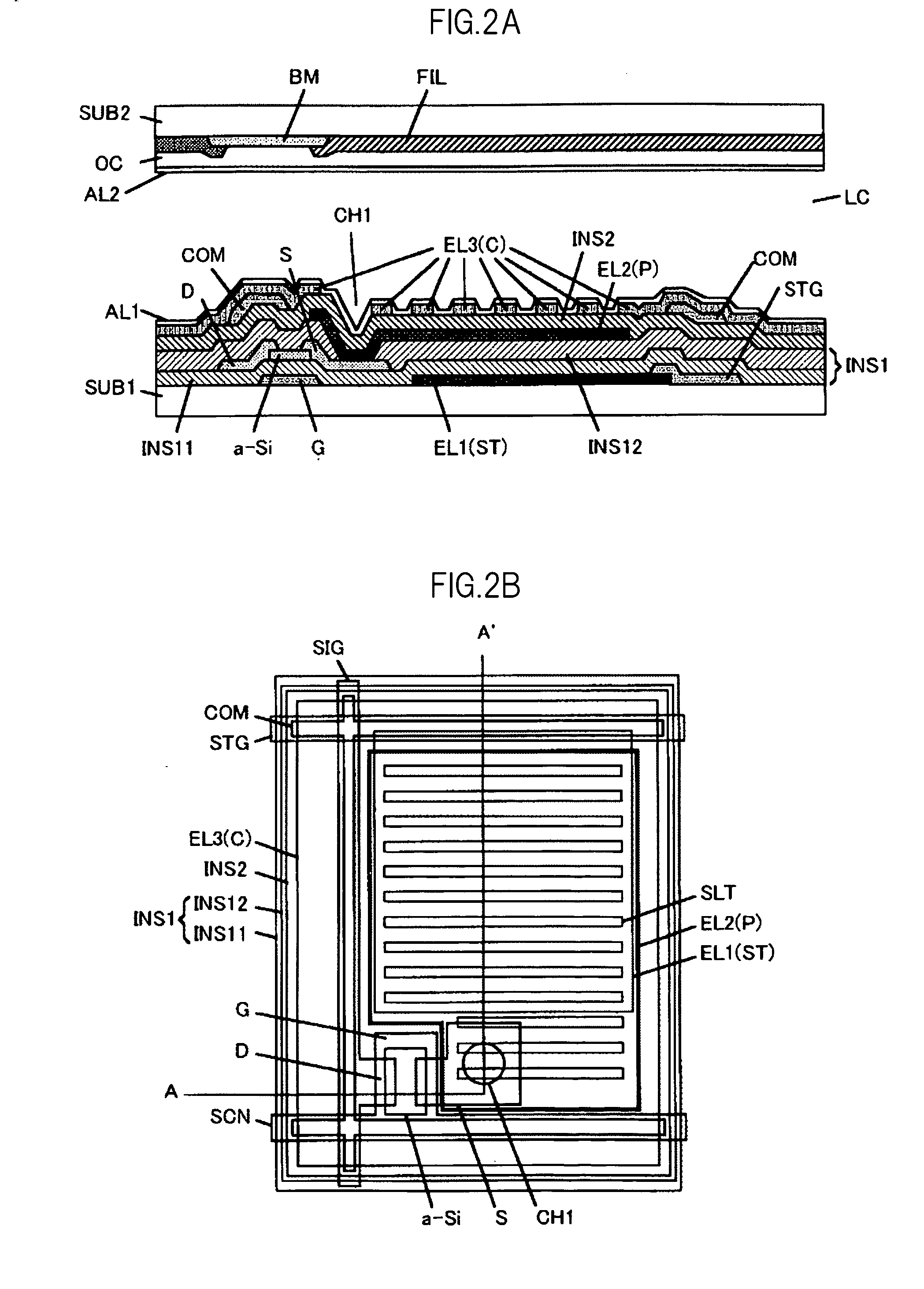

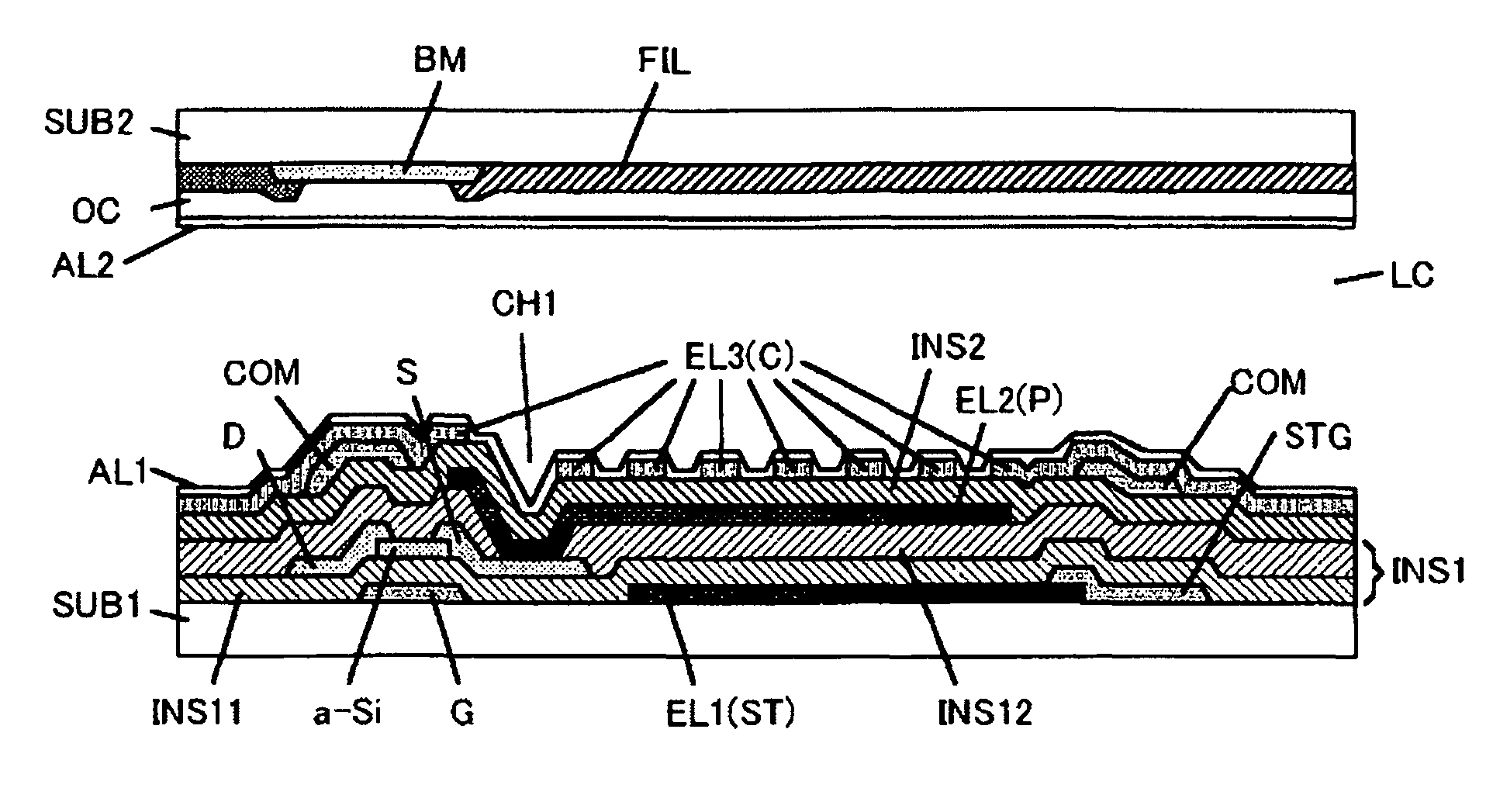

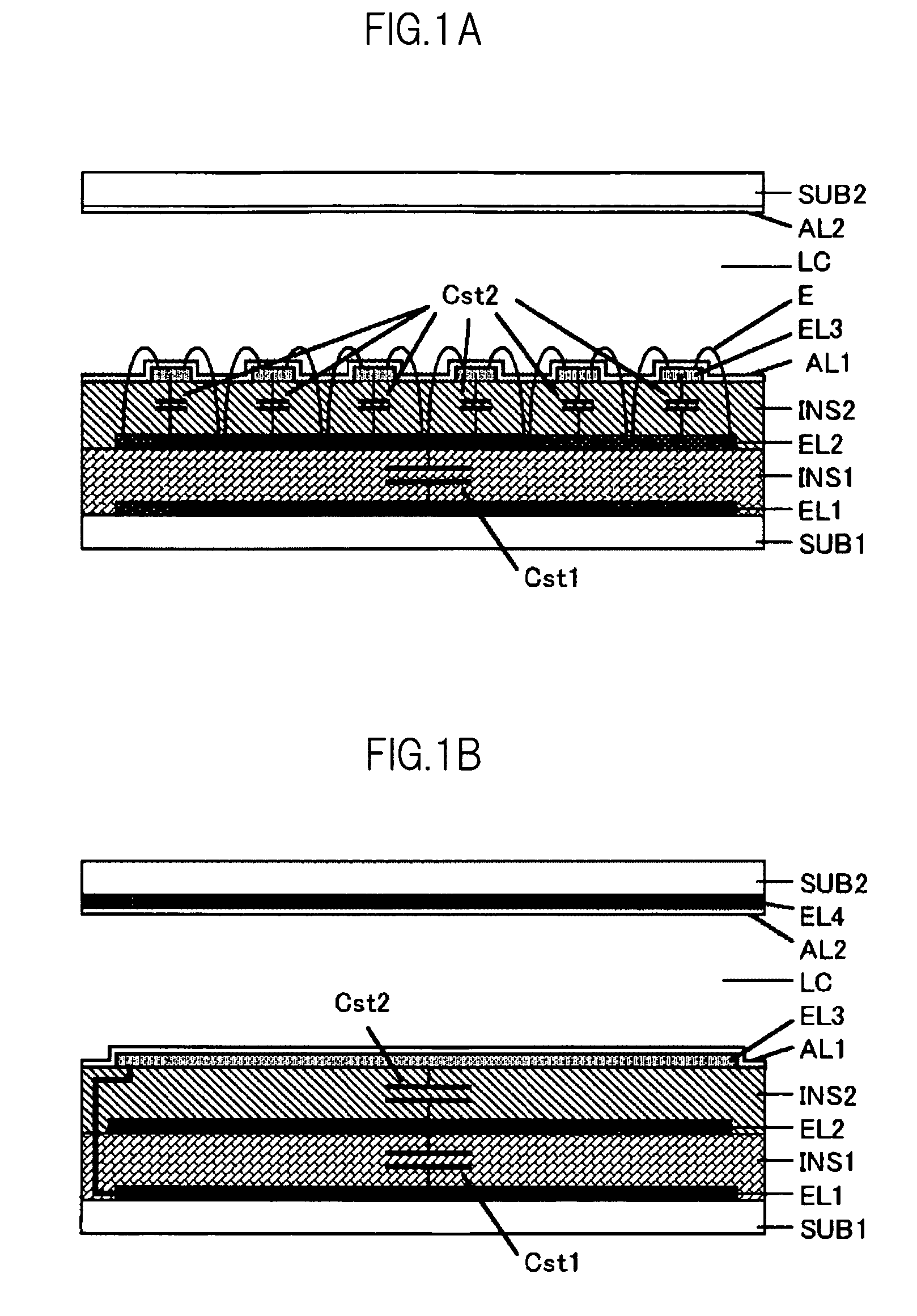

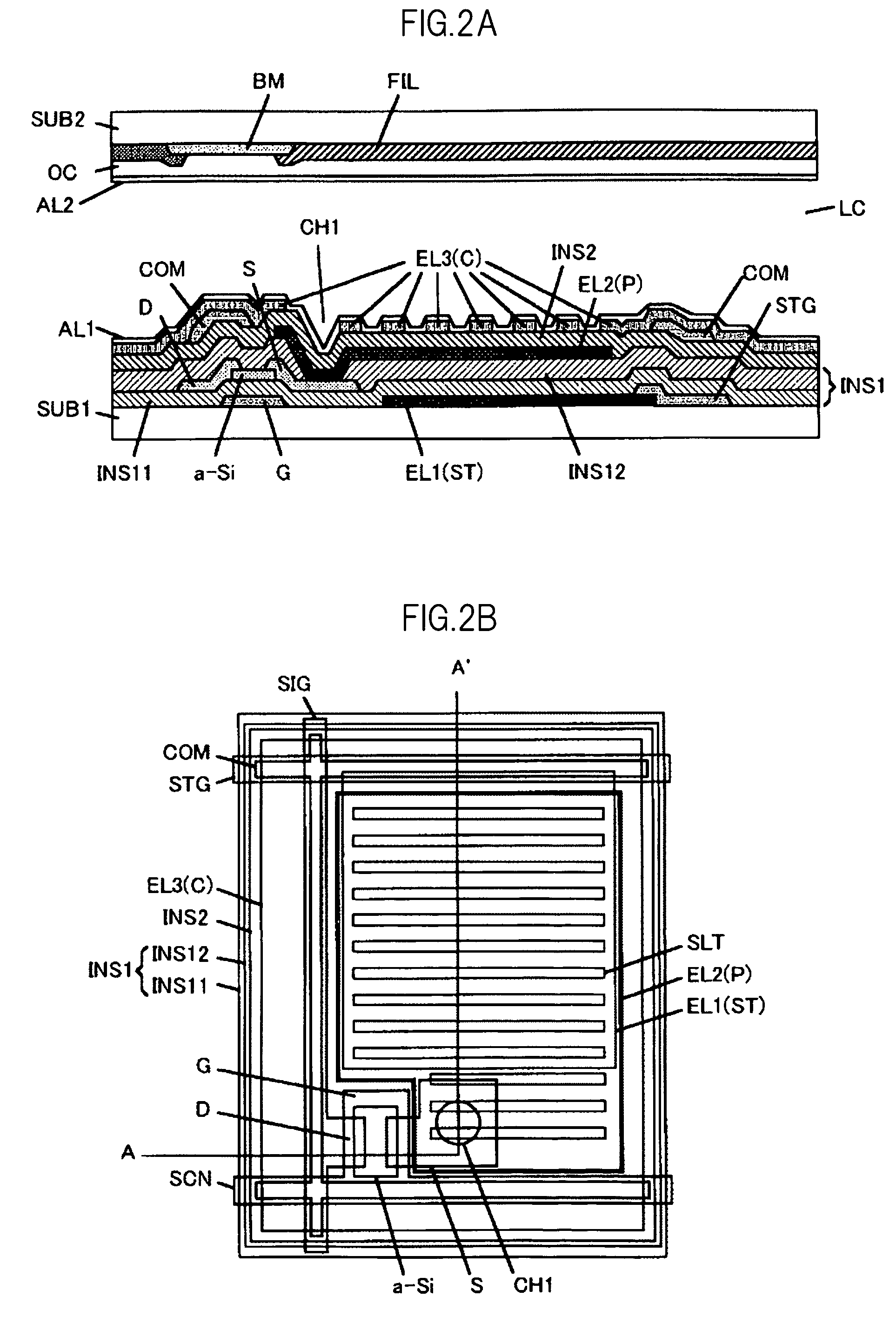

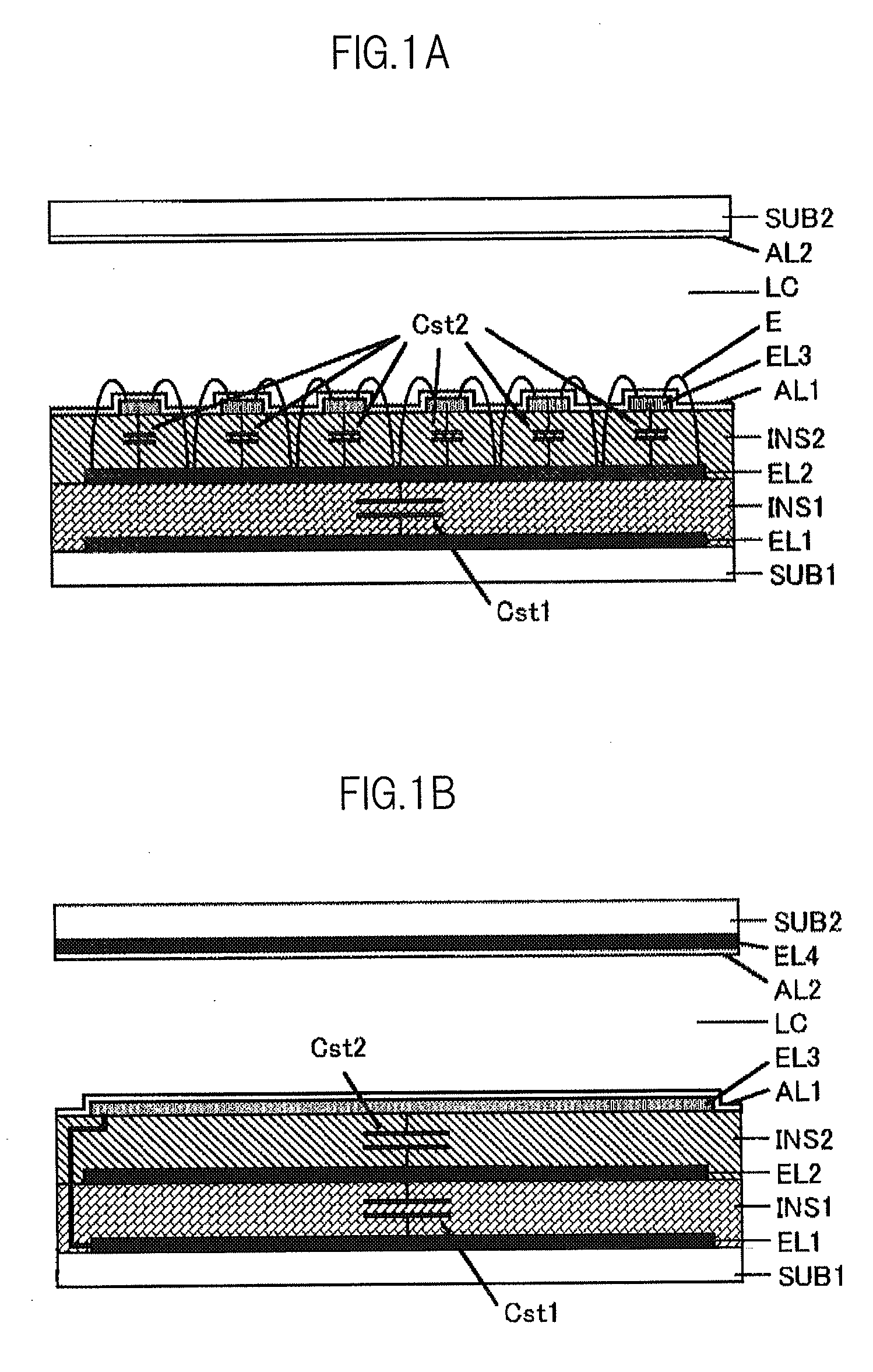

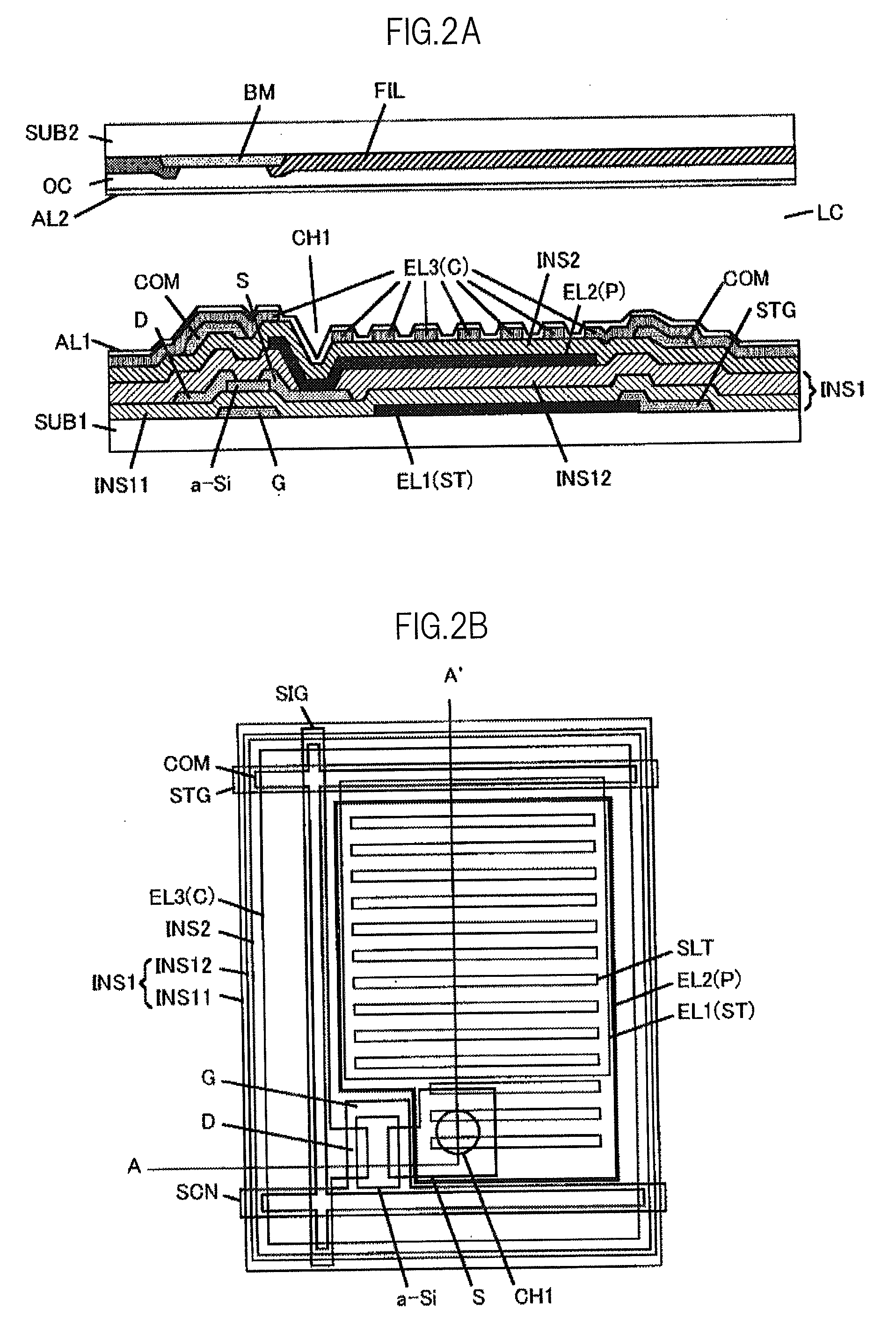

Liquid crystal display device

ActiveUS20090059110A1Reduce areaReduce capacitanceSolid-state devicesNon-linear opticsLiquid-crystal displayEngineering

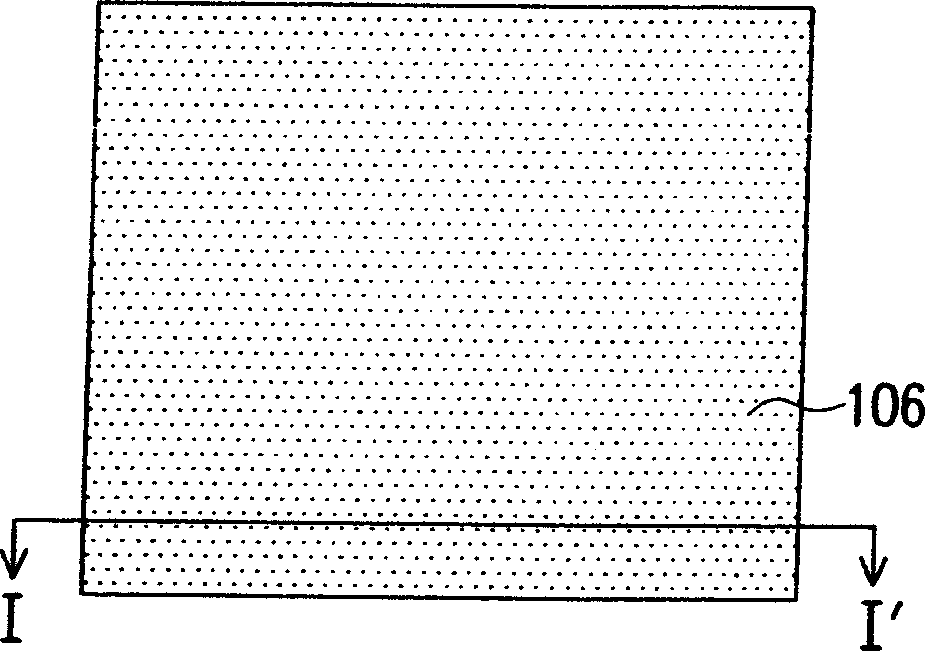

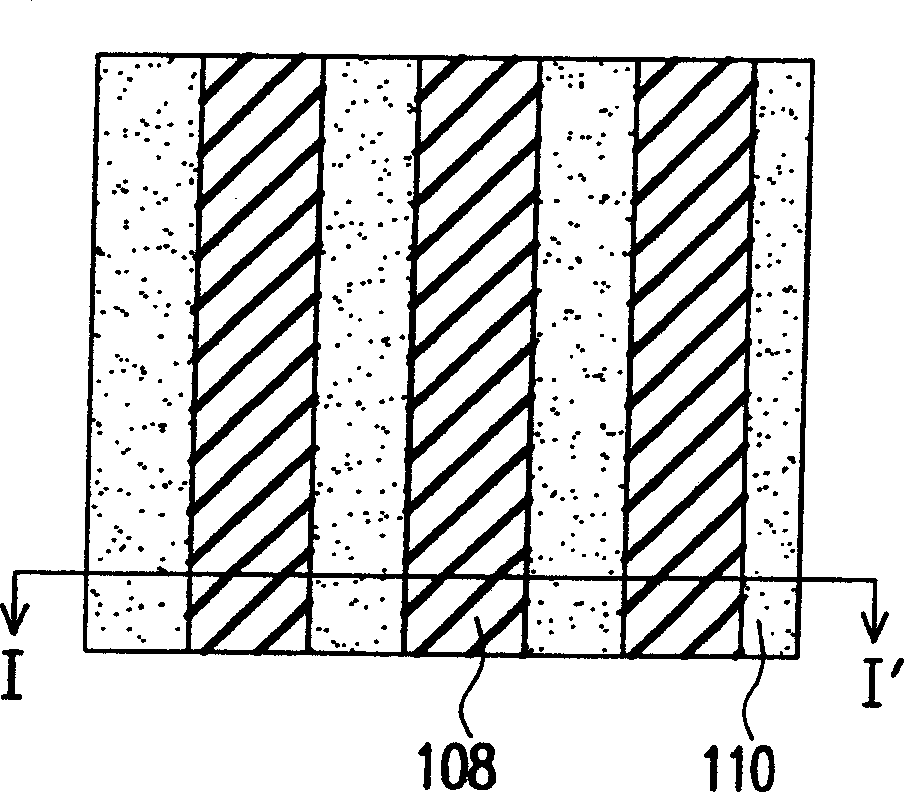

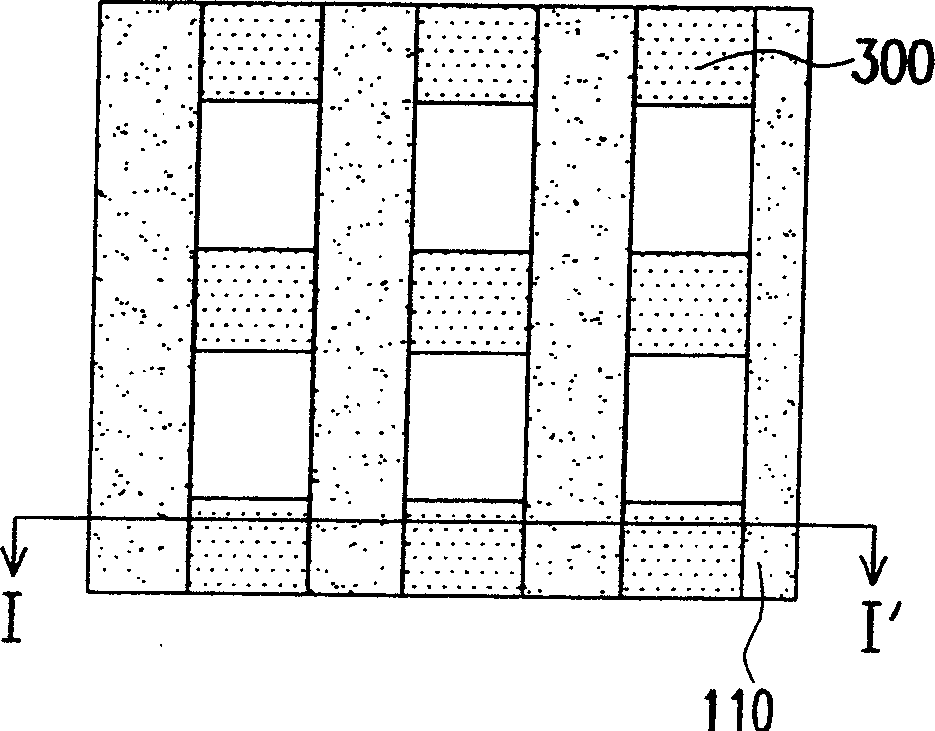

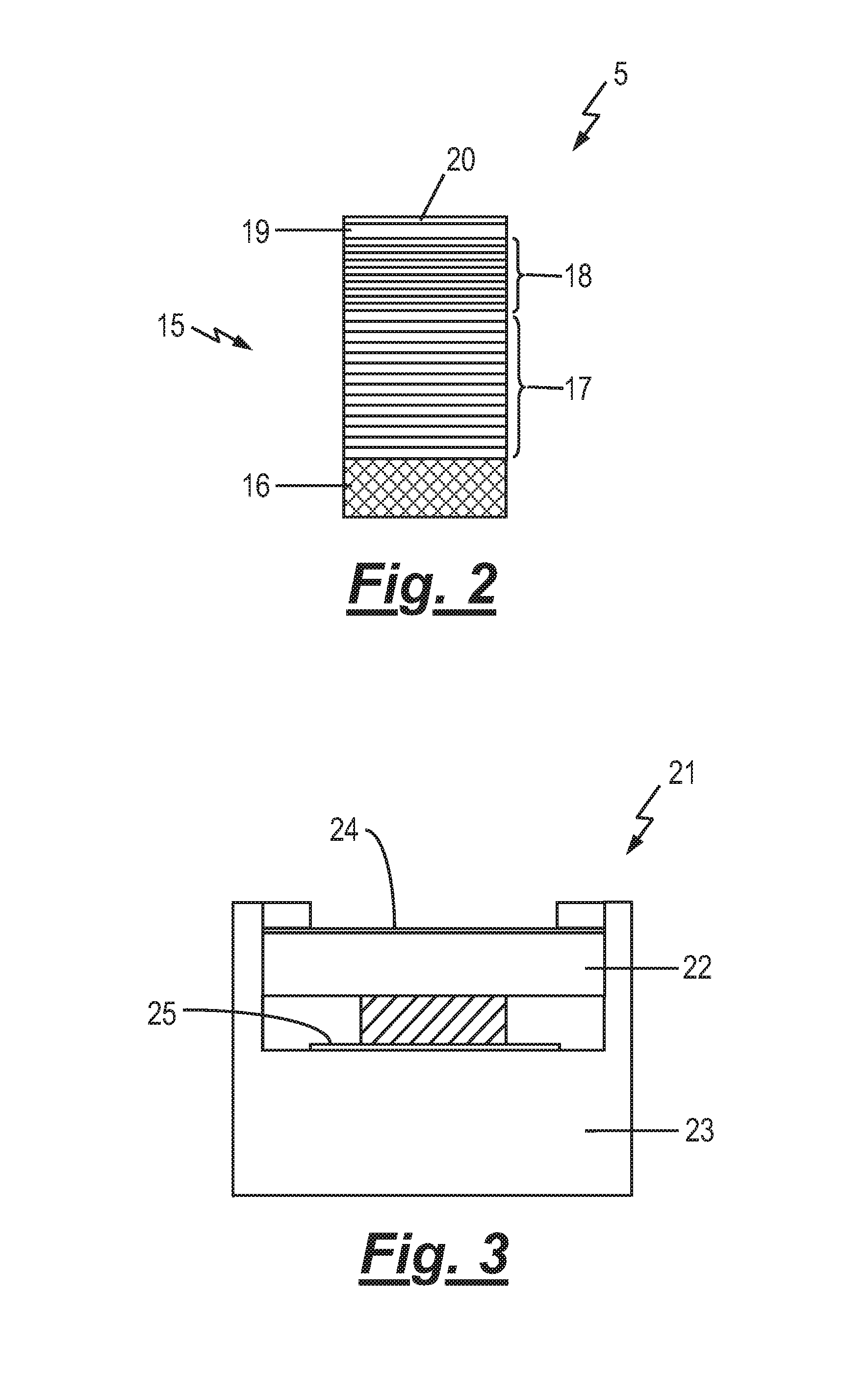

To form a sufficiently large storage capacitor, a liquid crystal display device includes a liquid crystal display panel having a first substrate, a second substrate, and a liquid crystal held between the first substrate and the second substrate, the liquid crystal display panel having multiple pixels arranged in matrix. The first substrate has, in a transmissive display area provided in each of the pixels, a laminated structure containing a first transparent electrode, a first insulating film, a second transparent electrode, a second insulating film, and a third transparent electrode which are laminated in this order. The first transparent electrode and the second transparent electrode are electrically insulated from each other and together form a first storage capacitor through the first insulating film, and the second transparent electrode and the third transparent electrode are electrically insulated from each other and together form a second storage capacitor through the second insulating film.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

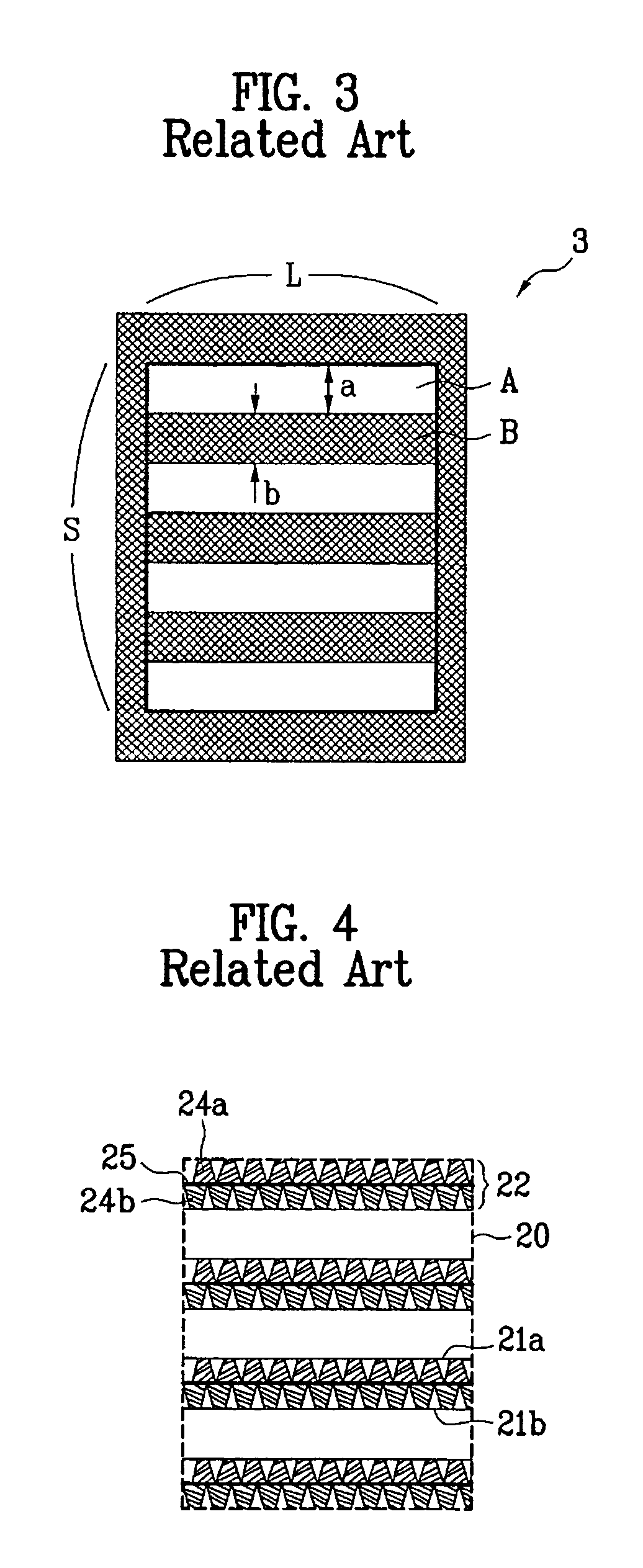

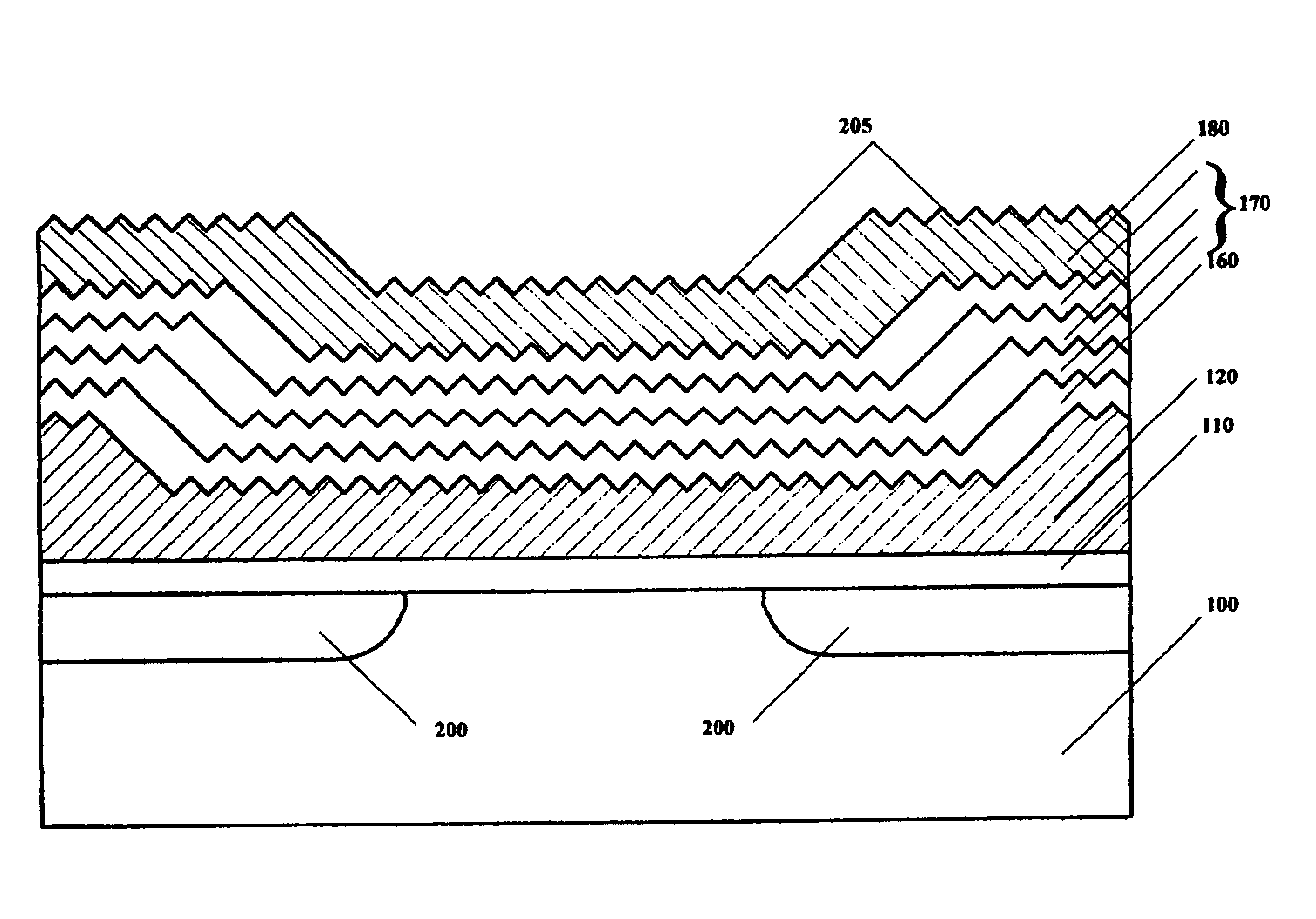

Laser beam pattern mask and crystallization method using the same

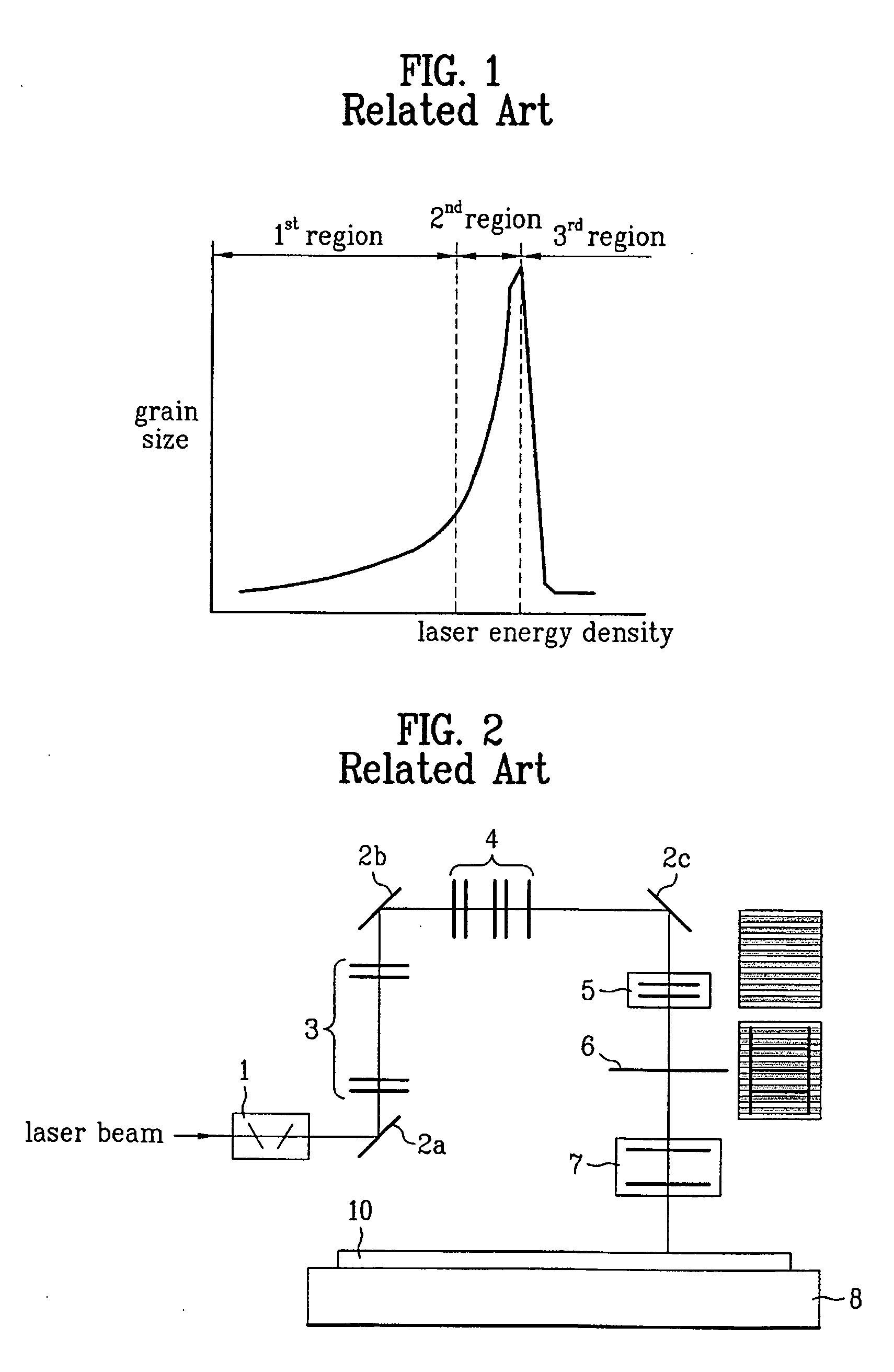

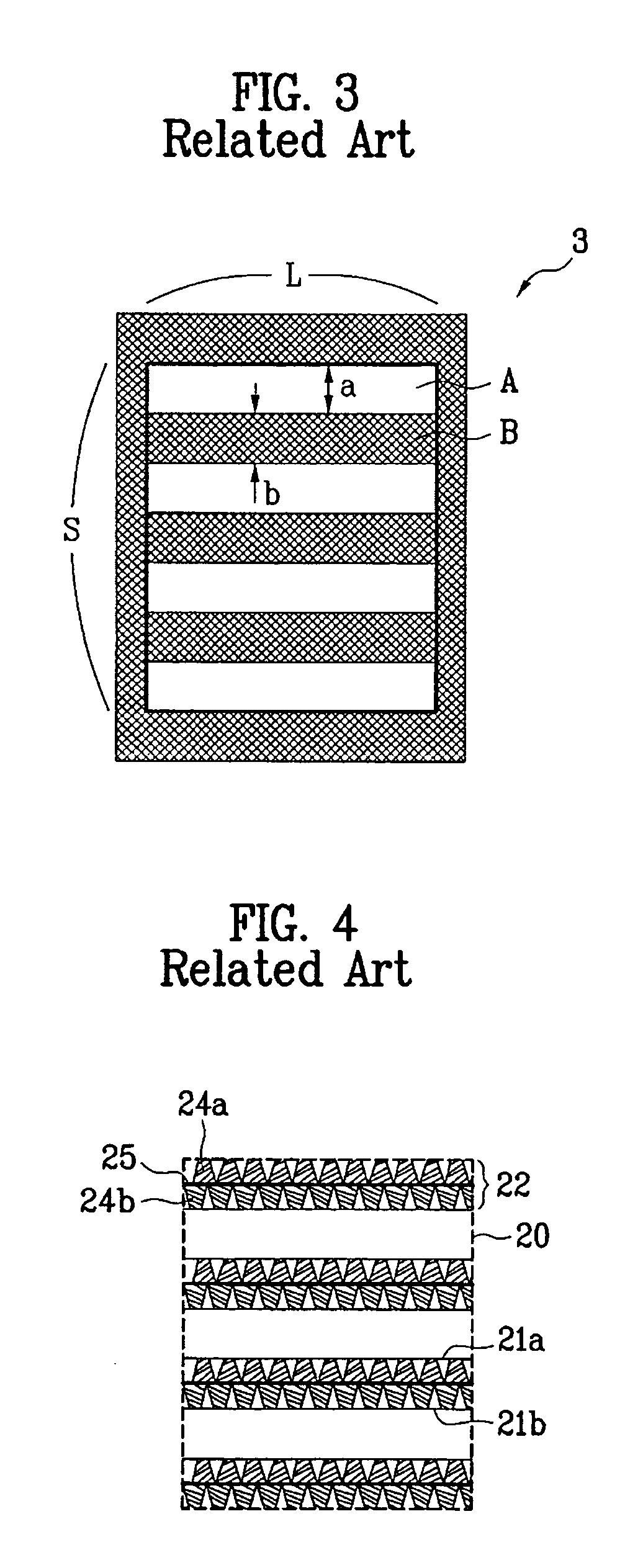

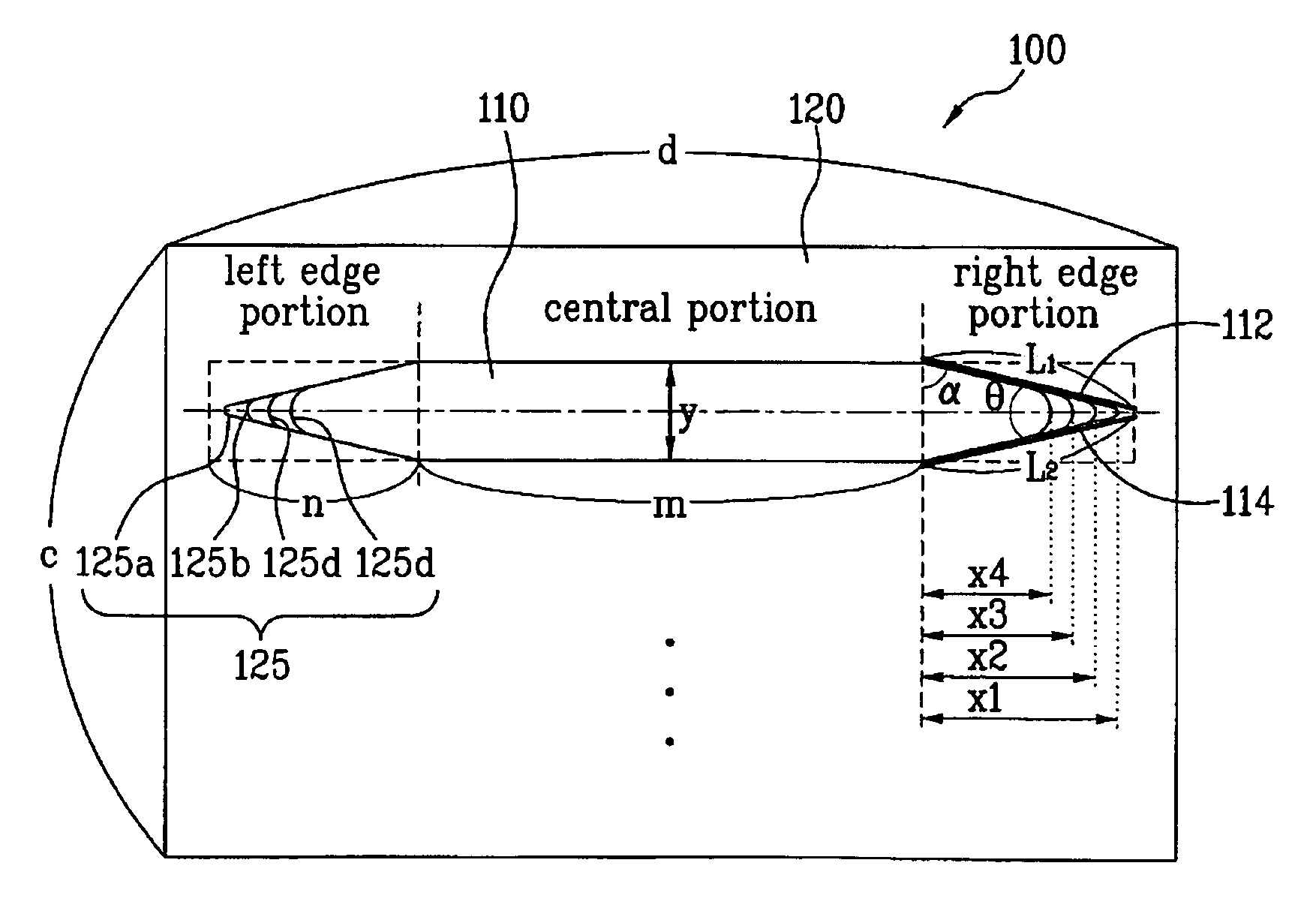

ActiveUS20050142450A1Increase the overlapping areaImprove featuresSolid-state devicesSemiconductor/solid-state device manufacturingAcute angleEngineering

A laser beam pattern mask includes at least one or more transmitting parts, each transmitting part having a central portion and a pair of edge portions provided to both sides of the central portion, each having a substantially triangular shape defined by a virtual boundary line between the central portion and the corresponding edge portion, an upper outside extending from an upper end of the boundary line at an acute angle, and a lower outside extending from a lower end of the boundary line at the acute angle to meet the upper outside at a rounded corner.

Owner:LG DISPLAY CO LTD

Laser beam pattern mask and crystallization method using the same

ActiveUS7132204B2Increase the overlapping areaImprove featuresSolid-state devicesSemiconductor/solid-state device manufacturingAcute angleEngineering

A laser beam pattern mask includes at least one or more transmitting parts, each transmitting part having a central portion and a pair of edge portions provided to both sides of the central portion, each having a substantially triangular shape defined by a virtual boundary line between the central portion and the corresponding edge portion, an upper outside extending from an upper end of the boundary line at an acute angle, and a lower outside extending from a lower end of the boundary line at the acute angle to meet the upper outside at a rounded corner.

Owner:LG DISPLAY CO LTD

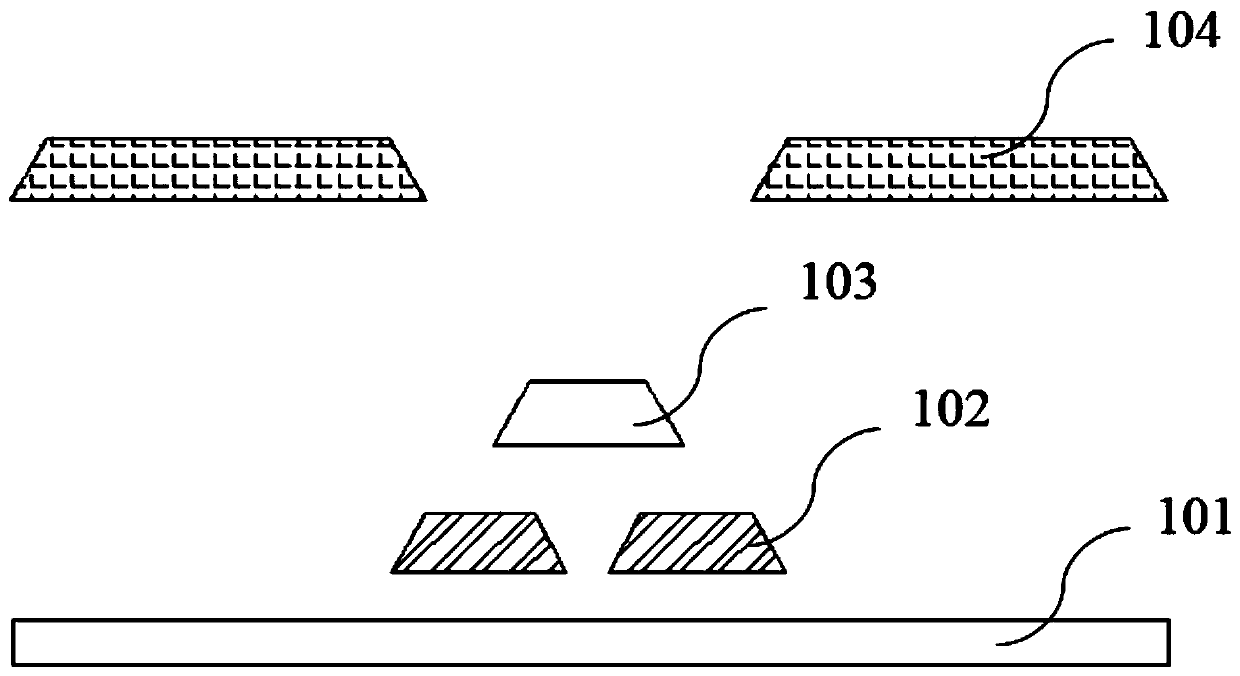

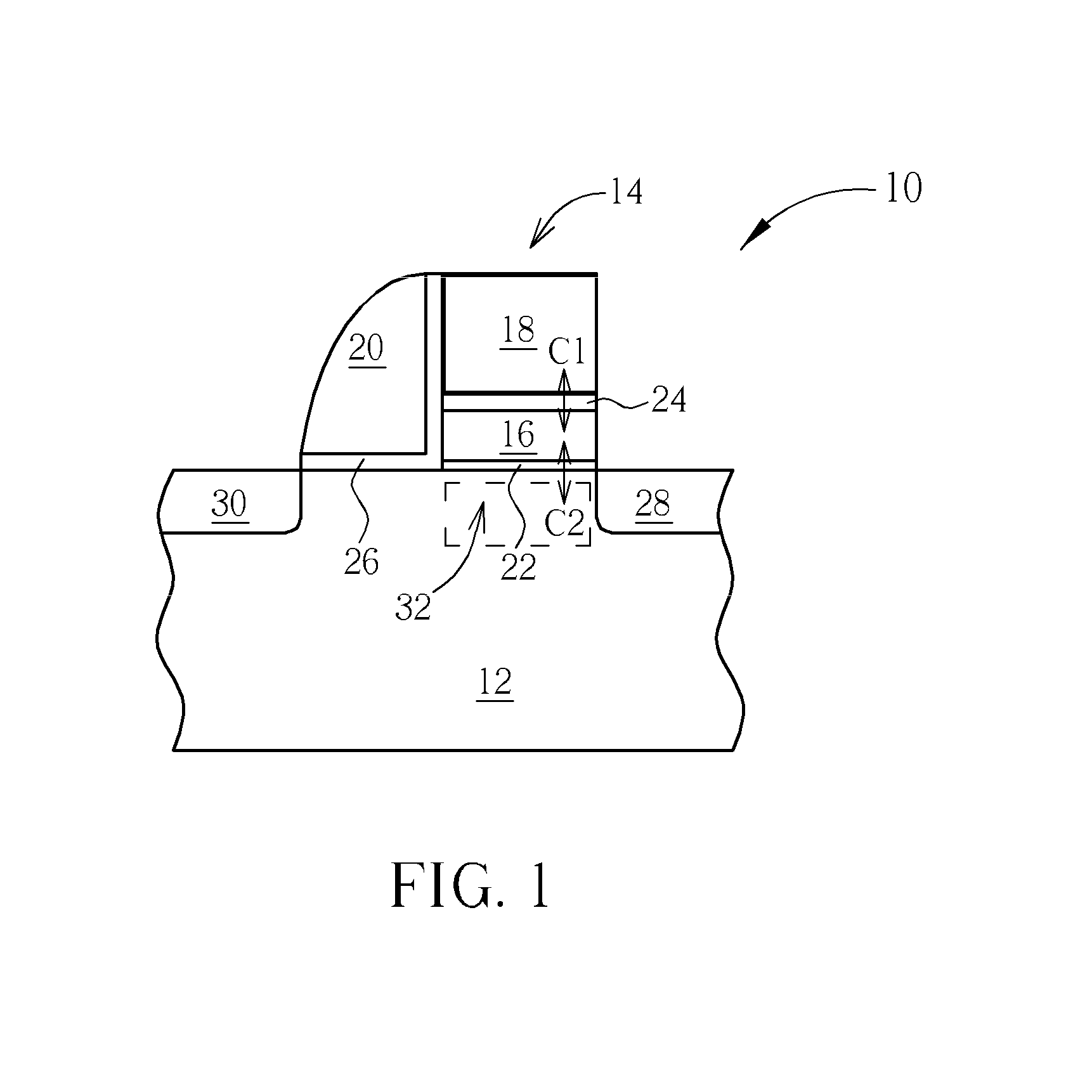

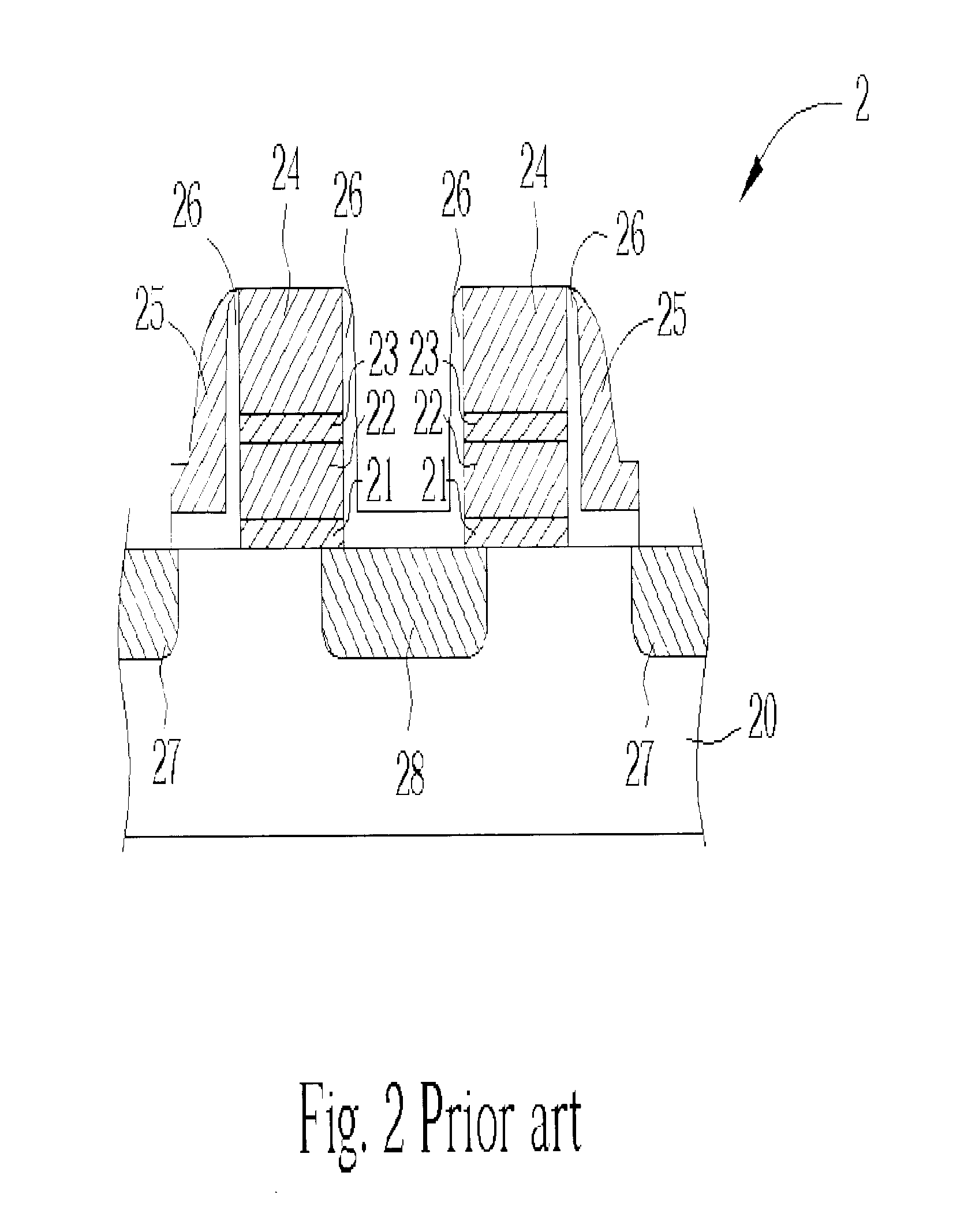

Split gate type flash memory and forming method thereof

ActiveCN102938406AImprove work efficiencyReduce coupling capacitanceSolid-state devicesSemiconductor/solid-state device manufacturingState of artCapacitance

The invention discloses a split gate type flash memory which comprises a semiconductor substrate, a word line, two discrete storage bit units and oxidation layers, wherein the word line is located at the bottom surface of the semiconductor substrate; the two storage bit units are located at two sides of the word line; the oxidation layers are arranged between the two storage bit units and the word line; each storage bit unit comprises a first insulation layer which is located on the bottom surface of the semiconductor substrate, a floating gate which is located on the surface of the first insulation layer, a second insulation layer which is located on the surface of the floating gate, a control gate which is located on the surface of the second insulation layer and a side wall structure which covers the floating gate and the control gate; each floating gate comprises a first floating gate and a second floating gate; and the distance between each first floating gate and the word line is greater than the distance between each second floating gate and the word line. The distance between the first floating gates and the word line is greater than the distance in the prior art, so that the coupling capacitance between the floating gates and the word line is smaller than the capacitance in the prior art, the coupling capacitance between the word line and the floating gates is as small as possible and then the erasing efficiency and the read-write efficiency of the flash memory are improved.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

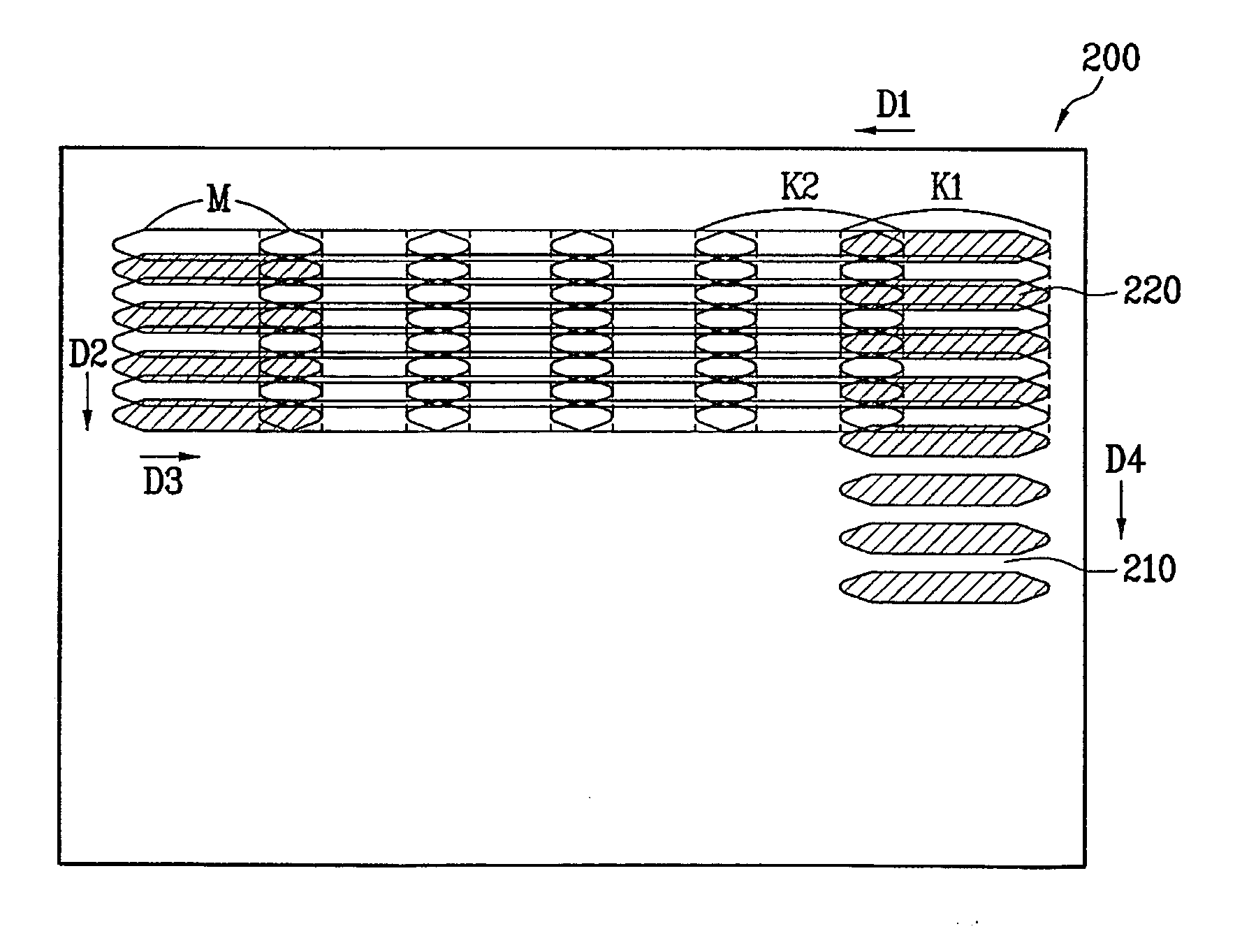

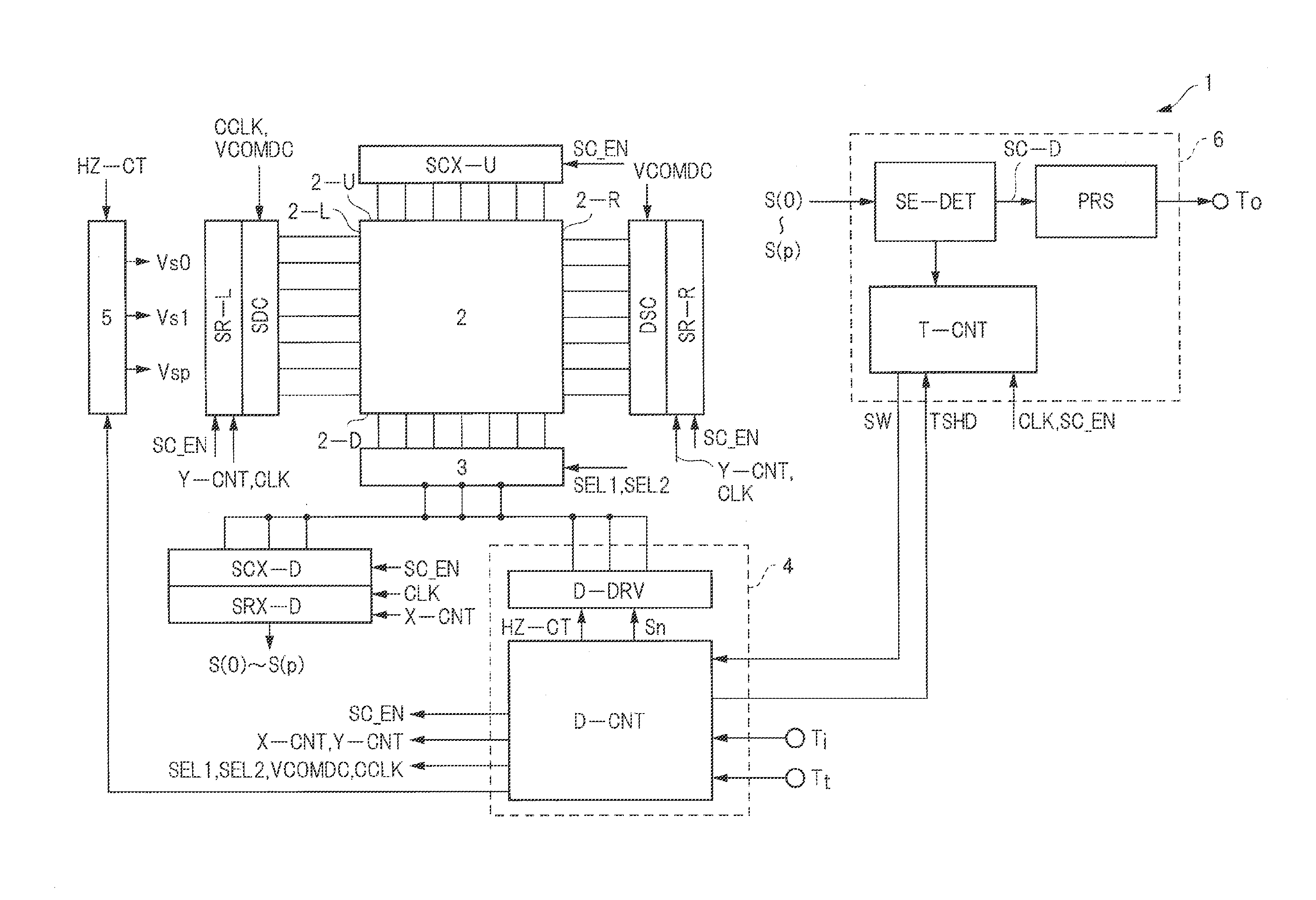

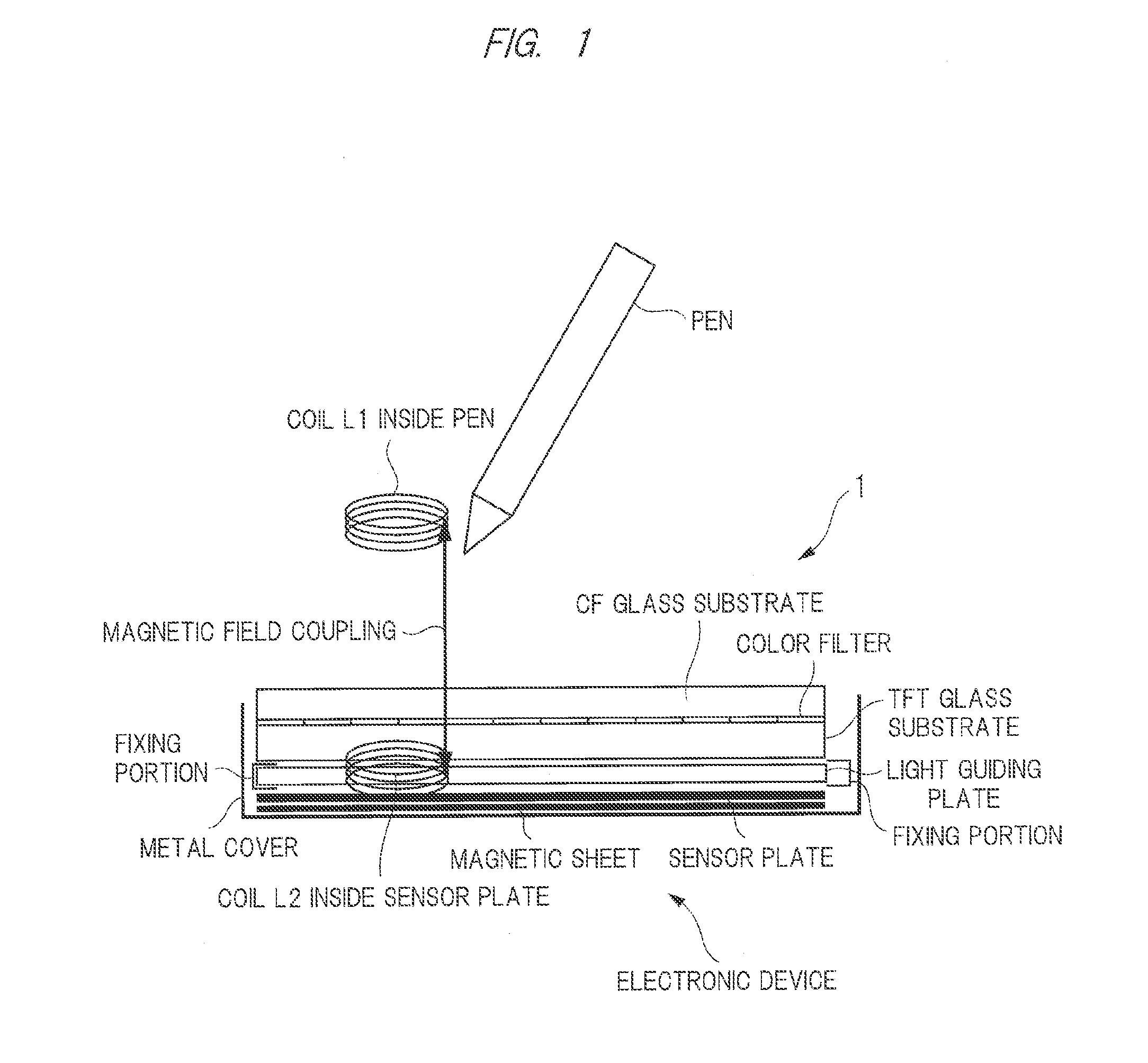

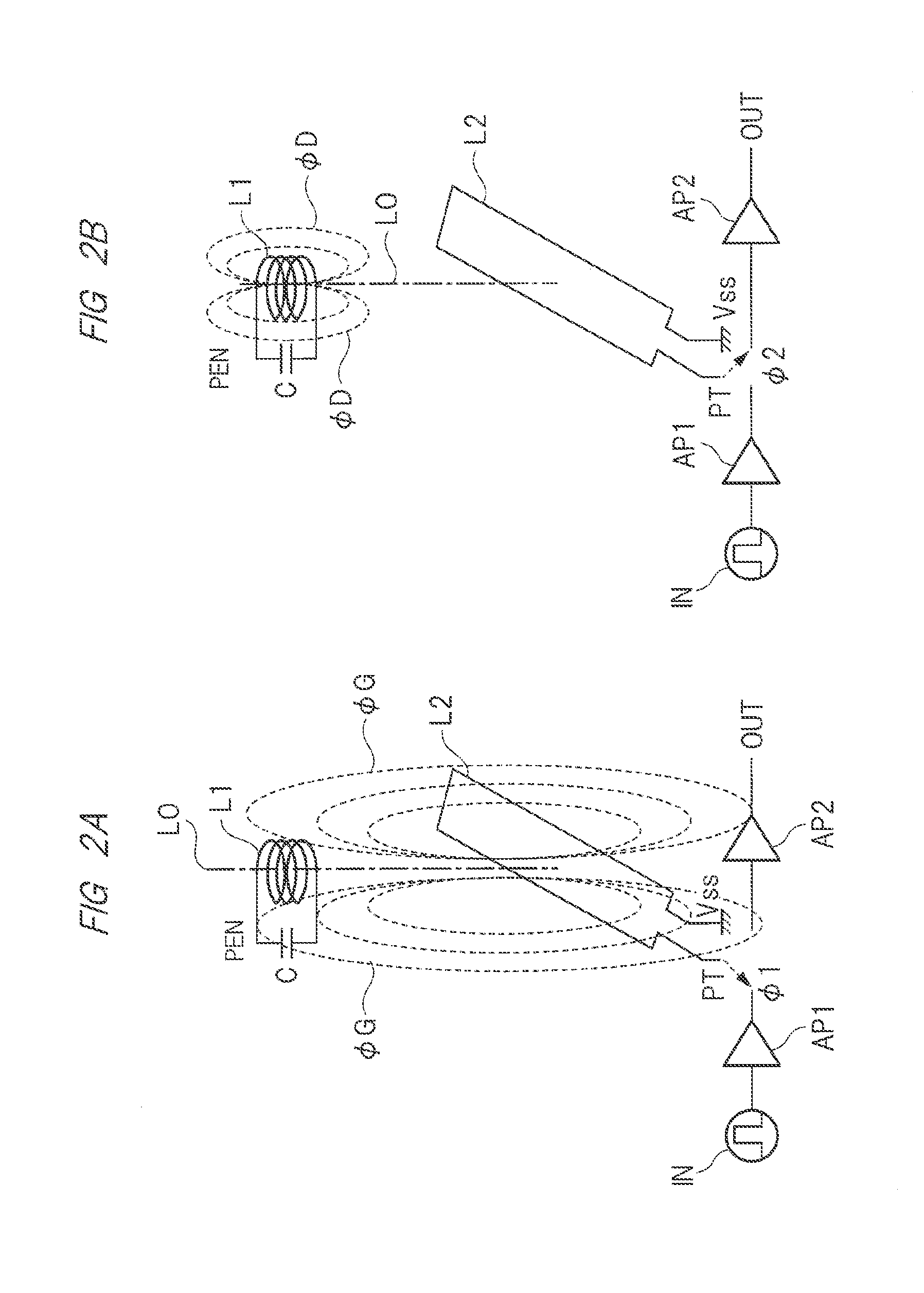

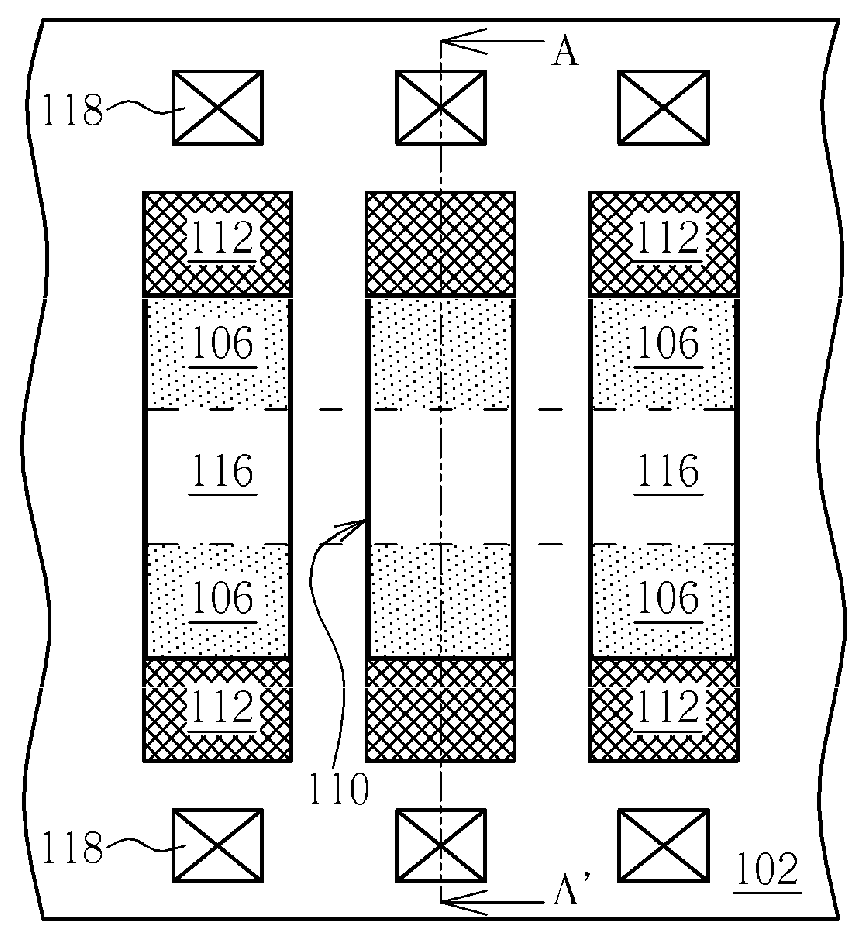

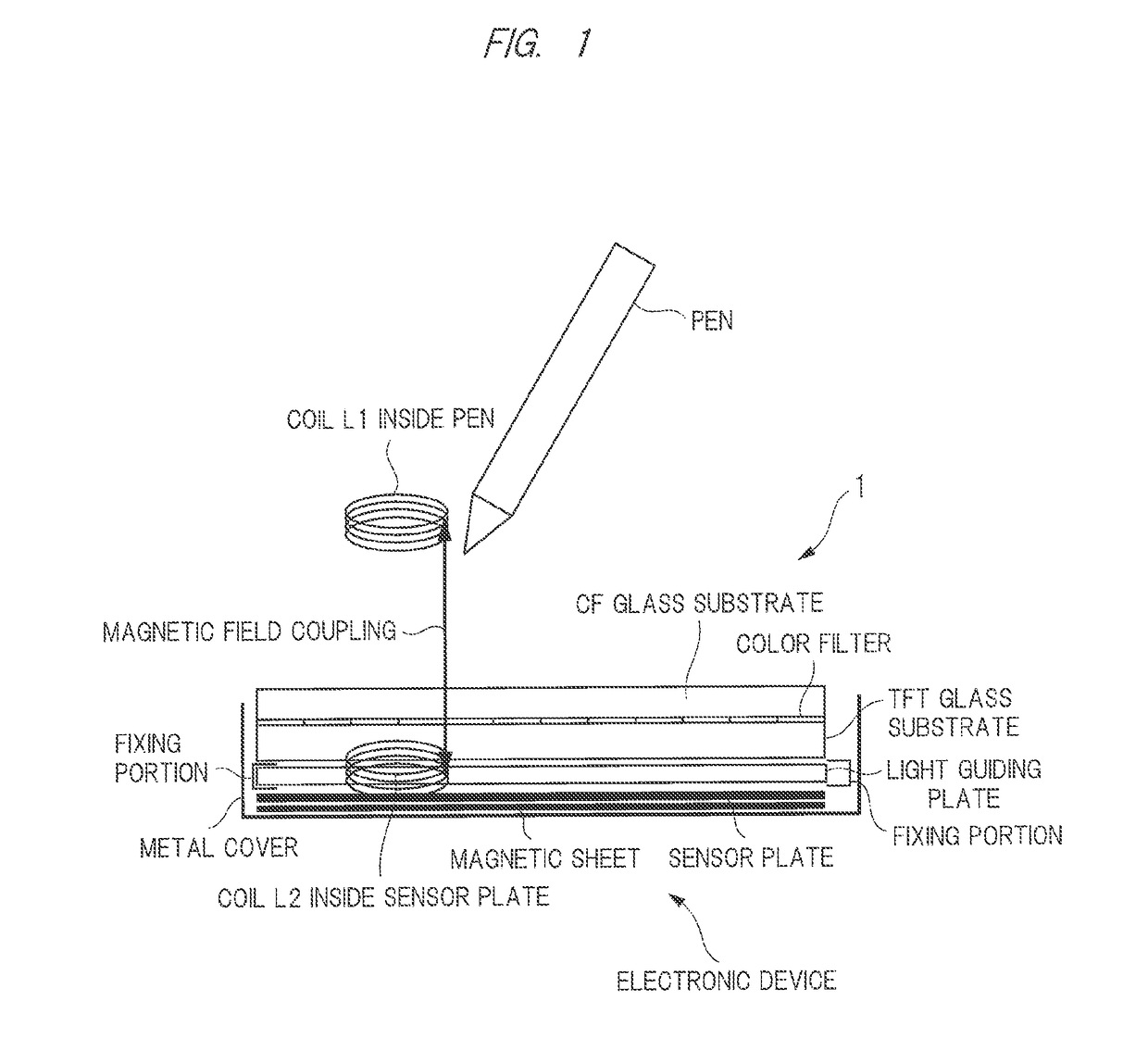

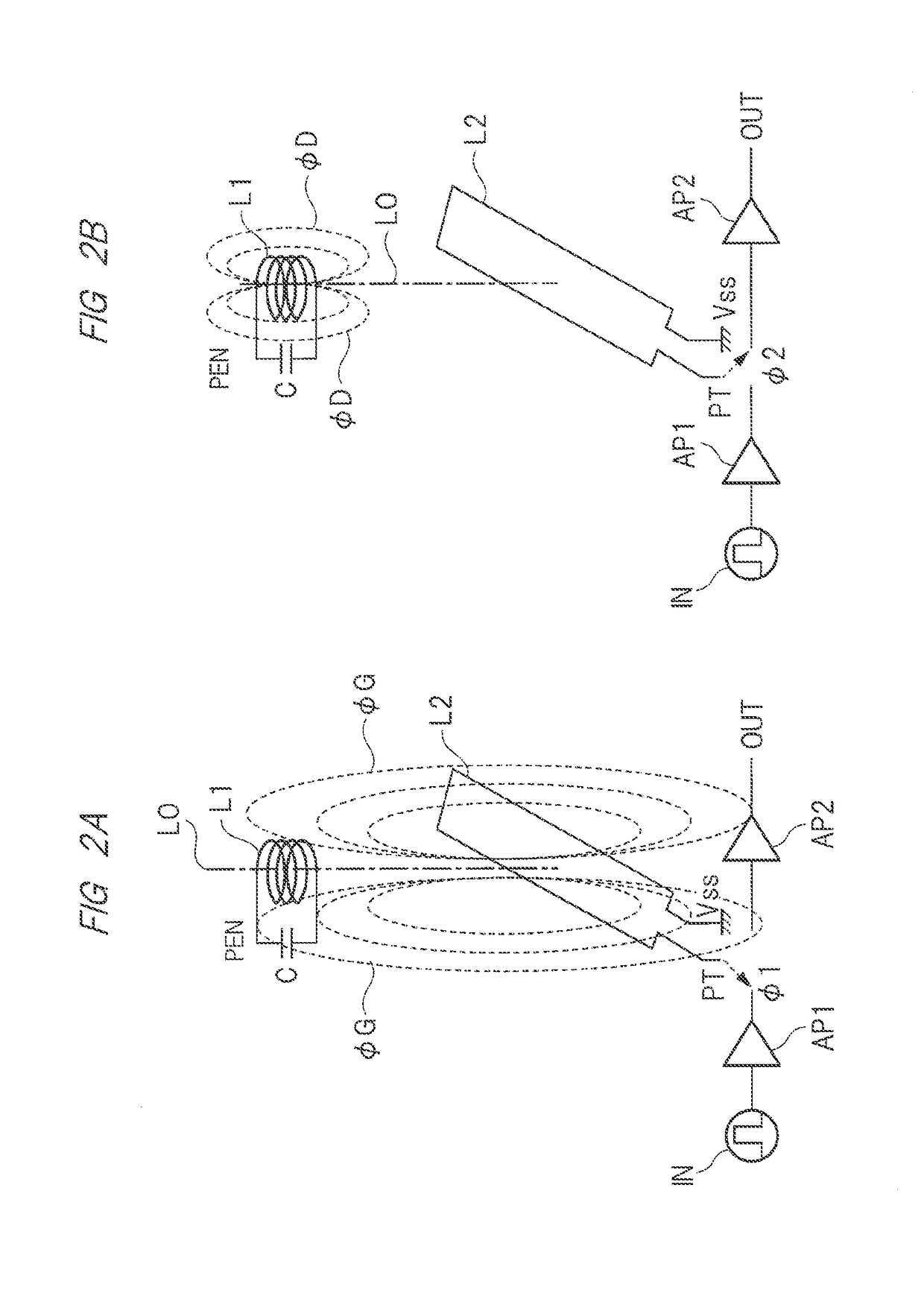

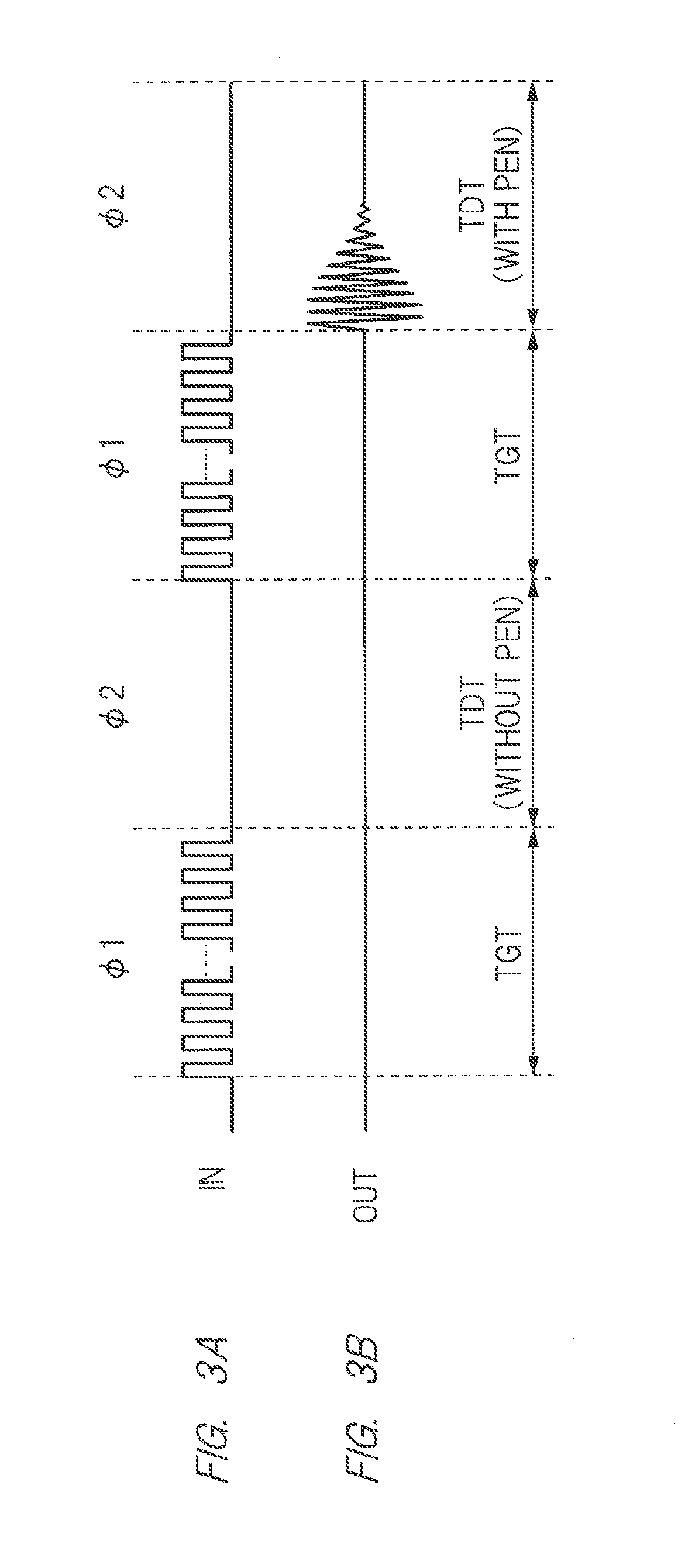

Display apparatus

ActiveUS20160349921A1Improve accuracyMagnetic fields can be enhancedInput/output processes for data processingComputer sciencePixel array

A display apparatus with a touch detection function capable of improving accuracy is provided. The display apparatus includes: a pixel array having a plurality of pixels arranged in a matrix form; and a plurality of signal wires arranged in the pixel array. Here, when an externally-detecting object is detected, a plurality of coils having areas overlapping with each other are formed of a plurality of signal wires (drive electrodes) among the plurality of signal wires, and a magnetic field generated in the plurality of respective coils are superimposed in an overlapped area by supplying a drive signal to the plurality of coils.

Owner:JAPAN DISPLAY INC

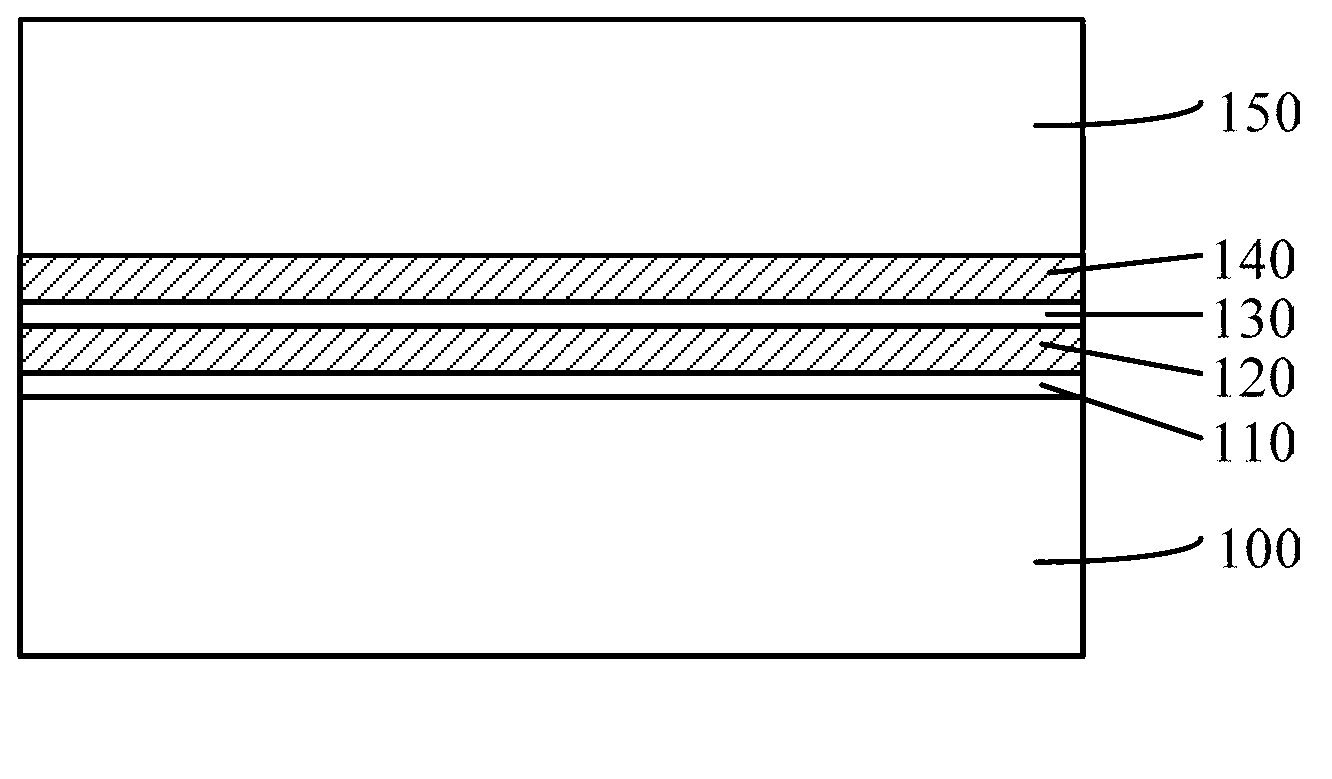

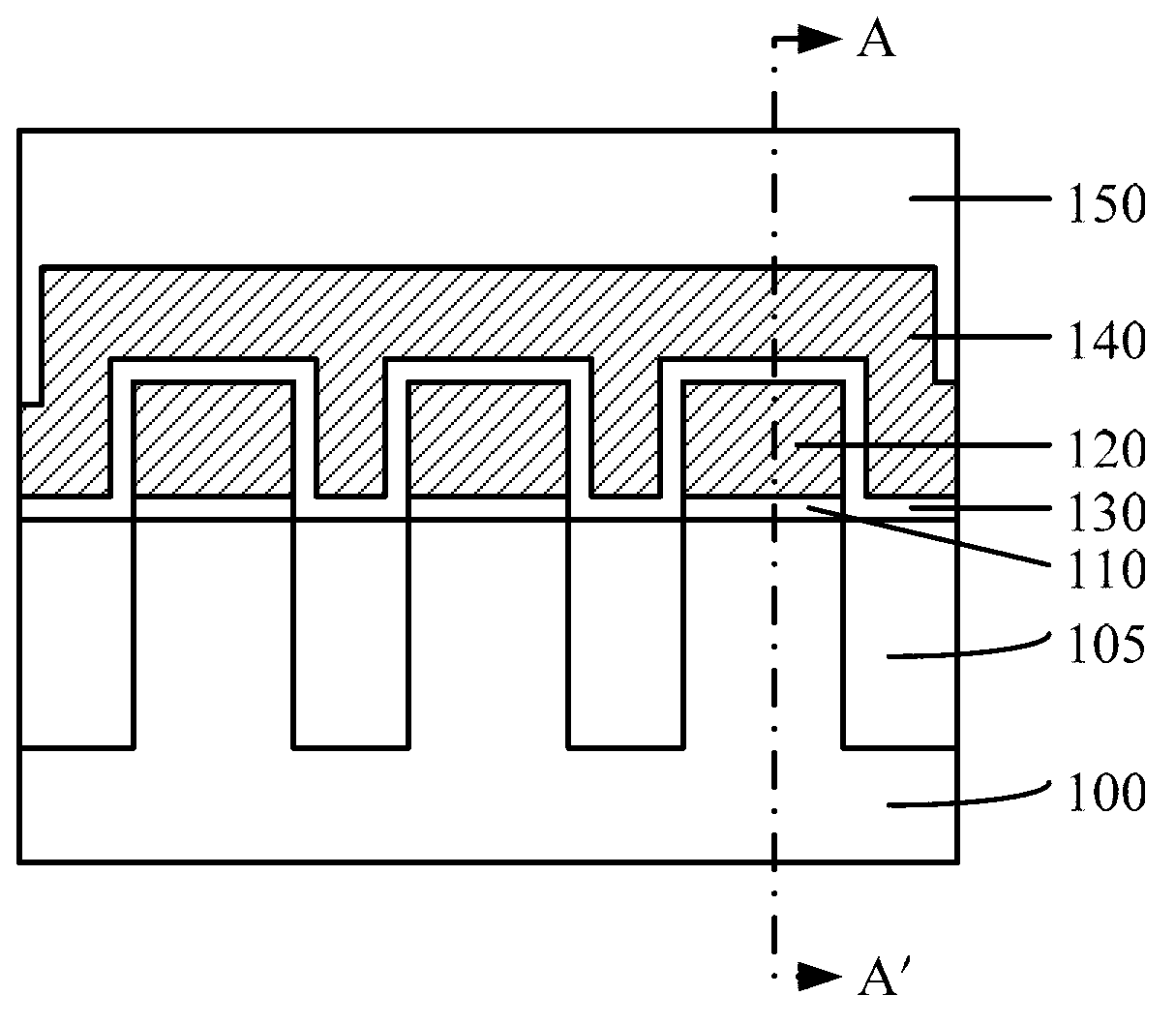

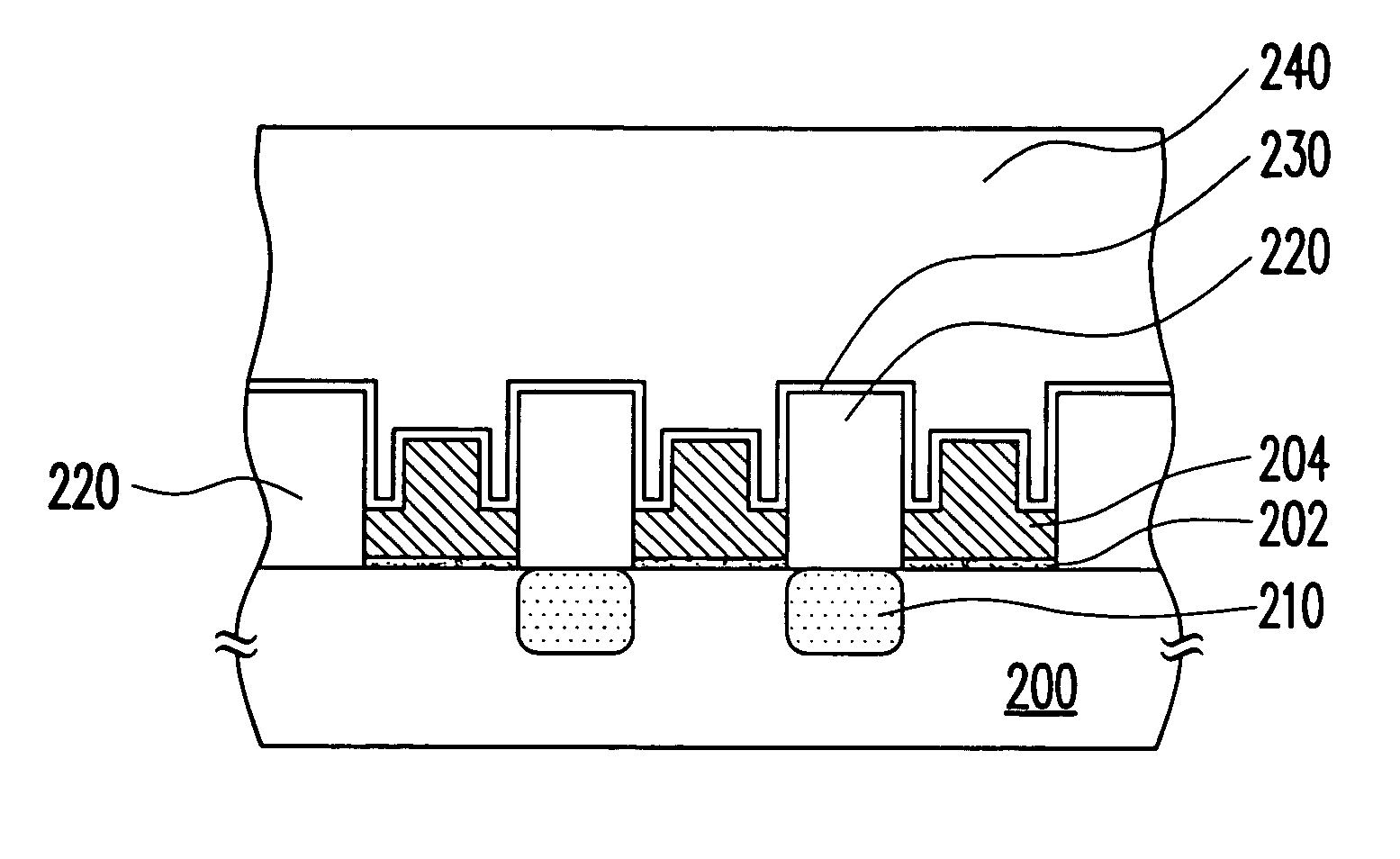

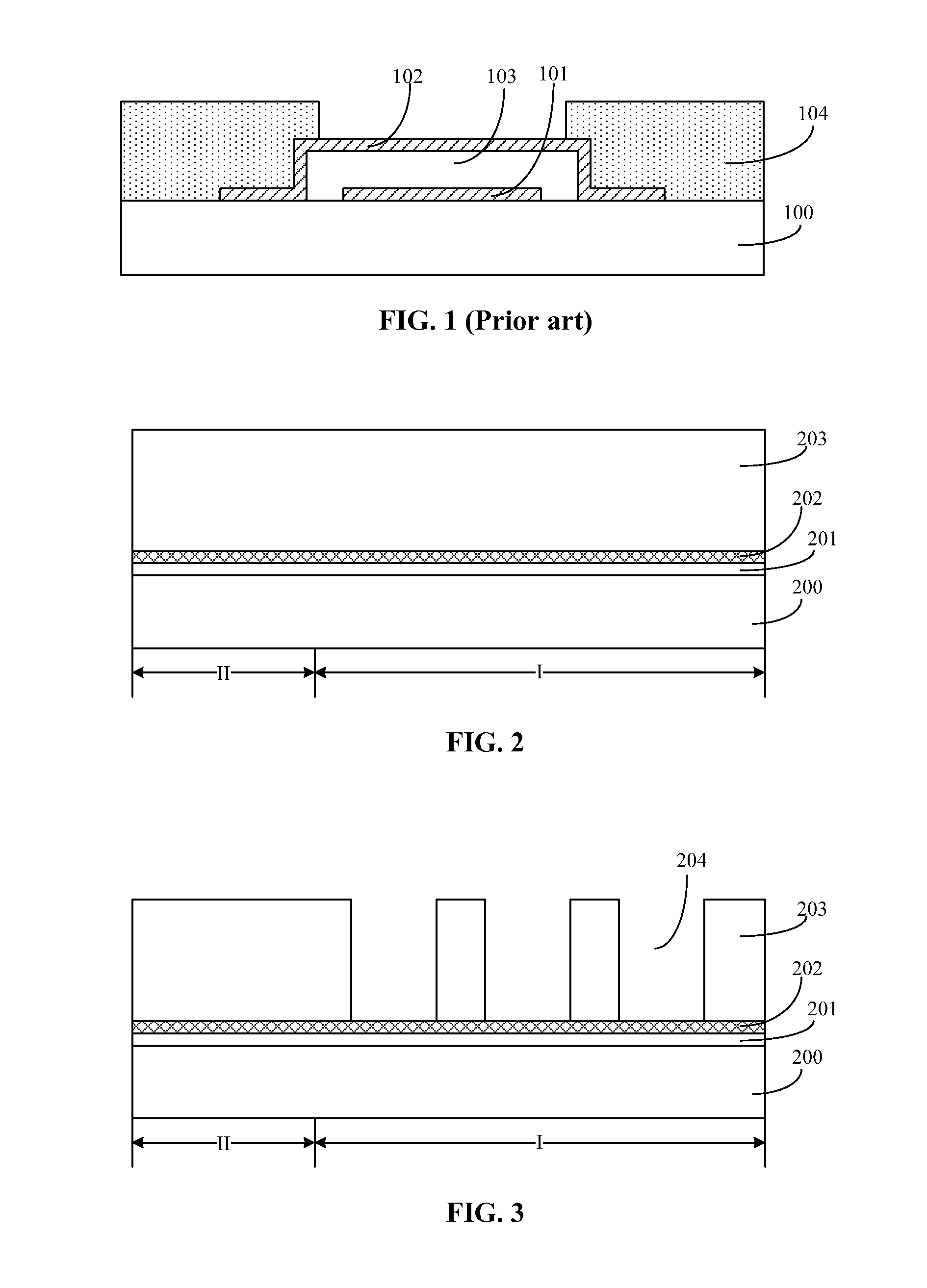

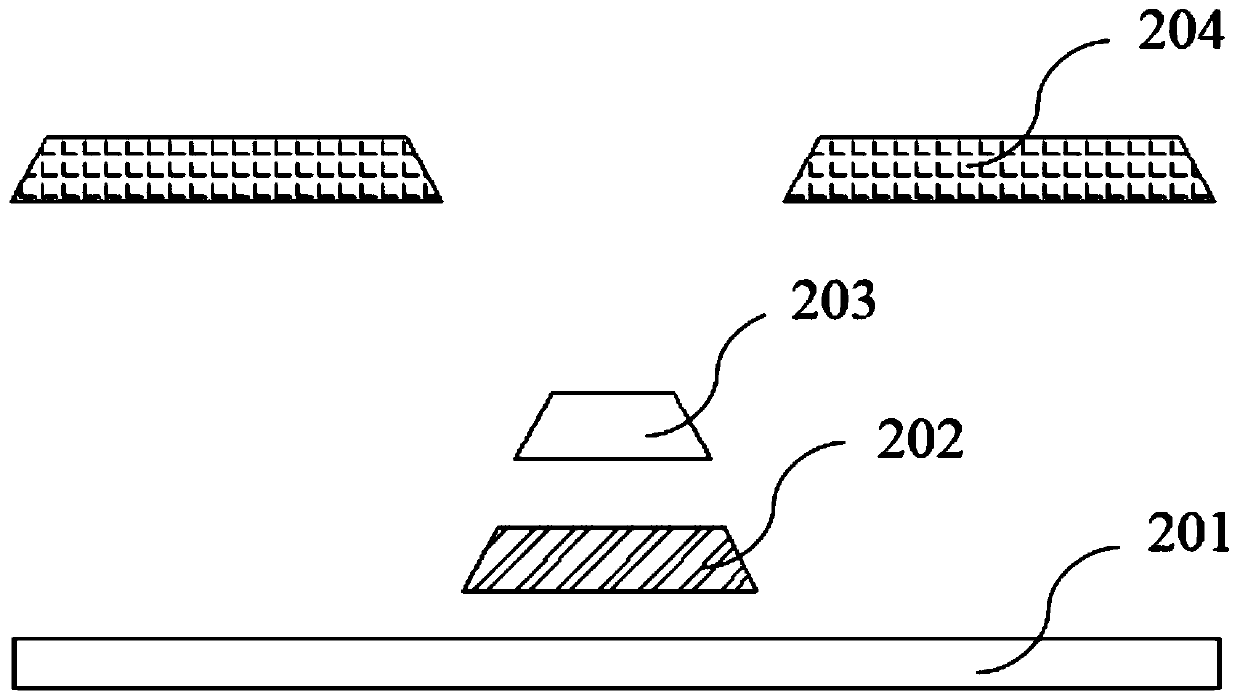

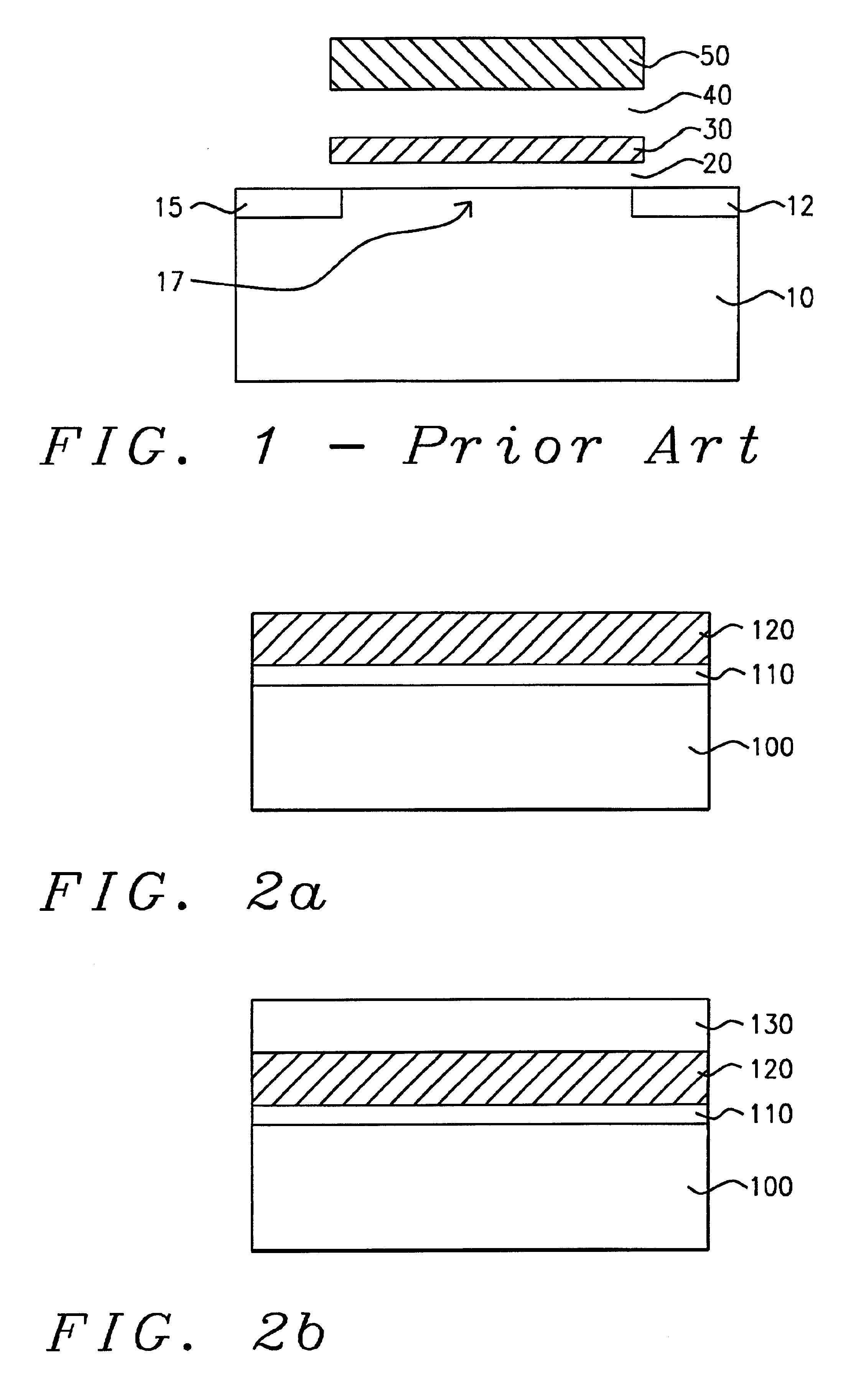

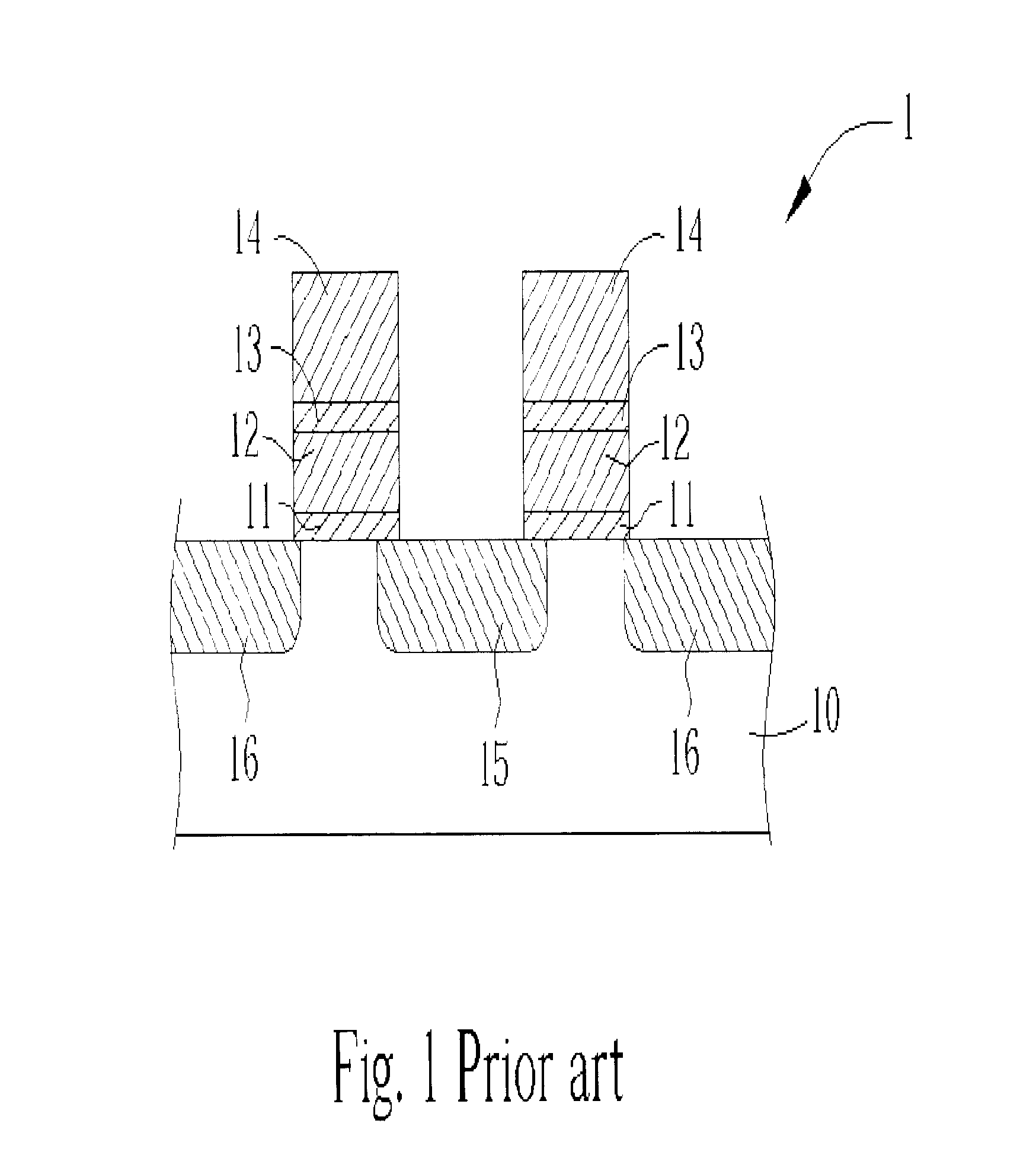

Flash memory device and manufacturing method thereof

InactiveUS20060131635A1Simplify the manufacturing processImprove gate coupling ratioTransistorSolid-state devicesInter layerCoupling ratio

A method of manufacturing a flash memory device is provided. Multiple stack structures each comprising a tunneling oxide layer and a first conductive layer are formed over a substrate. Thereafter, multiple embedded doping regions is formed in the substrate between the stack structures. A dielectric layer is formed over the substrate to cover the stack structures and then the dielectric layer is etched back and a portion of dielectric layer is remained on the stack structures. Using a portion of the remaining dielectric layer as a mask, a portion of the first conductive layer is removed. An inter-layer dielectric layer and a second conductive layer are sequentially formed over the first conductive layer. Because a self-aligned process is used to define the floating gate and the floating gate has a narrow-top / wide-bottom configuration, the fabrication process is simplified and the coupling ratio of the stack gate is increased.

Owner:MACRONIX INT CO LTD

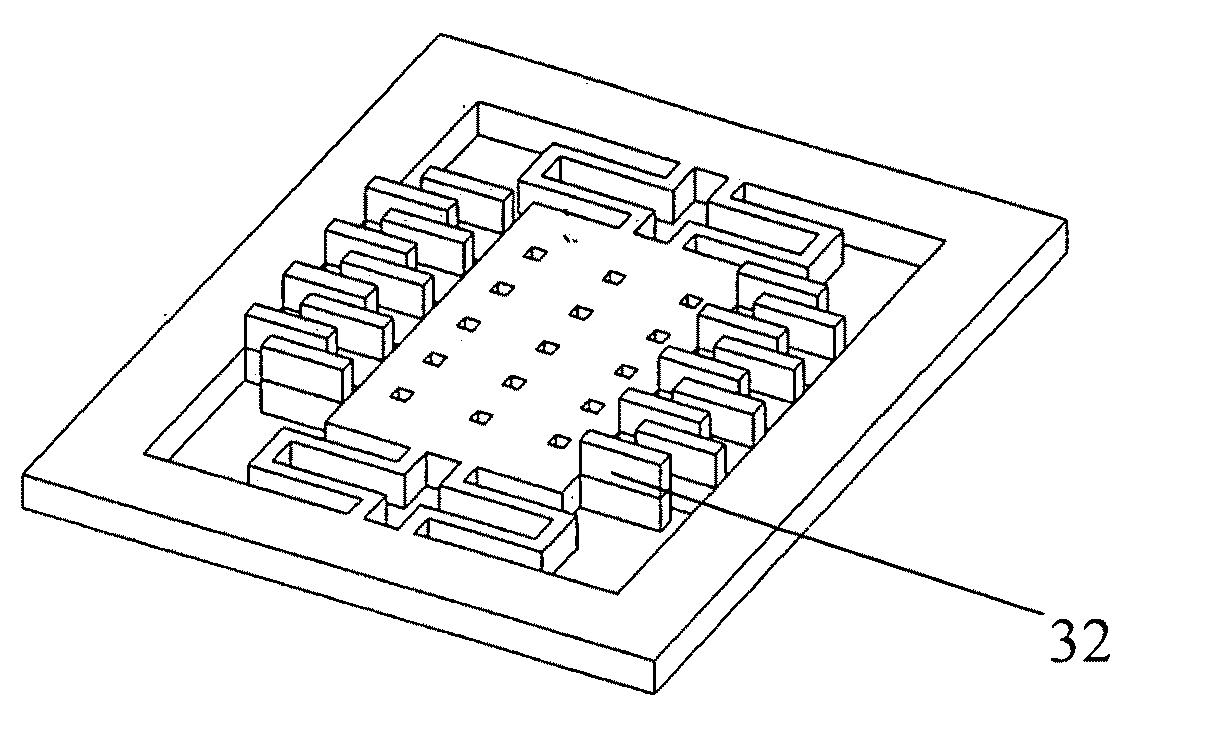

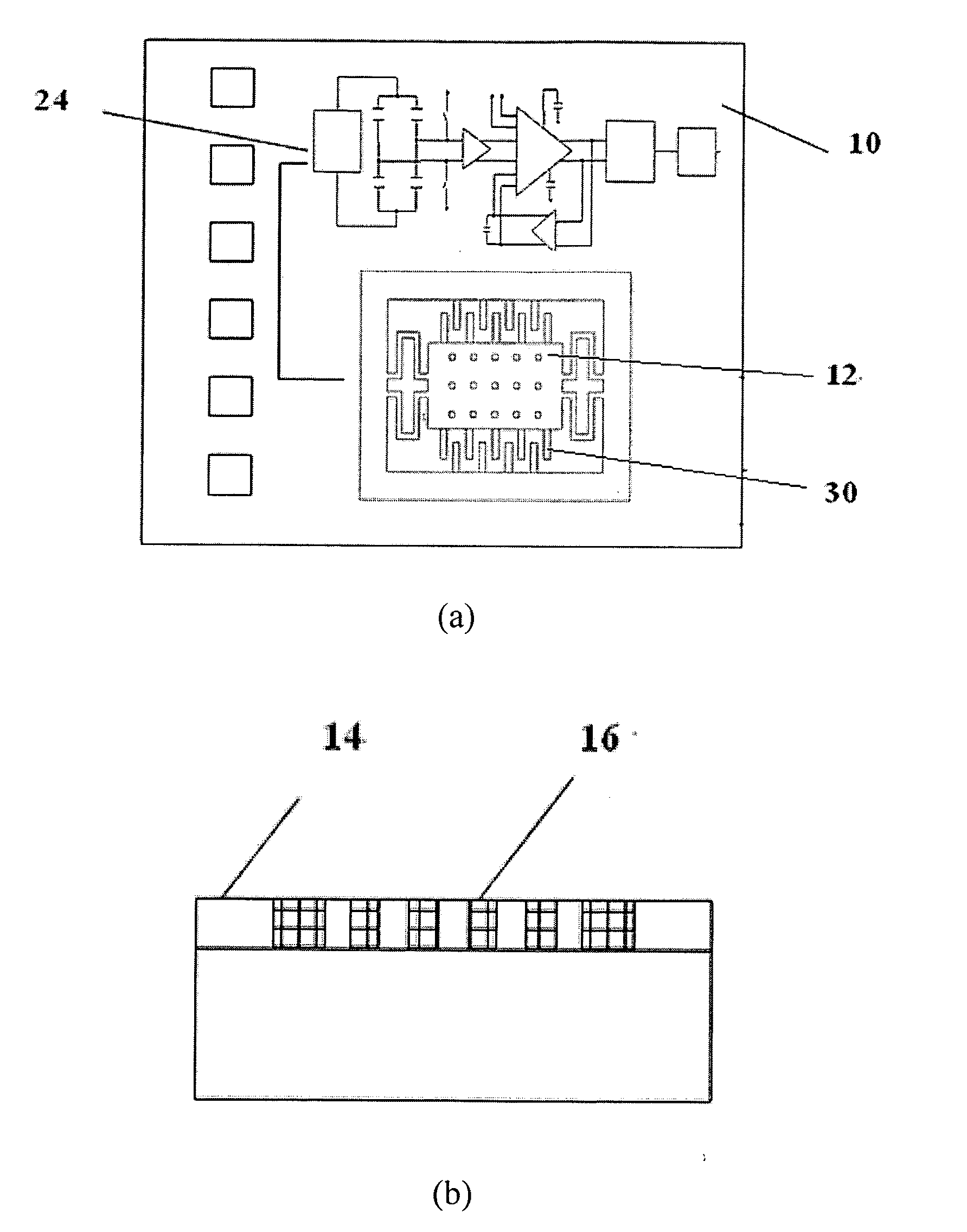

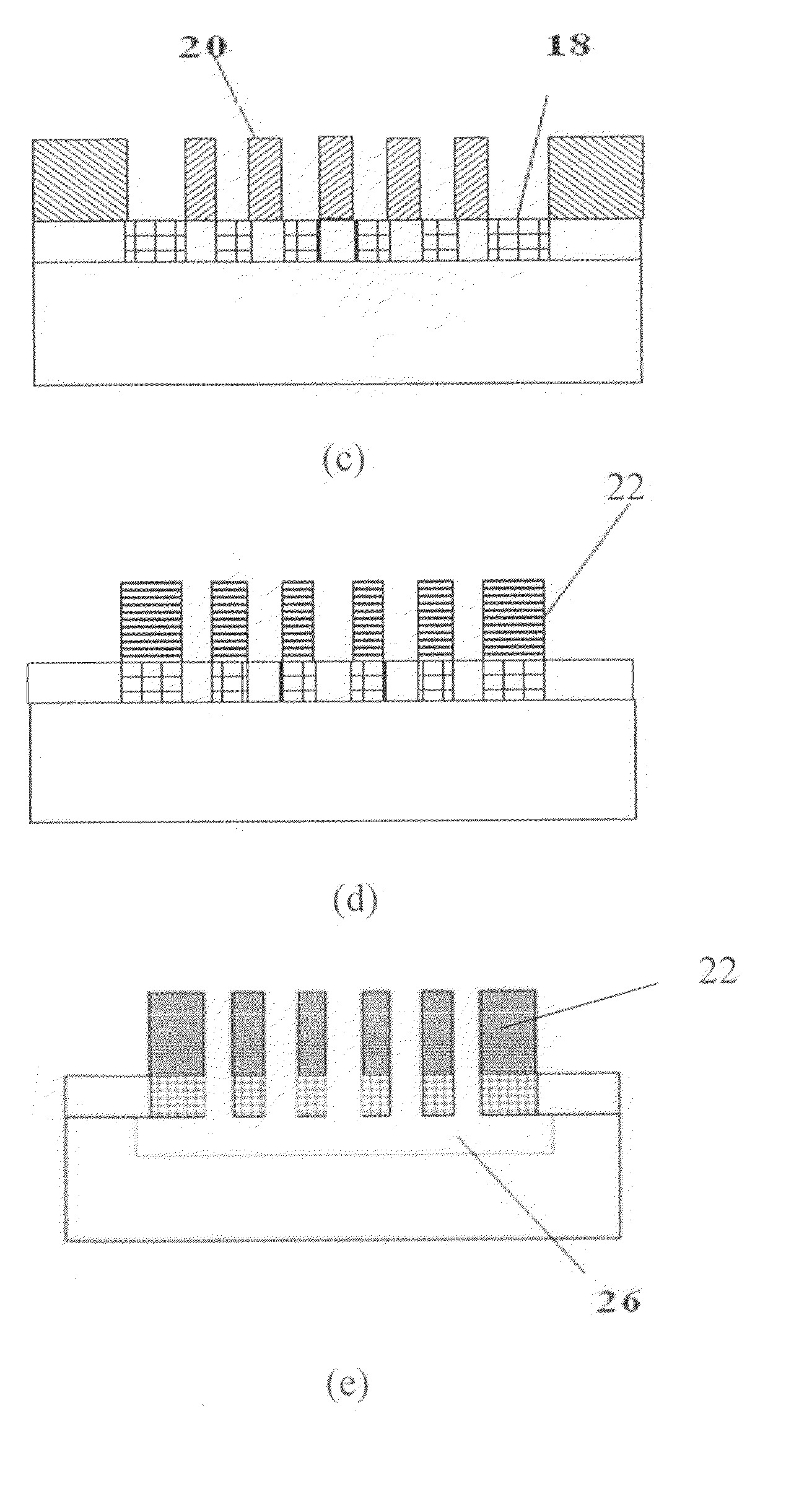

MEMS pressure sensors and fabrication method thereof

ActiveUS20150008541A1Large deformationSignificant changeDecorative surface effectsFluid pressure measurement by electric/magnetic elementsCapacitive pressure sensorMems pressure sensor

A MEMS capacitive pressure sensor is provided. The pressure sensor includes a substrate having a first region and a second region, and a first dielectric layer formed on the substrate. The pressure sensor also includes a first electrode layer formed on the first dielectric layer, and a second dielectric layer having first openings formed on the first electrode layer. Further, the pressure sensor includes conductive sidewalls connecting with the first electrode layer formed on sidewalls of the first openings, and a second electrode layer with a portion formed on the second dielectric layer in the second region and the rest suspended over the conductive sidewalls in the first region. Further, the pressure sensor also includes a chamber between the conductive sidewalls and the second electrode layer; and a third dielectric layer formed on the second electrode layer exposing a portion of the second electrode layer in the first region.

Owner:SEMICON MFG INT (SHANGHAI) CORP

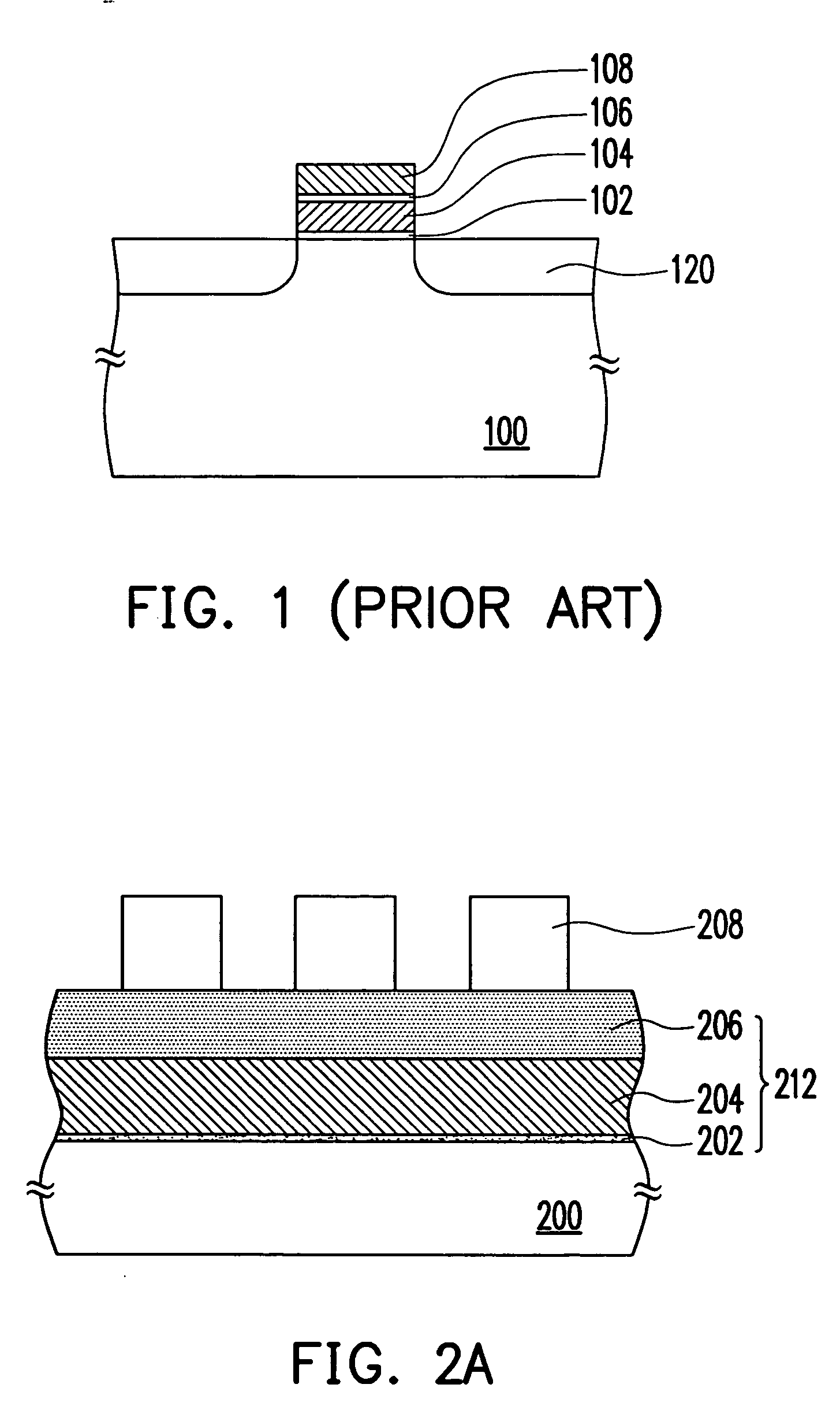

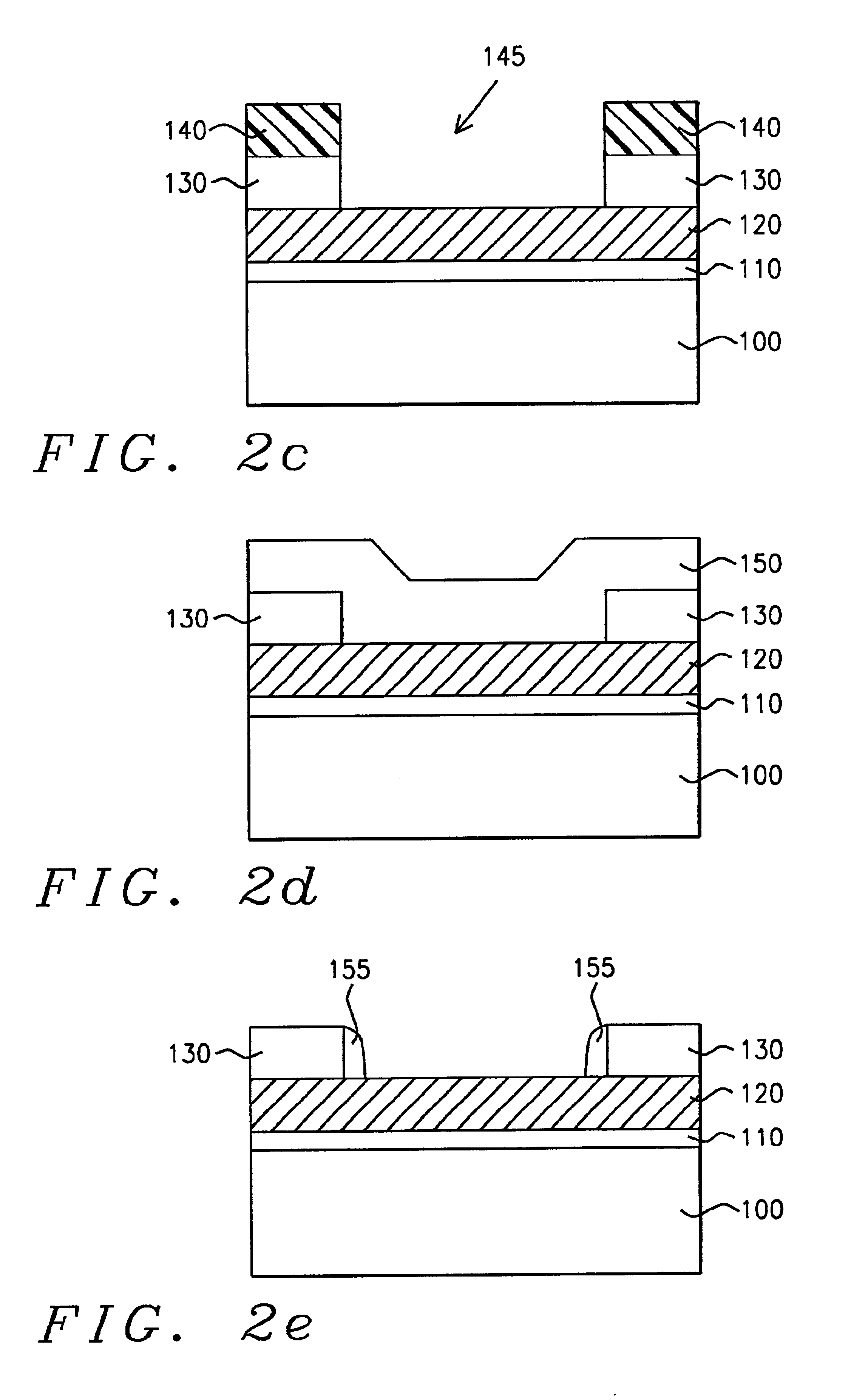

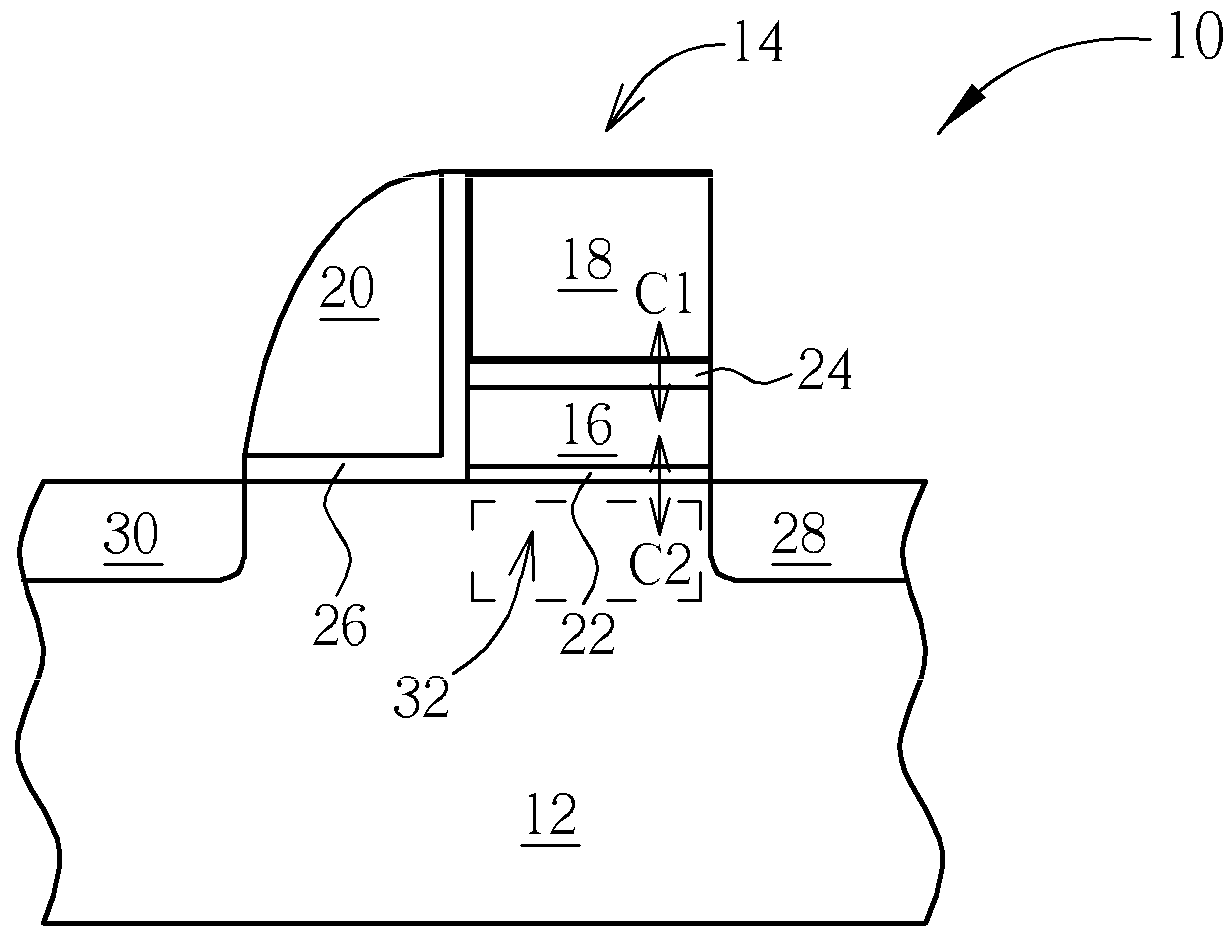

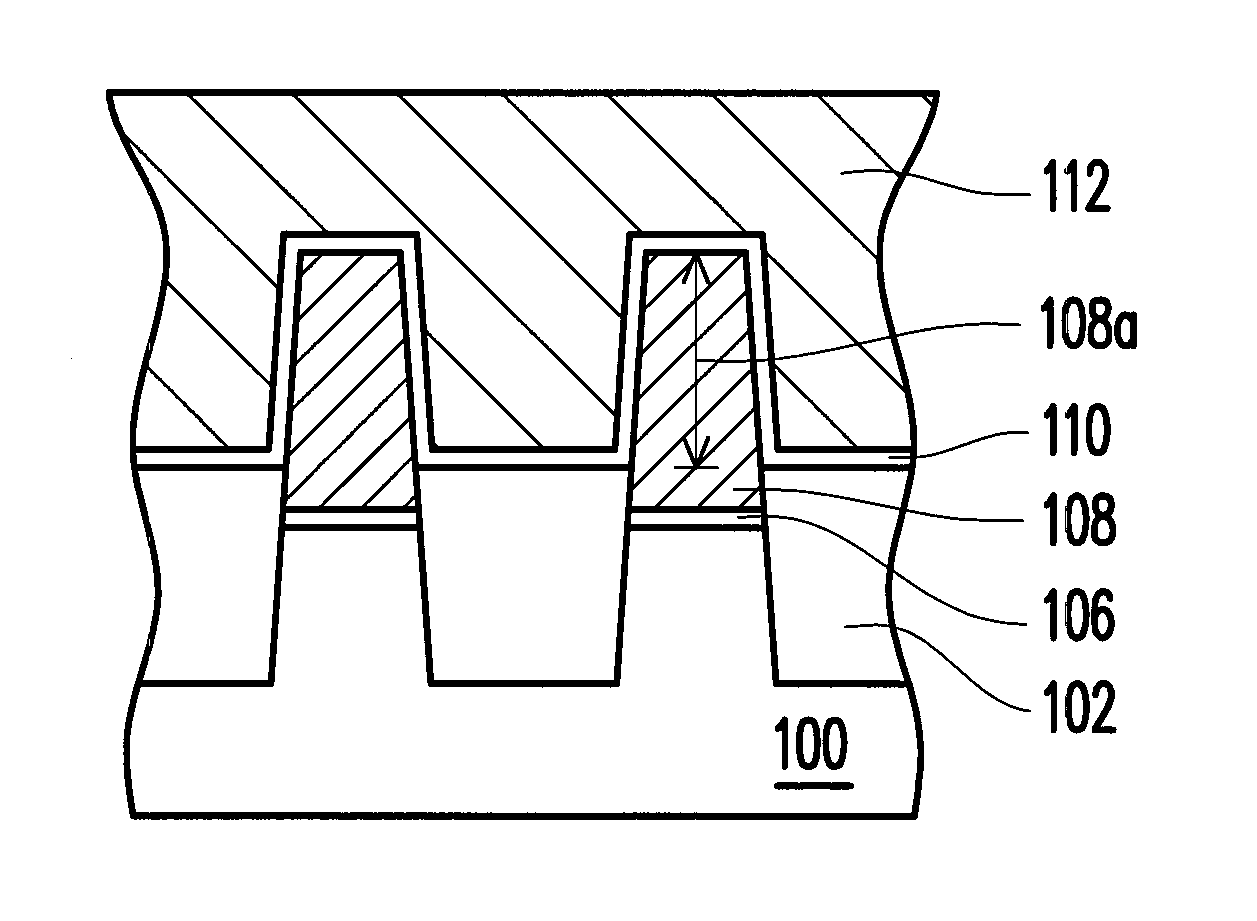

Method and structure to improve the gate coupling ratio (GCR) for manufacturing a flash memory device

InactiveUS6897116B2Increase the overlapping areaImprove gate coupling ratioSolid-state devicesSemiconductor/solid-state device manufacturingElectrical conductorCoupling ratio

Method and structure to improve the gate coupling ratio (GCR) for manufacturing a flash memory device are provided. The method and structure include the following steps. A gate oxide layer, a first semiconductor layer, and an insulating layer are formed sequentially over a provided semiconductor substrate. An etching process is used to etch the insulating layer. A semiconductor spacer is then deposited and used as a self-aligned etching mask. After the self-aligned etching, the insulating layer is removed and an insulating stacked structure is deposited. Finally, a second semiconductor layer is deposited and etched to form the control gate region.

Owner:UNITED MICROELECTRONICS CORP

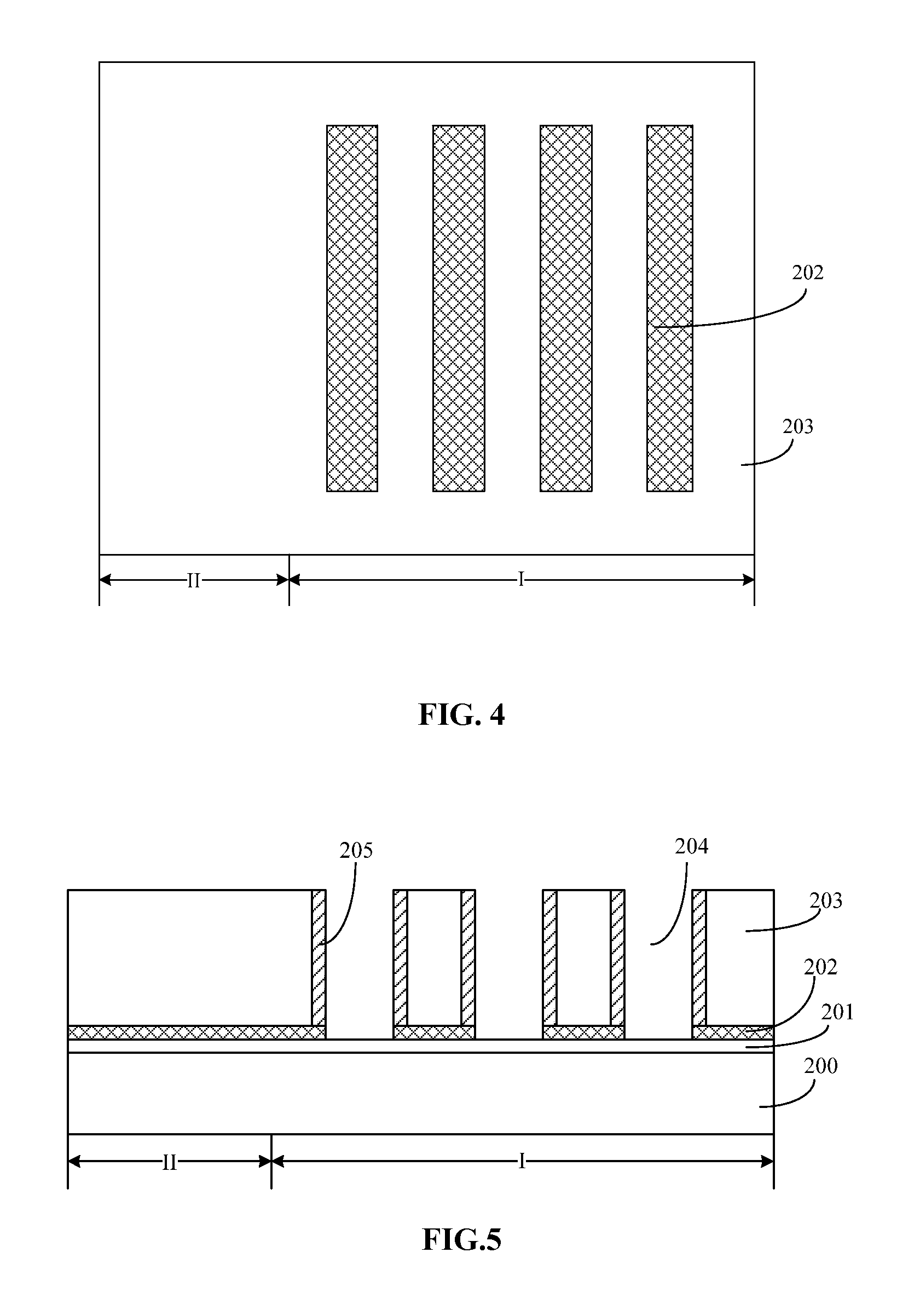

Substrate and liquid crystal display panel

InactiveCN110824795AIncrease the overlapping areaIncrease shieldingNon-linear opticsLiquid-crystal displayEngineering

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

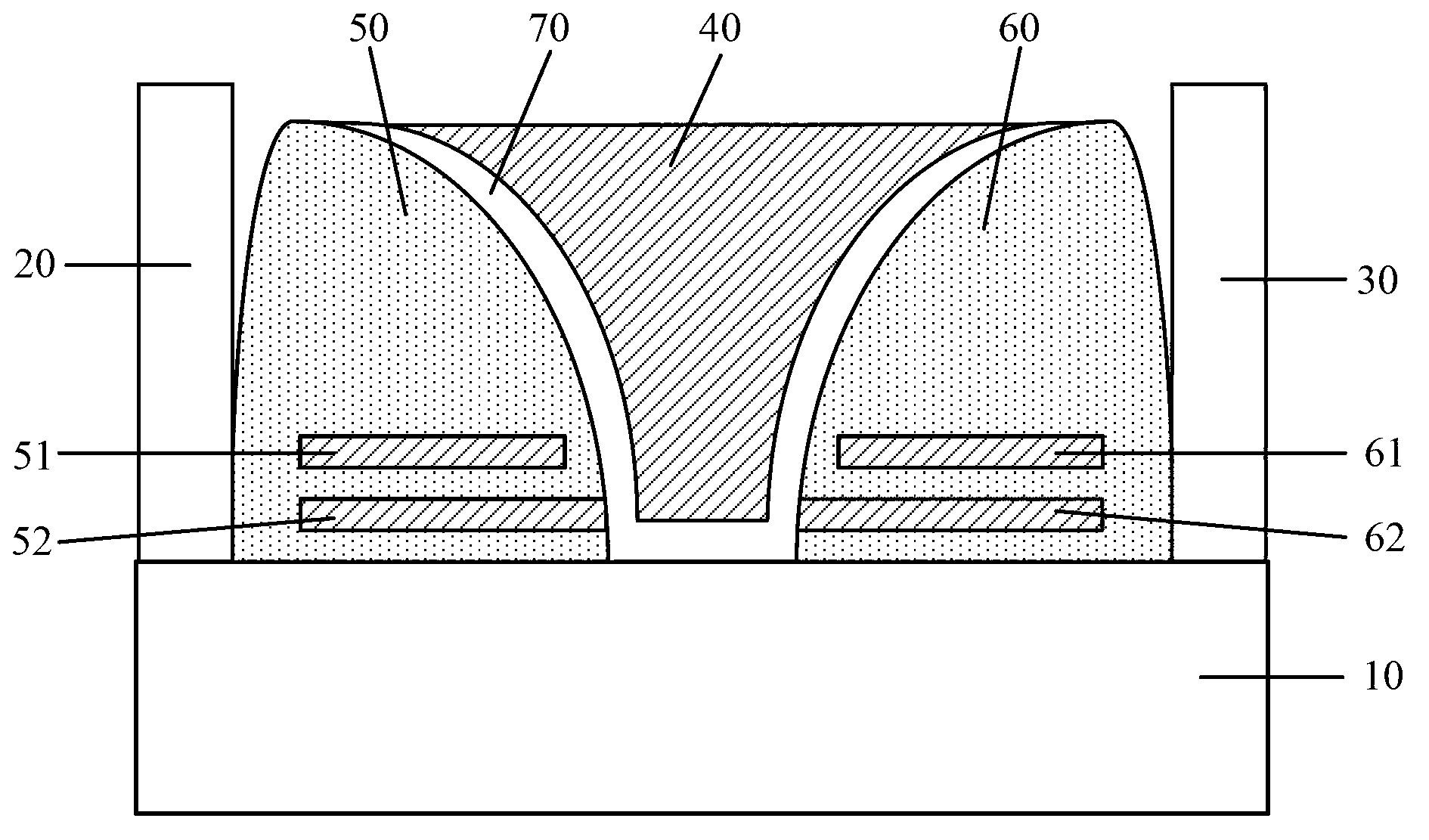

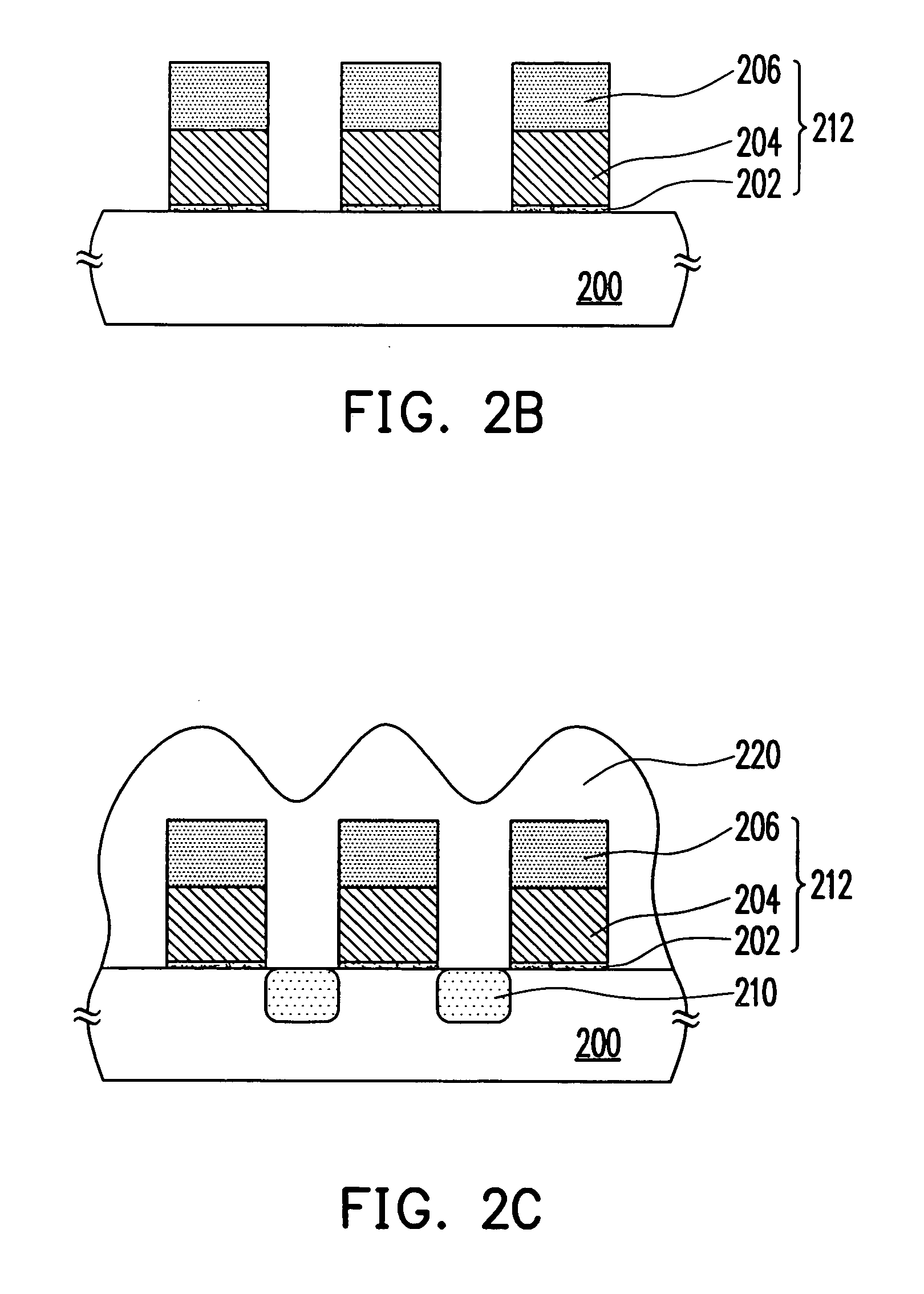

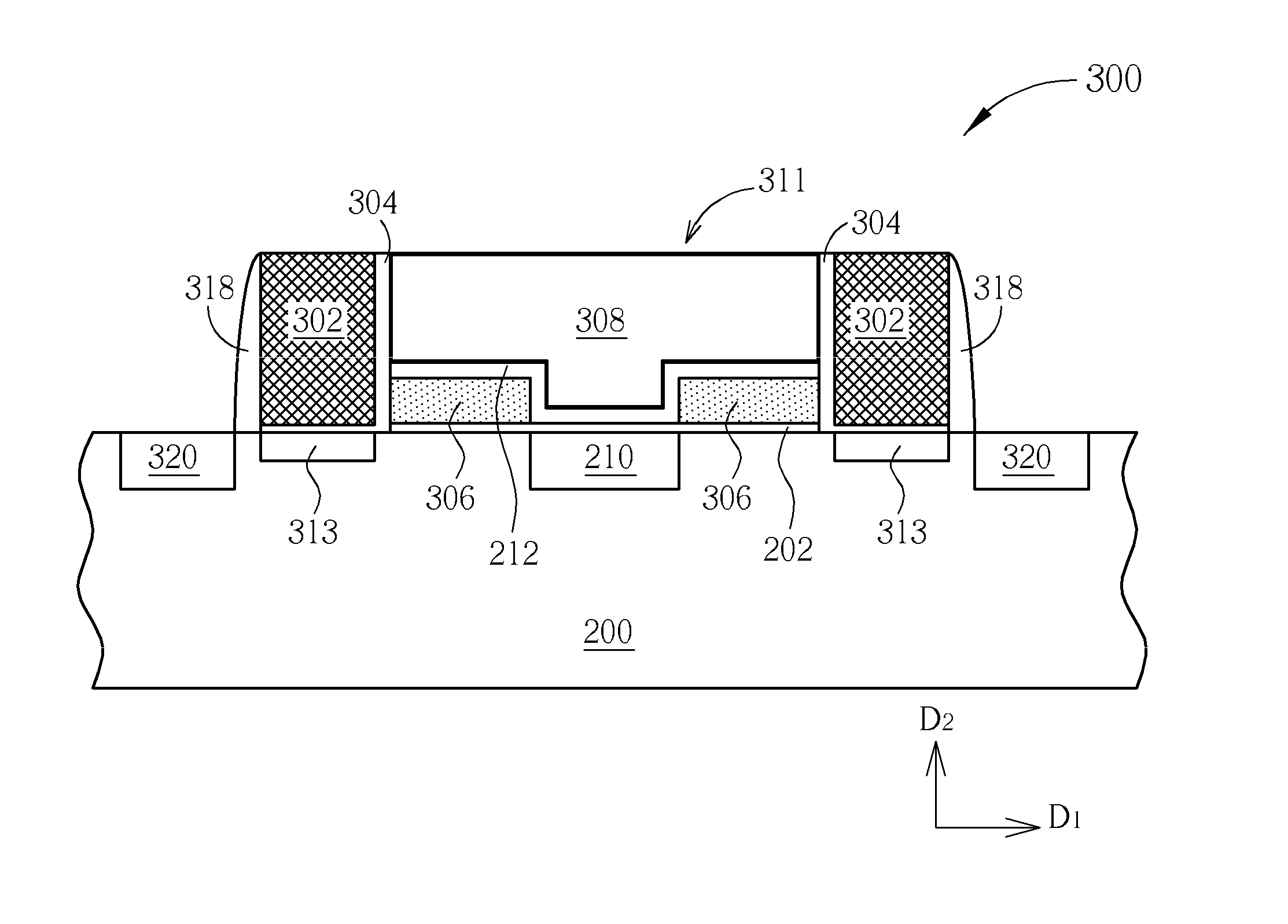

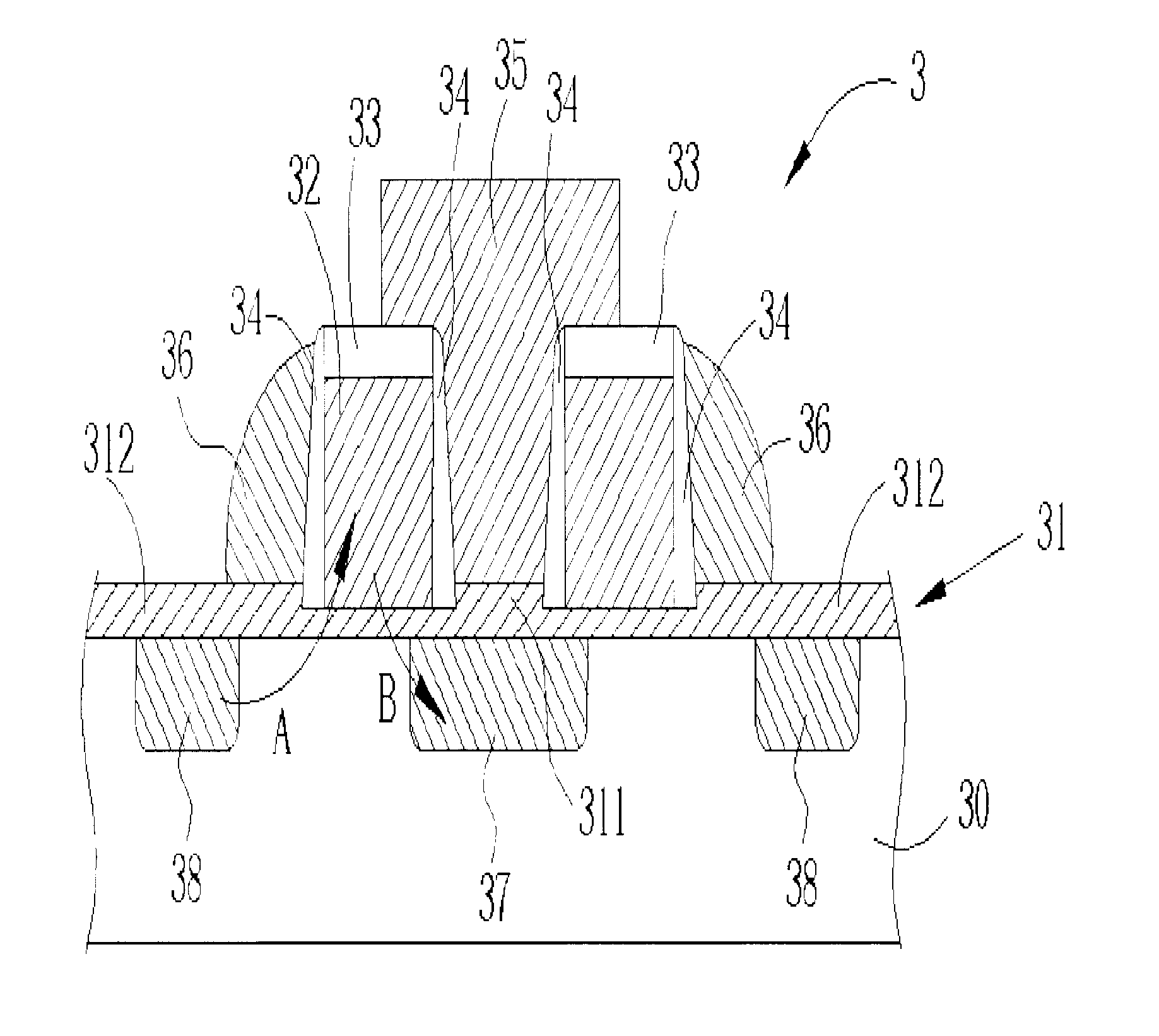

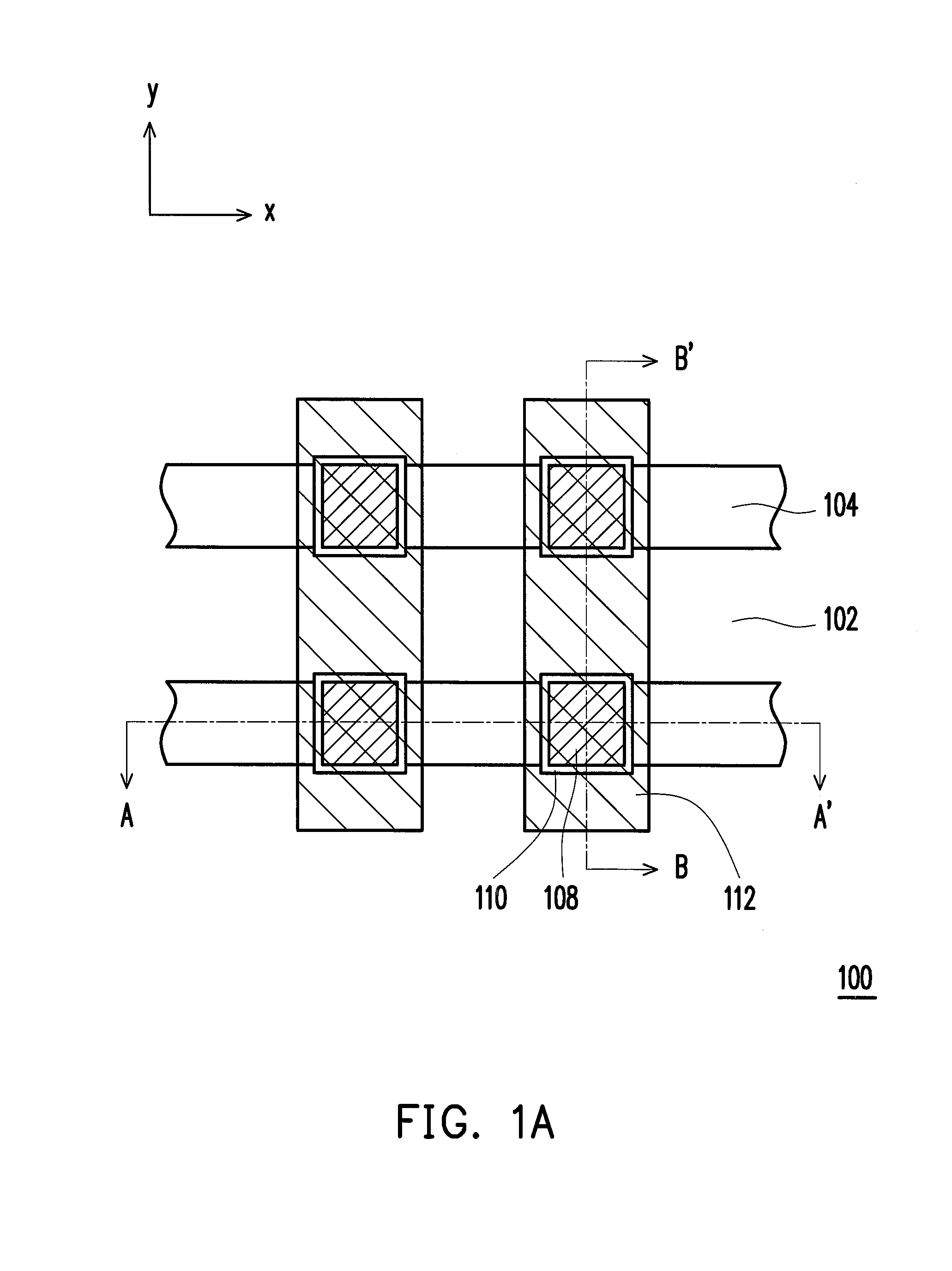

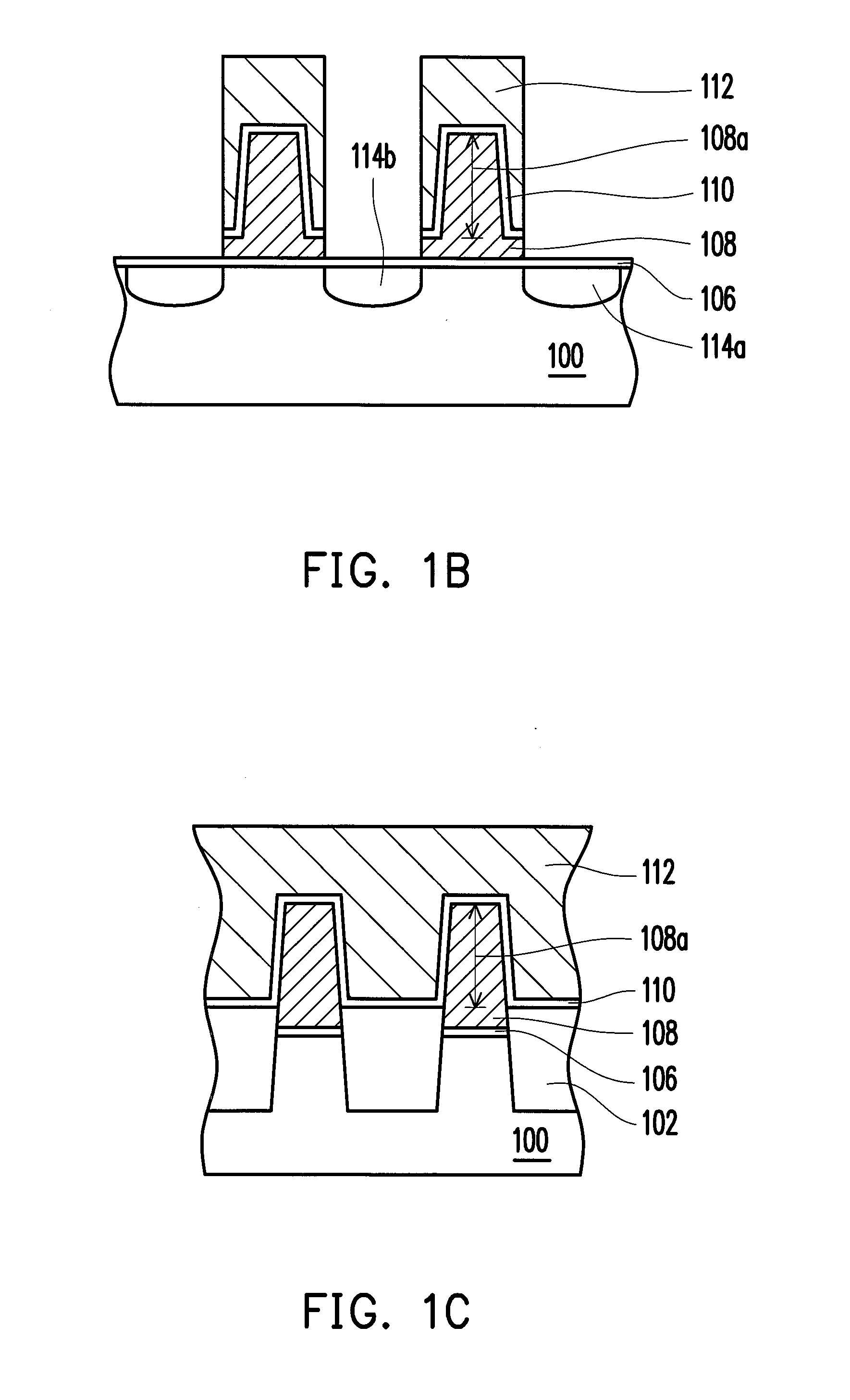

Semiconductor device and method of fabricating the same

ActiveUS20140015029A1Increase the overlapping areaStable capacitanceTransistorSemiconductor/solid-state device manufacturingEngineeringDielectric layer

A semiconductor device includes two floating gates, a control gate and a first dielectric layer. The floating gates are disposed on a semiconductor substrate. The control gate partially overlaps each of the floating gates, and a part of the control gate is disposed between the two floating gates. Furthermore, the first dielectric layer disposed between the two floating gates and the control gate has a fixed thickness.

Owner:UNITED MICROELECTRONICS CORP

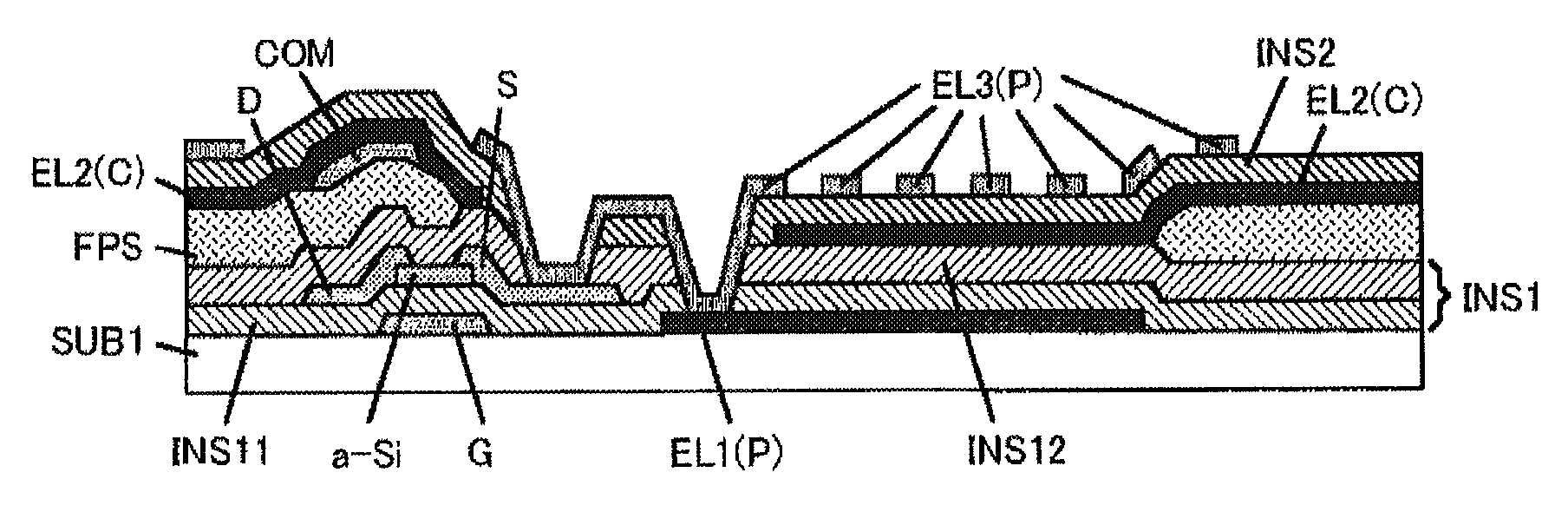

Liquid crystal display device having first, second, and third transparent electrodes that form first and second storage capacitors

ActiveUS8253873B2Reduce areaReduce capacitanceSolid-state devicesNon-linear opticsLiquid-crystal displayEngineering

To form a sufficiently large storage capacitor, a liquid crystal display device includes a liquid crystal display panel having a first substrate, a second substrate, and a liquid crystal held between the first substrate and the second substrate, the liquid crystal display panel having multiple pixels arranged in matrix. The first substrate has, in a transmissive display area provided in each of the pixels, a laminated structure containing a first transparent electrode, a first insulating film, a second transparent electrode, a second insulating film, and a third transparent electrode which are laminated in this order. The first transparent electrode and the second transparent electrode are electrically insulated from each other and together form a first storage capacitor through the first insulating film, and the second transparent electrode and the third transparent electrode are electrically insulated from each other and together form a second storage capacitor through the second insulating film.

Owner:JAPAN DISPLAY INC

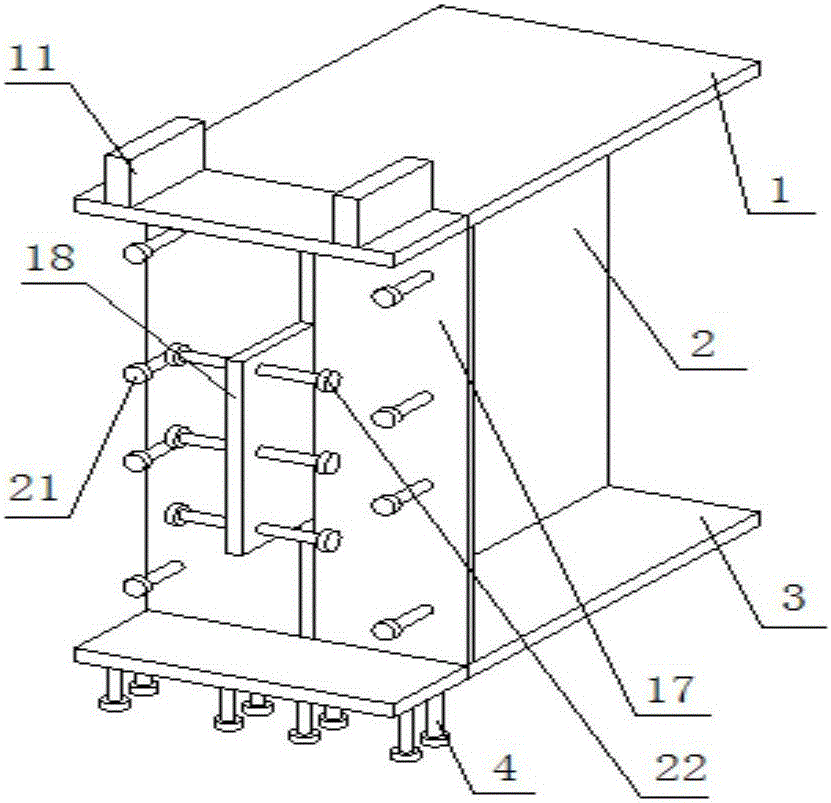

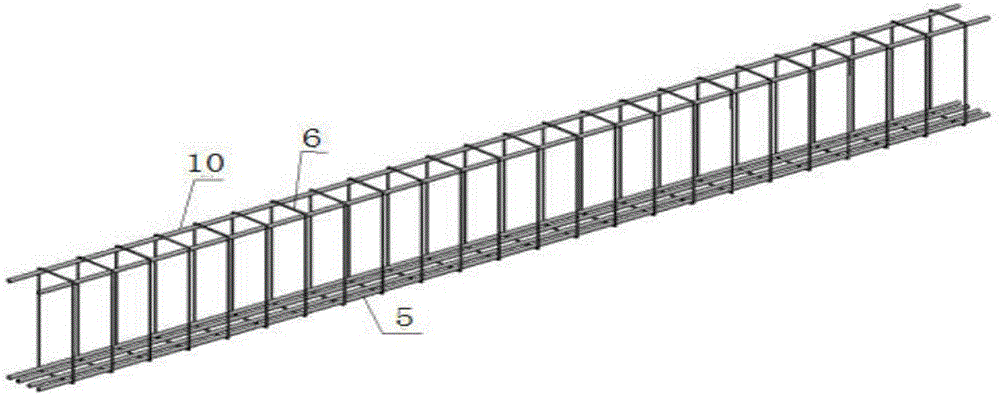

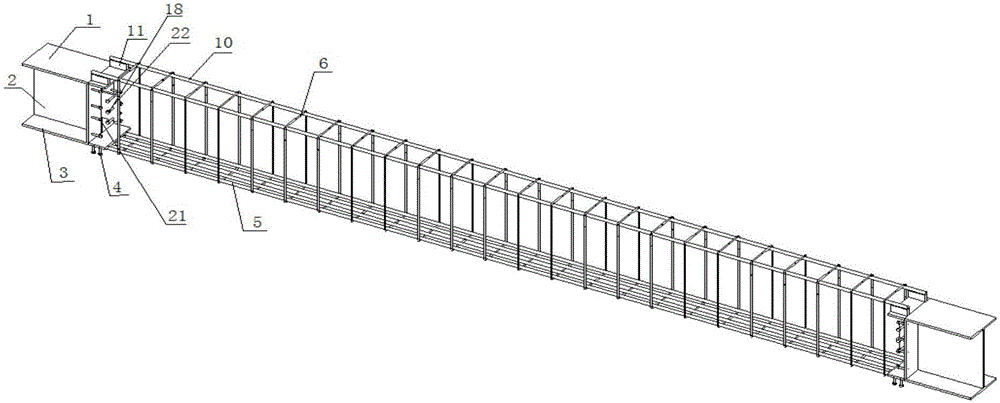

Manufacturing method of assembly type prefabricated superposed beam with steel structure connection joints

InactiveCN106320607ASolve the complex connectionFirmly connectedLoad-supporting elementsCeramic shaping apparatusAbsorbed energyBeam column

The invention discloses a manufacturing method of an assembly type prefabricated superposed beam with steel structure connection joints. The manufacturing method comprises the following steps that first, main structures, located under the top face of a concrete part, of a superposed beam reinforcement cage and the steel structure connection joints are manufactured; second, the main structures of the steel structure connection joints are connected to the ends of the superposed beam reinforcement cage; third. A formwork is erected, then concrete is poured, and the concrete part of the prefabricated superposed beam is formed; fourth, the formwork is disassembled, and then the parts, protruding the top face of the concrete part, of the steel structure connection joints are welded on the top face of the main structures of the steel structure connection joints. The prefabricated superposed beam manufactured by the method enables the structure of beam column connection joints to be simple, and construction is convenient. According to the prefabricated superposed beam, under the loading effect, the steel structure connection joints can deform and absorb energy first, has good ductility under the earthquake load effect, and is suitable for being applied and popularized to a construction site.

Owner:TIANJIN UNIV RES INST OF ARCHITECTRUAL DESIGN & URBAN PLANNING +1

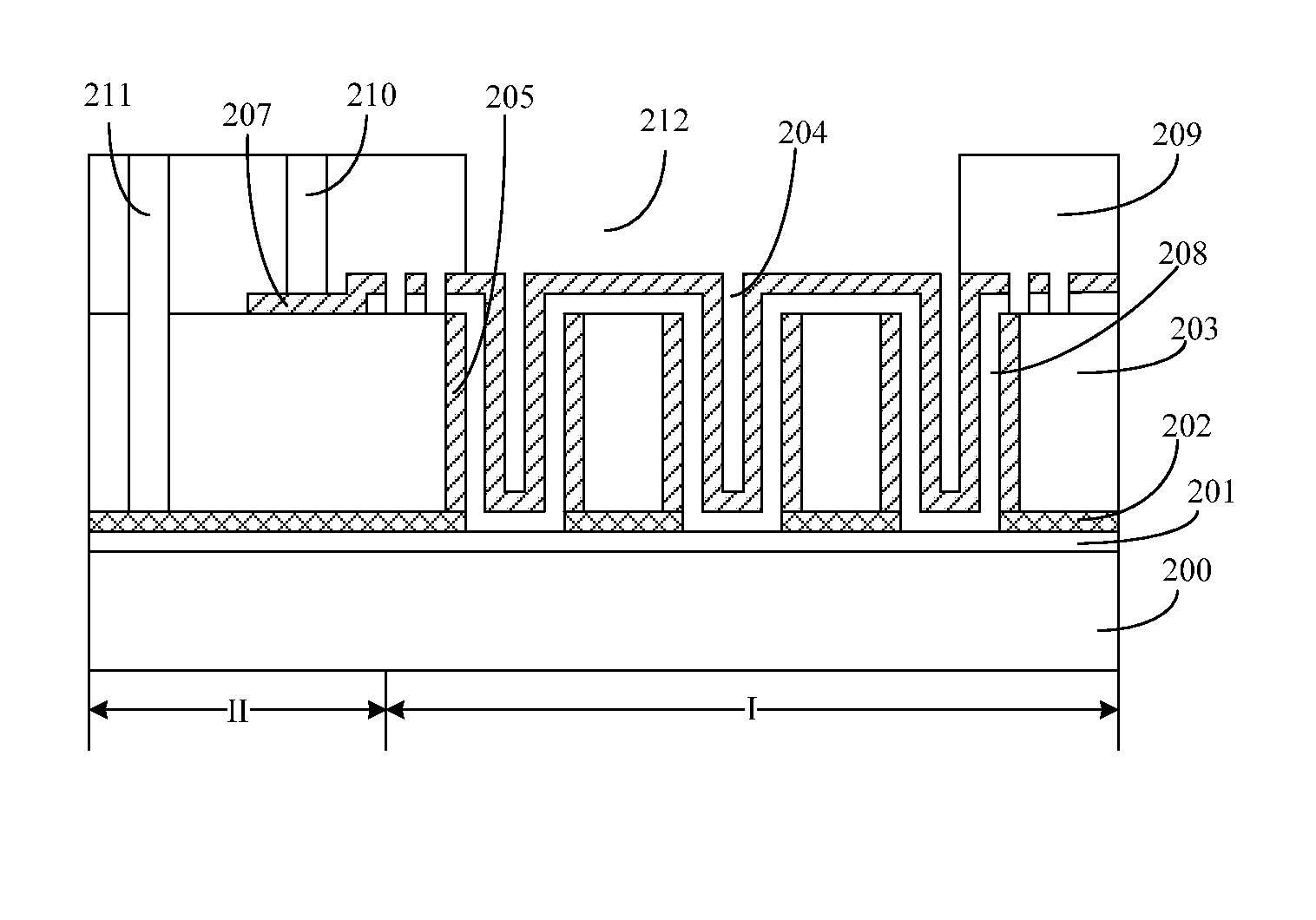

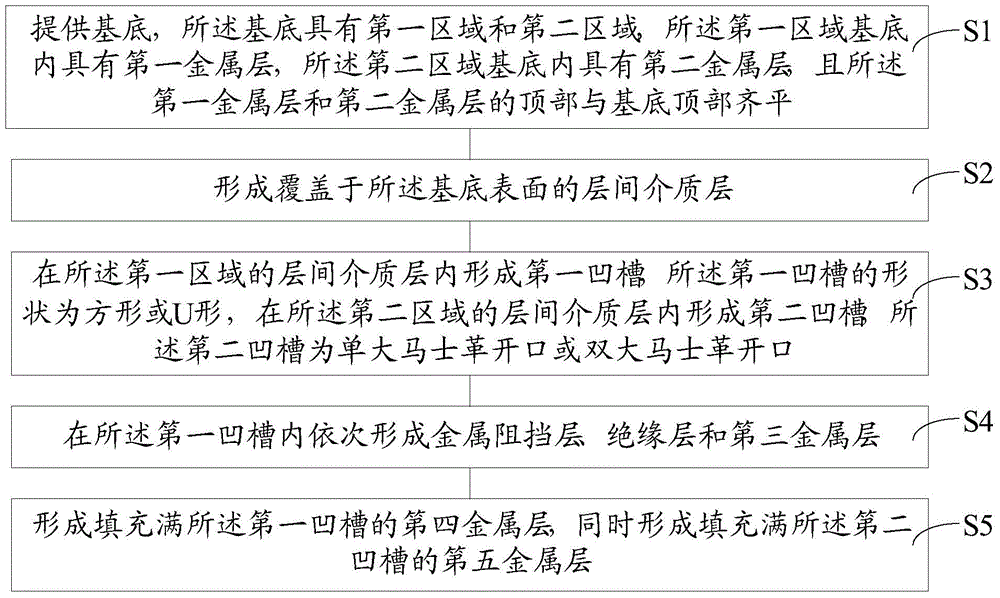

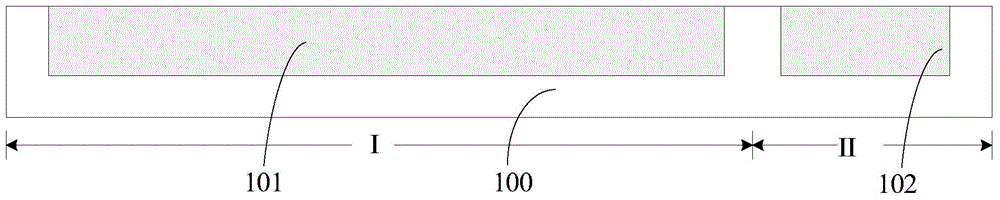

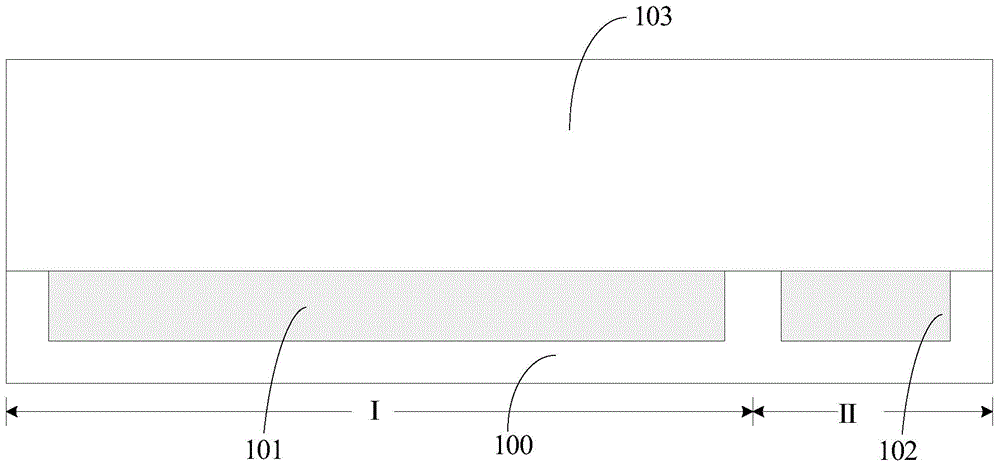

Semiconductor and forming method thereof

InactiveCN104681403AIncrease productivityShorten the production cycleSemiconductor/solid-state device detailsSolid-state devicesCapacitanceInsulation layer

The invention provides a semiconductor and a forming method thereof, wherein the forming method of the semiconductor device comprises the following steps that a semiconductor substrate is provided, and a first interlayer dielectric layer is formed on the surface of the semiconductor substrate; a second interlayer dielectric layer is formed on the surface of the first interlayer dielectric layer; meanwhile, second interlayer dielectric layers in a first region and a second region are etched, a first groove is formed in the second interlayer dielectric layer formed in the first region, a second groove is formed in the second interlayer dielectric layer formed in the second region, in addition, the first groove comprises a first trench and a plurality of first through holes positioned at the bottom of the first trench, and a bulge is formed between the adjacent through holes; a metal blocking layer, an insulation layer and a third metal layer are sequentially formed in the first region, the metal blocking layer covers the bottom and the side wall of the first groove, and the metal blocking layer also covers the side wall and the top of the bulges. The semiconductor method and the forming method have the advantages that the mutual connection structure is formed, meanwhile, an MIM capacitor is formed, the unit area capacitance is increased, and the chip area is saved.

Owner:SEMICON MFG INT (SHANGHAI) CORP

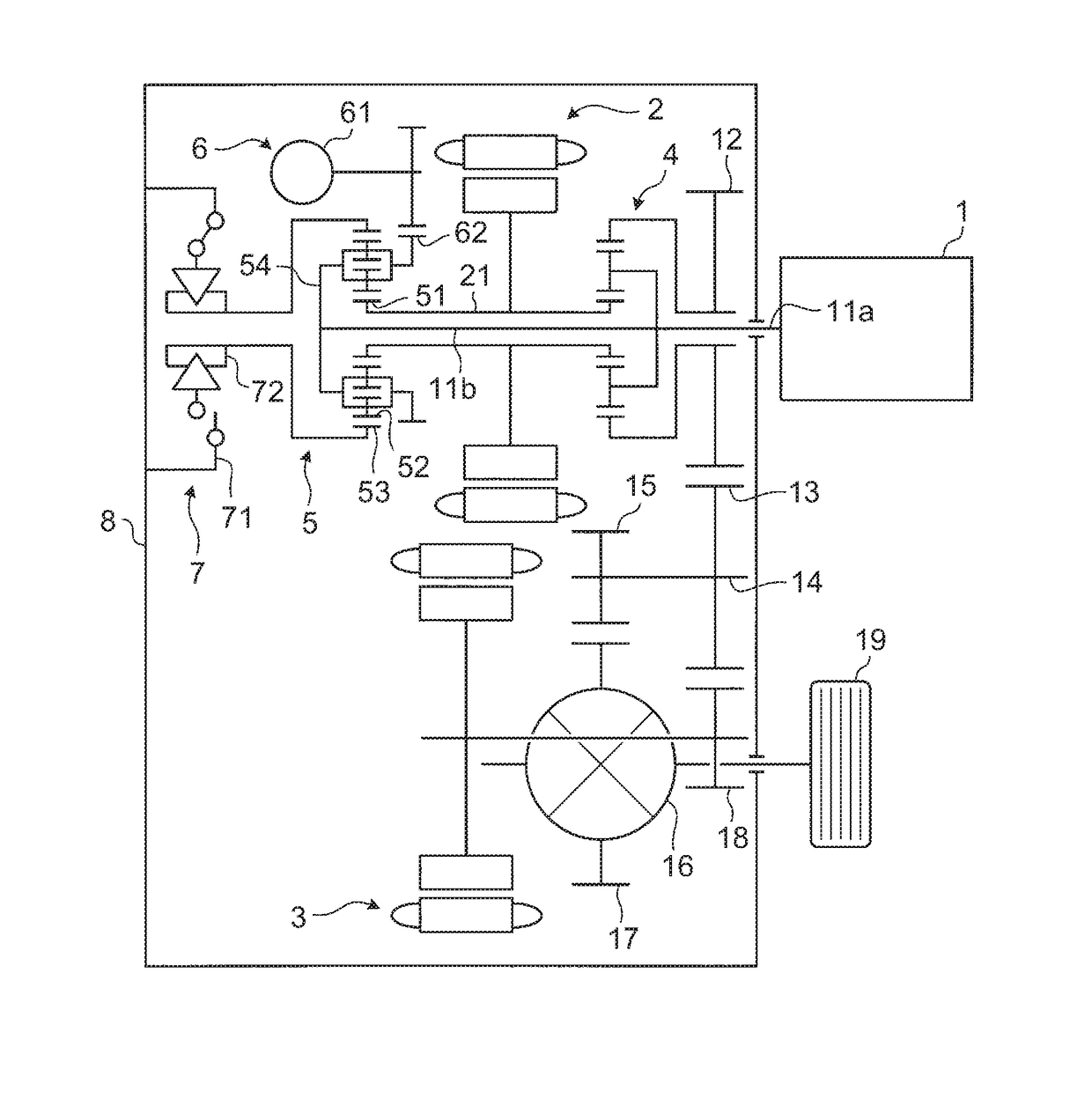

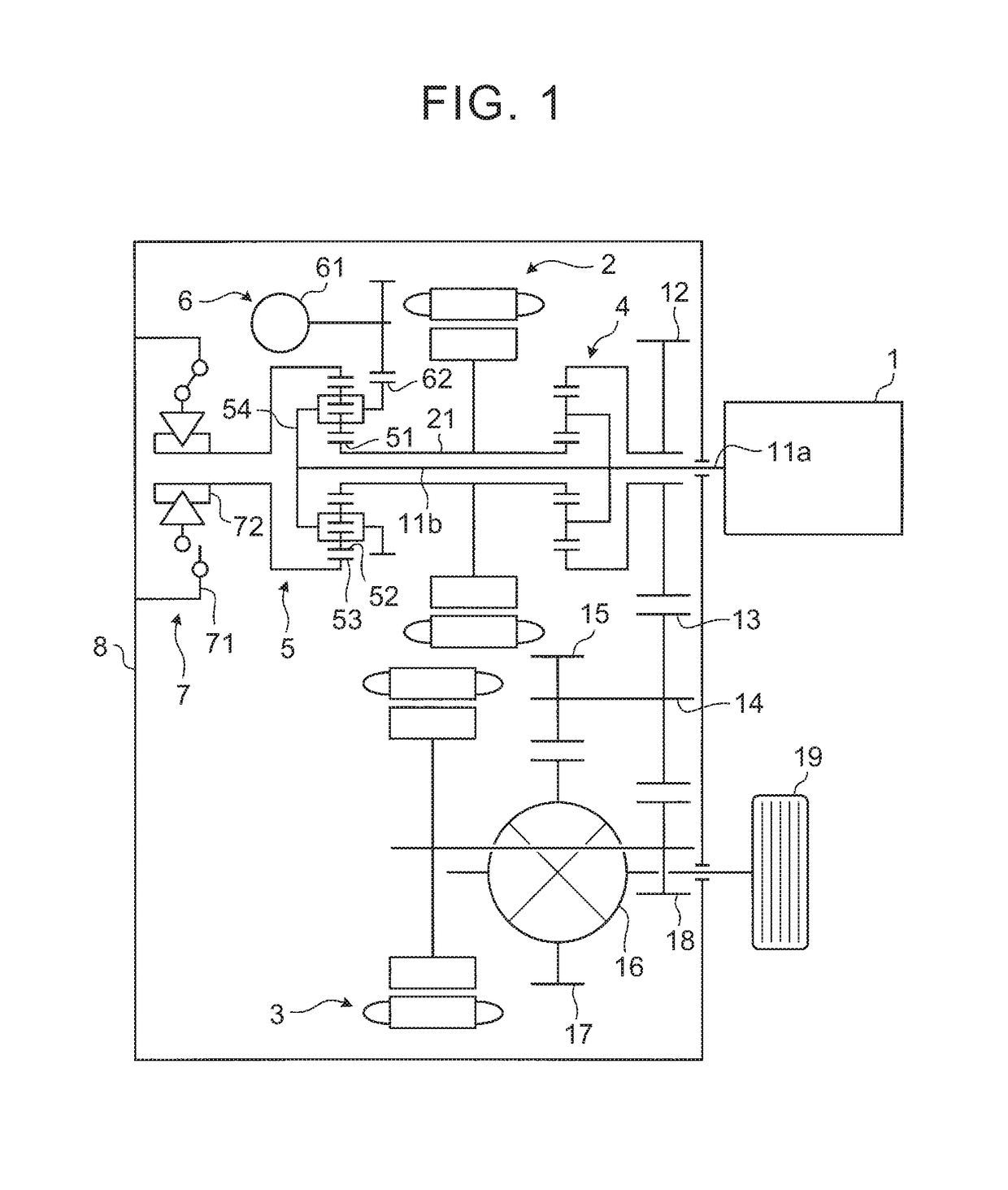

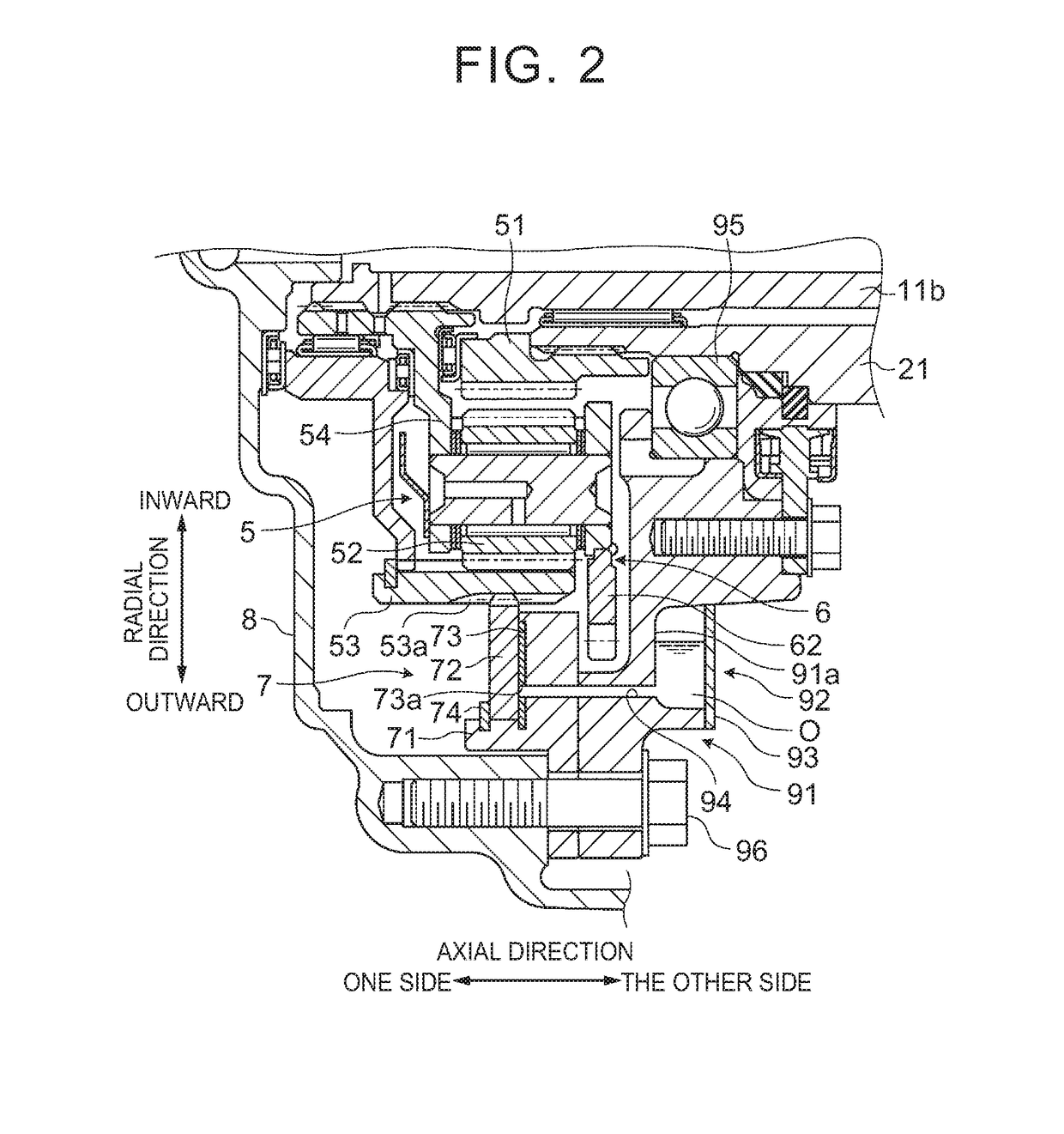

Power transmission apparatus

ActiveUS20170066317A1Increase the overlapping areaSmall rangeHybrid vehiclesGear lubrication/coolingEngineeringClutch

A power transmission apparatus includes: an input shaft; a selectable one-way clutch; a housing case; a center support; a lubricating oil reservoir; and an oil passage. The oil passage extends through a pocket plate disposed between the lubricating oil reservoir and a selector plate. The selector plate includes a through-hole. The through-hole is located at a position where the through-hole is not lined up with the opening of the oil passage in a radial direction and a circumferential direction of the selector plate in a non-engagement state of the selectable one-way clutch, and also at a position where the through-hole is lined up with the opening of the oil passage in the radial direction and the circumferential direction of the selector plate in an engagement state of the selectable one-way clutch.

Owner:TOYOTA JIDOSHA KK +1

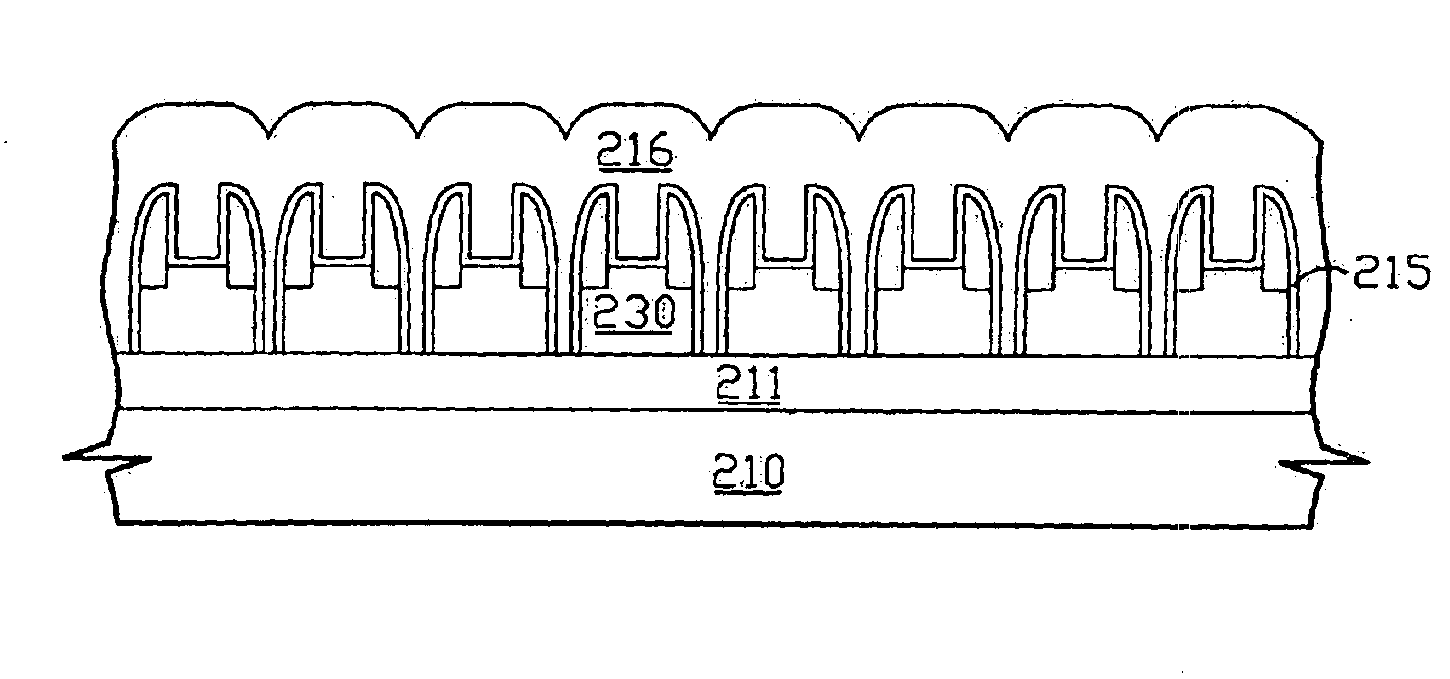

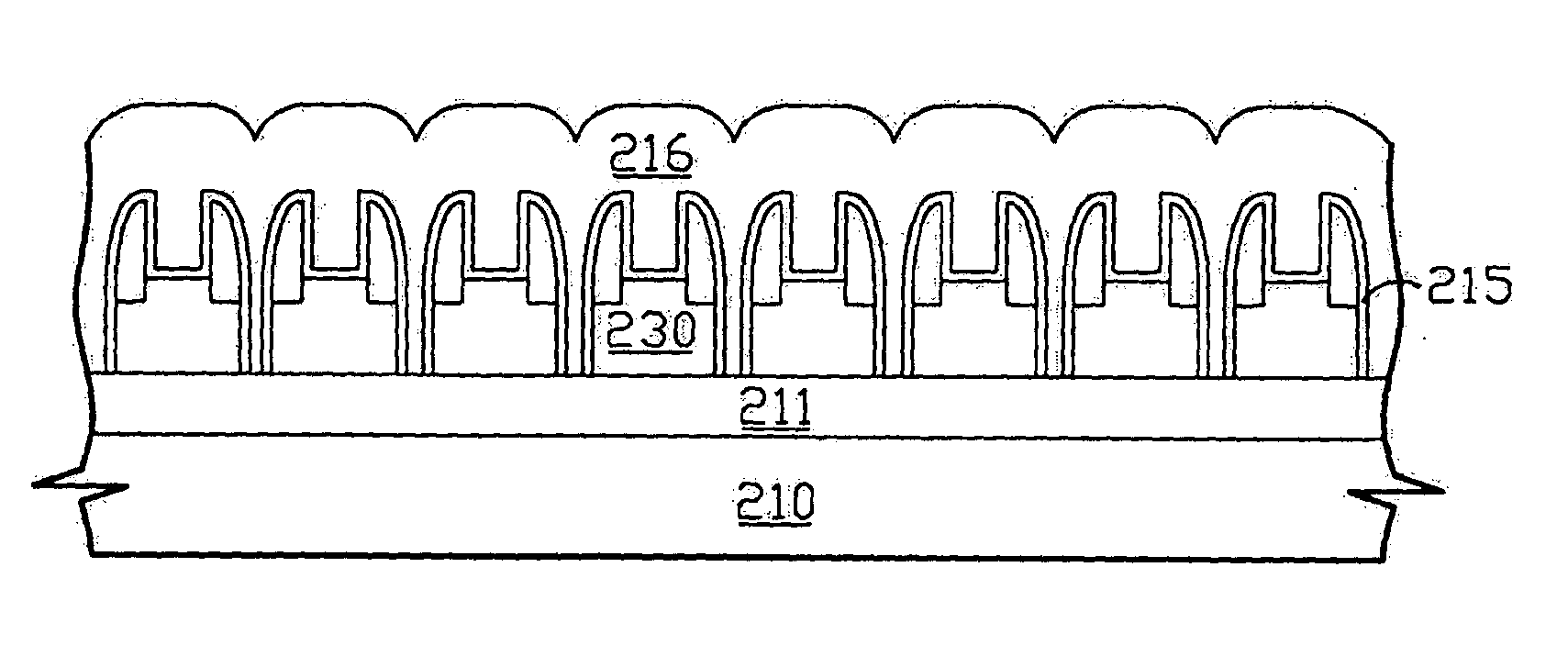

Step-shaped floating poly-si gate to improve a gate coupling ratio for flash memory application

InactiveUS6838725B2Increase the overlapping areaAccelerated programTransistorSemiconductor/solid-state device manufacturingDielectricCoupling ratio

A stacked-gate flash memory cell is provided having step-shaped poly-gates with increased overlap area between them in order to increase the coupling ratio and hence the program speed of the cell. The floating gate is first formed with a step and the intergate dielectric is conformally shaped thereon followed by the forming of the control gate thereon. The increase in the-overlap area can be achieved by forming gates with multiply connected surfaces of different shapes.

Owner:TAIWAN SEMICON MFG CO LTD

Method and structure to improve the gate coupling ratio (GCR) for manufacturing a flash memory device

InactiveUS20050056879A1Increase the overlapping areaImprove gate coupling ratioSolid-state devicesSemiconductor/solid-state device manufacturingElectrical conductorCoupling ratio

Method and structure to improve the gate coupling ratio (GCR) for manufacturing a flash memory device are provided. The method and structure include the following steps. A gate oxide layer, a first semiconductor layer, and an insulating layer are formed sequentially over a provided semiconductor substrate. An etching process is used to etch the insulating layer. A semiconductor spacer is then deposited and used as a self-aligned etching mask. After the self-aligned etching, the insulating layer is removed and an insulating stacked structure is deposited. Finally, a second semiconductor layer is deposited and etched to form the control gate region.

Owner:UNITED MICROELECTRONICS CORP

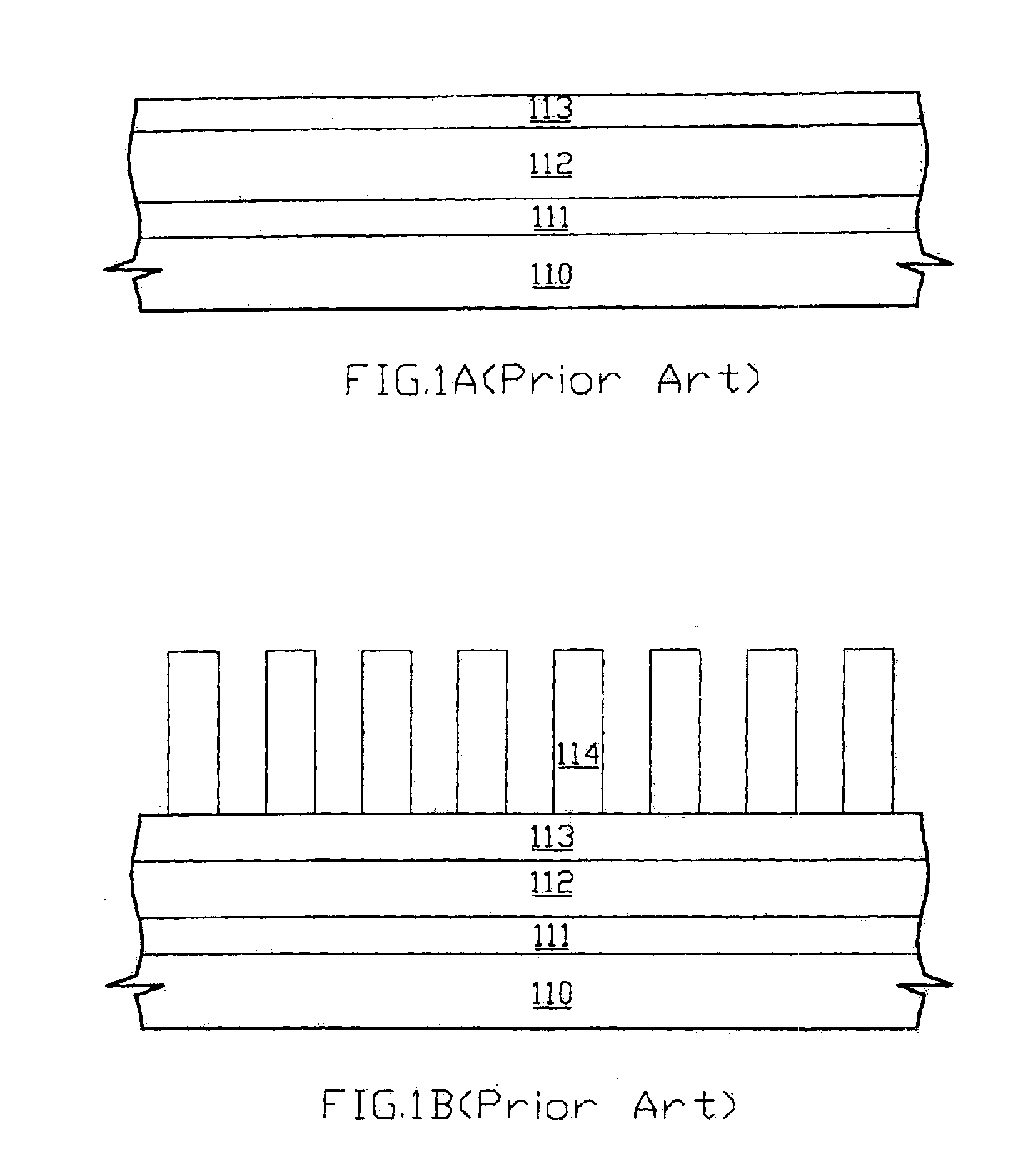

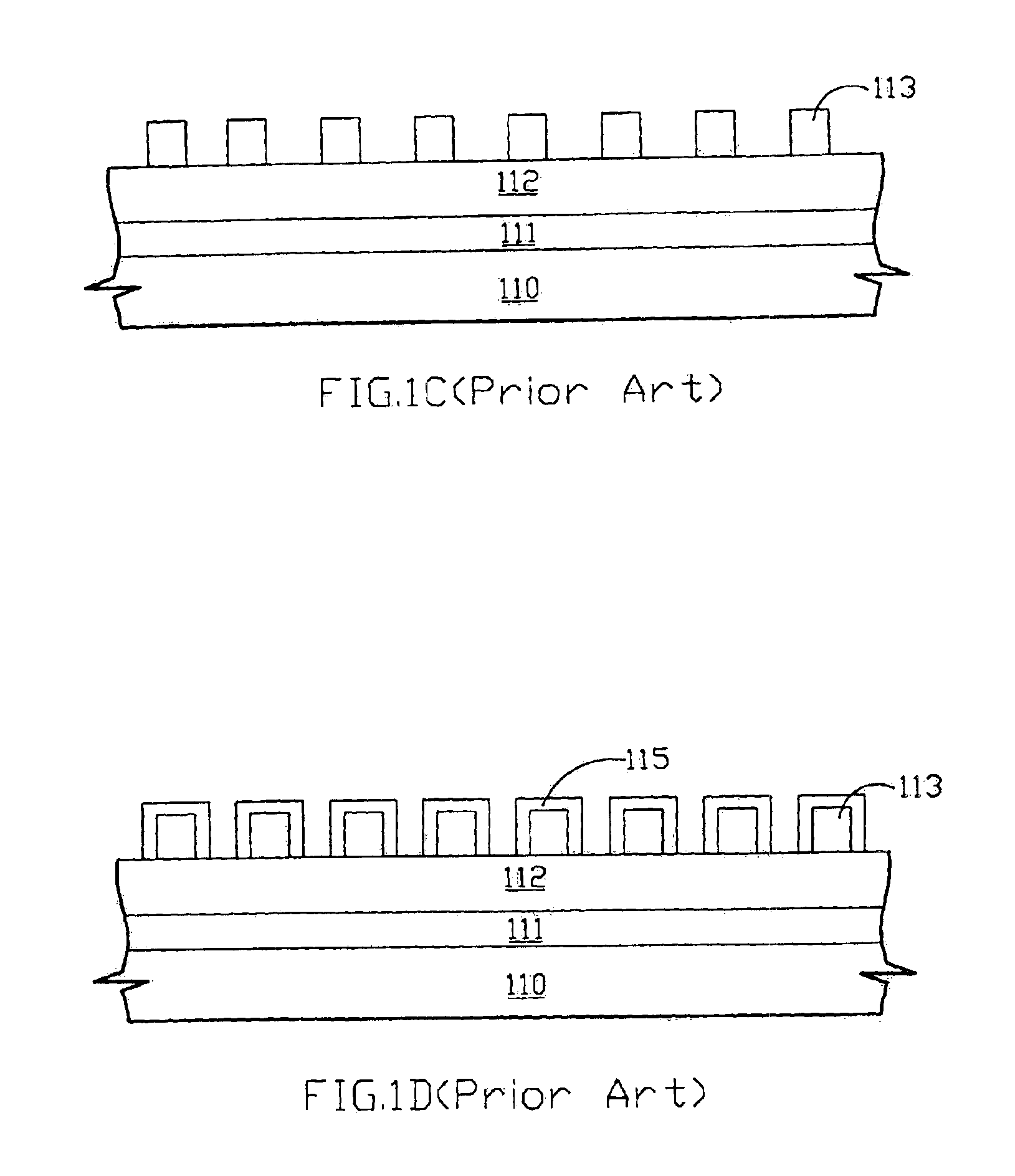

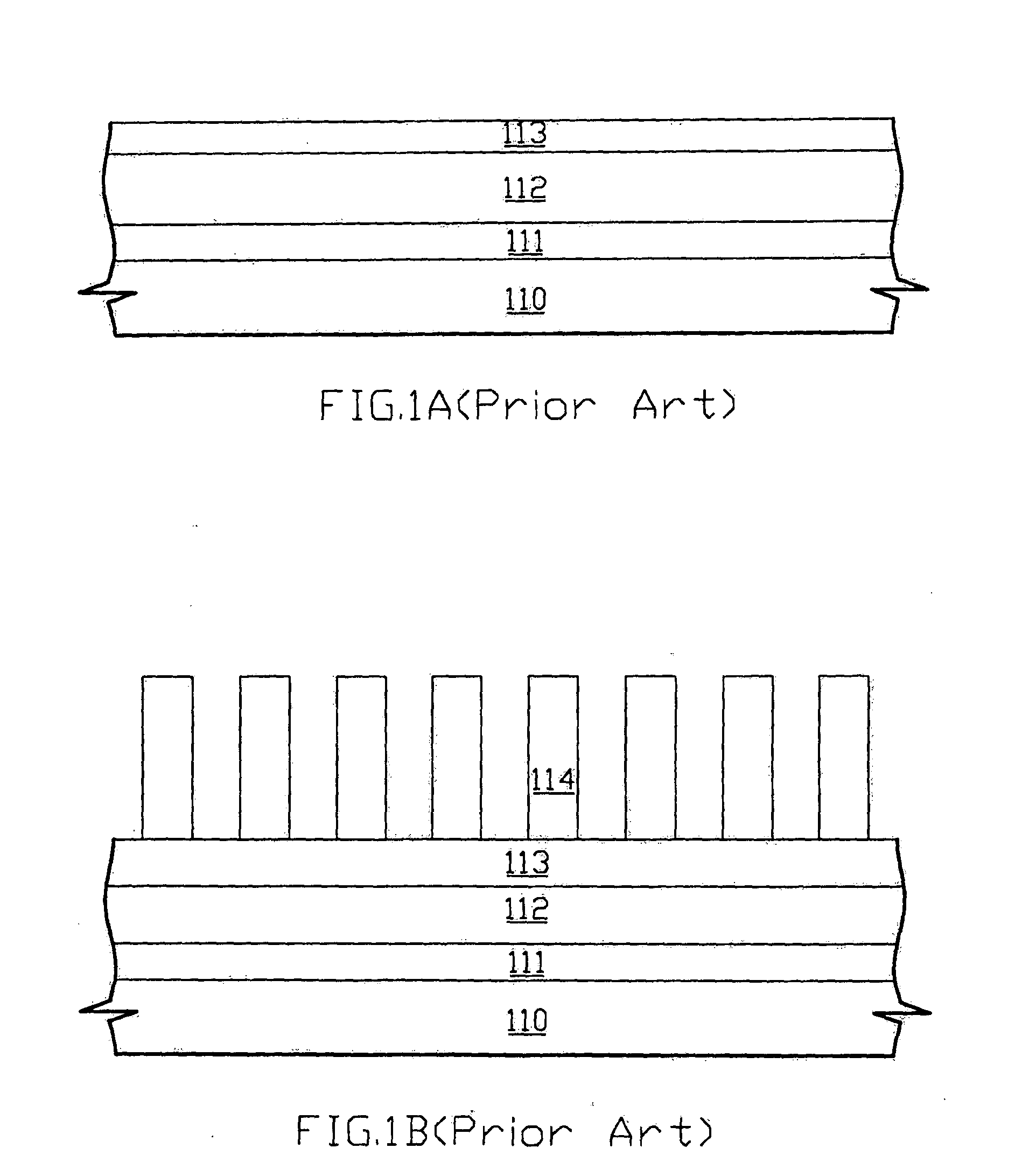

Manufacturing method of flash memory

InactiveCN1571146ALower the altitudeIncrease the overlapping areaSemiconductor/solid-state device manufacturingElectrical conductorEngineering

The invention is a flash memory manufacturing method, in turn forming tunneled dielectric layer, conductor layer and mask layer on a substrate, then patternizing the conductor layer and the mask layer, forming vertically-arranged sticks on the substrate, then forming a buried drain region in the substrate between two adjacent sticks, successively patternizing the sticks, and forming floating grid structure on the substrate, then forming insulating layer around the floating grid structure, where the surface of the insulating layer is lower than the top surface of the patternized conductor layer in the floating grid structure to expose partial surface of side wall around the patternized conductor layer, successively removing the mask layer, forming grid-grid dielectric layer on the conductor layer and then forming control grid on the grid-grid dielectric layer.

Owner:MACRONIX INT CO LTD

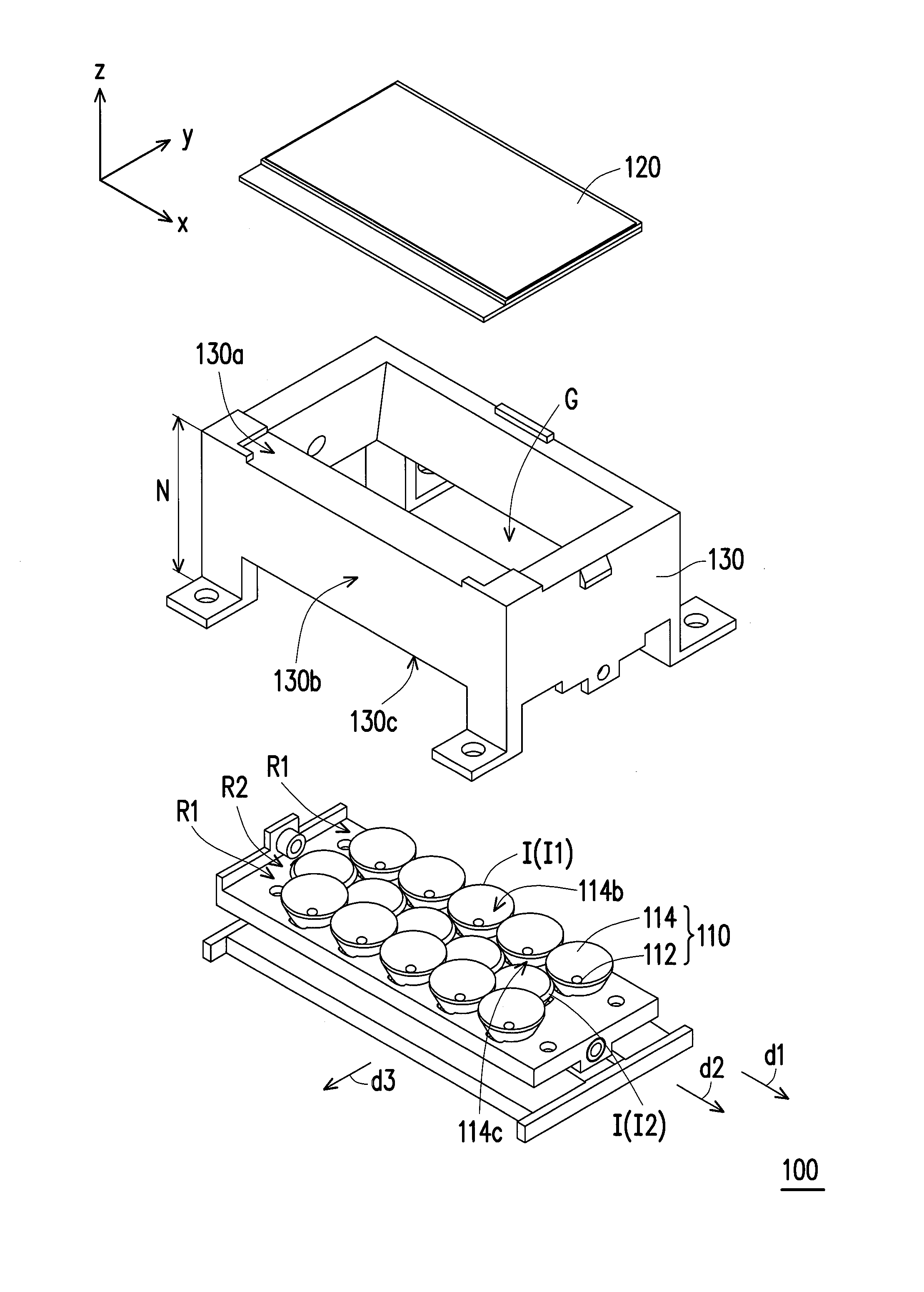

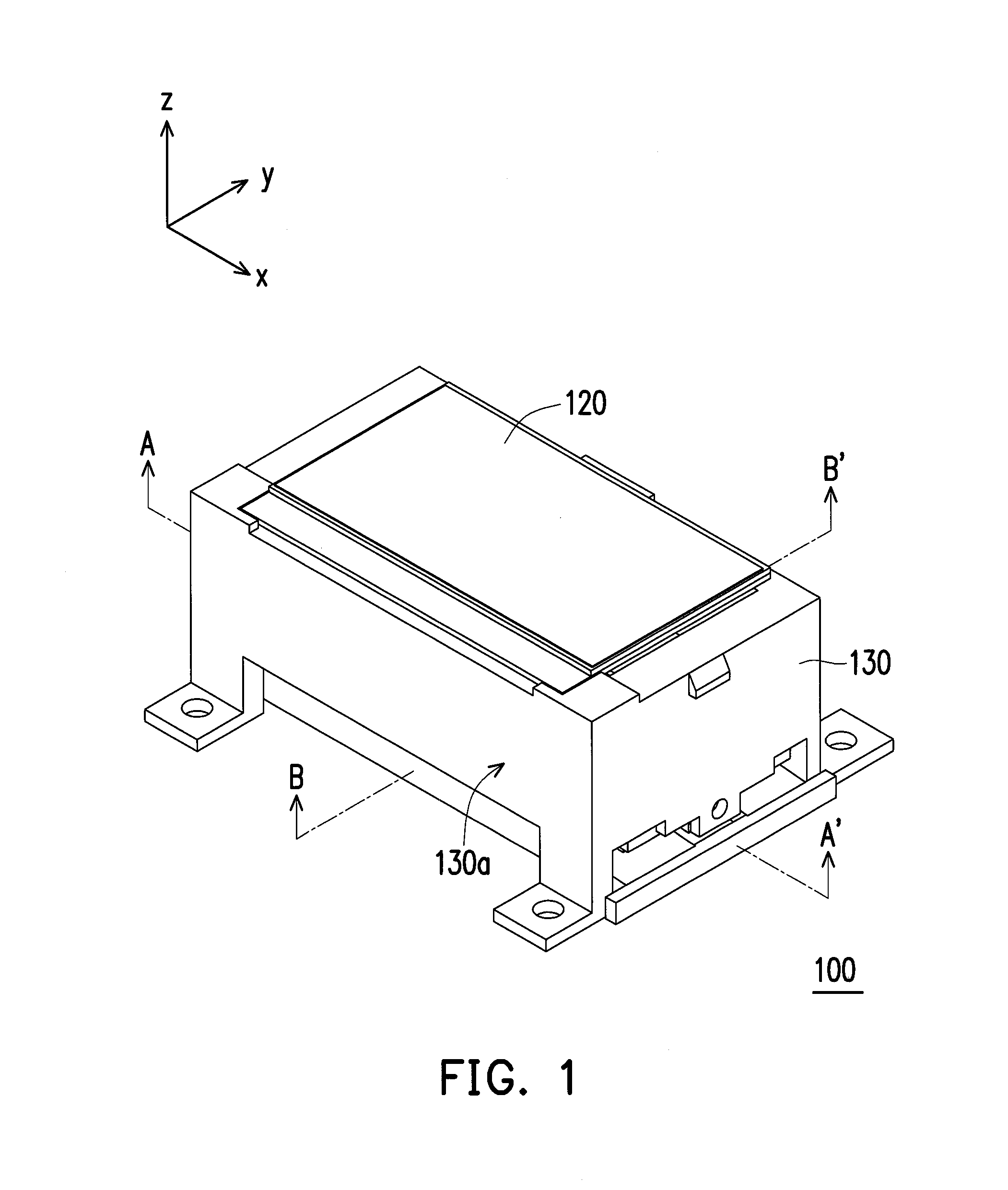

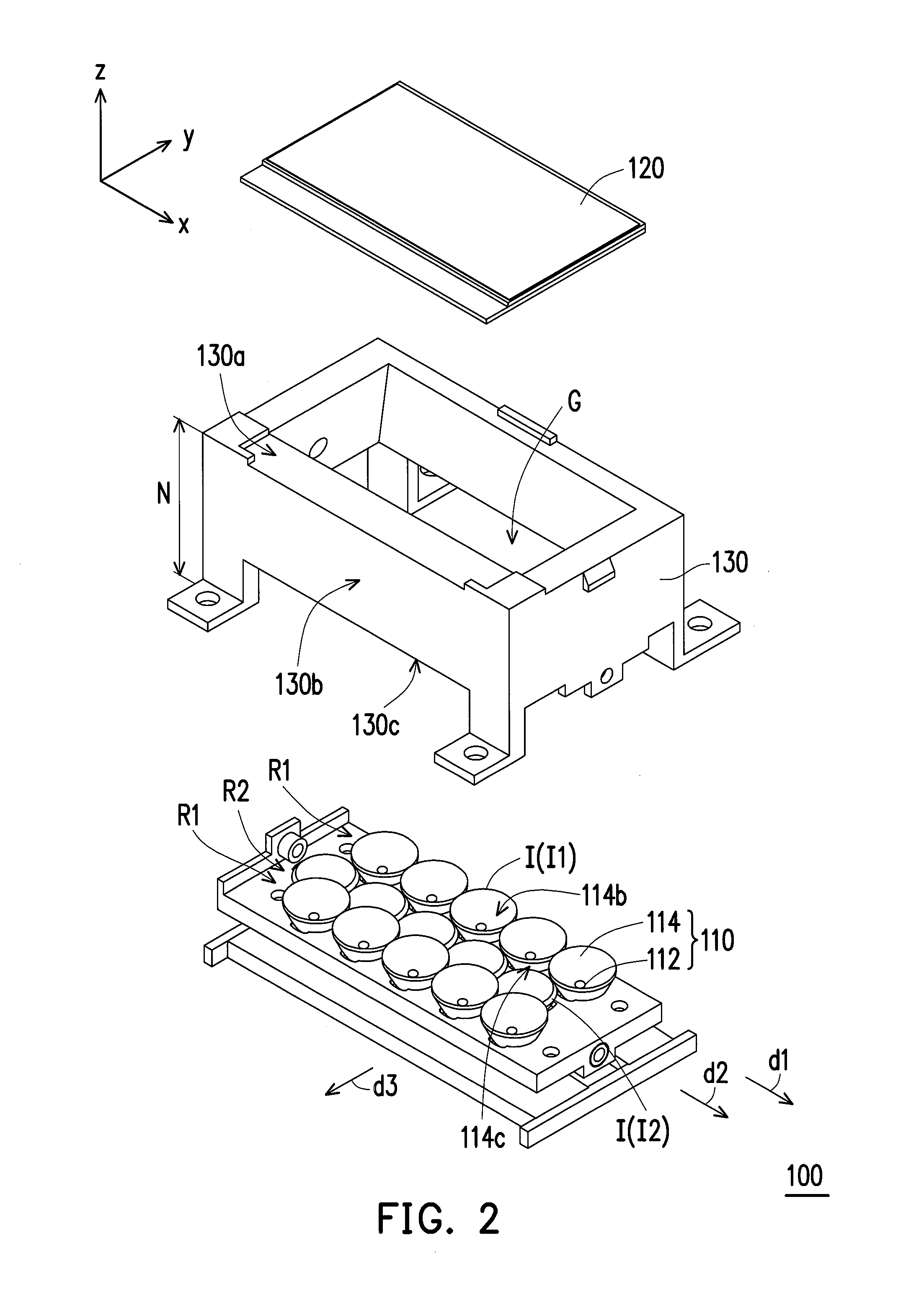

Display module and head up display

ActiveUS20150168717A1Improve the display effectIncrease the overlapping areaOptical elementsHead-up displayOptoelectronics

A display module including light emitting units and a display panel is provided. Each of the light emitting units includes a light source and a light converging element. The light emitting units are divided into at least one first light emitting unit row and a second light emitting unit row adjacent to the first light emitting unit row. Top surfaces of the light converging elements of the first light emitting unit row are disposed on a first surface. Top surfaces of the light converging elements of the second light emitting unit row are disposed on a second surface. The first surface is located between the display panel and the second surface. Moreover, a head up display including the display module is also provided.

Owner:AU OPTRONICS CORP

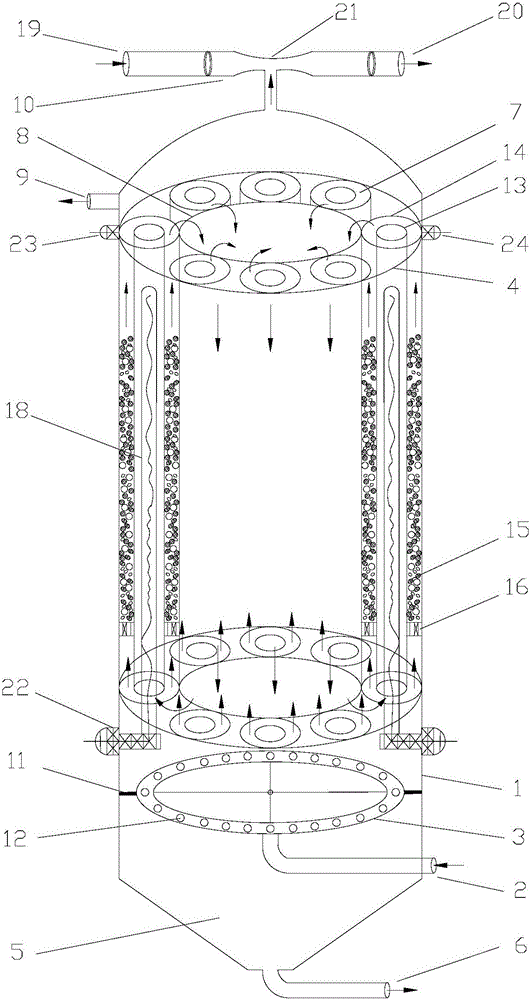

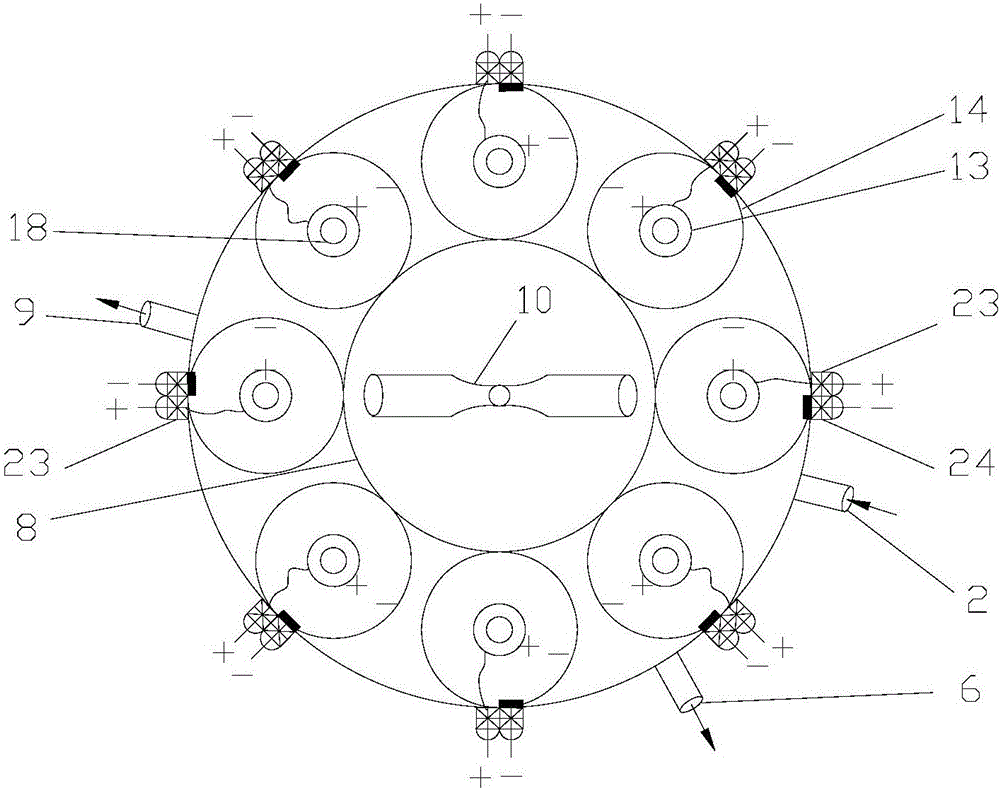

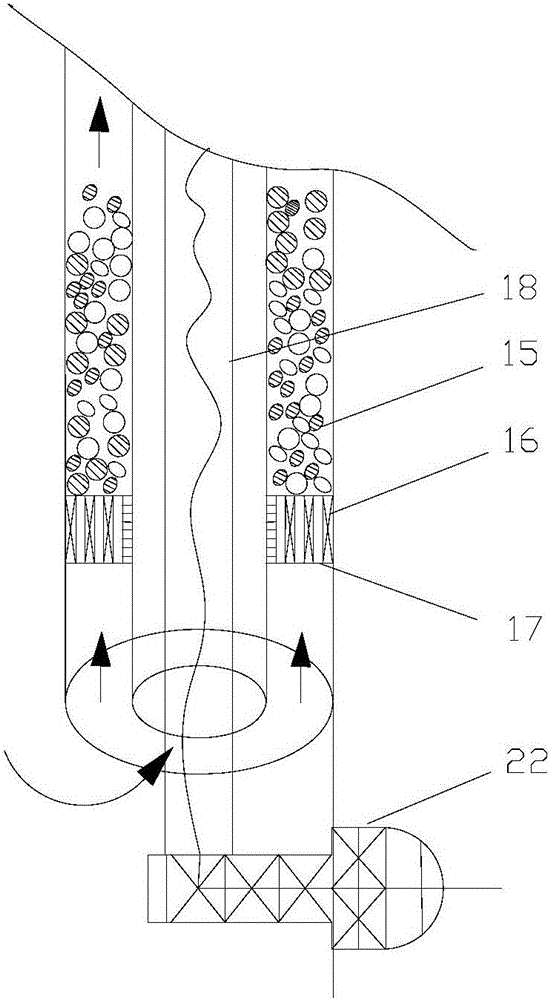

Internal recycle photoelectron-catalytic oxidation combined treatment device

ActiveCN105967313AAcid resistantCorrosiveWater/sewage treatment by irradiationWater treatment compoundsCatalytic oxidationWastewater

The invention discloses an internal recycle photoelectron-catalytic oxidation combined treatment device. According to the treatment device, a water inlet (2) is formed in the bottom of a treatment device cylinder (1) and is communicated with a circular water distributor (3); wastewater is uniformly distributed to the bottom of the device through the circular water distributor (3); a photoelectron-catalytic oxidation combined treatment system (4) is arranged above the circular water distributor (3); a sediment mud bucket (5) is arranged under the circular water distributor (3) and is communicated with a mud discharge hole (6); under the condition that a direct-current power supply is loaded to the photoelectron-catalytic oxidation combined treatment system (4), the wastewater is lifted to the top of the device from the bottom of a photoelectron-catalytic oxidation unit (7); part of the wastewater is discharged out from a water outlet (9) in the upper part of the device; another part of the wastewater is further circulated to the bottom of the photoelectron-catalytic oxidation unit (7) through a central partitioning cylinder (8) and is mixed with water, then circulation of the wastewater inside the photoelectron-catalytic oxidation combined treatment system (4) is achieved, mud dregs generated from reaction can be discharged out from the mud discharge hole (6) at regular time, and generated tail gases can be discharged out from a top tail gas treater (10).

Owner:CHINA NAT OFFSHORE OIL CORP +2

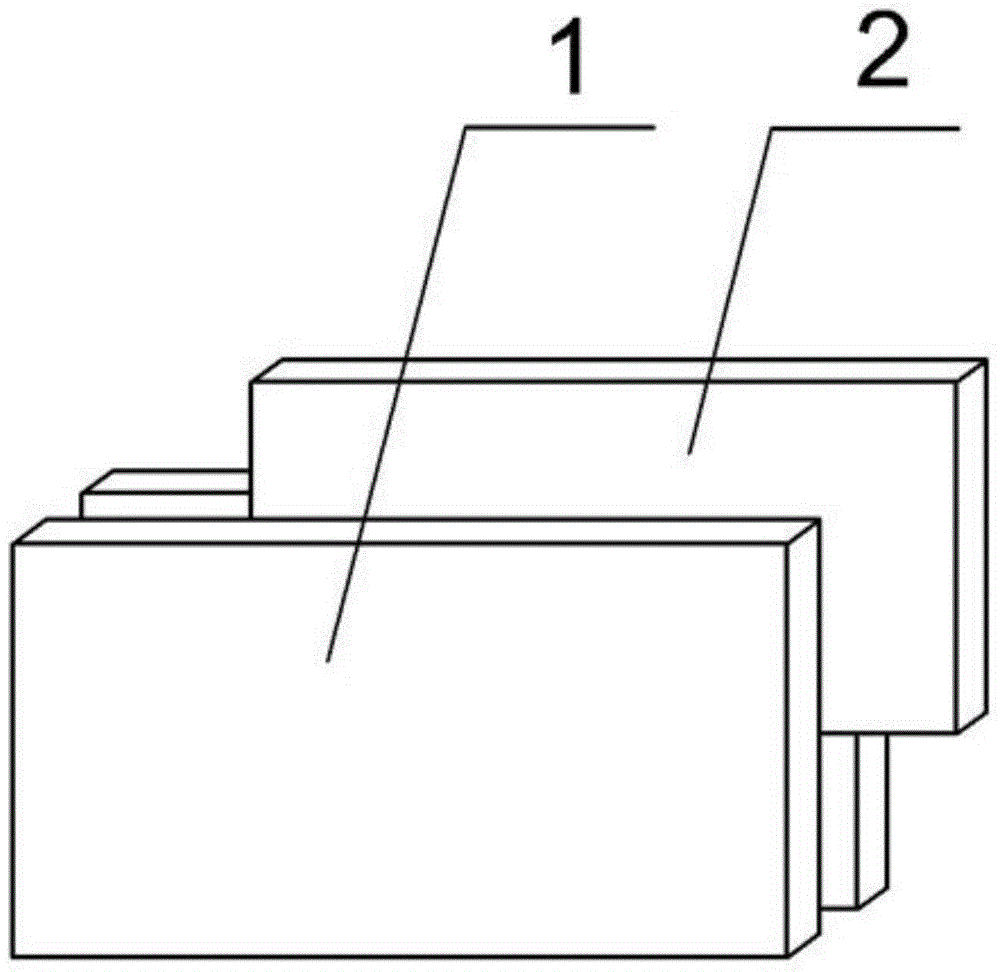

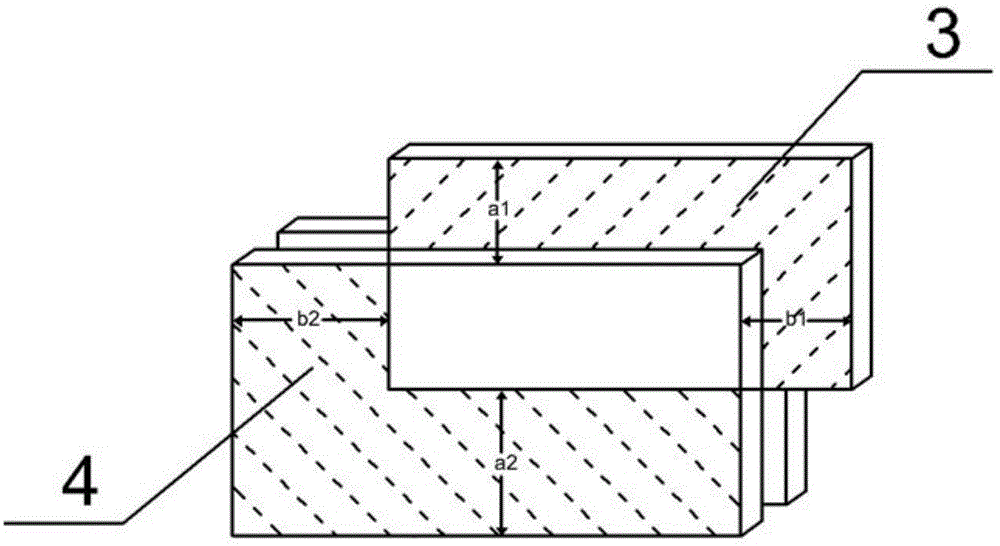

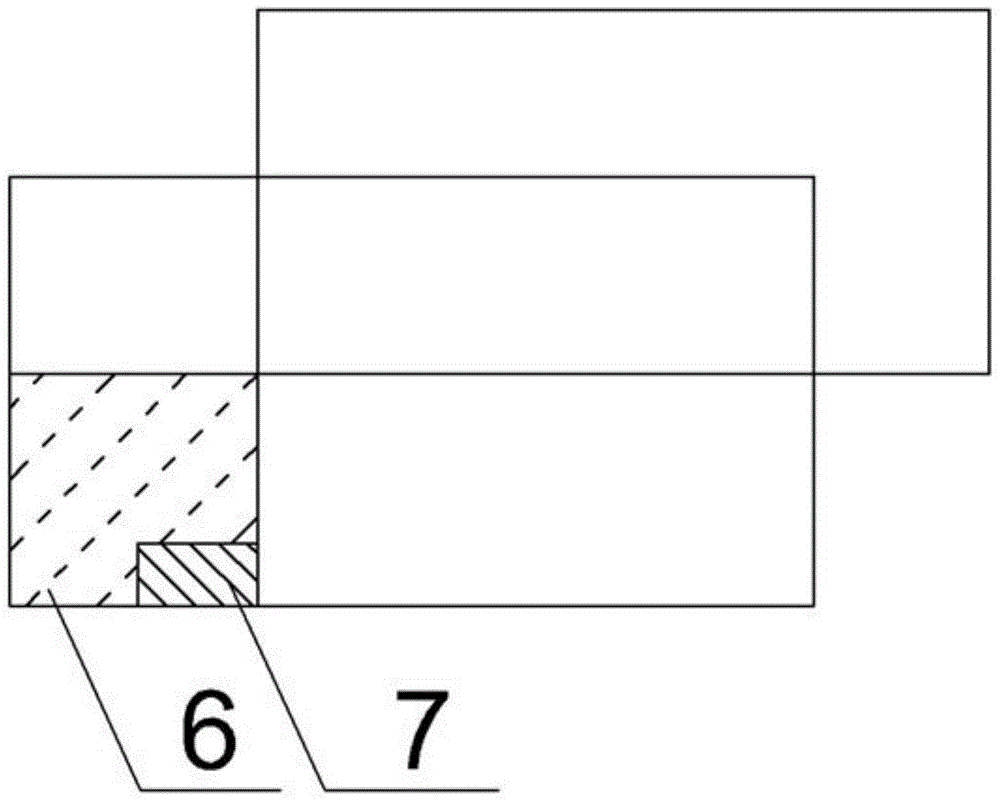

Tenon-and-mortise structure mortarless prefabrication assembled wall body building block

The invention discloses a tenon-and-mortise structure mortarless prefabrication assembled wall body building block, which is integrally formed by a pair of first cuboid sub building blocks in opposite arrangement and second cuboid sub building blocks clamped between the first sub building blocks in a staggered way, wherein parts, not in contact with the first sub building blocks, of the second sub building blocks form L-shaped tenons; and the parts, in contact with the second sub building blocks, of the first sub building blocks form L-shaped mortises. The wall body building block provided by the invention can be fast dismounted and mounted, can be cyclically used, and has the advantages that the structure is simple; a wall body is firm; the efficacy is high; and the cost is low, and the like. The goal of fast building the wall surface in indoor and outdoor positions can be achieved. Compared with a conventional technical product, the tenon-and-mortise structure mortarless prefabrication assembled wall body building block has the advantages that 90 percent of work hours can be saved; 70 percent of cost can be reduced; the mounting and the dismounting are very convenient and fast; the tenon-and-mortise structure mortarless prefabrication assembled wall body building block can be repeatedly used for many times; construction waste is not generated during dismounting or mounting; great benefits are achieved on environment and economy; and obvious social benefits are achieved.

Owner:GUANGXI CHENYU BUILDING MATERIAL SCI & TECH

General strength and sensitivity enhancement method for micromachined device

InactiveUS20110115035A1Simple structureImprove performanceSemiconductor/solid-state device detailsSolid-state devicesGyroscopeAccelerometer

This invention disclosed a method to strengthen structure and enhance sensitivity for CMOS-MEMS micro-machined devices which include micro-motion sensor, micro-actuator and RF switch. The steps of the said method contain defining deposited region by metal and passivation layer, forming a cavity for depositing metal structure by lithography process, depositing metal structure on the top metal layer of micromachined structure by Electroless plating, polishing process and etching process. The method aims at strengthening structures and minimizing CMOS-MEMS device size. Furthermore, this method can also be applied to inertia sensors such as accelerometer or gyroscope, which can enhance sensitivity and capacitive value, and deal with curl issues for suspended CMOS-MEMS devices.

Owner:HUANG JUNG TANG

Liquid crystal display device having first, second, and third transparent electrodes wherein a second region of the second electrode protrudes from a first region

ActiveUS20120280240A1Reduce areaReduce capacitanceTransistorSolid-state devicesLiquid-crystal displayEngineering

To form a sufficiently large storage capacitor, a liquid crystal display device includes a liquid crystal display panel having a first substrate, a second substrate, and a liquid crystal held between the first substrate and the second substrate, the liquid crystal display panel having multiple pixels arranged in matrix. The first substrate has, in a transmissive display area provided in each of the pixels, a laminated structure containing a first transparent electrode, a first insulating film, a second transparent electrode, a second insulating film, and a third transparent electrode which are laminated in this order. The first transparent electrode and the second transparent electrode are electrically insulated from each other and together form a first storage capacitor through the first insulating film, and the second transparent electrode and the third transparent electrode are electrically insulated from each other and together form a second storage capacitor through the second insulating film.

Owner:JAPAN DISPLAY INC +1

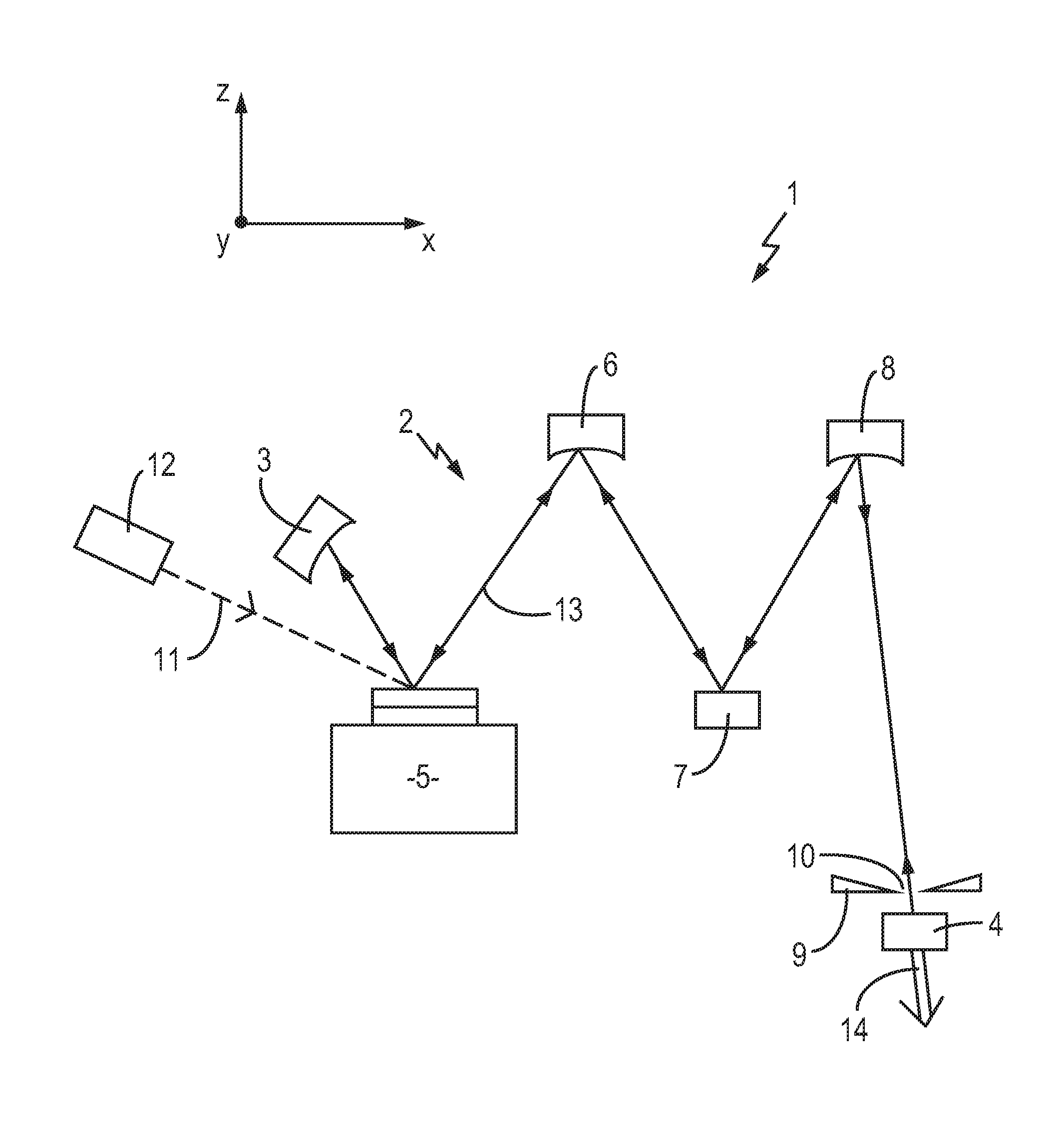

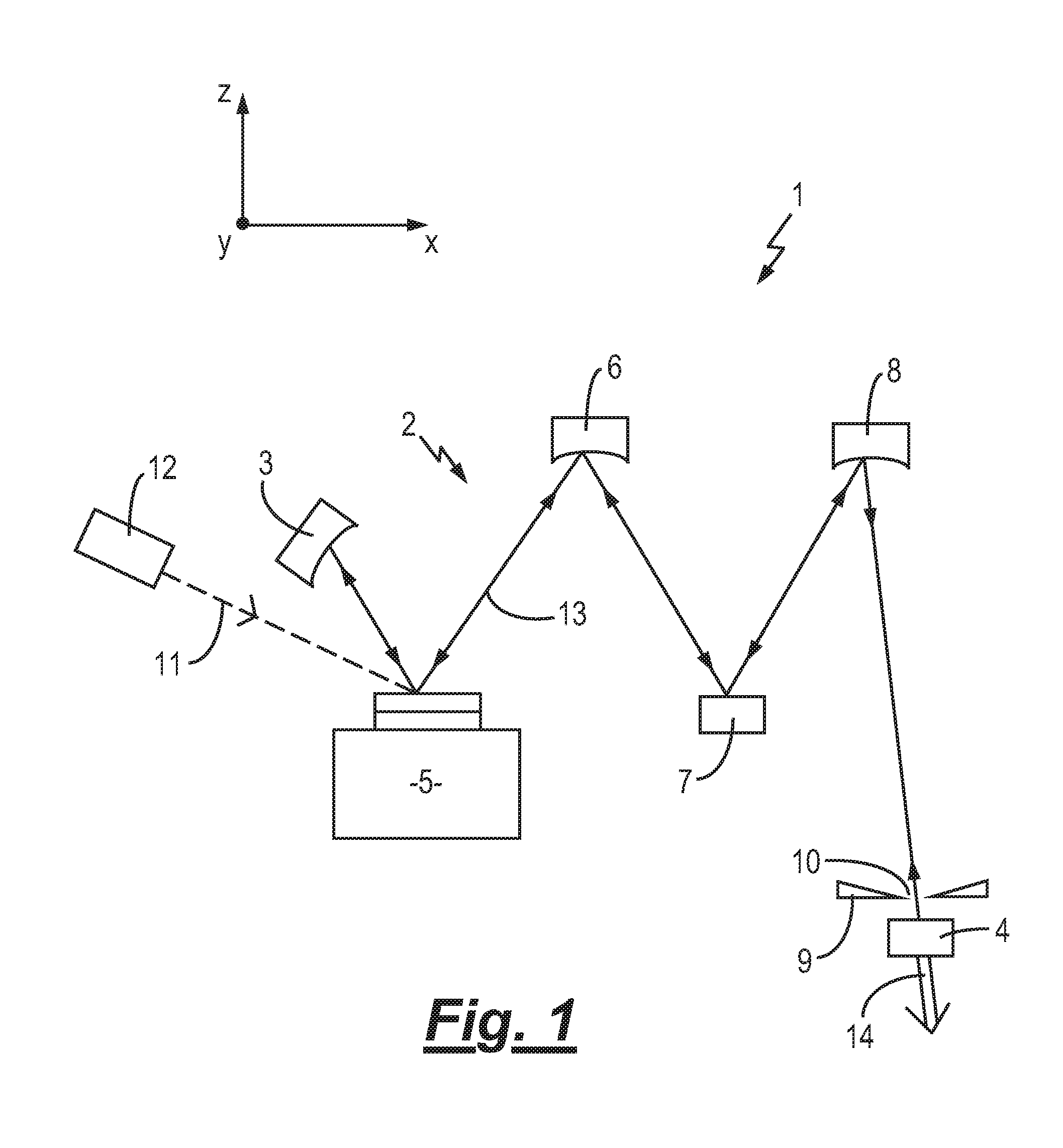

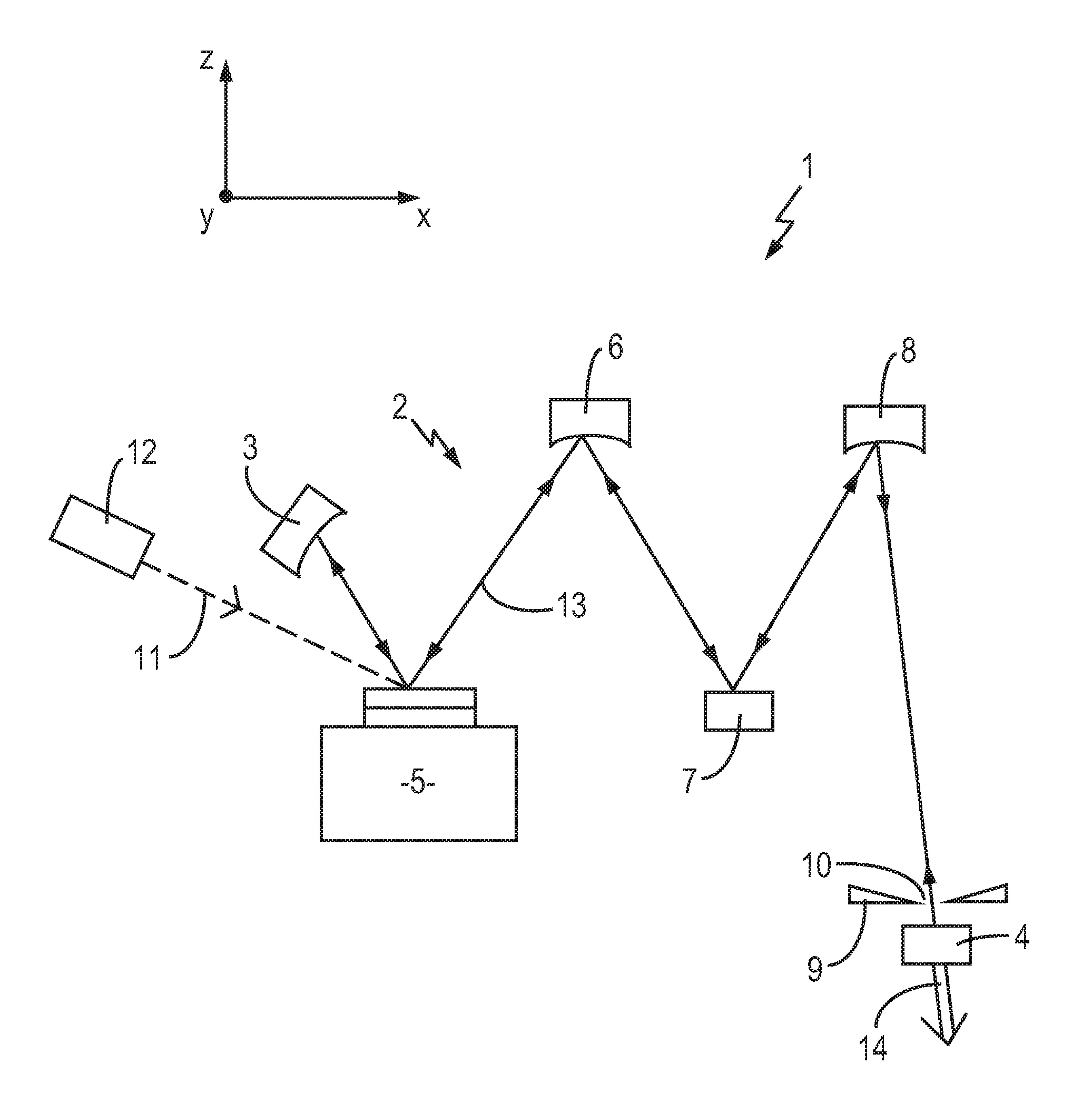

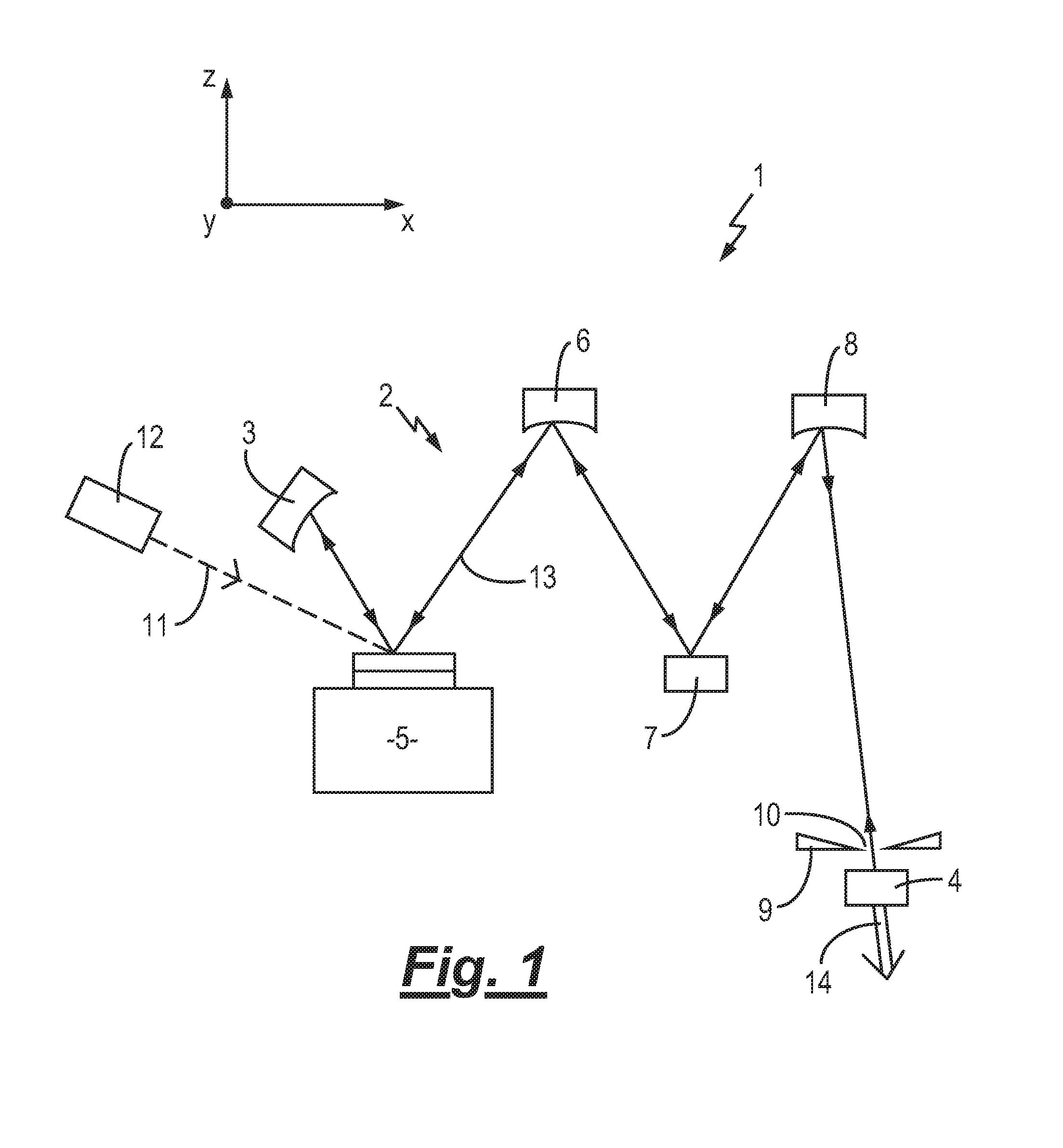

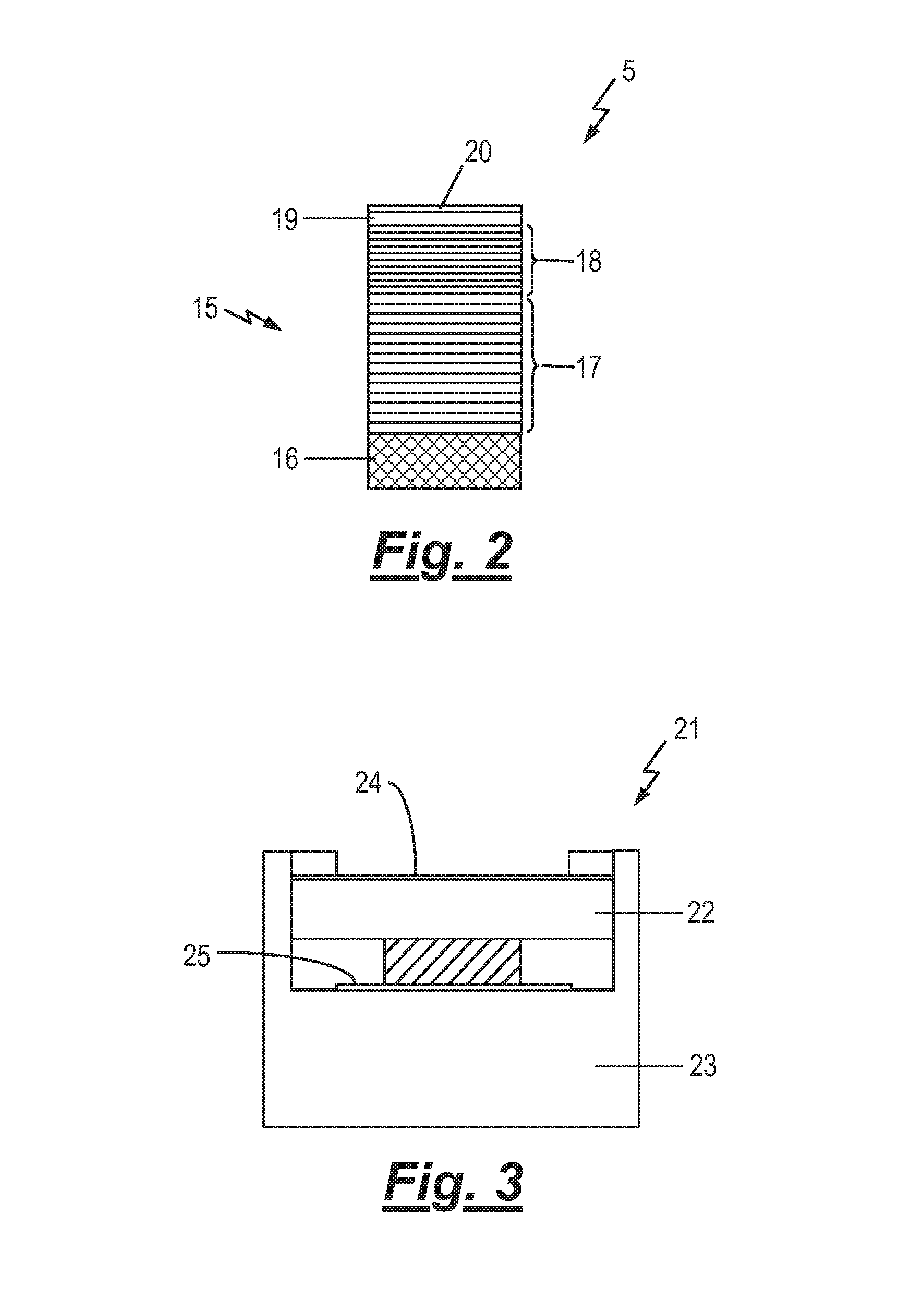

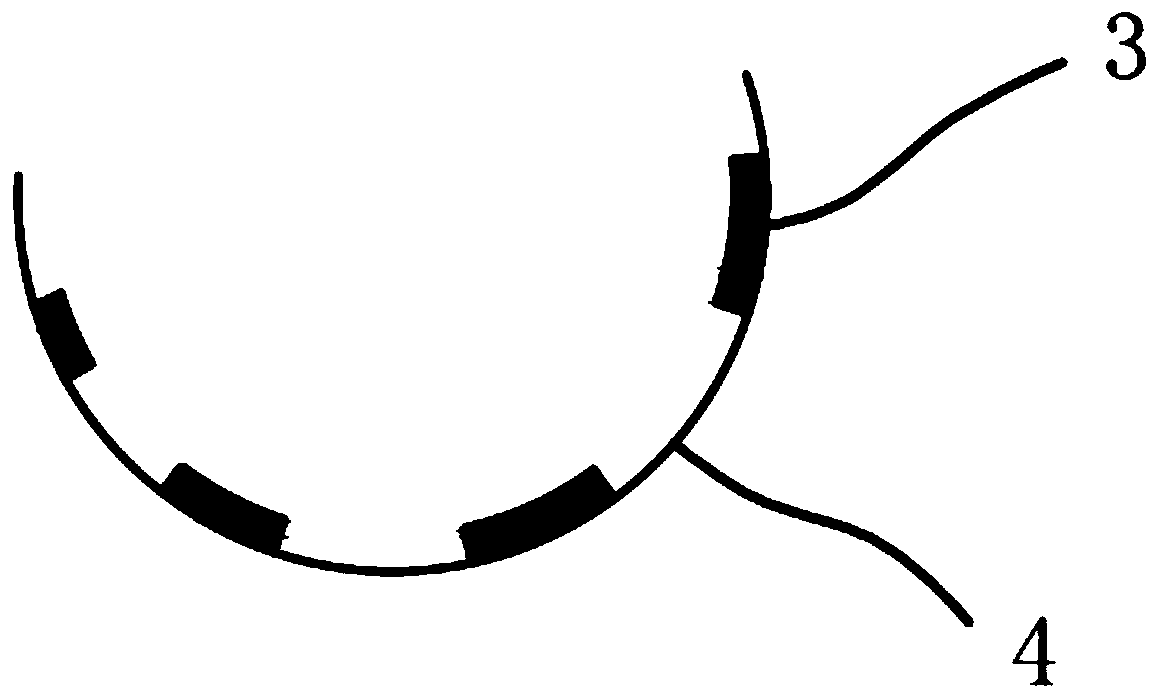

Self mode-locking semiconductor disk laser

ActiveUS20150063390A1Increase the angle of incidenceIncrease overlapLaser detailsLaser active region structureAstigmatismResonator

The present invention describes a self mode locking laser and a method for self mode locking a laser. The laser (1) comprises a resonator terminated by first (3) and second (4) mirrors and folded by a third mirror (5). The third mirror comprises a single distributed Bragg reflector (17) upon which is mounted a multilayer semiconductor gain medium (18) and which includes at least one quantum well layer and an optical Kerr lensing layer (22). Self mode locking may be achieved by configuring the laser resonator such that the lensing effect of the Kerr lensing layer acts to reduce an astigmatism deliberately introduced to the cavity mode. The self mode locking of the laser may be further enhanced by selecting the length of the resonator such that a round trip time of a cavity mode is matched with an upper-state lifetime of one or more semiconductor carriers located within the gain medium.

Owner:SOLUS TECH

Semiconductor device

ActiveUS8890230B2Raise the ratioImprove semiconductor device performanceTransistorSolid-state devicesDielectric layerSemiconductor

Owner:UNITED MICROELECTRONICS CORP

Self mode-locking semiconductor disk laser

ActiveUS20150063389A1Increase angle of incidenceIncrease overlap areaOptical wave guidanceLaser detailsAstigmatismResonator

The present invention describes a self mode locking laser and a method for self mode locking a laser. The laser (1) comprises a resonator terminated by first (3) and second (4) mirrors and folded by a third mirror (5). The third mirror comprises a single distributed Bragg reflector (17) upon which is mounted a multilayer semiconductor gain medium (18) and which includes at least one quantum well layer and an optical Kerr lensing layer (22). Self mode locking may be achieved by configuring the laser resonator such that the lensing effect of the Kerr lensing layer acts to reduce an astigmatism deliberately introduced to the cavity mode. The self mode locking of the laser may be further enhanced by selecting the length of the resonator such that a round trip time of a cavity mode is matched with an upper-state lifetime of one or more semiconductor carriers located within the gain medium.

Owner:SOLUS TECH

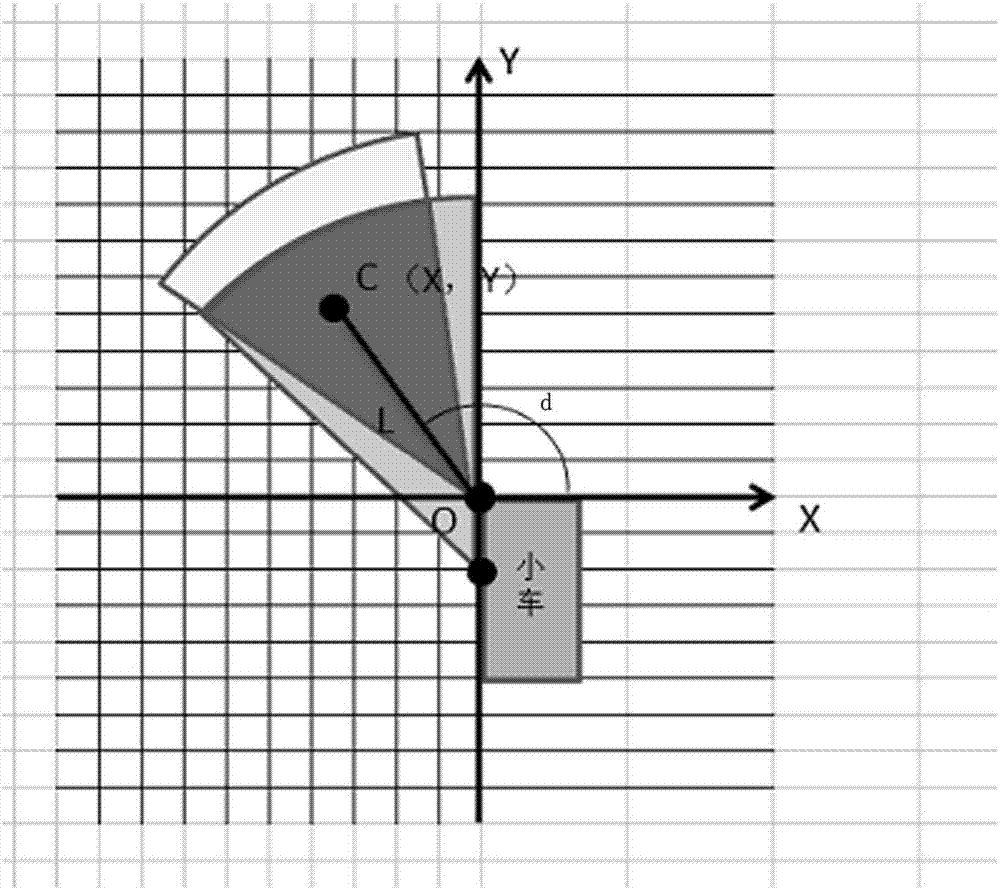

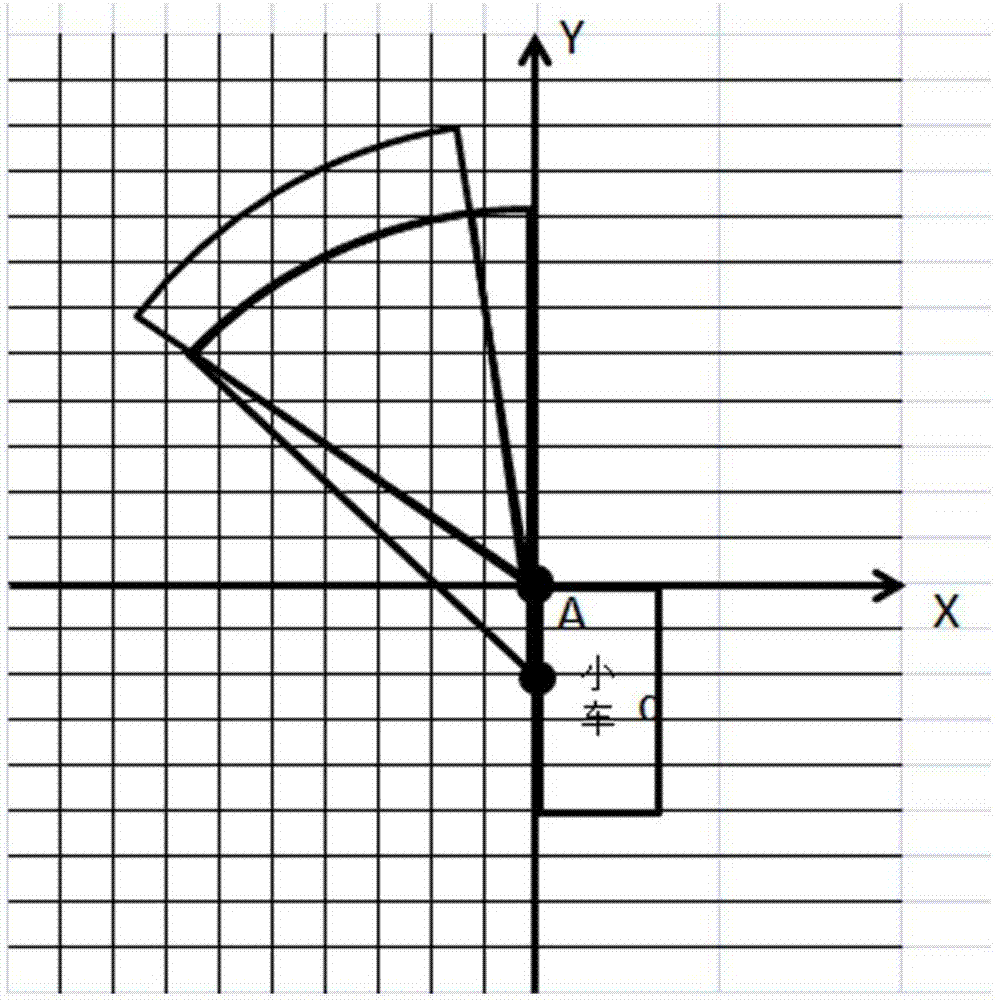

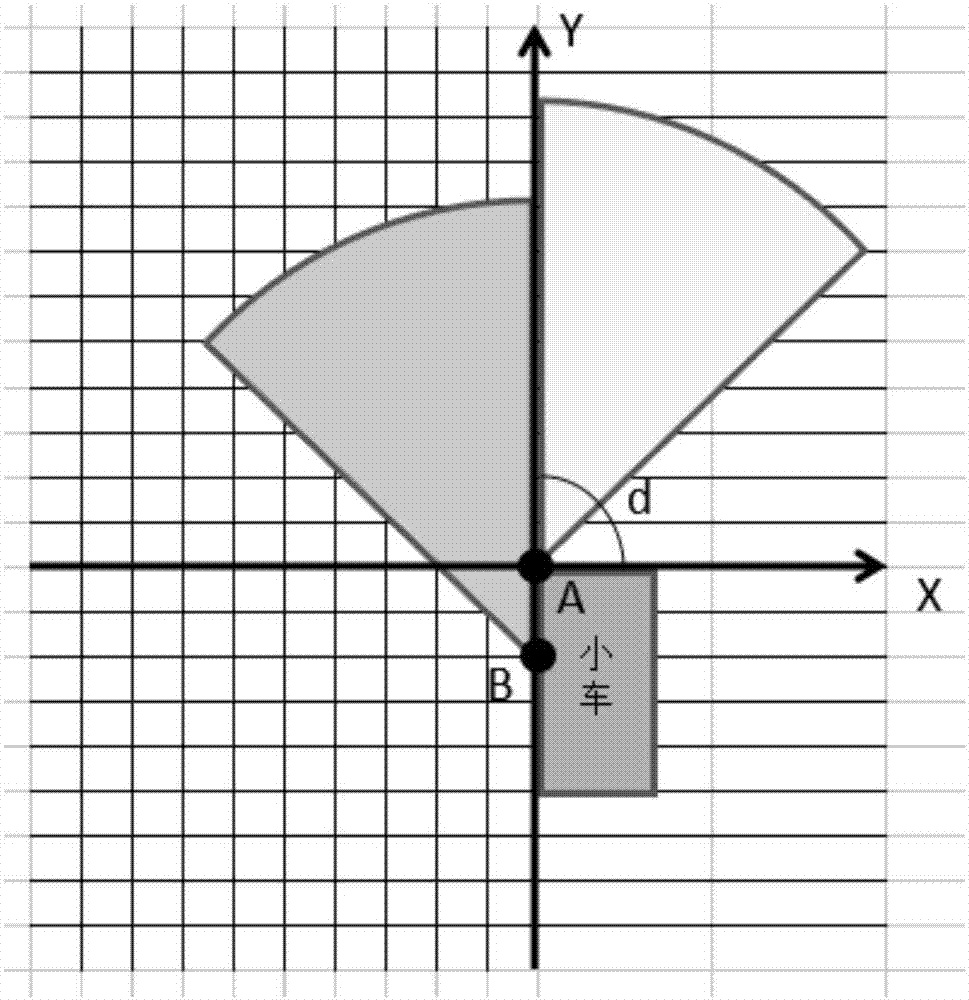

Infrared ranging and guiding method applied to servo-actuated dolly

ActiveCN107463174AAccurately determine the mobile locationAccurately judge the directionPosition/course control in two dimensionsMoving speedMobile object

The invention relates to an infrared ranging and guiding method applied to a servo-actuated dolly. According to the method, a module erected by an infrared ranging sensor is used for detecting location information of a followed object in real time, thereby realizing guidance of a servo-actuated dolly by a moving object within a certain range. The method comprises the following steps that: (1), two infrared ranging sensors are arranged on the dolly to erect an infrared ranging sensor device; (2), a two-dimensional coordinate system is established between the dolly and a followed object, the sensors scan corresponding ranges at certain frequencies continuously, and initial position information of the followed object is record; (3), the dolly moves based on the changing location information to realize accurate determination of a moving location, a moving direction, and a moving speed of the followed object, so that the dolly moves by following the target at any time and avoids obstacles in front of the dolly. Therefore, an objective of accurate determination of a moving location, a moving direction, and a moving speed of a target object by a dolly is achieved; and thus the dolly moves by following the target at any time and avoids obstacles in front of the dolly.

Owner:SHENYANG POLYTECHNIC UNIV

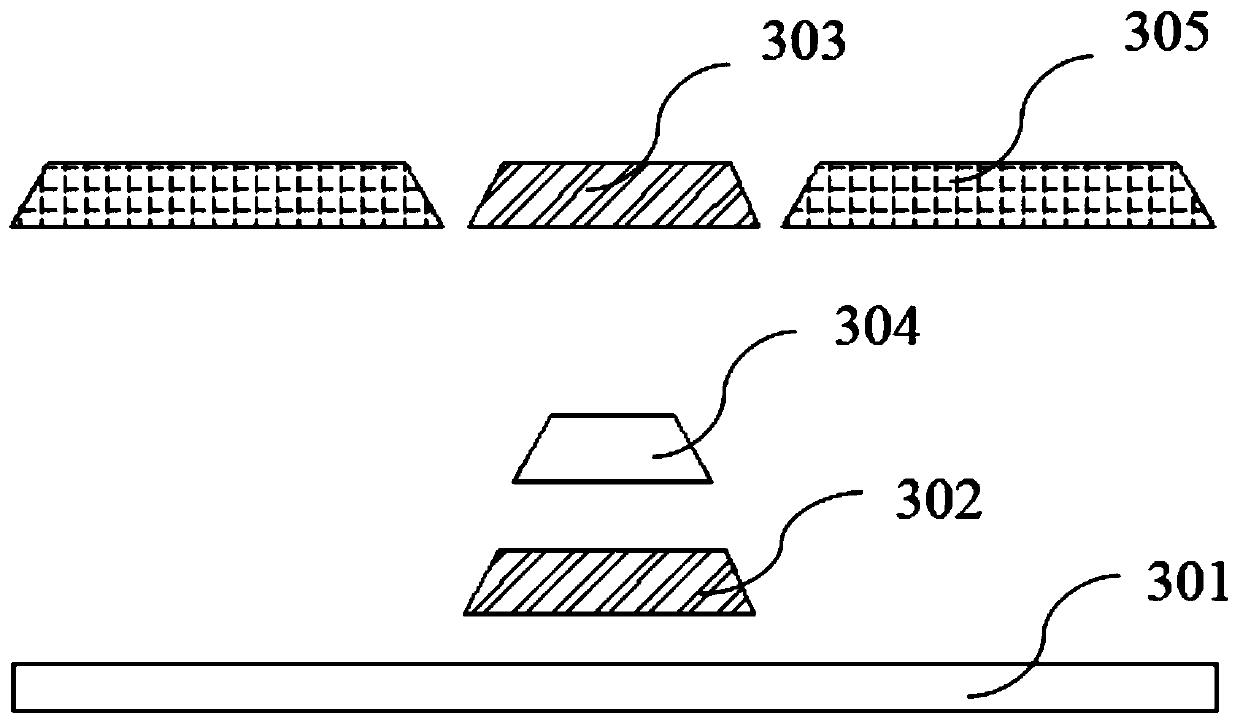

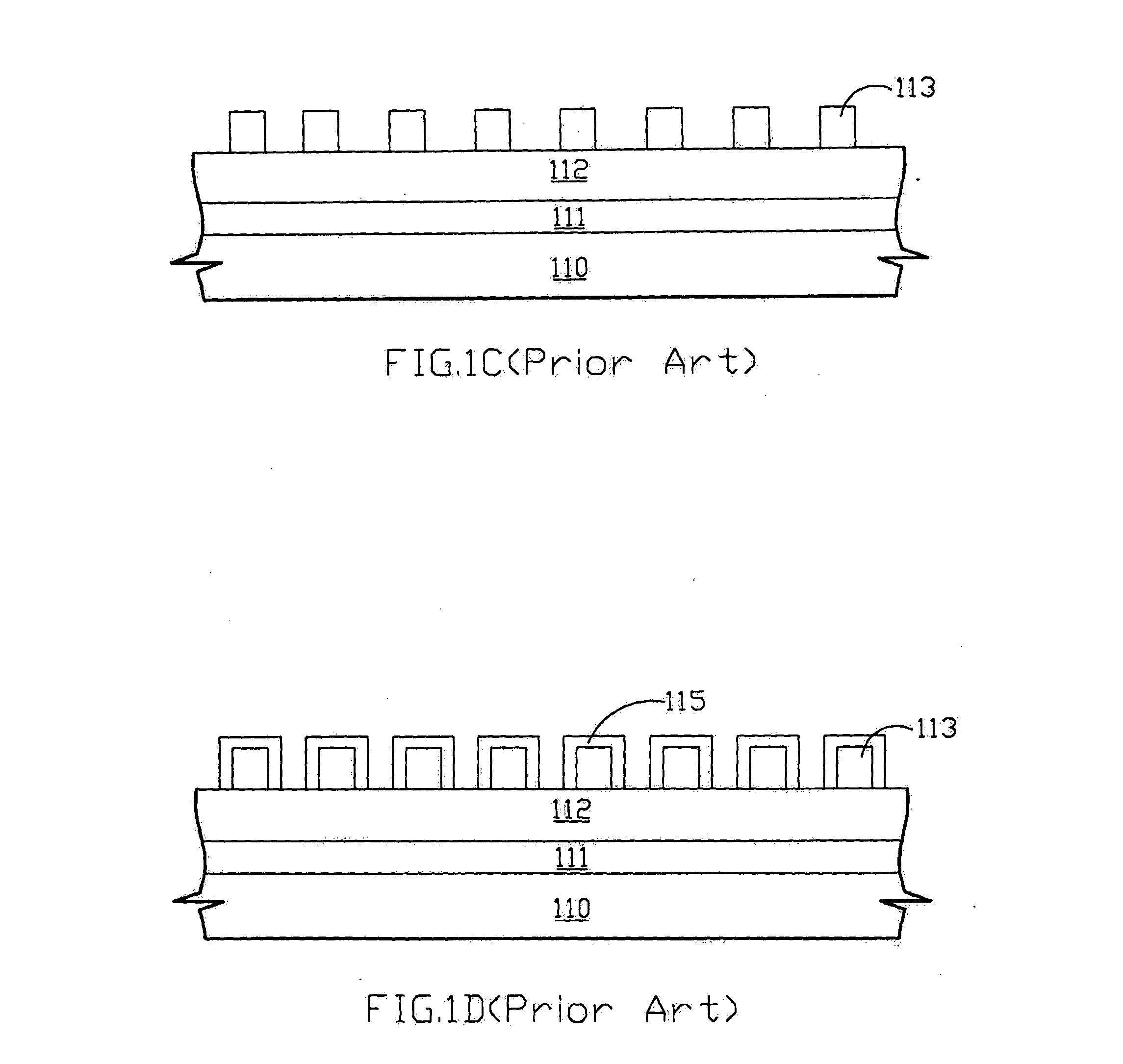

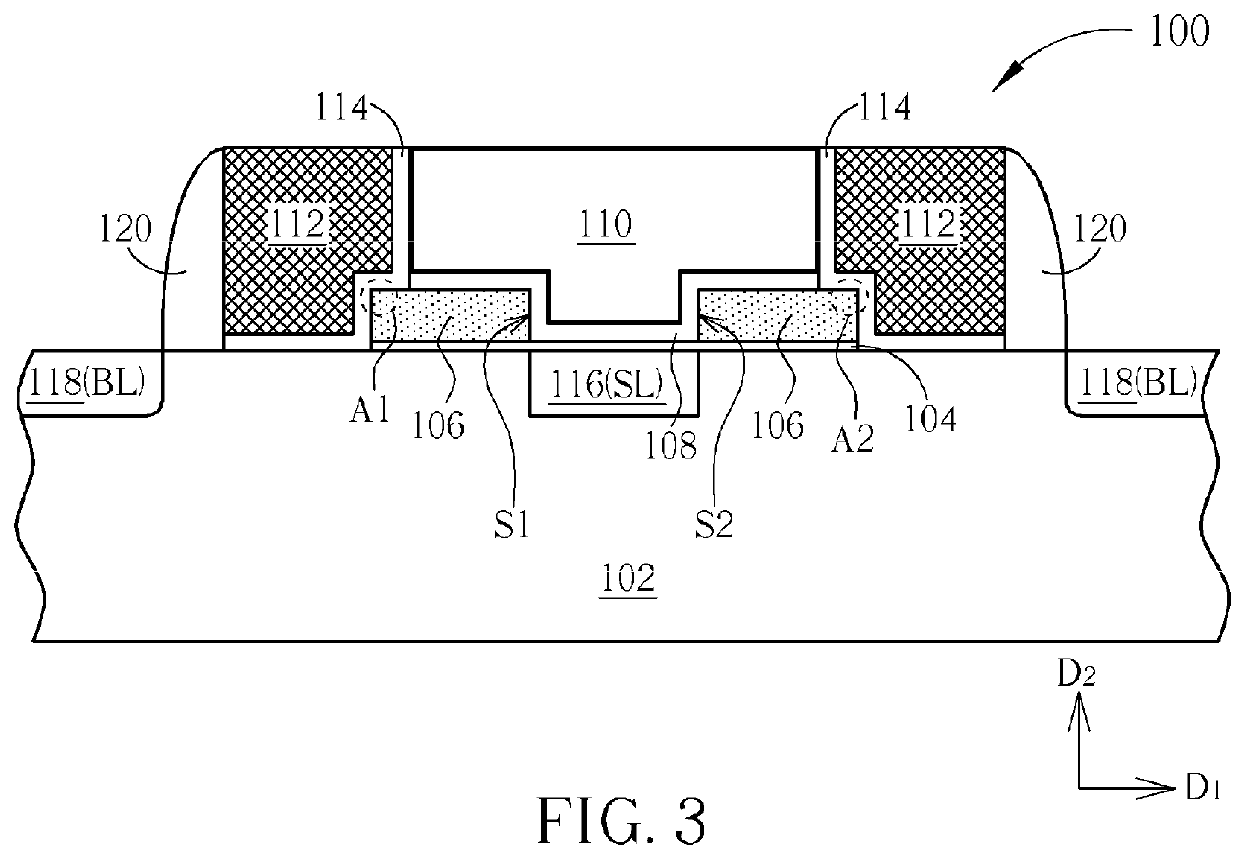

Method for manufacturing non-volatile memory cell

ActiveUS6869842B2Reduce numberImprove cell structureTransistorSolid-state devicesOxideNon-volatile memory

A non-volatile memory cell having a symmetric cell structure is disclosed. The non-volatile memory cell includes a substrate, a tunnel oxide layer, two floating gates, a dielectric layer, a plurality of spacers, a control gate, and two split gates. The substrate has at least two sources and a drain that is located between the sources. The floating gates are formed on the tunneling oxide layer, and each of floating gates is located between each source and the drain. The dielectric layer is formed on the floating gates. The control gate is formed over the drain and is between the floating gates. The split gates are located adjacent to outward sidewalls of the floating gates, respectively. Therefore, each of the split gates is opposite to the control gate through each of the floating gates.

Owner:POWERCHIP SEMICON MFG CORP

Display apparatus

ActiveUS10139927B2Improve accuracyMagnetic fields can be enhancedInput/output processes for data processingComputer sciencePixel array

A display apparatus with a touch detection function capable of improving accuracy is provided. The display apparatus includes: a pixel array having a plurality of pixels arranged in a matrix form; and a plurality of signal wires arranged in the pixel array. Here, when an externally-detecting object is detected, a plurality of coils having areas overlapping with each other are formed of a plurality of signal wires (drive electrodes) among the plurality of signal wires, and a magnetic field generated in the plurality of respective coils are superimposed in an overlapped area by supplying a drive signal to the plurality of coils.

Owner:JAPAN DISPLAY INC

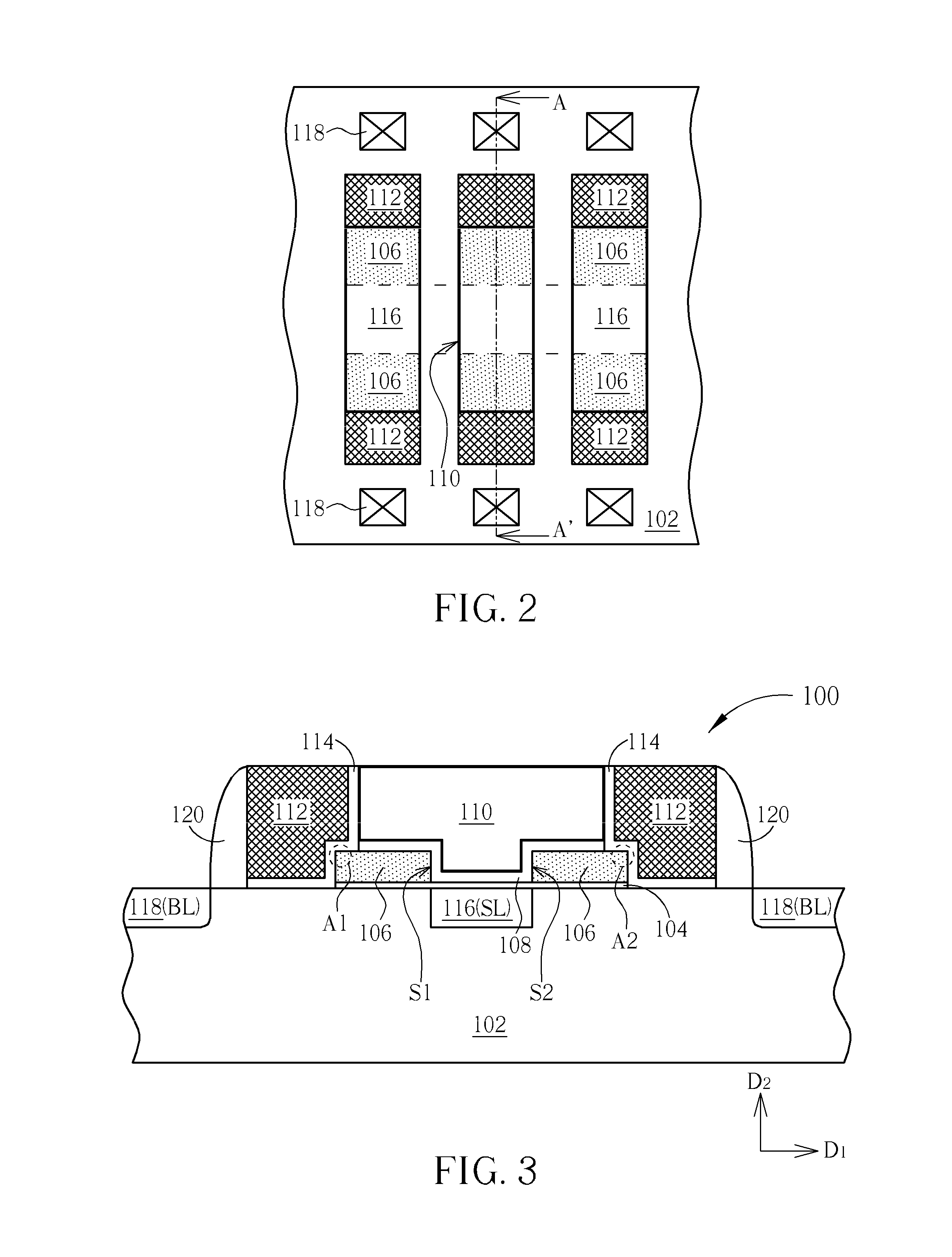

Non-volatile memory and fabricating method thereof

ActiveUS20120161221A1Increase the overlapping areaReduce distractionsTransistorSolid-state devicesBit lineGate dielectric

A non-volatile memory having a tunneling dielectric layer, a floating gate, a control gate, an inter-gate dielectric layer and a first doping region and a second doping region is provided. The tunneling dielectric layer is disposed on a substrate. The floating gate is disposed on the tunneling dielectric layer, and has a protruding portion. The control gate is disposed over the floating gate to cover and surround the protruding portion. The protruding portion of the floating gate is fully covered and surrounded by the control gate in any direction, including extending directions of bit lines, word lines and an included angle formed between the word line and the bit line. The inter-gate dielectric layer is disposed between the floating gate and the control gate. The first doping region and the second doping region are respectively disposed in the substrate at two sides of the control gate.

Owner:POWERCHIP SEMICON MFG CORP

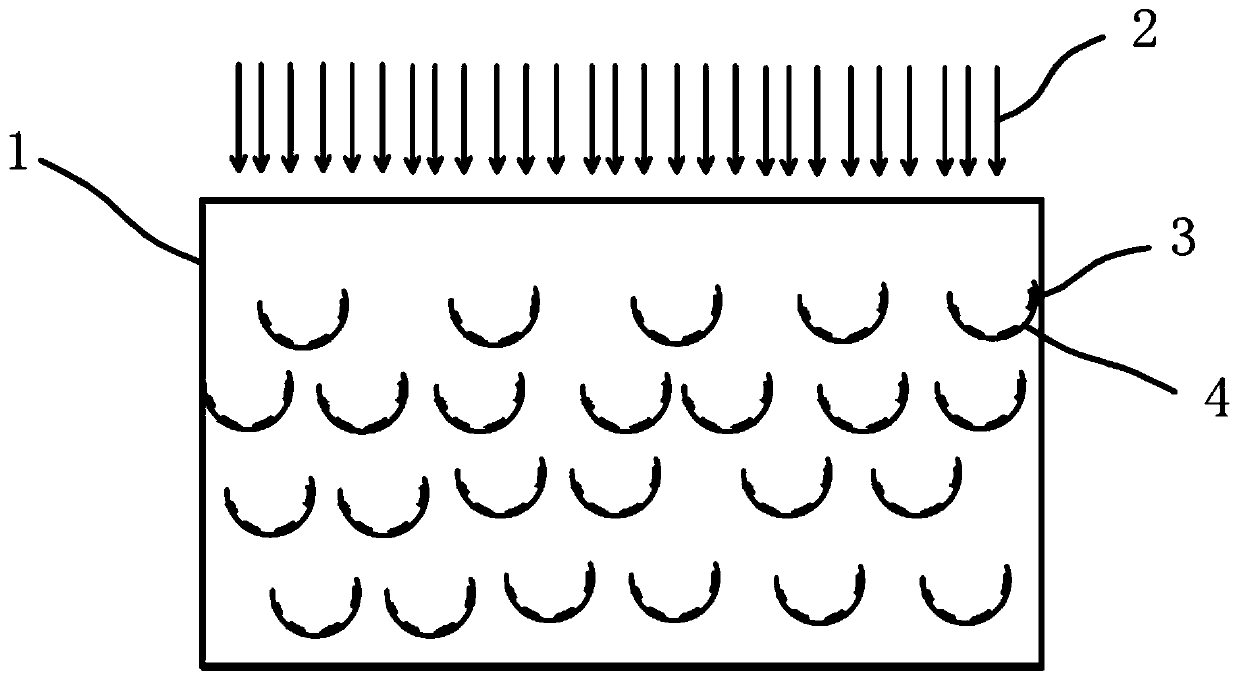

Titanium dioxide photocatalytic reactor

InactiveCN110694567AReduce secondary pollutionImprove stabilityEnergy based chemical/physical/physico-chemical processesPhotocatalytic reactionLight guide

The invention discloses a titanium dioxide photocatalytic reactor, which comprises a light guide film, a channel arranged on the inner side of the light guide film, and a plurality of light guide members arranged in the channel, wherein at least a light source member is arranged at the end portion of the light guide film, a light source emitted by the light source member extends along the channel,the plurality of the light guide members are distributed in the channel in a staggered manner so as to project at least part of the light source emitted by the light source member on the light guidemembers, at least a reaction point is arranged on one side, close to the light source member, of the light guide member, an overlapping area is formed by the overlapping area of the surface of the reaction point, the light source and a catalyzed object, and the overlapping area can conduct a photocatalytic reaction.

Owner:FOSHAN JINJINGCHUANG ENVIRONMENTAL PROTECTION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com