Pre-melting slag for electroslag remelting titanium-containing steel and method for preparing electroslag remelting low-oxygen titanium-containing steel through deoxidation

A technology of electroslag remelting and oxygen-containing titanium steel, which is applied in the field of electroslag metallurgy and electroslag remelting high-end special steel, which can solve the problems of titanium dioxide volatile, uneven titanium dioxide, uneven aluminum and titanium composition, surface quality, etc. problems, to achieve the effect of reducing oxygen content, uniform content, and uniform composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] A pre-melted slag for electroslag remelting titanium-containing steel, consisting of A pre-melted slag and B pre-melted slag;

[0047] In A pre-melted slag, each component and weight percent are as follows:

[0048]

[0049] In the B pre-slag, each component and weight percentage are as follows:

[0050] .

[0051] Using conventional methods, the CaF 2 , CaO, MgO, Al 2 o 3 After mixing and stirring, melt in an electric arc furnace, and obtain A pre-slag after cooling and crushing; CaF 2 , CaO, MgO, Al 2 o 3 、TiO 2 After mixing and stirring, it is melted in an electric arc furnace, cooled and crushed to obtain B pre-slag.

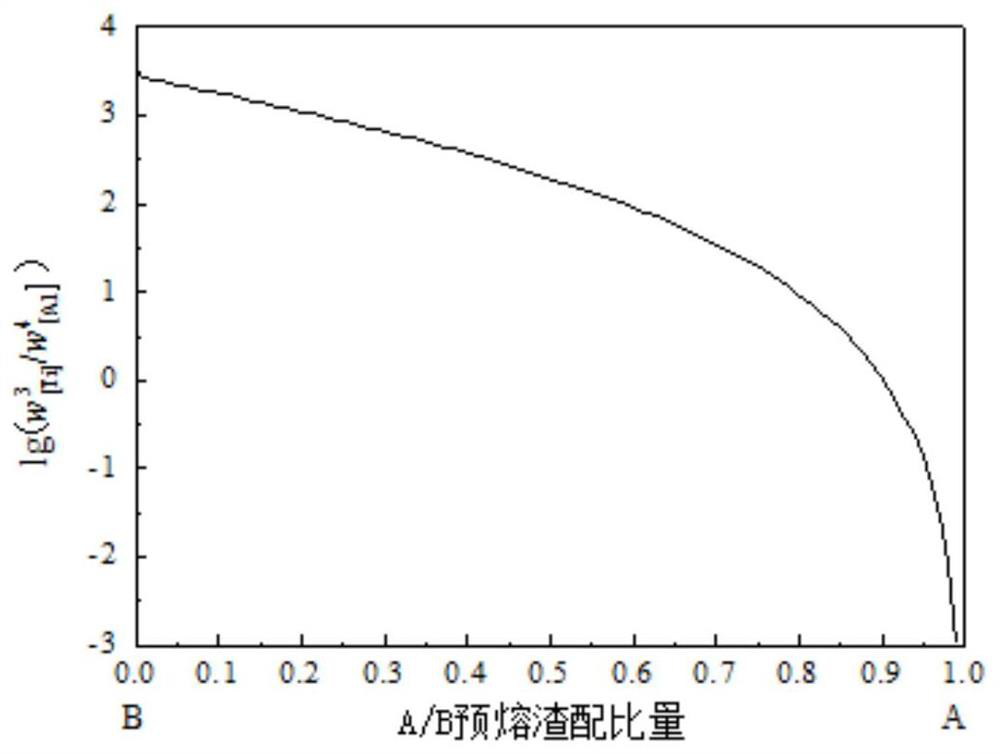

[0052] Mix A pre-melted slag and B pre-melted slag to obtain pre-melted slag for electroslag remelting titanium-containing steel; assuming x For the ratio content of pre-slag A, (1- x ) is the ratio of pre-slag B, x The selection of is shown in the formula (4), according to the formula (4) to draw figure 1 ,for With the change curve...

Embodiment 2

[0057] For the GH2132 superalloy, the composition of its products is shown in Table 1. The upper limit of aluminum and titanium elements in the product is Al: 0.35%, Ti: 2.3%. Vacuum induction melting furnace is used to conventionally smelt and cast electrode rods as consumable electrodes; in consumable electrodes, Al: 0.3%, Ti: 2%, O: 0.0006%, adopt the method established by the present invention, refer to figure 1 And formula (4), the mixing ratio of A and B slags is determined to be 2.2:7.8, that is, the mass percentage of A pre-melted slag is 22%, and the mass percentage of B pre-melted slag is 78%.

[0058] Using the A pre-melted slag and B pre-melted slag of Example 1, the electroslag remelting is carried out on an electroslag furnace with a capacity of 5000kg and an inner diameter of the crystallizer of 66cm. The current and voltage are respectively 15000A and 60V, and the electrode diameter is 50cm. The amount of slag is 180kg (A pre-melted slag is 39.6kg, B pre-melted...

Embodiment 3

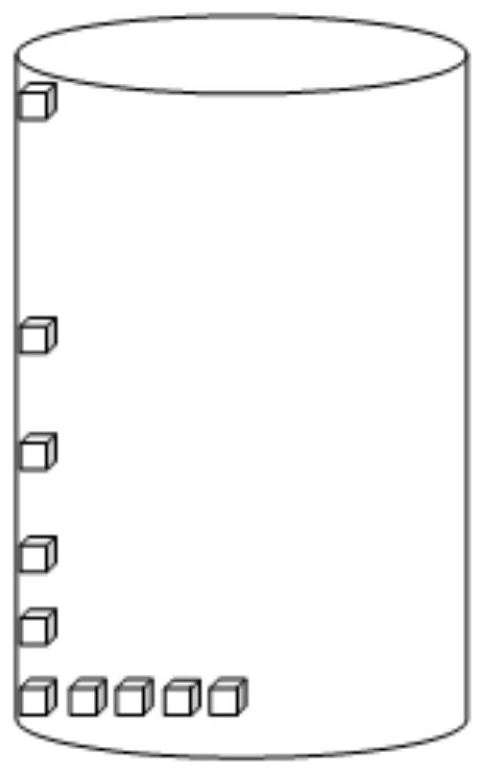

[0085] see Figure 7 , a deoxidizer conveying device for electroslag remelting, consisting of a frequency conversion motor 2, a frequency converter 3, a gear box 4, a deoxidizer loading bin 5, a deoxidizer conveying chamber 6, a deoxidizer conveying screw rod 7, and a deoxidizer conveying pipe 9. The deoxidizer slide tube 15 and the base 17 are composed of an insulating ferrule 16 between the deoxidizer delivery pipe and the deoxidizer slide tube. The deoxidizer delivery pipe and the deoxidizer slide tube are not in contact, and are respectively inserted into the insulating ferrule for communication. In this way, insulation communication is formed to avoid electric transmission; a stirring rod 18 is installed on the gear box, and the stirring rod is inserted into the deoxidizer delivery chamber to stir the deoxidizer in the deoxidizer delivery chamber.

[0086] The deoxidizer conveying screw and stirring rod are installed on the gearbox (double-shaft gearbox), and the gearbox ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com