Oil-based cutting waste liquid treatment and separation system and working method thereof

A cutting waste liquid and separation system technology, applied in separation methods, metallurgical wastewater treatment, gas treatment, etc., can solve the problems of long process flow, equipment corrosion, secondary pollution of operating environment, etc., to improve the reaction rate and reduce operating costs. , the effect of eliminating mass transfer resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

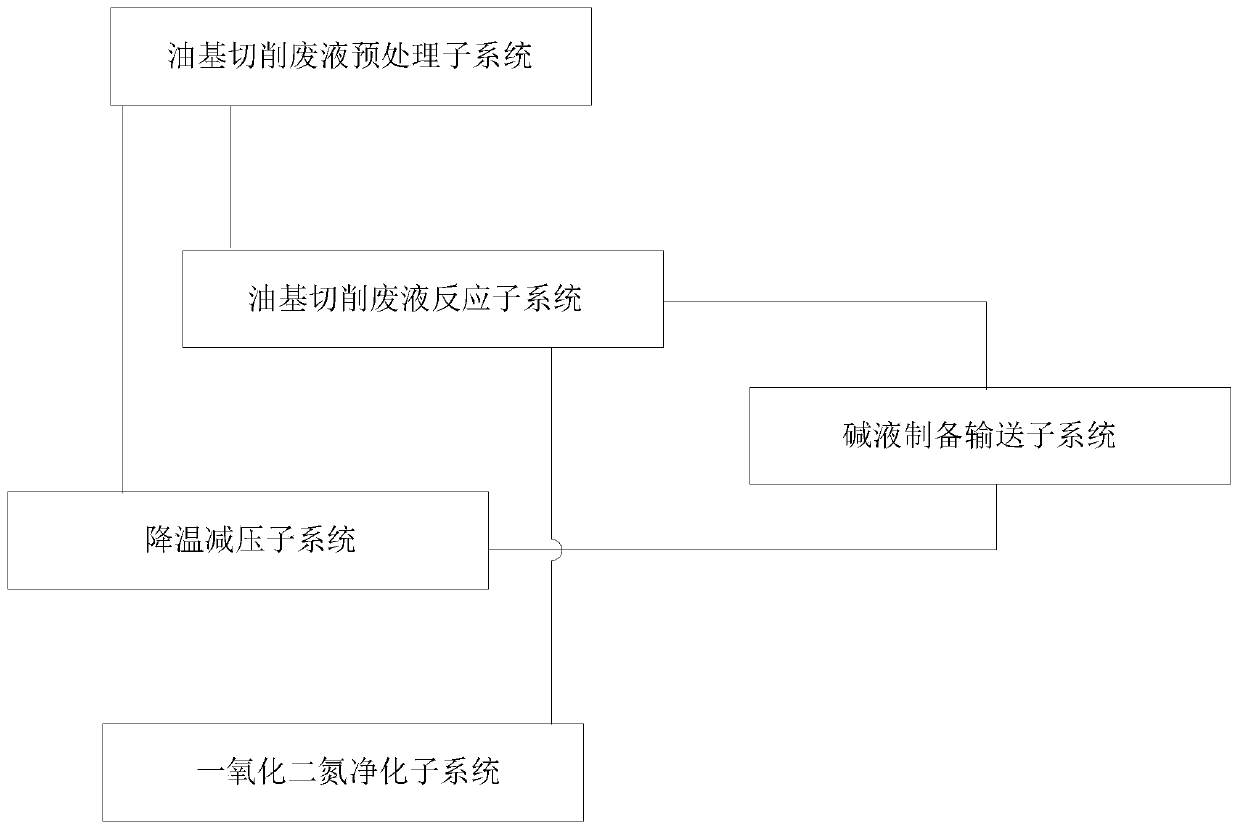

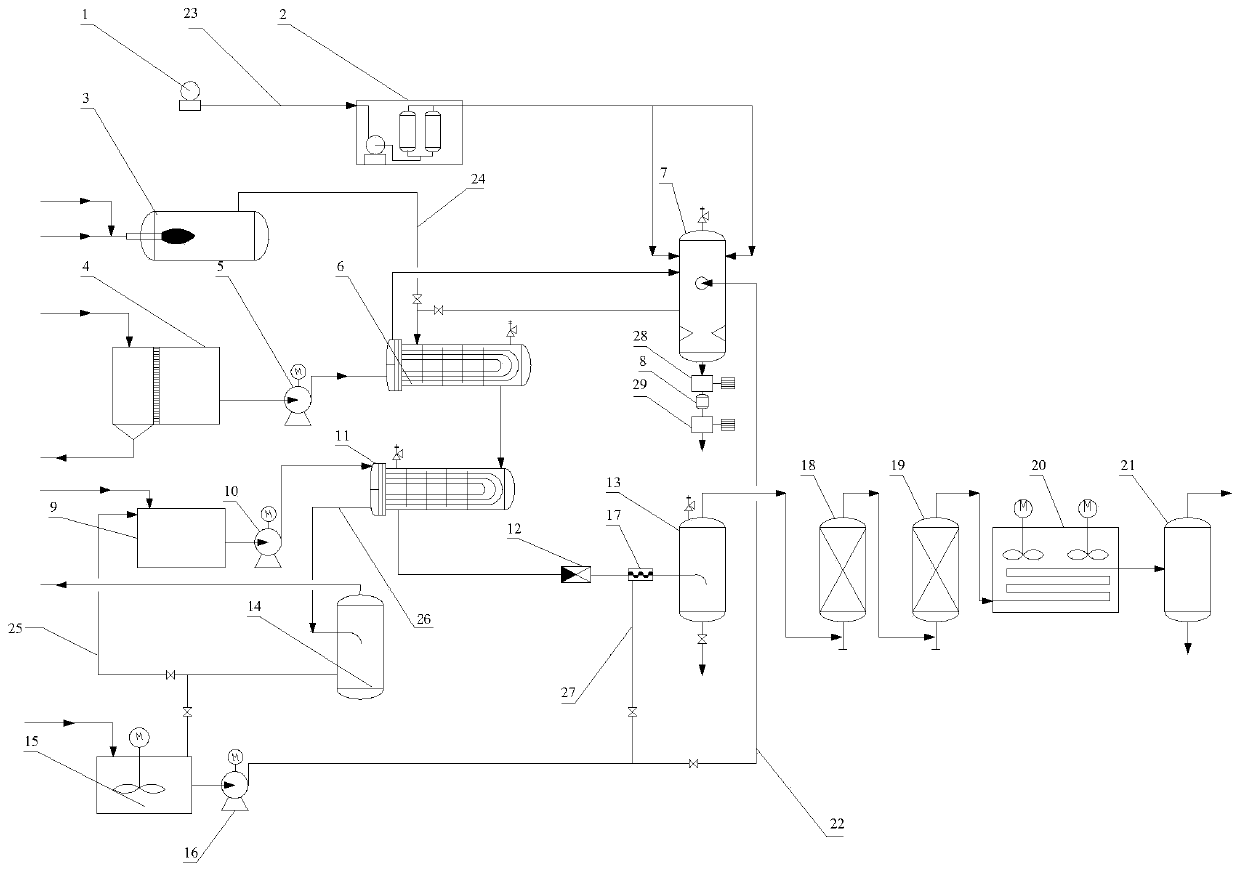

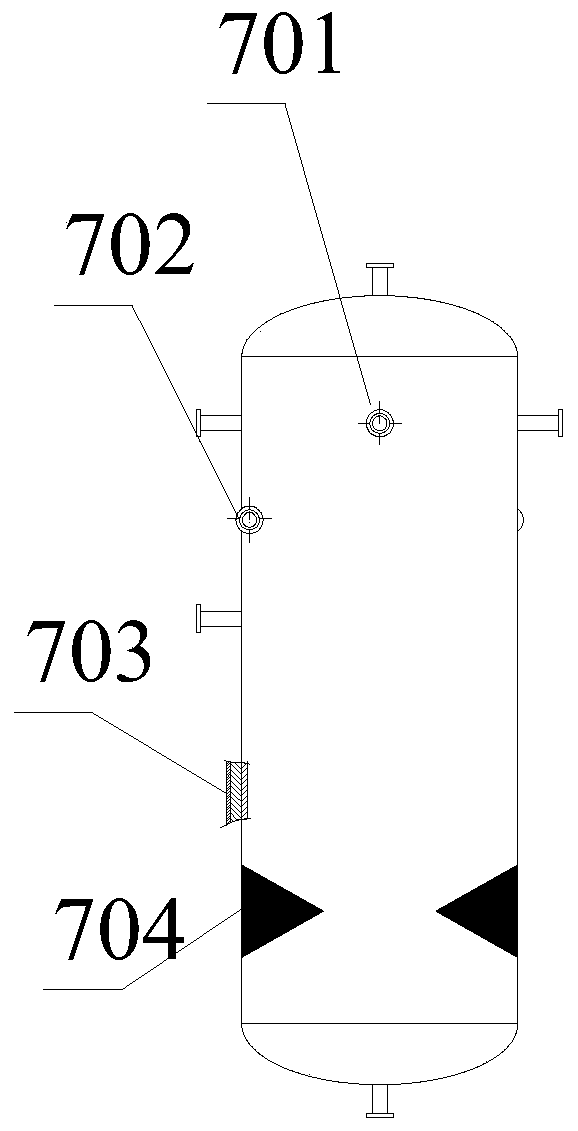

[0026] Embodiment 1: as Figure 1-5 As shown, it is an oil-based cutting waste liquid treatment and separation system and its working method proposed by the present invention, including: oil-based cutting waste liquid pretreatment subsystem, oil-based cutting waste liquid reaction subsystem, cooling and decompression sub-system system, nitrous oxide purification subsystem and lye preparation and delivery subsystem, the oil-based cutting waste fluid pretreatment subsystem is connected with the oil-based cutting waste fluid reaction subsystem and the cooling and decompression subsystem respectively , the oil-based cutting waste liquid reaction subsystem is respectively connected with the nitrous oxide purification subsystem and the lye preparation and delivery subsystem, and the cooling and decompression subsystem is connected with the lye preparation and delivery subsystem connected;

[0027] The oil-based cutting waste fluid pretreatment subsystem includes a filtration storag...

Embodiment 2

[0032] Embodiment 2: as Figure 1-5 As shown, the treatment and separation system of oil-based cutting waste liquid based on supercritical water oxidation technology proposed by the present invention includes: oil-based cutting waste liquid pretreatment subsystem, oil-based cutting waste liquid reaction subsystem, cooling and decompression Subsystem, nitrous oxide purification subsystem and lye preparation and delivery subsystem, the oil-based cutting waste fluid pretreatment subsystem is connected with the oil-based cutting waste fluid reaction subsystem and the cooling and decompression subsystem respectively connected, the oil-based cutting waste liquid reaction subsystem is connected with the nitrous oxide purification subsystem and the lye preparation and delivery subsystem respectively, and the cooling and decompression subsystem is connected with the lye preparation and delivery subsystem system connected;

[0033] The oil-based cutting waste fluid pretreatment subsyst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com