Light gasoline hydrocarbon recombination etherification catalytic rectification process and device thereof

A technology of catalytic distillation and light gasoline, which is applied in the petroleum industry and the treatment of hydrocarbon oil, etc. It can solve the problems of ineffective use of heat, large difference in reaction temperature, and poor etherification effect, so as to avoid heat-induced sulfonic acid groups. The effects of mass loss, improving balance conversion rate, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

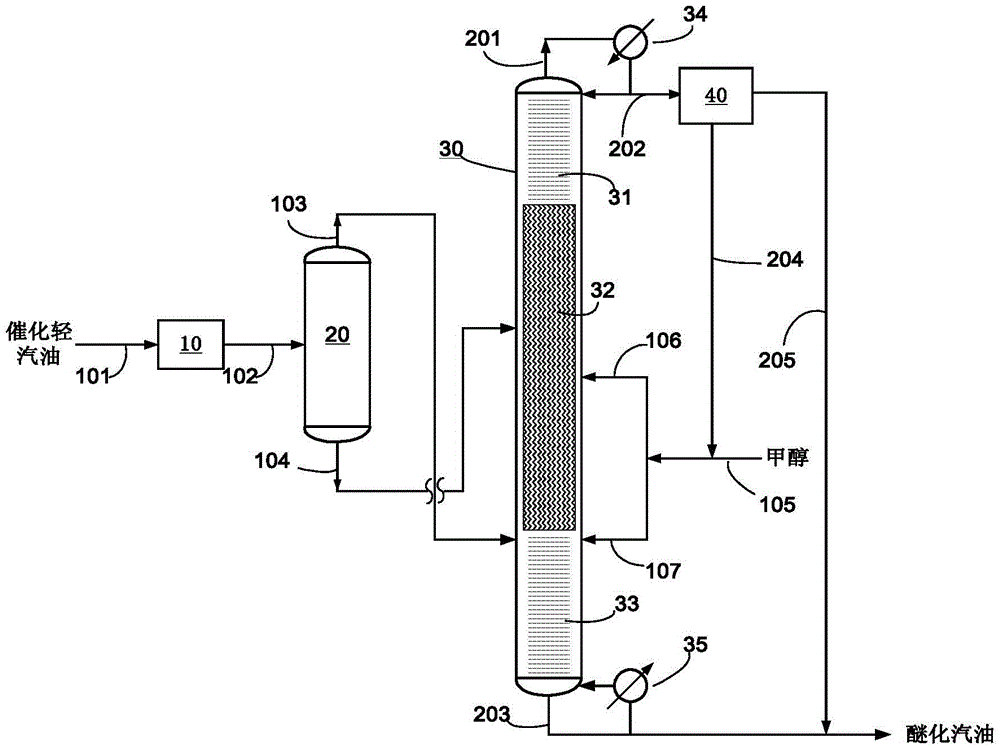

[0054] This embodiment provides a light gasoline hydrocarbon reforming etherification catalytic rectification device ( figure 1 It is the device schematic diagram of embodiment 1 of the present invention), and the device comprises the following parts:

[0055] Preprocessor 10, flash tank 20, catalytic distillation tower 30, alcohol and hydrocarbon separation device 40; catalytic distillation tower 30 includes total condenser 34, reboiler 35 and rectification section 31 of main part, reaction section 32, Stripping section 33;

[0056] The light gasoline feedstock pipeline 101 is communicated with the inlet of the preprocessor 10, and the outlet of the preprocessor 10 is communicated with the inlet of the flash tank 20 through the flash tank feed line 102 arranged in the middle of the flash tank;

[0057] The top of the flash tank 20 communicates with the bottom of the reaction section 32 of the catalytic distillation tower through the light component feed line 103, and the bot...

Embodiment 2

[0062] This embodiment provides a catalytic rectification process for reforming etherification of light gasoline hydrocarbons, which utilizes the catalytic rectification device for reforming etherification of light gasoline hydrocarbons in Example 1.

[0063] The diameter of the catalytic rectification tower 30 is 50mm, the height of the rectification section 31 is 800mm, and the stainless steel corrugated wire mesh packing is packed, the height of the reaction section 32 is 1600mm, and the macroporous sulfonic acid resin catalyst component is packed, and the height of the stripping section 33 is 900mm. Stainless steel θ ring packing;

[0064] The light gasoline hydrocarbon reforming etherification catalytic rectification process provided in this embodiment comprises the following steps:

[0065] The light gasoline raw material is firstly removed from the basic nitrogen through the preprocessor 10, and then enters the flash tank 20 through the flash tank feed line 102. The g...

Embodiment 3

[0070] This embodiment provides a catalytic rectification process for reforming etherification of light gasoline hydrocarbons. The difference between the catalytic rectification device for reforming etherification of light gasoline hydrocarbons used in this process and the device in Example 1 is that the bottom of the flash tank 20 is Communication with the top of the reaction section 32 of the catalytic distillation column is through a heavies feed line 104 .

[0071] The light gasoline hydrocarbon reforming etherification catalytic rectification technological process in the present embodiment is identical with embodiment 2, and difference is that the liquid phase component that flash tank 20 comes out is introduced from the top of reaction section 32 of catalytic distillation tower, And the relative height and process condition parameter changes of rectification section, reaction section and stripping section, specifically:

[0072] The diameter of the catalytic rectificatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com