Aluminum oxide for chemical mechanical polishing liquid and preparation method of aluminum oxide

A technology of chemical machinery and preparation technology, applied in the direction of alumina/aluminum hydroxide, aluminate/aluminum oxide/aluminum hydroxide purification, and other chemical processes, to achieve good polishing stability, simple preparation process, and wide source of raw materials Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

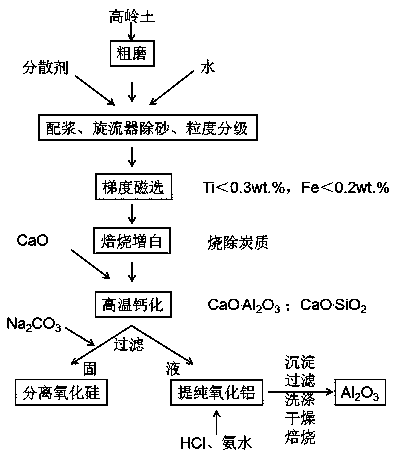

Method used

Image

Examples

Embodiment 1

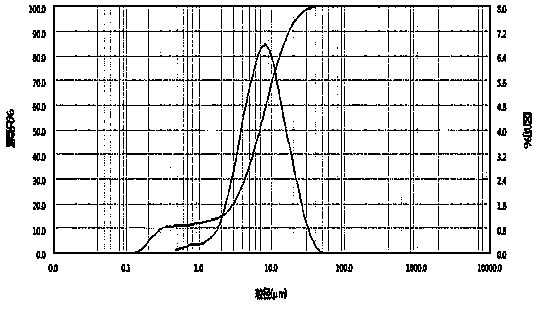

[0043] A process for preparing aluminum oxide for chemical mechanical polishing fluid, comprising the steps of:

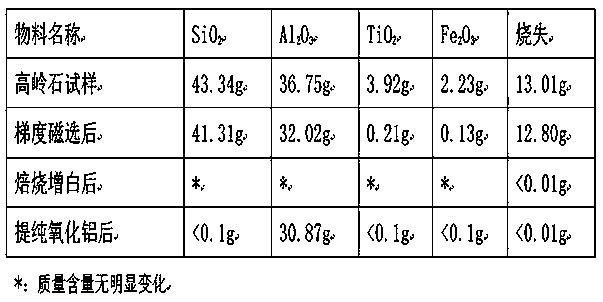

[0044] (1) Pulping and grading to obtain magnetic separation materials: Coarsely grind kaolinite, mix slurry, and perform sand removal and particle size classification in a cyclone. The mass ratio of the slurry mix is kaolin after coarse grinding: dispersant: water =0.05:0.001:1, the stirring speed of mixing slurry is 500r / min, the stirring time is 1h, the content of kaolin with the particle size less than 3mm is greater than 90%, and the raw material for magnetic separation is obtained.

[0045] (2) Gradient magnetic separation to remove iron and titanium: background magnetic field strength 1.5*10 4 Oe, flow rate 1cm / s; magnetization period 3min, so that the titanium content is lower than 0.3wt.%, and the iron content is lower than 0.2wt.%.

[0046] (3) Roasting whitening and simple phase transition: dehydration, drying, roasting, roasting temperature 800 o C,...

Embodiment 2

[0056] 1. A process for preparing aluminum oxide for chemical mechanical polishing fluid, comprising the steps of:

[0057] (1) Pulping and grading to obtain magnetic separation materials: Coarsely grind kaolinite, mix slurry, and perform sand removal and particle size classification in a cyclone. The mass ratio of the slurry mix is kaolin after coarse grinding: dispersant: water =(0.1):(0.005):1, the mixing speed of slurry is 650r / min, the stirring time is 2h, the content of kaolin with a particle size of less than 3mm is greater than 90%, and the raw material for magnetic separation is obtained.

[0058] (2) Gradient magnetic separation to remove iron and titanium: background magnetic field strength 1.5*10 4 Oe, flow rate 1.5cm / s; magnetization period 5.5min, so that the titanium content is lower than 0.3wt.%, and the iron content is lower than 0.2wt.%.

[0059] (3) Roasting whitening and simple phase transition: dehydration, drying, roasting, roasting temperature 950 o ...

Embodiment 3

[0066] A process for preparing aluminum oxide for chemical mechanical polishing fluid, comprising the steps of:

[0067] (1) Pulping and grading to obtain magnetic separation materials: Coarsely grind kaolinite, mix slurry, and perform sand removal and particle size classification in a cyclone. The mass ratio of the slurry mix is kaolin after coarse grinding: dispersant: water =0.15:0.01:1, the mixing speed of slurry is 800r / min, the stirring time is 3h, the content of kaolin with the particle size less than 3mm is greater than 90%, and the raw material for magnetic separation is obtained.

[0068] (2) Gradient magnetic separation to remove iron and titanium: background magnetic field strength 1.5*10 4 Oe, flow rate 2cm / s; magnetization period 8min, so that the titanium content is lower than 0.3wt.%, and the iron content is lower than 0.2wt.%.

[0069] (3) Roasting whitening and simple phase transition: dehydration, drying, roasting, roasting temperature 1100 o C, heating ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com