Hydrogen sulfide wet sulfuric acid preparation method with low emission

A process method, hydrogen sulfide technology, applied in chemical instruments and methods, sulfur compounds, chemical industry, etc., can solve the problems of unattainable concentration, and achieve the effect of improving the equilibrium conversion rate and the total conversion rate of SO2

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

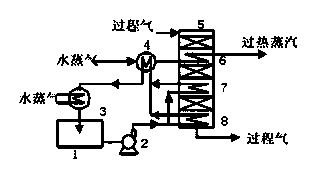

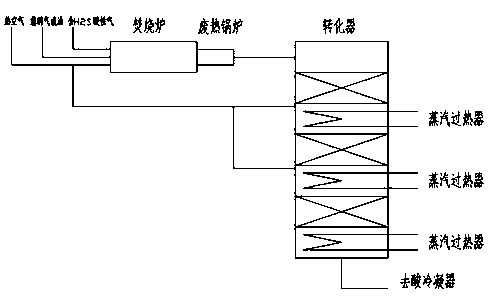

Image

Examples

Embodiment 1

[0022] Taking the hydrogen sulfide acid gas removed from a certain coke oven gas as an example, the process method of the present invention is illustrated.

[0023] Hydrogen sulfide acid gas conditions:

[0024] Flow 3482Nm 3 / h

[0025] Pressure 0.03MPa

[0026] temperature 40°C

[0027] Gas composition (volume%)

[0028] h 2 S 13.92

[0029] CO 2 82.25

[0030] NH 3 0.11

[0031] HCN 0.19

[0032] h 2 O 3.45

[0033] CH 4 772PPM

[0034] N 2 balance

[0035] Combust hydrogen sulfide acid gas and excess hot air in an incinerator to generate process gas with composition:

[0036] Gas composition (volume%)

[0037] SO 2 3.41

[0038] SO 3 0.18

[0039] o 2 10.0

[0040] CO 2 21.3

[0041] h 2 O 6.61

[0042] N 2 58.49

[0043] The process gas is catalyzed and oxidized...

Embodiment 2

[0045] Taking the hydrogen sulfide acid gas eluted by a certain low-temperature methanol as an example, the process method of the present invention is illustrated.

[0046] Hydrogen sulfide acid gas conditions:

[0047]Flow 200Nm 3 / h

[0048] Pressure 0.03 MPa

[0049] temperature 40°C

[0050] Gas composition (volume%)

[0051] h 2 S 30.0

[0052] CO 2 62.84

[0053] C 3 h 8 1.0

[0054] C 4 h 10 1.85

[0055] CH 3 OH 0.15

[0056] N 2 0.75

[0057] Combust hydrogen sulfide acid gas and excess hot air in an incinerator to generate process gas with composition:

[0058] Gas composition (volume%)

[0059] SO 2 3.07

[0060] SO 3 0.16

[0061] o 2 12.07

[0062] CO 2 7.91

[0063] h 2 O 6.06

[0064] N 2 70.73

[0065] The process gas is catalyzed and oxidized thro...

Embodiment 3

[0067] Taking the hydrogen sulfide acid gas removed by a certain refinery as an example, the process method of the present invention is illustrated.

[0068] Hydrogen sulfide acid gas conditions:

[0069] Flow 2000Nm 3 / h

[0070] Pressure 0.06MPa

[0071] temperature 61 °C

[0072] Gas composition (volume%)

[0073] h 2 S 73.1

[0074] CO 2 21.7

[0075] C 3 h 8 0.4

[0076] NH 3 1.07

[0077] h 2 O 3.37

[0078] Combust hydrogen sulfide acid gas and excess hot air in an incinerator to generate process gas with composition:

[0079] Gas composition (volume%)

[0080] SO 2 4.35

[0081] SO 3 0.23

[0082] o 2 12.75

[0083] CO 2 1.44

[0084] h 2 O 6.65

[0085] N 2 74.59

[0086] The process gas is catalyzed and oxidized by the three-stage catalyst bed. After the first and second be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com