Manufacturing method of flash memory

A manufacturing method and technology of flash memory, which is applied in the field of flash memory manufacturing, can solve problems such as area reduction, and achieve the effect of improving the coupling rate and increasing the overlapping area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the above-mentioned and other objects, features, and advantages of the present invention more obvious and easy to understand, preferred embodiments are given below, and in conjunction with the accompanying drawings, are described in detail as follows:

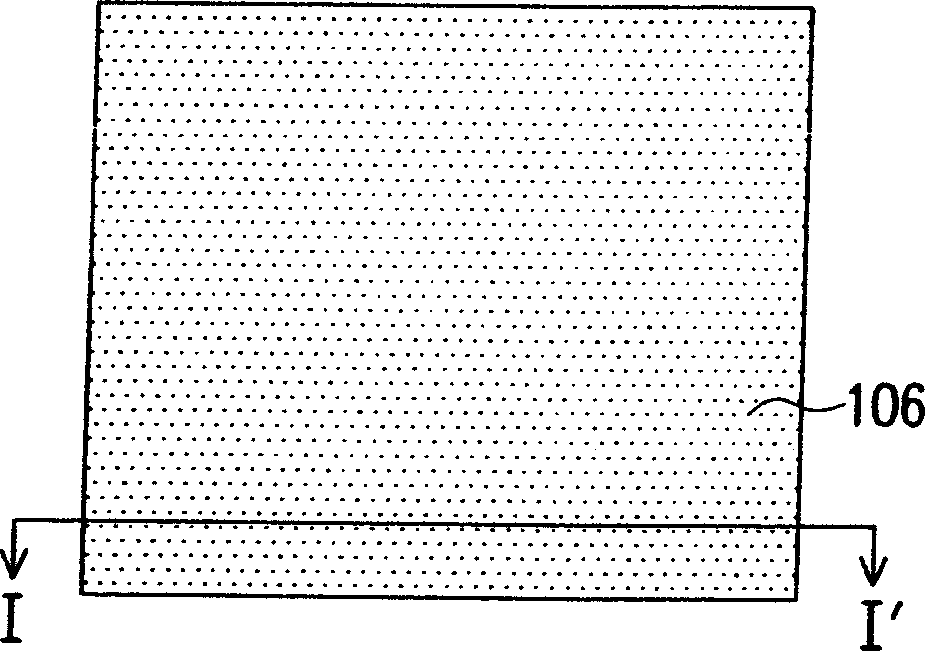

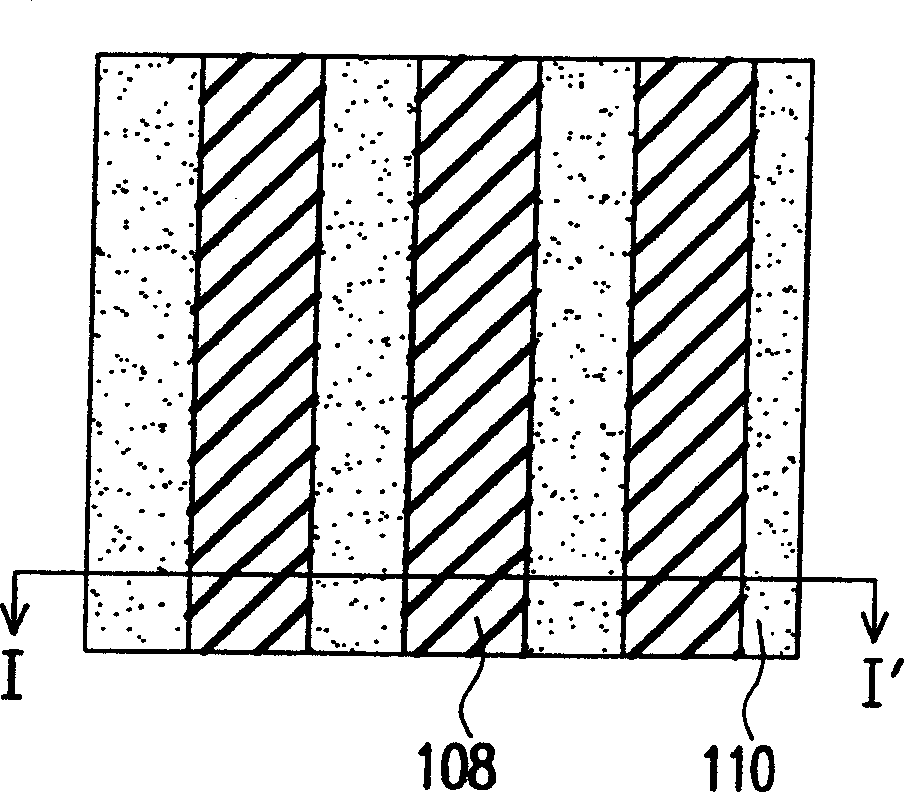

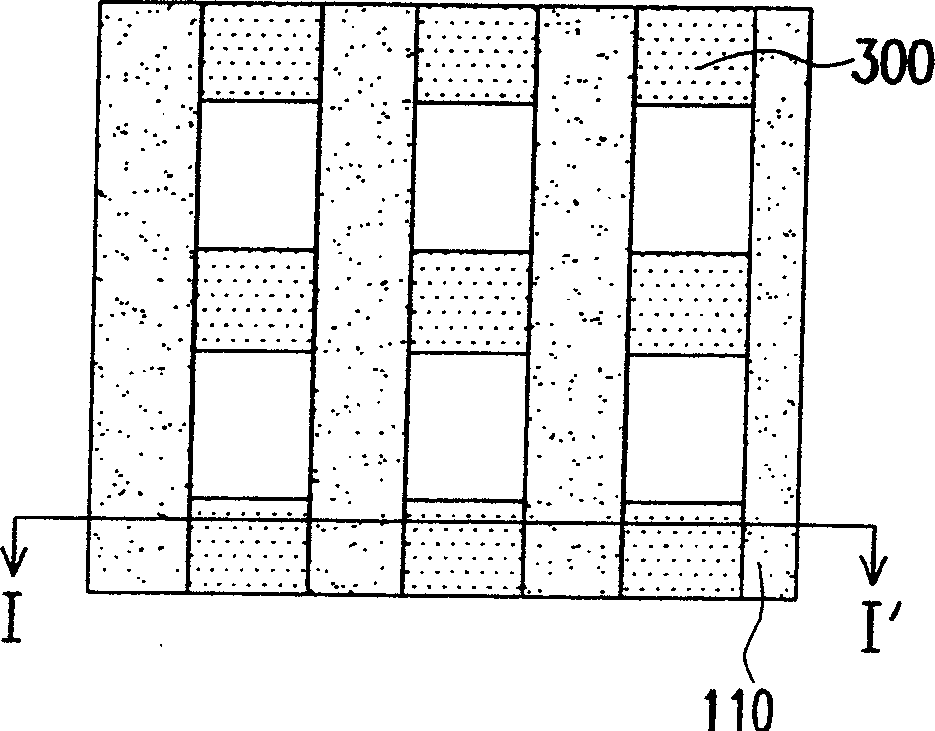

[0029] Figure 1A to Figure 1G A top view of a manufacturing process of a flash memory according to a preferred embodiment of the present invention is shown. Figure 2A to Figure 2G for Figure 1A to Figure 1G A cross-sectional view of the I-I' line. First, please also refer to Figure 1A and Figure 2A , a substrate 100 is provided, and the substrate 100 is, for example, a silicon substrate. Then, a tunnel dielectric layer 102 , a conductor layer 104 and a mask layer 106 are sequentially formed on the substrate 100 . The material of the tunnel dielectric layer 102 is, for example, silicon oxide, and the thickness thereof is, for example, about 50 angstroms to 100 angstroms.

[0030] The formation me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com