A kind of method for preparing sec-butyl acetate

A technology of sec-butyl acetate and n-butene, applied in the field of preparation of sec-butyl acetate, can solve the problems such as difficult control of reaction hot spot temperature, poor selectivity of sec-butyl acetate, different reaction heat, etc., and prolong the service life. , The effect of strong controllability of response and precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

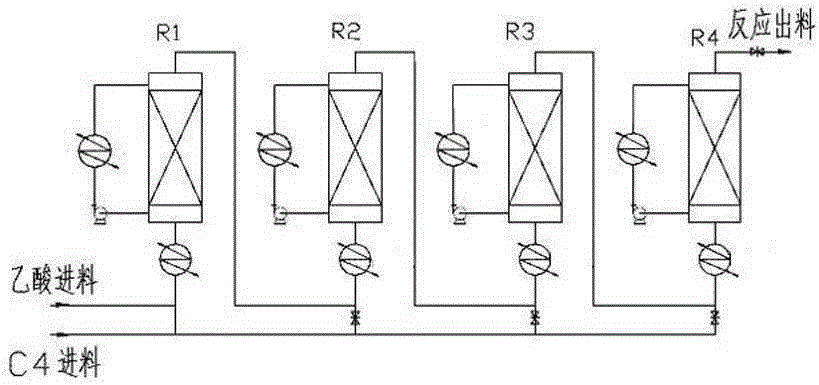

[0027] 300ml of good strong acidic cation exchange resin catalysts with catalytic activity are respectively housed in four series-connected tubular fixed-bed reactors R1, R2, R3, R4. At the same time, the speed is continuously passed into R1, and flows through R2, R3 and R4 in sequence. The mass composition of the C4 mixture is: isobutane 11%, n-butane 16.9%, 1-butene 38.96%, cis-2-butene 13.58%, trans-2-butene 18.76%, and the total content of n-butene is 71.3%. The reactor feed temperature is sequentially: 50°C, 53°C, 60°C, 65°C. The jacket water temperature of the four reactors is controlled by adjusting the jacket water volume and the circulating water volume of the jacket water cooler: 50°C, 53°C, 60°C, and 65°C. The pressure of the reaction system is maintained at 1.20 MPa by controlling the back pressure valve.

[0028] The results of sampling and analysis at the outlet of R4 are as follows: the conversion rate of butene is 92%, and the mass content of sec-butyl aceta...

Embodiment 2

[0030] 300ml of strong acidic cation exchange resin catalysts with good catalytic activity are respectively housed in four series-connected tubular fixed-bed reactors R1, R2, R3, and R4, and acetic acid is continuously passed through from R1 at a speed of 4.5 kg / hour. into and flow through R2, R3 and R4 in sequence, and the C4 mixture is divided into four streams and enters R1, R2, R3, R4 respectively at a feed rate of 0.75 kg / h, 0.75 kg / h, 0.50 kg / h, and 0.50 kg / h. middle. The mass composition of the C4 mixture is: isobutane 6.21%, n-butane 11.95%, 1-butene 45.64%, cis-2-butene 14.74%, trans-2-butene 20.77%, and the total content of n-butene is 81.15%. The reactor feed temperature is sequentially: 52°C, 55°C, 58°C, 63°C. The jacket water temperature of the four reactors is controlled by adjusting the jacket water volume and the circulating water volume of the jacket water cooler: 52°C, 55°C, 58°C, and 63°C. The pressure of the reaction system is controlled by the back pres...

Embodiment 3

[0033] 300ml of strong acidic cation exchange resin catalyst with good catalytic activity is installed in each of R1 and R2 two tubular fixed-bed reactors, and 300ml of catalytic activity catalyst is installed in each of R3 and R4 two tubular fixed-bed reactors. Same catalyst in the mid-term. Acetic acid is simultaneously and continuously fed into R1 at a rate of 4.5 kg / h and C4 mixture at a rate of 2.5 kg / h, and flows through R2, R3 and R4 in sequence. The mass composition of the C4 mixture is: isobutane 11.37%, n-butane 16.22%, 1-butene 33.19%, cis-2-butene 17.01%, trans-2-butene 20.99%, and the total content of n-butene is 71.19%. The reactor feed temperature is: 55°C, 60°C, 90°C, 90°C in sequence. The jacket water temperature of the four reactors is controlled by adjusting the jacket water volume and the circulating water volume of the jacket water cooler: 55°C, 60°C, 90°C, and 90°C. The pressure of the reaction system is controlled by the back pressure valve to be 1.20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com