Calcium-titanium composite material as well as preparation method and application thereof

A composite material, perovskite technology, applied in the field of photoactive materials, can solve the problems of low infrared light water splitting efficiency, high energy consumption, high titanium content and other problems of perovskite composite materials, which is beneficial to commercial production and industrial application, Effects of energy consumption reduction and titanium content reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

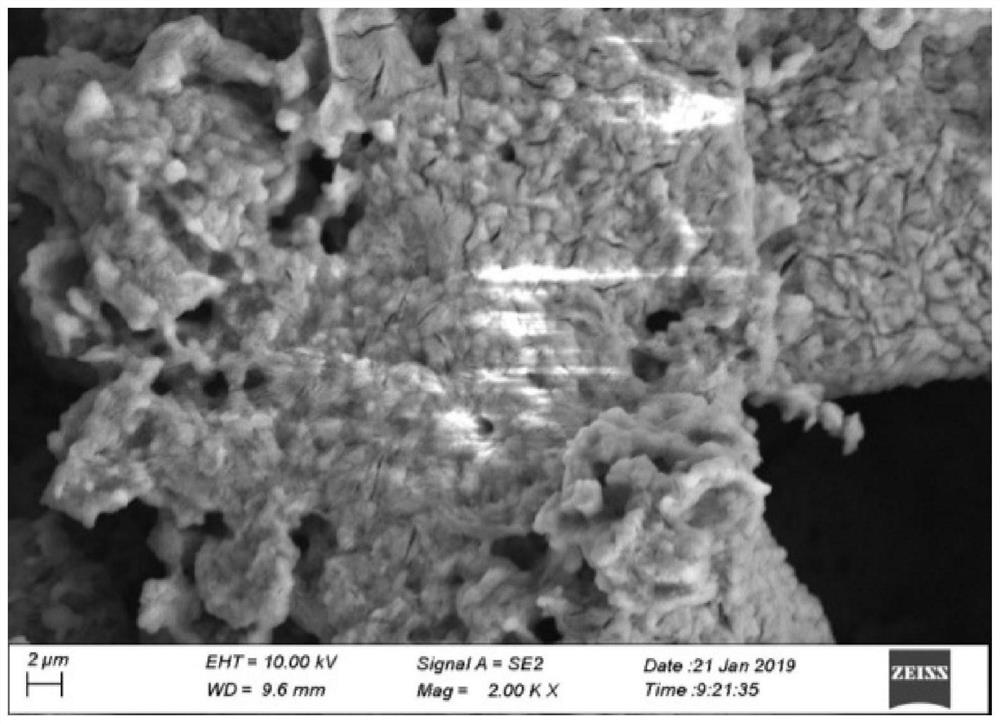

[0077] Preparation method of calcium titanium composite material:

[0078] (1) Under the condition of 16° C., 5 g of calcium source powder was dispersed in 50 mL of water by stirring to obtain a suspension of calcium source powder, and the calcium source was calcium carbonate;

[0079] (2) The glass bottle that titanium tetrachloride liquid is housed is connected on the glass bottle that the suspension of calcium source powder is housed by plastic pipe, the reaction time of the suspension of the calcium source powder of control titanium tetrachloride steam and stirring 10min;

[0080] (3) After the reaction time finishes, disconnect the pipeline that feeds titanium tetrachloride, add the CaCl that forms in the sodium hydroxide neutralization suspension 2 , until the pH of the suspension is 9-10;

[0081] (4) The product of step (3) is filtered and washed with water until it does not contain Cl - , and then dried at 60° C. for 4 hours to obtain the perovskite composite mater...

Embodiment 2

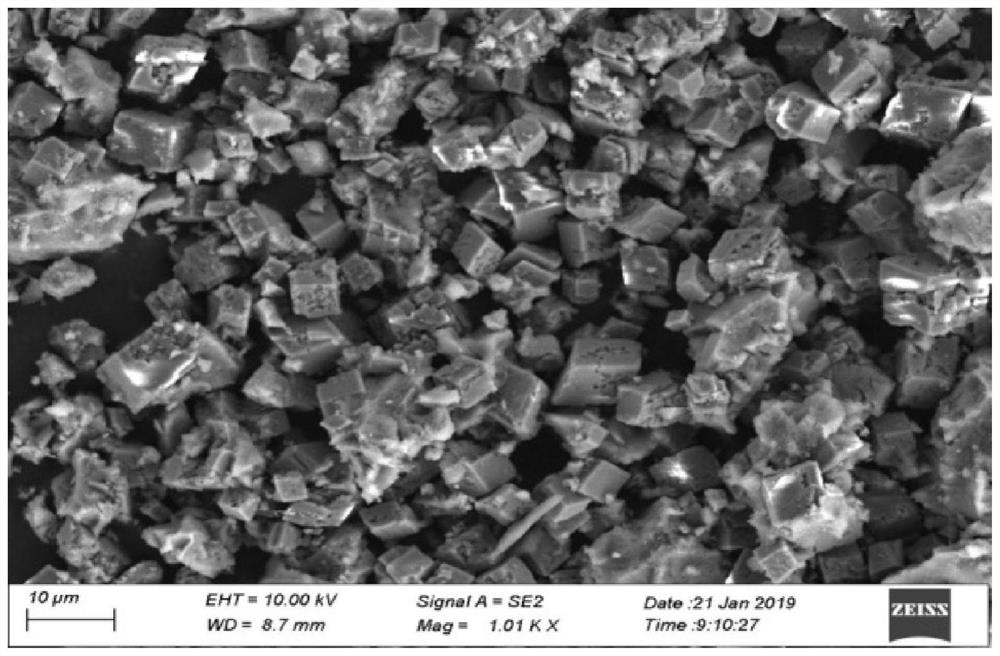

[0083] Preparation method of calcium titanium composite material:

[0084] (1) Under the condition of 16° C., 5 g of calcium source powder was dispersed in 50 mL of water by stirring to obtain a suspension of calcium source powder, and the calcium source was calcium carbonate;

[0085] (2) The glass bottle that titanium tetrachloride liquid is housed is connected on the glass bottle that the suspension of calcium source powder is housed by plastic pipe, the reaction time of the suspension of the calcium source powder of control titanium tetrachloride steam and stirring 10min;

[0086] (3) After the reaction time finishes, disconnect the pipeline that feeds titanium tetrachloride, add the CaCl that forms in the sodium carbonate neutralization suspension 2 , until the pH of the suspension is 9-10;

[0087] (4) The product of step (3) is filtered and washed with water until it does not contain Cl - , and then dried at 60° C. for 4 hours to obtain the perovskite composite mater...

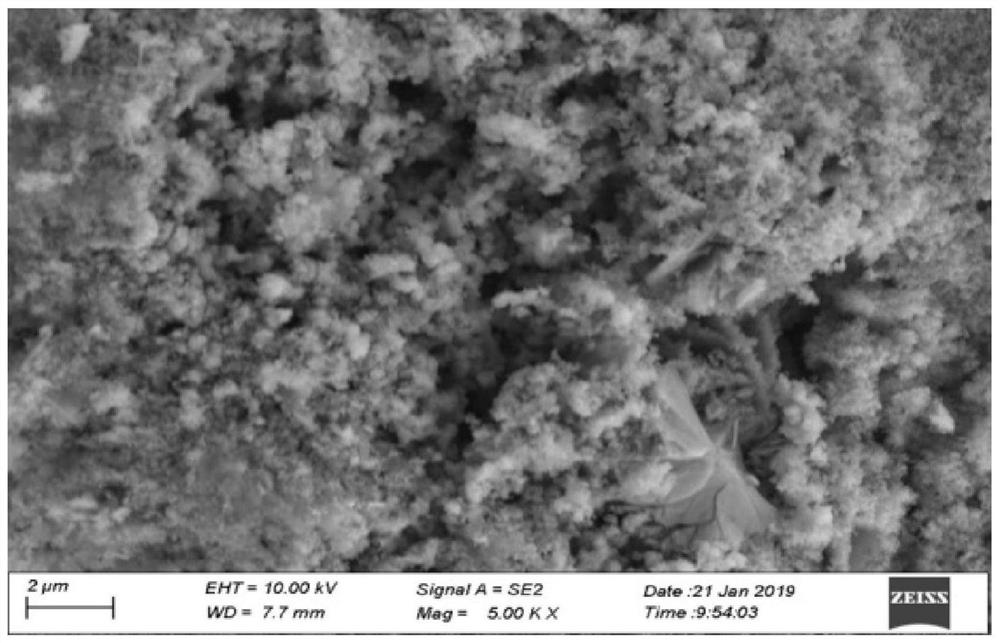

Embodiment 3

[0089] In this embodiment, the calcium source in Example 1 is replaced by calcium oxide, and other conditions are completely the same as those in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com