Low-nitrogen low-aluminum ferrotitanium, manufacturing method thereof and core-spun yarn

A manufacturing method and a cored wire technology are applied in the field of titanium-iron alloy, its manufacturing method and the field of cored wire containing the titanium-iron alloy, which can solve problems such as nozzle blockage and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

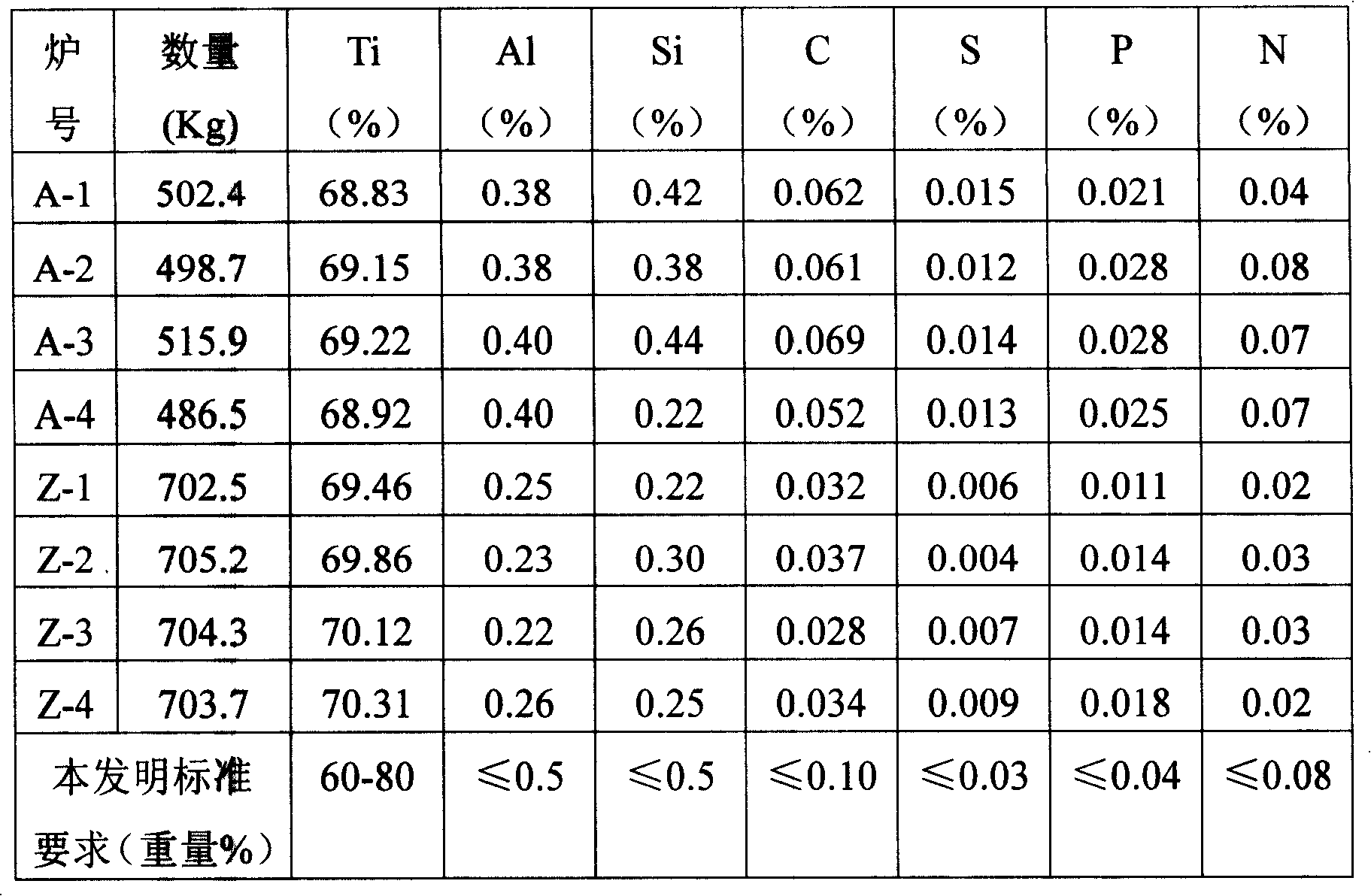

[0058] Embodiment 1 The manufacture method of low-nitrogen, low-aluminum ferro-titanium of the present invention

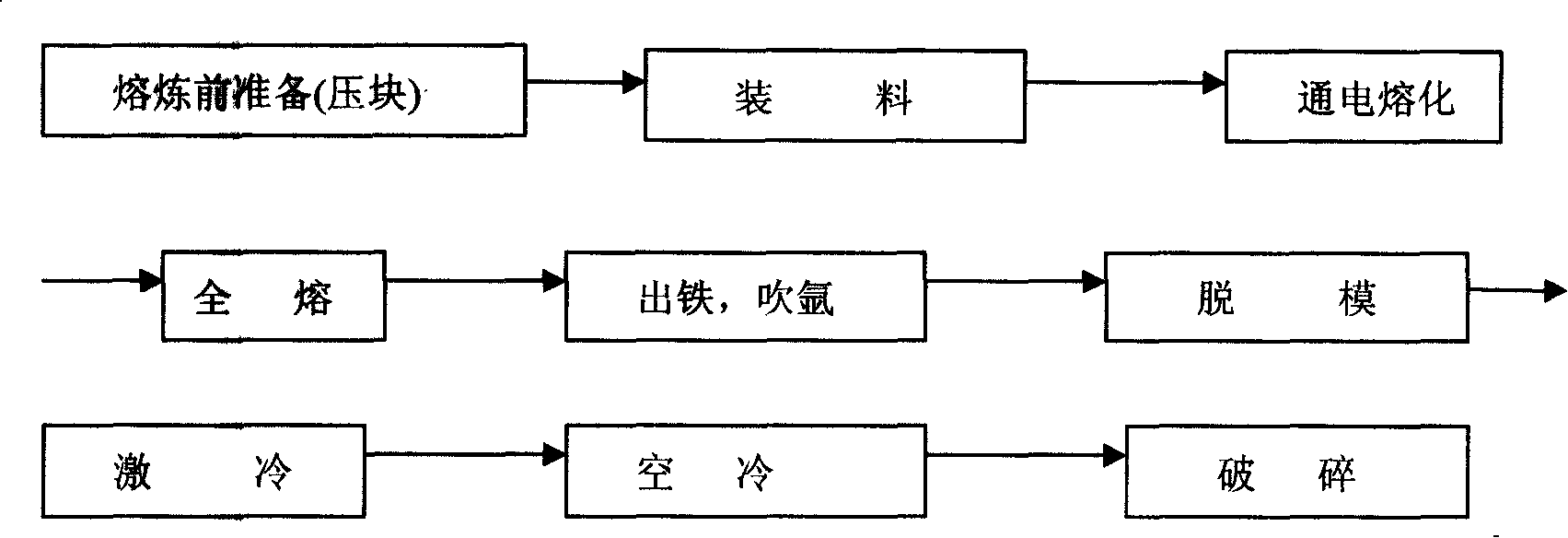

[0059] 1. Process flow such as figure 1 shown.

[0060] 2. Equipment

[0061] Oil press, argon melting furnace (or vacuum consumable furnace), jaw crusher and double roller machine.

[0062] 3. Raw materials

[0063] (1) Sponge titanium or scrap pure titanium, high-quality scrap steel or pure iron with low content of impurity elements such as nitrogen, aluminum, silicon, carbon, phosphorus, and sulfur are used as the main raw materials.

[0064] (2) Auxiliary material: Argon is the shielding gas.

[0065] 4. Preparatory process before smelting

[0066] Sponge titanium (or waste pure titanium) and high-quality scrap steel (or pure iron) are pressed into blocks on a hydraulic press at a ratio of 71-75%: 29-25%. If a vacuum consumable furnace is used for melting, the blocks need to be welded into blocks. electrode.

[0067] 5. Furnace loading

[0068] Put the...

Embodiment 2

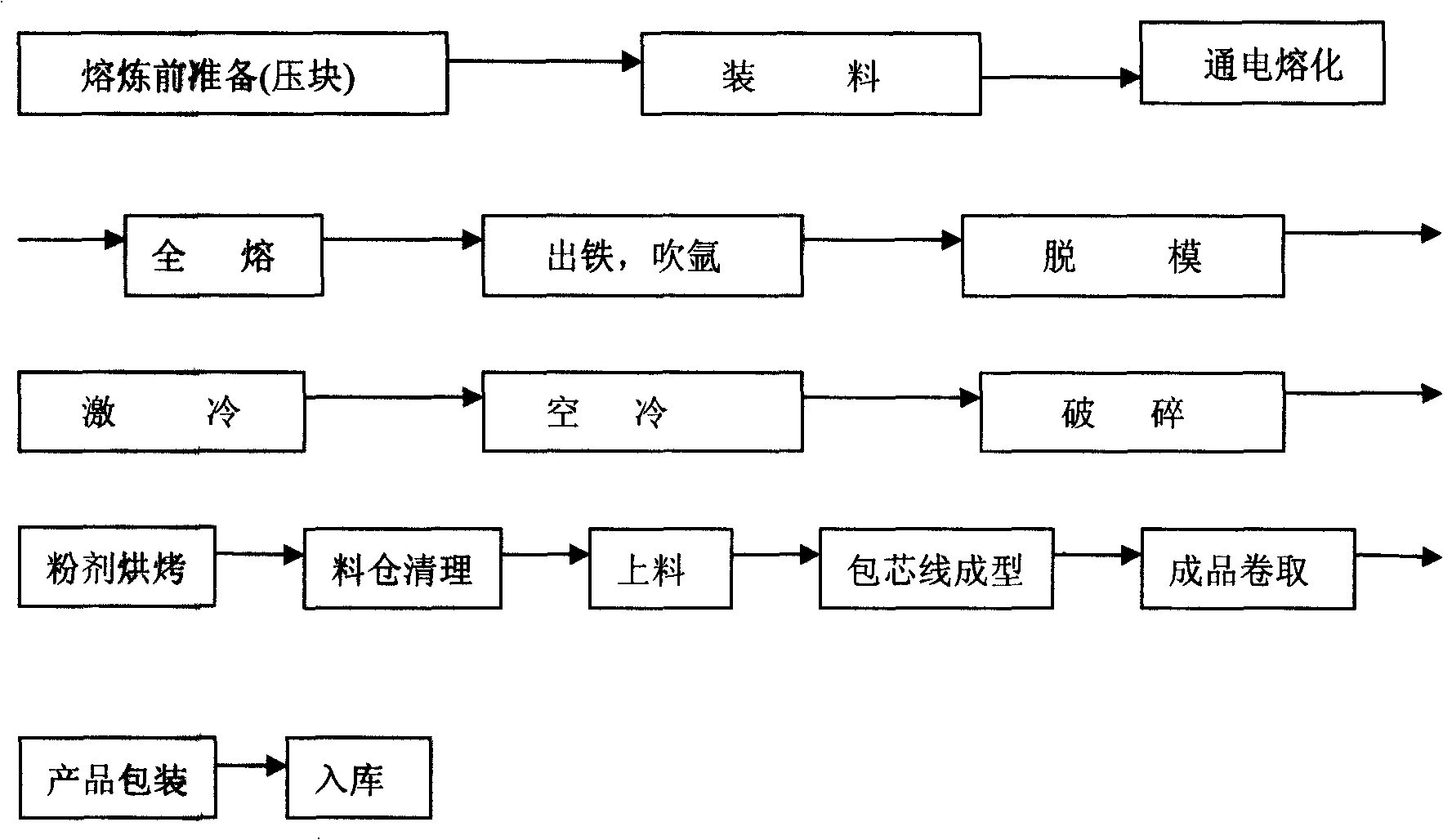

[0090] Embodiment 2 The manufacturing method of the cored wire using the low nitrogen and low aluminum ferro-titanium of the present invention

[0091] Artificially crush the cooled low-nitrogen, low-aluminum ferrotitanium to particles of about 60mm, and then use a jaw crusher to crush it to 20-60mm, and then continue to crush the 20-60mm ferrotitanium block to less than 2mm by using a double-roller machine titanium powder.

[0092] At this time, the content of nitrogen in the low-nitrogen and low-aluminum ferro-titanium is ≤0.08% by weight, and the content of aluminum in weight percentage is ≤0.5%;

[0093] Then, the low-nitrogen, low-aluminum ferro-titanium iron powder is wound into a cored wire by using a cored wire machine and a steel belt.

[0094] According to the manufacturing method of the low-nitrogen, low-aluminum titanium-iron cored wire of the present invention, the core-spun strip used for the low-nitrogen, low-aluminum titanium-iron cored wire is a high-quality ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com