New energy automobile motor rotor casting aluminum alloy and preparation method thereof

A technology for casting aluminum alloys and new energy vehicles. It is applied in the field of casting aluminum alloys for new energy vehicle motor rotors and its preparation. It can solve problems such as difficulty in synchronously improving performance, and achieve the effects of increasing strength, strengthening crystallization cores, and increasing titanium content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

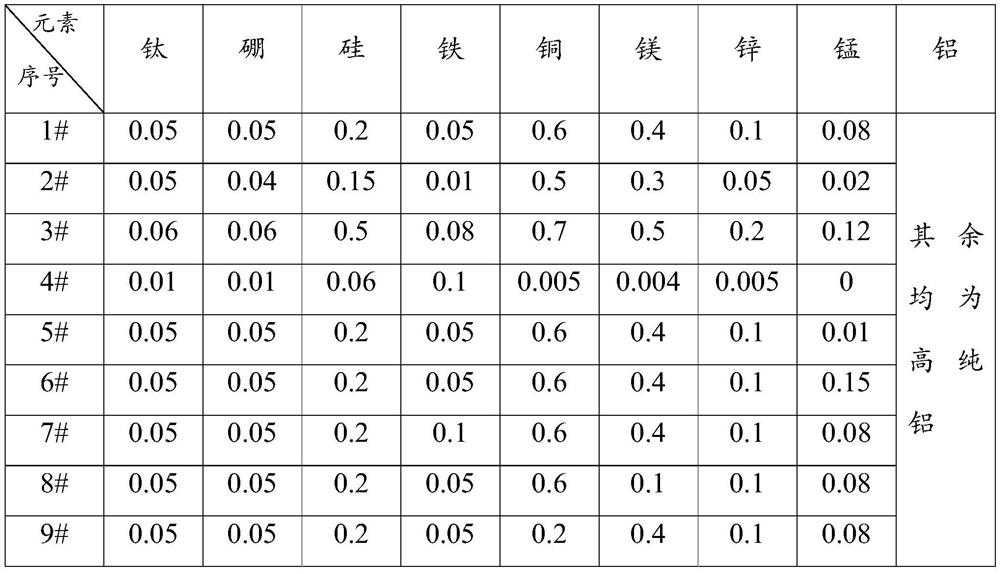

[0023] The preparation of embodiment 1 aluminum alloy 1#

[0024] The composition of aluminum alloy 1# is: 0.05wt% of titanium, 0.05wt% of boron, 0.2wt% of silicon, 0.05wt% of iron, 0.6wt% of copper, 0.4wt% of magnesium, 0.1wt% of zinc, 0.08wt% of manganese, and the rest is High-purity aluminum, high-purity aluminum is pure aluminum with a purity greater than 99.8%.

[0025] The preparation method is as follows: (1) melting the aluminum ingot at 720°C, adding various element components, and stirring evenly;

[0026] (2) The rotor cavity is preheated to 700°C, and the motor rotor cast aluminum alloy 1# is manufactured by conventional centrifugal casting process.

Embodiment 2

[0027] The preparation of embodiment 2 aluminum alloy 2#

[0028] The composition of aluminum alloy 2# is: titanium 0.05wt%, boron 0.04wt%, silicon 0.15wt%, iron 0.01wt%, copper 0.5wt%, magnesium 0.3wt%, zinc 0.05wt%, manganese 0.02wt%, the rest is High-purity aluminum, high-purity aluminum is pure aluminum with a purity greater than 99.8%.

[0029] The preparation method is as follows: (1) melting the aluminum ingot at 700°C, adding various element components, and stirring evenly;

[0030] (2) The rotor cavity is preheated to 680°C, and the motor rotor cast aluminum alloy 2# is manufactured by conventional centrifugal casting process.

Embodiment 3

[0031] The preparation of embodiment 3 aluminum alloy 3#

[0032] The composition of aluminum alloy 3# is: titanium 0.06wt%, boron 0.06wt%, silicon 0.5wt%, iron 0.08wt%, copper 0.7wt%, magnesium 0.5wt%, zinc 0.2wt%, manganese 0.12wt%, the rest is High-purity aluminum, high-purity aluminum is pure aluminum with a purity greater than 99.8%.

[0033] The preparation method is as follows: (1) melting the aluminum ingot at 760°C, adding various element components, and stirring evenly;

[0034] (2) The rotor cavity is preheated to 720°C, and the motor rotor cast aluminum alloy 3# is manufactured by conventional centrifugal casting process.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com