Semiconductor and forming method thereof

A semiconductor and device technology, applied in the field of semiconductor manufacturing, can solve problems such as the inability to maintain the linear demand of logic circuits and the lack of carriers, and achieve the effects of shortening the production cycle, improving reliability, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] It can be seen from the background art that in order to meet the development of semiconductor chips toward high integration, it is more and more important to increase the capacitance per unit chip area.

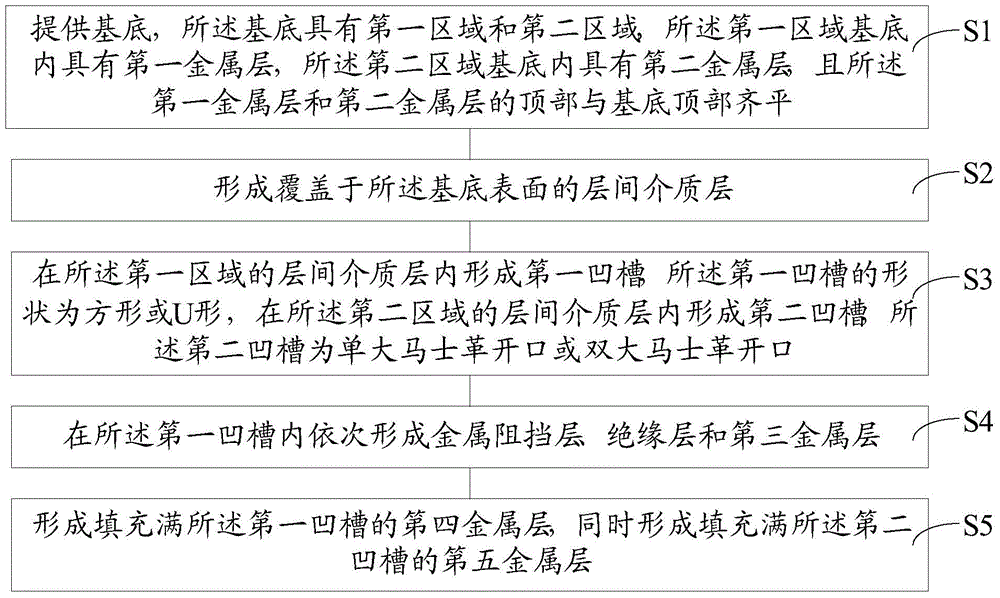

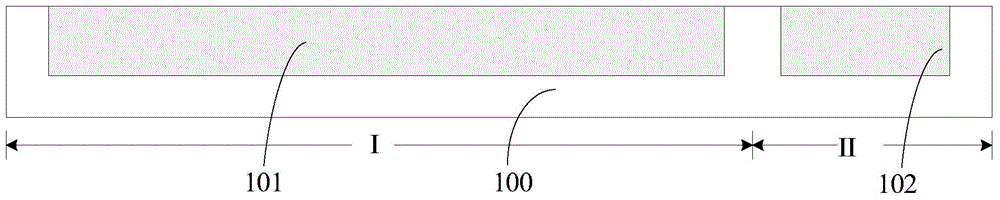

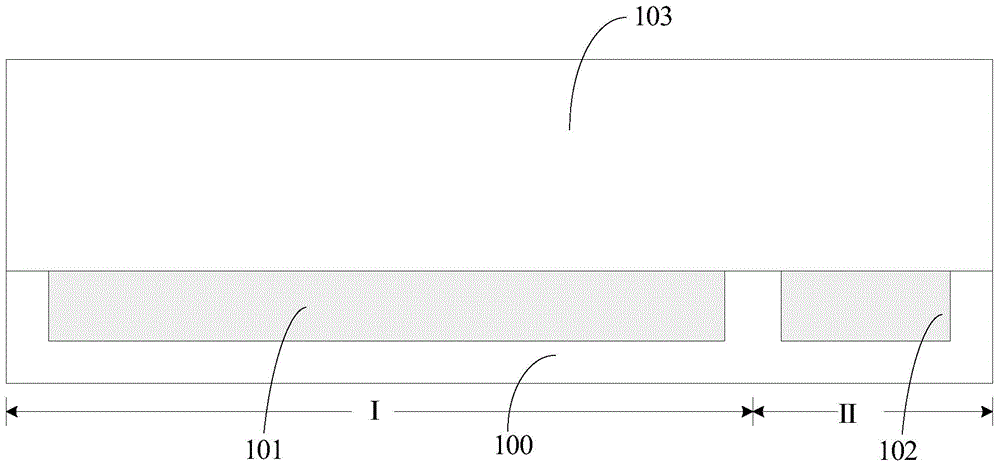

[0036] In order to solve the above problems, the formation method of semiconductor devices is studied. At present, the most common method is to form MIM capacitors while performing dual damascene process (dual damascene). Specifically, the formation method of semiconductor devices includes the following steps, please refer to figure 1 : Step S1, providing a substrate, the substrate has a first region and a second region, the first region has a first metal layer in the substrate, the second region has a second metal layer in the substrate, and the first The tops of the metal layer and the second metal layer are flush with the top of the substrate; step S2, forming an interlayer dielectric layer covering the surface of the substrate; step S3, forming a first recess in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com