Production method of aluminum-free bearing steel

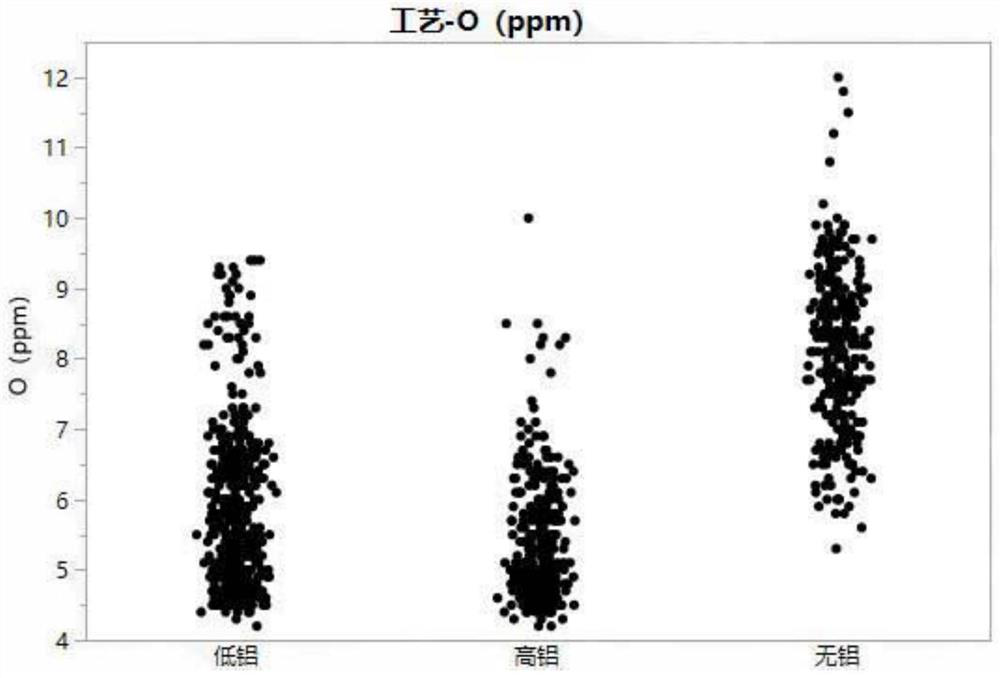

A production method and technology of aluminum bearings, which are applied in the field of metallurgy, can solve problems such as the quality of clogged molten steel, the inner diameter of the nozzle becomes smaller, and the pourability of molten steel is low, so as to solve the problem of castability, improve castability, and improve the quality of finished products. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) After the steel scrap and desulfurized hot metal are decarburized, dephosphorized, carbon-preserved and heated up in the primary smelting furnace, the steel is tapped, and the target carbon content is controlled above 0.15%;

[0033] (2) The tapping process uses low-aluminum and low-titanium alloys for tapping alloying;

[0034] (3) Use sliding plate to stop slag in converter tapping;

[0035] (4) Molten steel is hoisted to refining using low-aluminum and low-titanium ferrosilicon, high-purity silicon carbide, and metal manganese for enhanced deoxidation alloying operations, and the basicity of the slag is controlled at 1.8;

[0036] (5) Add quartz sand after controlling the element composition to meet the process requirements and oxygen content requirements, and the alkalinity of the slag is reduced to 1.2;

[0037] (6) The high vacuum pressure holding time is controlled at 28 minutes, and soft blowing is performed until continuous casting after air breaking;

[...

Embodiment 2

[0041] (1) After the steel scrap and desulfurized hot metal are decarburized, dephosphorized, carbon-preserved and heated up in the primary smelting furnace, the steel is tapped, and the target carbon content is controlled above 0.15%;

[0042] (2) The tapping process uses low-aluminum and low-titanium alloys for tapping alloying;

[0043] (3) Use sliding plate to stop slag in converter tapping;

[0044] (4) Molten steel is hoisted to refining using low-aluminum and low-titanium ferrosilicon, high-purity silicon carbide, and metal manganese for enhanced deoxidation alloying operations, and the basicity of the slag is controlled at 1.9;

[0045] (5) Add quartz sand after controlling the element composition to meet the process requirements and oxygen content requirements, and the alkalinity of the slag is reduced to 1.1;

[0046] (6) The high-vacuum holding time is controlled at 32 minutes, and soft blowing is carried out to continuous casting after breaking the air;

[0047] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com