Titanium-silicon alloy material and preparation method thereof

A titanium-silicon alloy and raw material technology, which is applied in the field of metallurgy, can solve the problems of cumbersome raw material processing, etc., and achieve the effect of low alloy density, wide source of raw materials, and easy separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

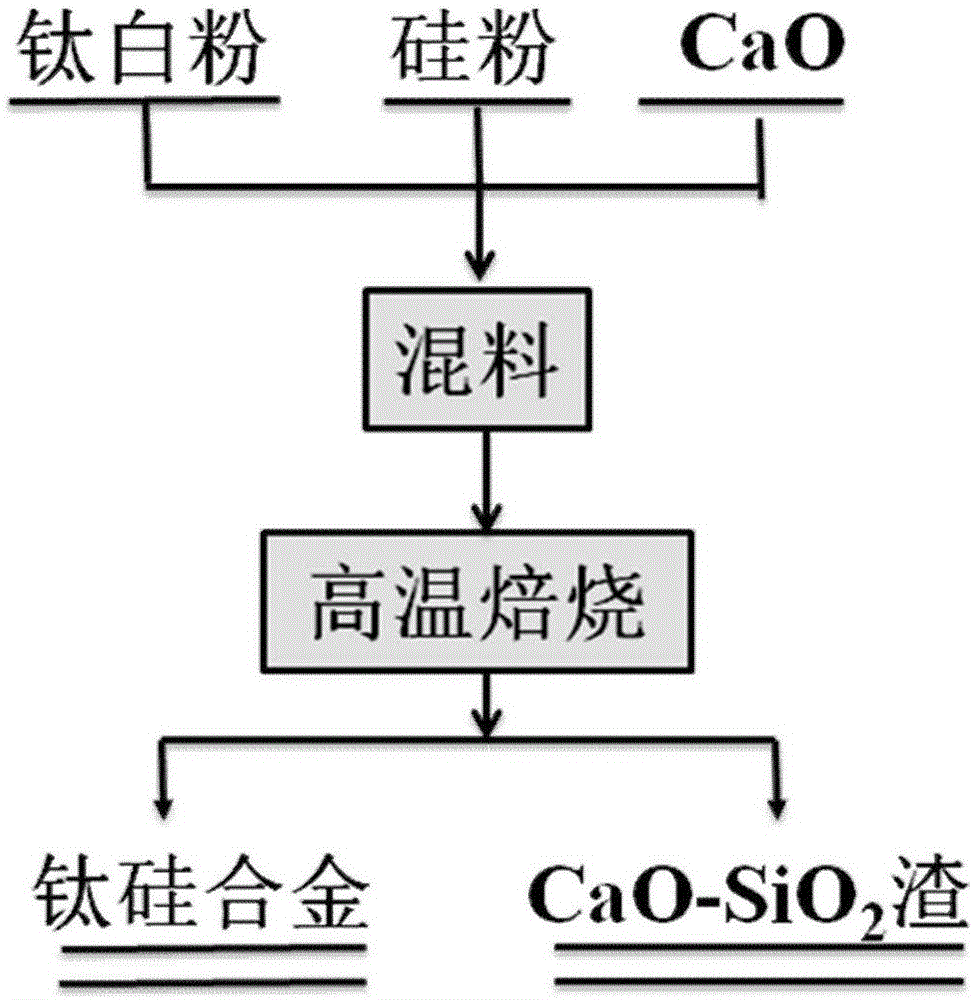

[0032] 2. The preparation method of titanium-silicon alloy material, such as figure 1 As shown in the flowchart of the preparation method of the titanium-silicon alloy material of the present invention, it comprises the following steps:

[0033] a. Ingredients: 35.7-38.5 parts by weight of titanium dioxide, 26.9-32 parts by weight of silicon powder, and 25-34.6 parts by weight of calcium oxide;

[0034] b. Mixing: Mix the ingredients prepared in step a evenly;

[0035] c. Roasting: roast the raw materials mixed in step b, the roasting temperature is 1450-1600°C, and the roasting time is 10-30 minutes;

[0036] d. Cooling: cooling the raw material roasted in step c to realize effective separation of titanium-silicon alloy and molten slag.

[0037] Wherein, after step d is cooled as figure 2 As shown in the figure of the titanium-silicon alloy material sample prepared by the present invention, the slag is on the surface of the titanium-silicon alloy, and the color is differe...

Embodiment 1

[0047] Weigh 37.1 parts by weight of titanium dioxide, 29.6 parts by weight of silicon powder, and 33.3 parts by weight of CaO. Add the above raw materials into a ball mill for mixing and ball milling for 1 hour. The samples obtained after mixing were placed in a muffle furnace for calcination at 1550°C, and the calcination time was 20 minutes. The calcined alloy material is naturally cooled in an air atmosphere to obtain titanium-silicon alloy and slag.

[0048] The measured main chemical components of the titanium-silicon alloy material are: 54.5 parts by weight of Ti, 43.5 parts by weight of Si, 1.3 parts by weight of O, and 0.8 parts by weight of others; the calculated titanium yield is 90%.

Embodiment 2

[0050] Weigh 38.5 parts by weight of titanium dioxide, 26.9 parts by weight of silicon powder, and 34.6 parts by weight of CaO. Add the above raw materials into a ball mill for mixing and ball milling for 1 hour. Add the mixed raw materials into the corundum crucible, and then put the mixed samples into the muffle furnace for roasting at 1500°C for 30 minutes. The calcined alloy material is naturally cooled in an air atmosphere to obtain titanium-silicon alloy and slag.

[0051] The measured main chemical components of the titanium-silicon alloy material are: 57.1 parts by weight of Ti, 41.9 parts by weight of Si, 2.3 parts by weight of O, and 1 part by weight of others; the calculated titanium yield is 92%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com