Patents

Literature

60results about How to "Reduce waste disposal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing L-ornithine-L-aspartate

InactiveCN101100435AReduce waste disposalSimple processOrganic compound preparationAmino-carboxyl compound preparationChemistryActivated carbon

Production of L-2, 5-diaminovaleric acid-L-asparto salt by chemical synthesis is carried out by dissolving L-2, 5-diaminovaleric acid sulfate into distilled water, putting L-asparto, heating while dissolving, neutralizing sulfuric acid by barium hydroxide, cooling, filtering to remove diluted barium sulfate, chelating residual barium ion (Ba+2) by D403 chelate resin, filtering to remove chelating resin, decompressing while concentrating, de-coloring by activated carbon, filtering to remove activated carbon, agitating by anhydrous alcohol, heating, crystallizing under reflux state, filtering and drying to obtain final product. It avoids resin adsorption, resin recovery process and acid water treatment.

Owner:上海依福瑞实业有限公司

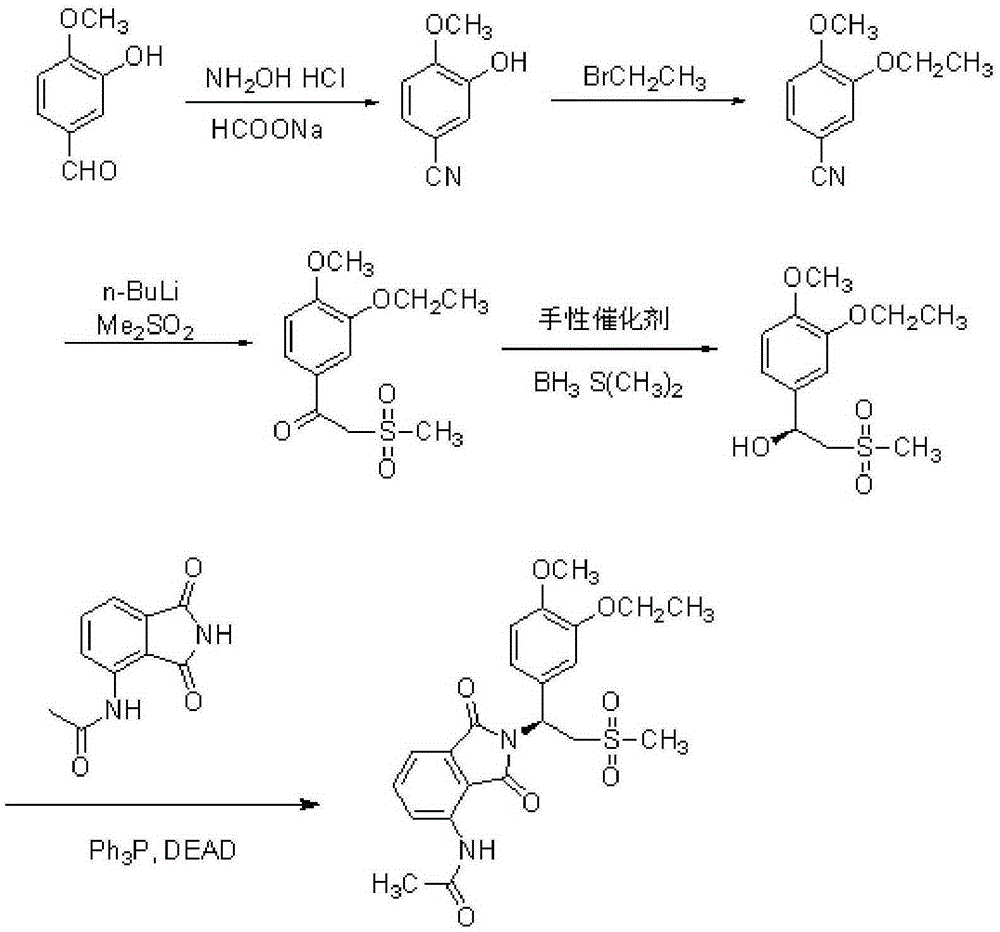

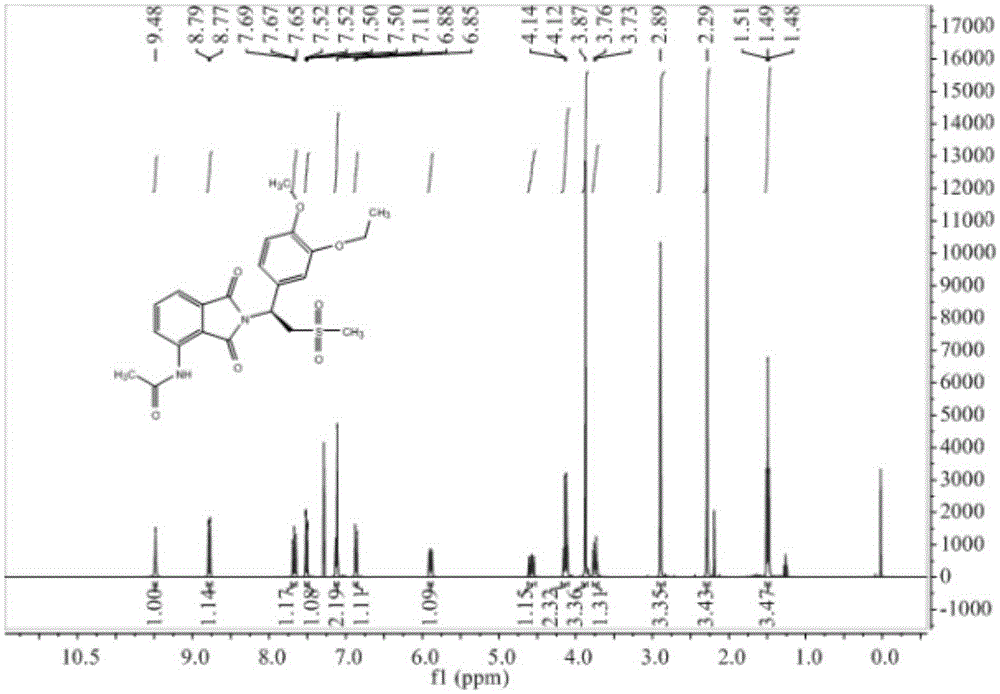

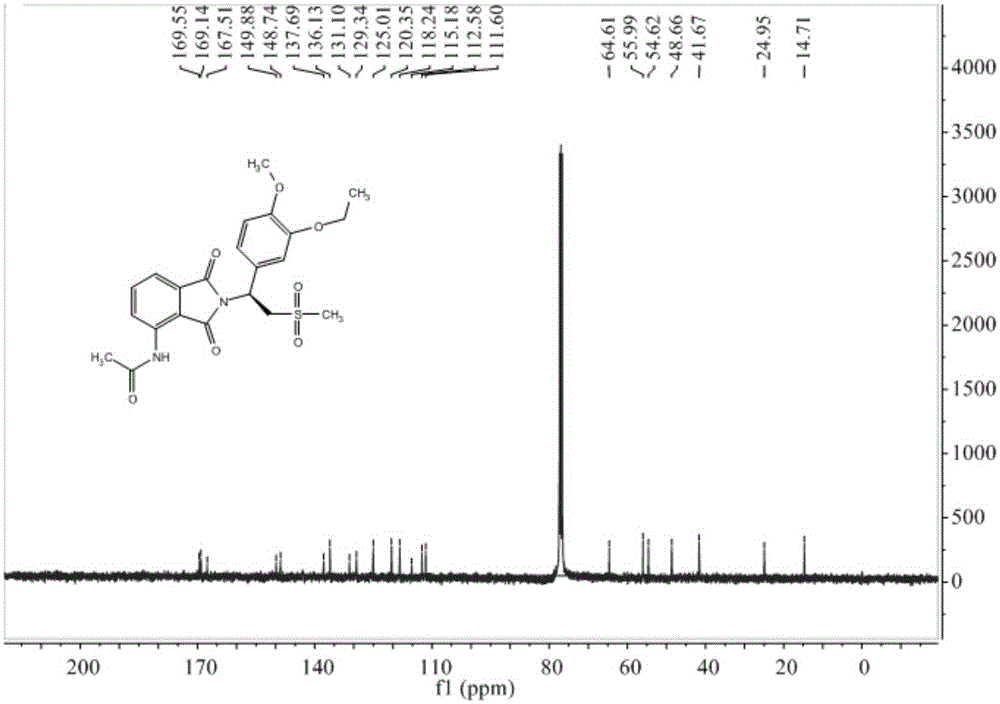

Preparation method of Apremilast

InactiveCN105330586AAvoid splittingReduce waste disposalOrganic chemistryBromineBENZYL ALCOHOL/WATER

The invention relates to a preparation method of Apremilast, comprising the following steps: by taking 3-hydroxy-4-methoxybenzaldehyde as a staring material, reacting with hydroxylamine hydrochloride to obtain 3-hydroxy-4-methoxy cyanobenzene, reacting with bromoethane to obtain 3-ethyoxyl-4-methoxy cyanobenzene, and then reacting with dimethyl sulfone under the action of n-butyllithium, and hydrolyzing in aqueous hydrochloric acid solution to obtain 1-(3-ethyoxyl-4-methoxyphenyl)-2-(mesyl)ketol); finally by taking S-(-)-alpha, alpha-diphenyl-2-pyrrolidine methanol as a chiral catalyst and taking borane dimethyl sulfide complex solution as a reductant, obtaining chirality S-3-ethyoxyl-4-methoxy group-alpha[(mesyl)benzyl alcohol], and then reacting with 3-acetamido-phthalimide under the action of triphenylphosphine and diethyl azodicarboxylate, thus obtaining the Apremilast. According to the preparation method, the process is effectively simplified, the reaction conditions are mild, the product yield and purity are relatively high, and large-scale industrial production is benefited.

Owner:DONGHUA UNIV

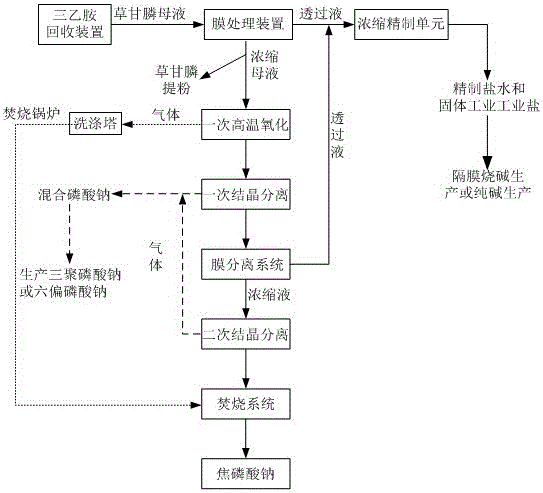

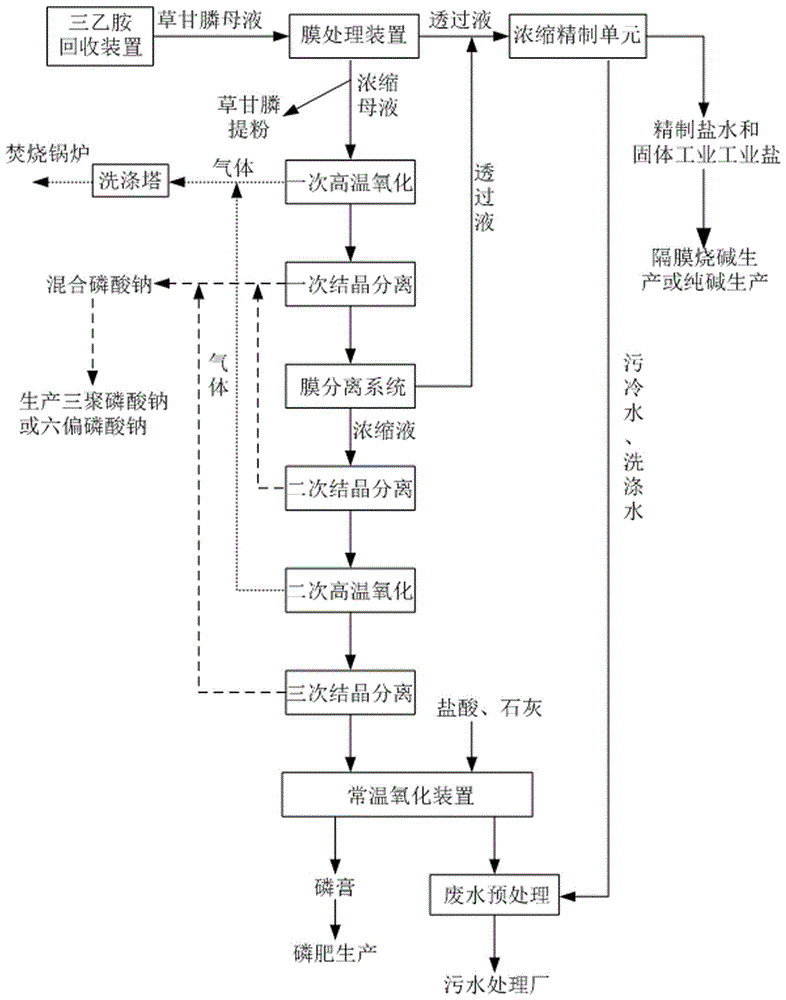

Incineration treatment process for glyphosate mother liquor

ActiveCN106082515ASolve the problem of low oxidation conversionSolve processing problemsGroup 5/15 element organic compoundsWater/sewage treatment bu osmosis/dialysisGlyphosateFlue gas

The invention discloses an incineration treatment process for glyphosate mother liquor. The incineration treatment process comprises the following steps: the glyphosate mother liquor is fed to a membrane treatment device, concentrated mother liquor and a permeate liquid are obtained; the concentrated mother liquor is subjected to glyphosate powder extraction and subjected to primary oxidation, primary crystalizing separation, treatment with a membrane separation system and secondary crystalizing separation, a product enters an incineration system, tetrasodium pyrophosphate is obtained, and flue gas produced through incineration is subjected to secondary burning after dust separation and then is emitted. The membrane treatment concentration technique for the glyphosate mother liquor is combined with the incineration process for the first time and used for completely solving the problem about treatment of the glyphosate mother liquor, salt obtained after incineration can be recycled, the flue gas produced through incineration is subjected to dust separation and secondary burning, so that dioxin in the flue gas can be reduced remarkably, and the environmental requirements are met.

Owner:SICHUAN LESHAN FUHUA TONGDA AGRO-CHEM TECH CO LTD

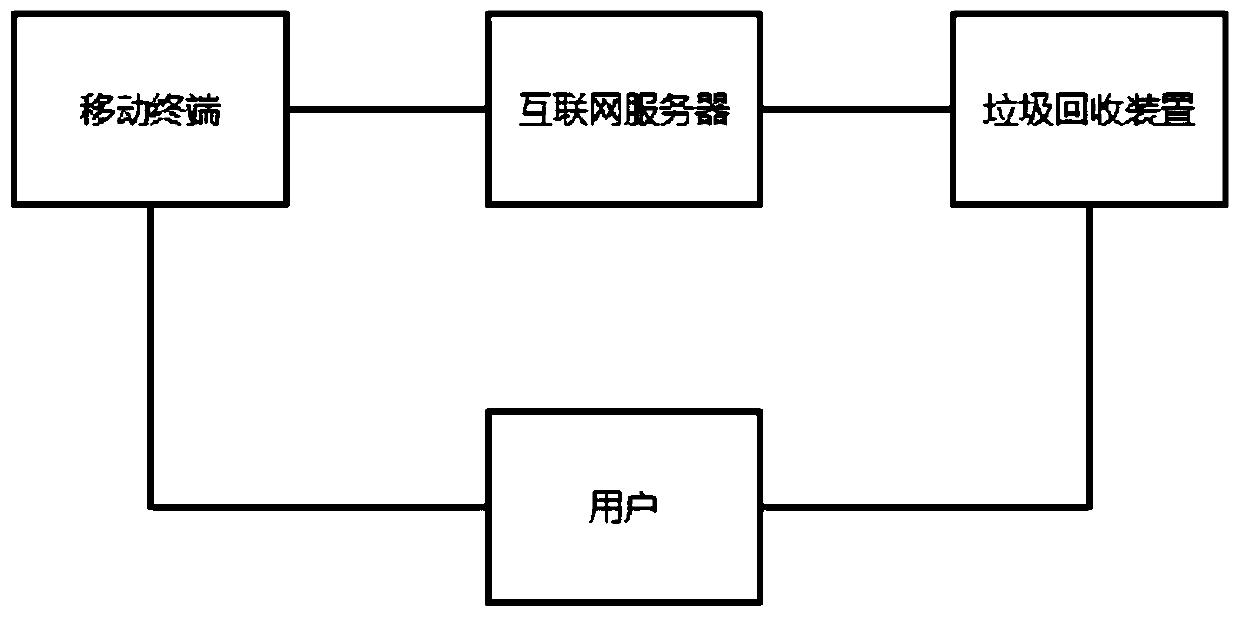

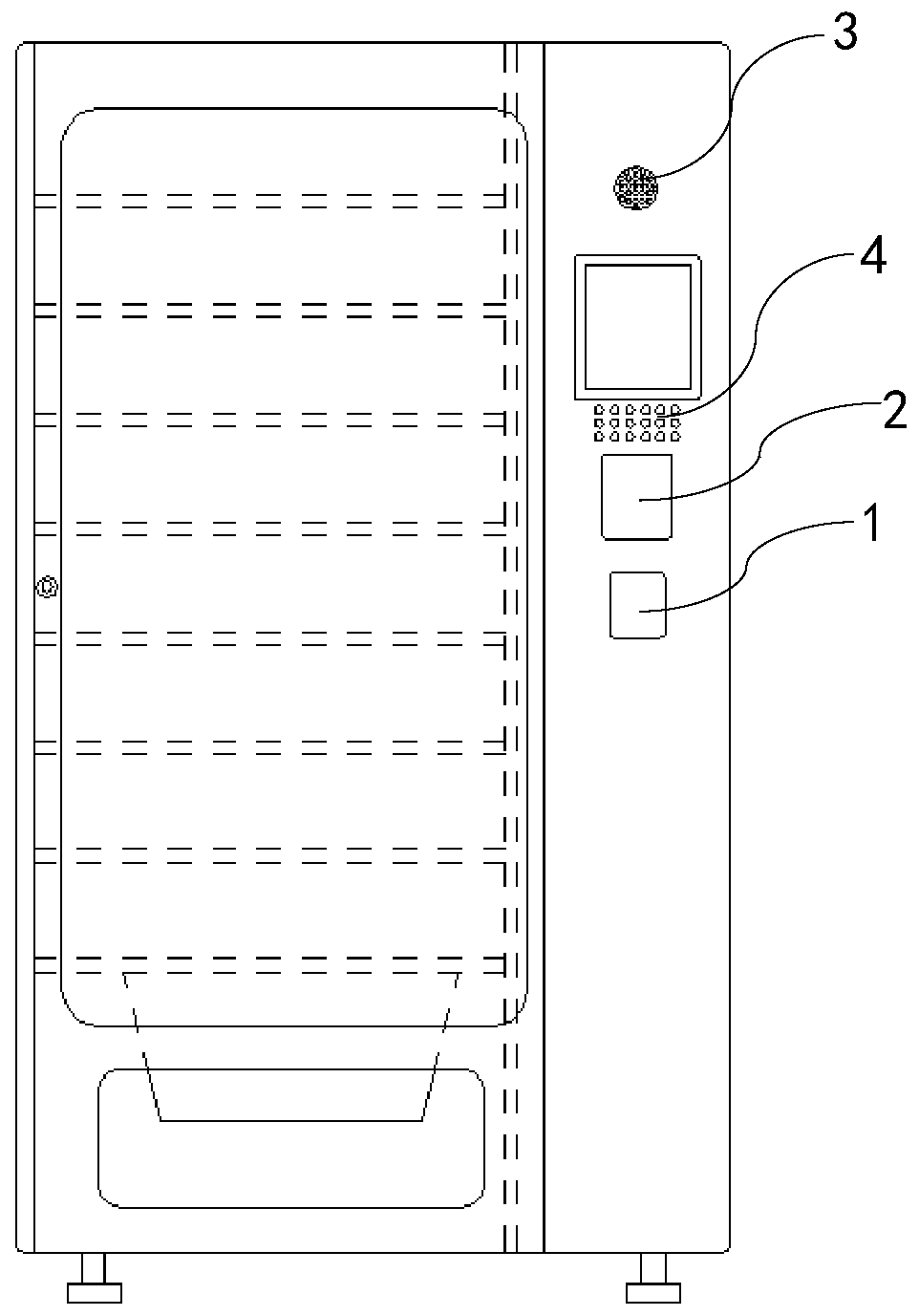

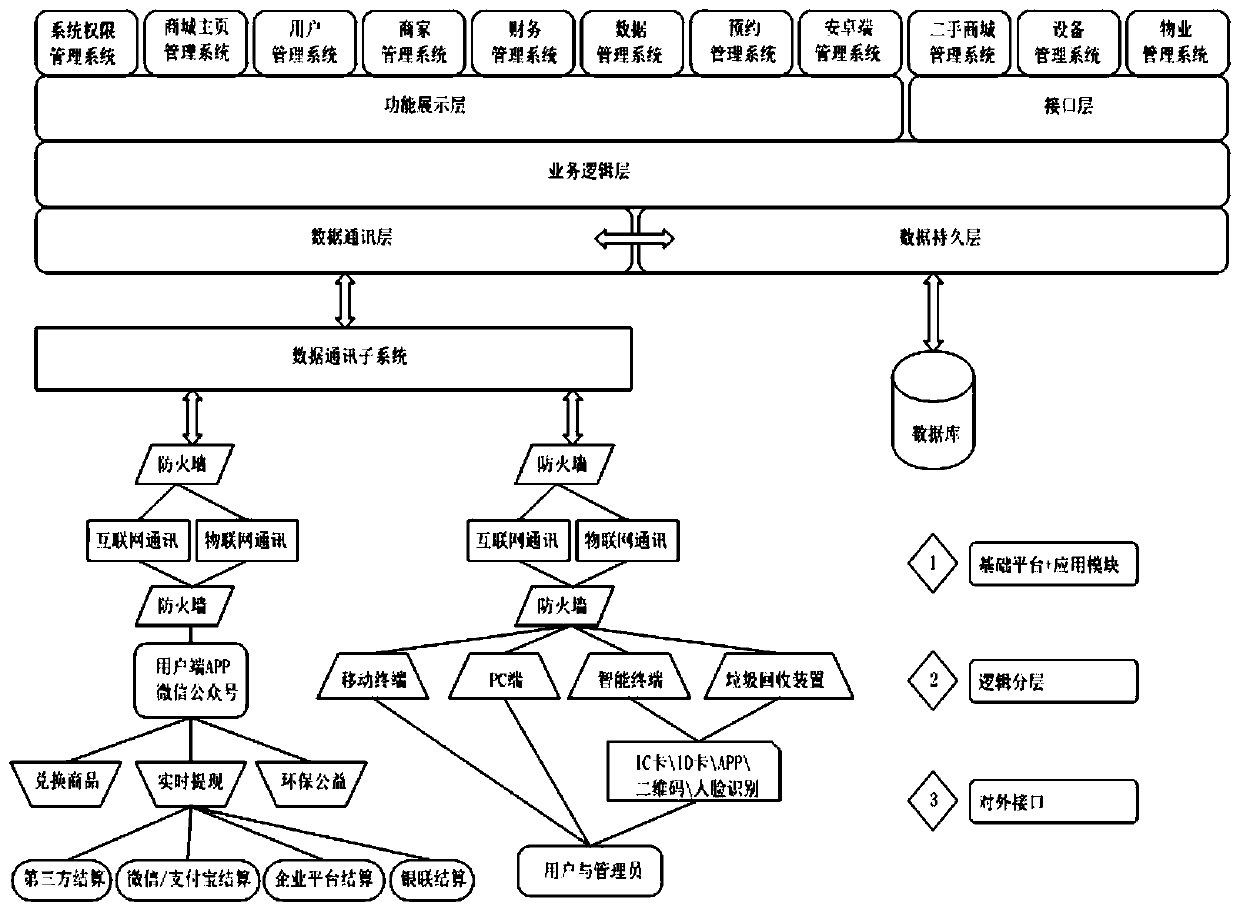

Smart garbage sorting and recycling mode

InactiveCN110021109ARealize the utilization of waste resourcesReduce waste disposalDiscounts/incentivesReturnable containers actuationThe InternetWaste sorting

The invention discloses a smart garbage sorting and recycling mode, which comprises the following steps: S1, when a user delivers garbage, the user logs in to an account in a garbage recycling device,and the corresponding garbage is delivered according to a fine garbage sorting guide; S2, after the user delivers the garbage, the garbage recycling device performs weighing and records the information to the Internet server, the Internet server records the delivery information of the user and performs related point conversion, and the Internet server establishes user garbage delivery big data and a credit information mechanism; S3, the information related to user garbage delivery is fed back to a client terminal through the Internet server, and a client can query related information; S4, theuser can use the earned integral for related exchange and amount exchange; and S5, when a garbage can is fully loaded, a corresponding warning light is on, the delivery port can not be opened, and early warning information is sent to workers. Garbage dumping service is provided for the user, a resident is helped with the garbage dumping problem, and garbage sorting and recycling can be realized at the same time.

Owner:广东沫益清环保科技有限公司

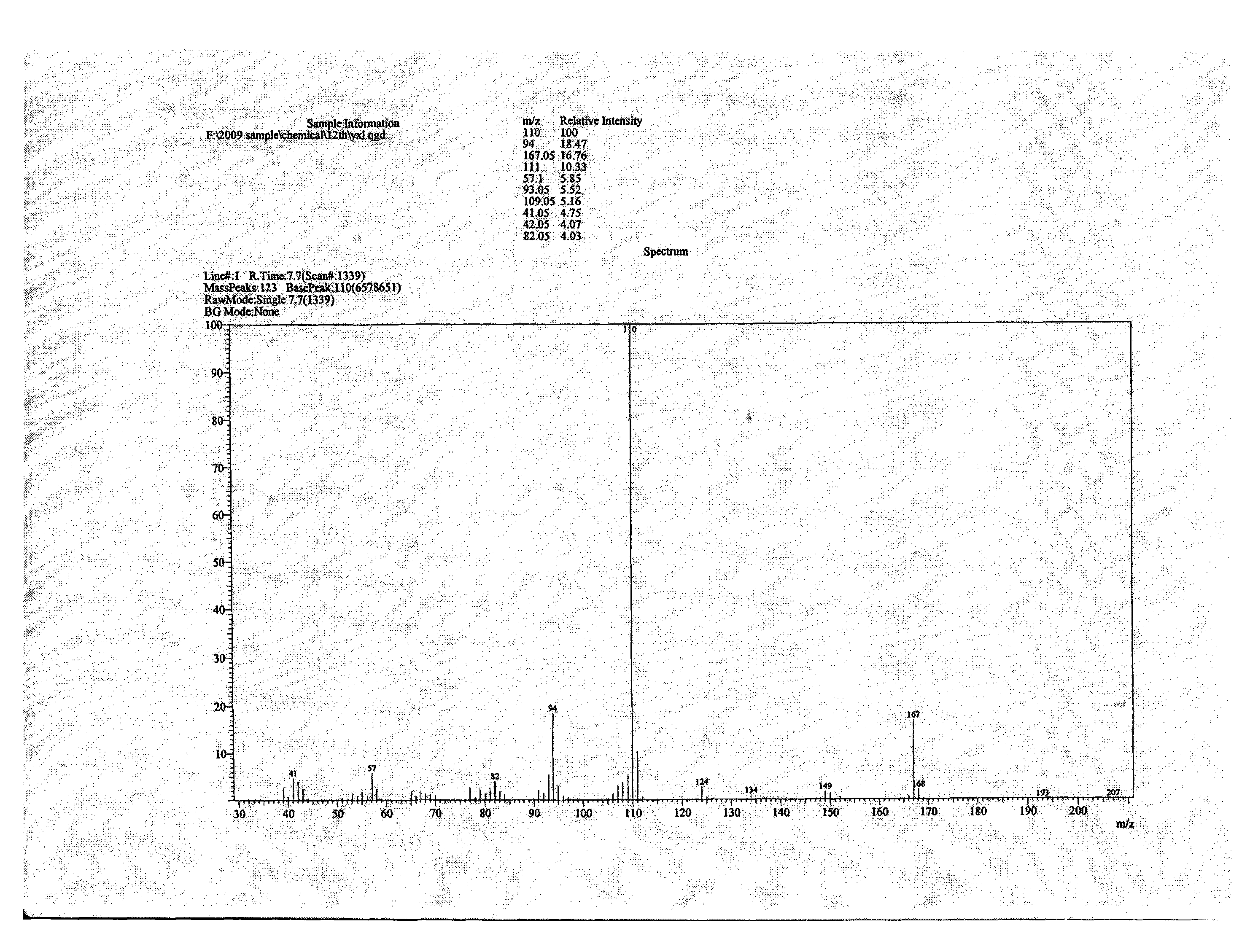

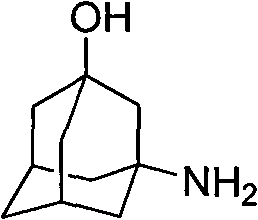

Method for preparing 3-amino-1-adamantane alcohol

InactiveCN101798270AReduce dosageReduce processing costsOrganic compound preparationAmino-hyroxy compound preparationWater bathsIce water

The invention relates to a method for preparing 3-amino-1-adamantane alcohol. The method comprises the following steps of: adding amantadine hydrochloride into a nitrating agent in batches, performing reaction for 1 to 2 hours in an ice-water bath and performing reaction for 1 to 30 hours at room temperature to obtain yellowish liquid; pouring the yellowish liquid into ice, continuously reacting for 0.5 to 2 hours with stirring to obtain blue-green liquid; and adding solid base into solution obtained by the step 2 with stirring, keeping temperature below 80 DEG C, regulating pH to be between 10 and 12, performing reaction for 30 minutes with stirring, leaching, extracting reaction liquid by using dichloromethane, drying the obtained product with anhydrous sodium sulfate, steaming off the dichloromethane and performing recrystallization by using ethyl acetate to obtain white solid. The preparation method has the advantages of readily available starting raw materials, simple reaction operation, short route, environmental friendliness, easy industrial production and good application prospect, and also reduces cost for the synthesis of Vildagliptin serving as a medicament for treatingdiabetes; and the yield of products reaches 75 percent.

Owner:DONGHUA UNIV

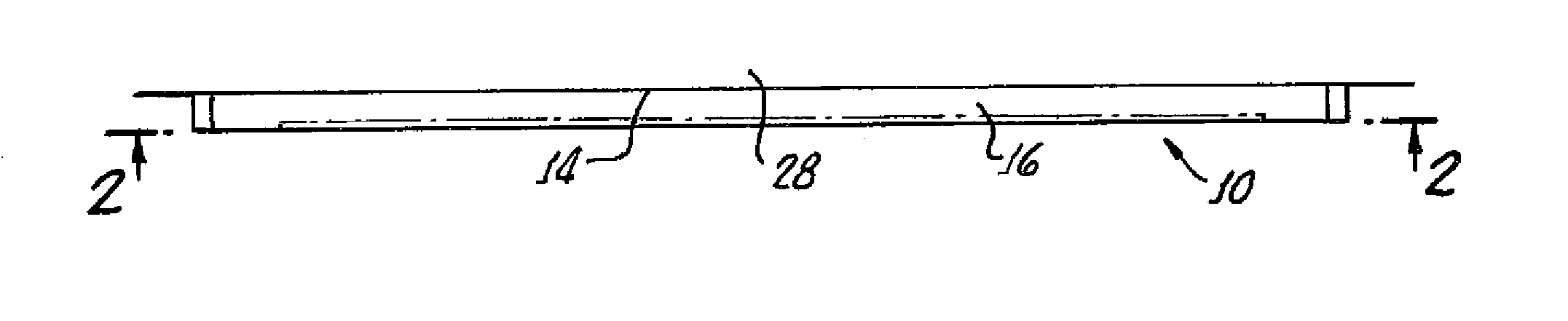

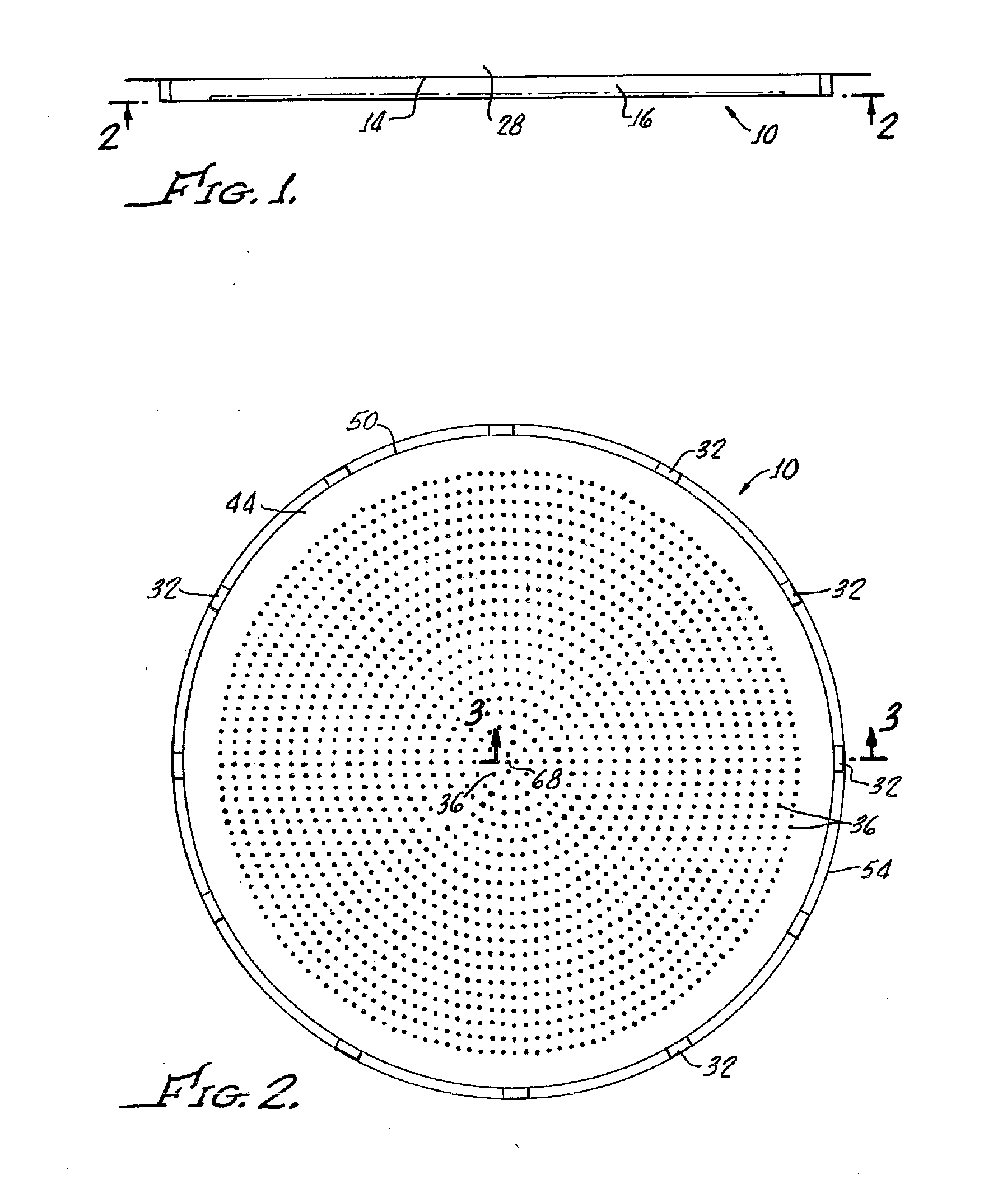

Luminaire

InactiveUS20110310616A1Extend your lifeImprove efficiencyPoint-like light sourceGlobesLight guideEffect light

A luminaire includes a planar light guide having a substrate with a back surface, a light emitting surface, and an edge therebetween with a light source disposed at the edge for emitting light thereinto. A geometric structure on the light guide provides for directing light entering the light guide edge outwardly from the light-emitting surface. The luminaire may be utilized for retrofitting of existing canned lighting or in flush mount applications.

Owner:TRILLION LIGHTING

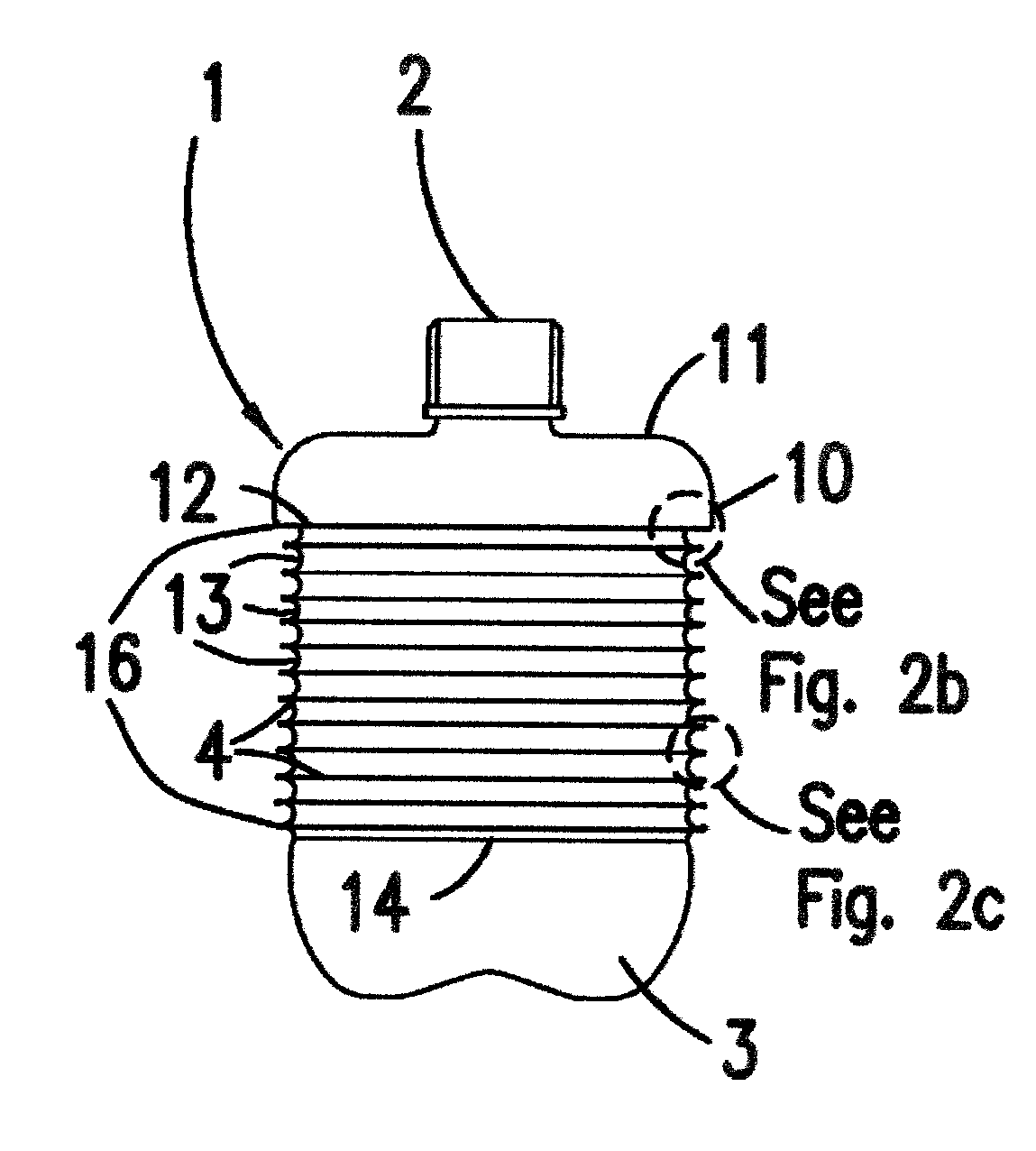

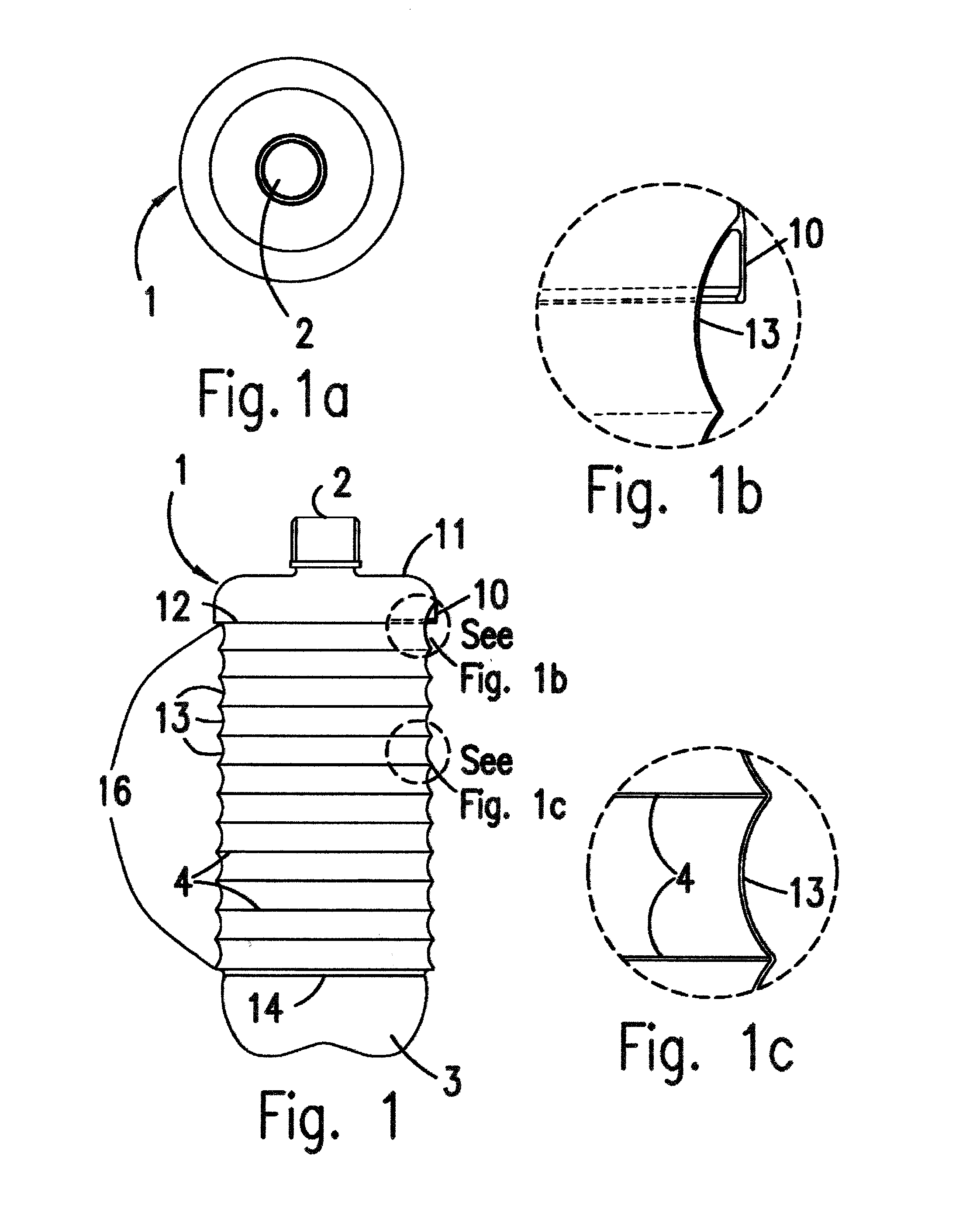

Sealable Collapsible Container

InactiveUS20150344181A1Easily disposeReduce volume of wasteClosuresBottlesWaste disposalWaste recycling

The present invention relates to a sealable collapsible container comprising a top portion including a lip, a body portion and a base portion, the body portion of the container structured with a series of horizontal inclusions forming collapsible scored corrugations capable of nesting together and a clip structure capable of securing the nested scored corrugations. When the container is fully expanded, it can contain and hold a maximum amount of a product, usually a liquid. The container may be compressed once the product is dispensed by applying downward pressure to the lip of the container. When fully compressed the container may be easily disposed of and helps to alleviate environmental waste disposal issues by reducing the volume of waste and assisting the waste recycling process.

Owner:CANDY KATRINA GOFF +1

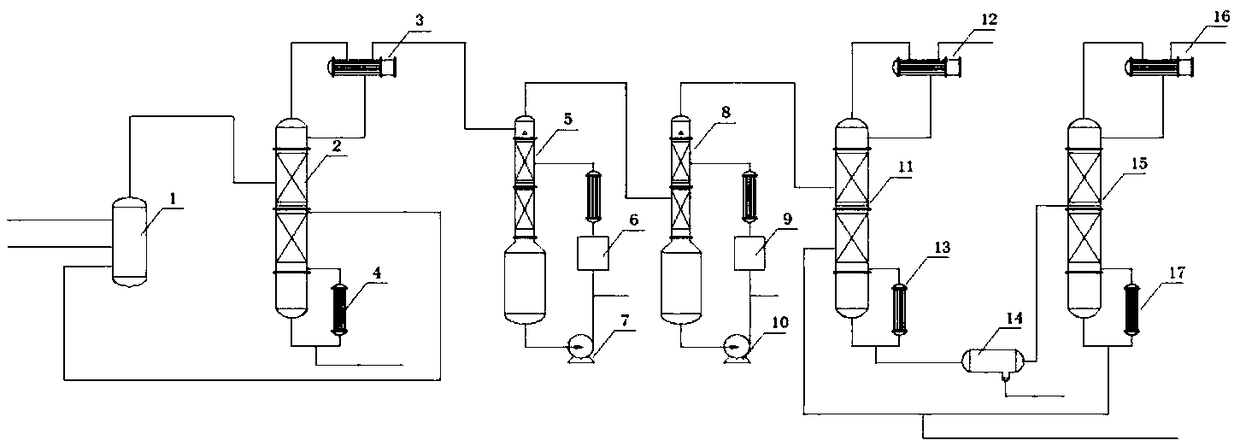

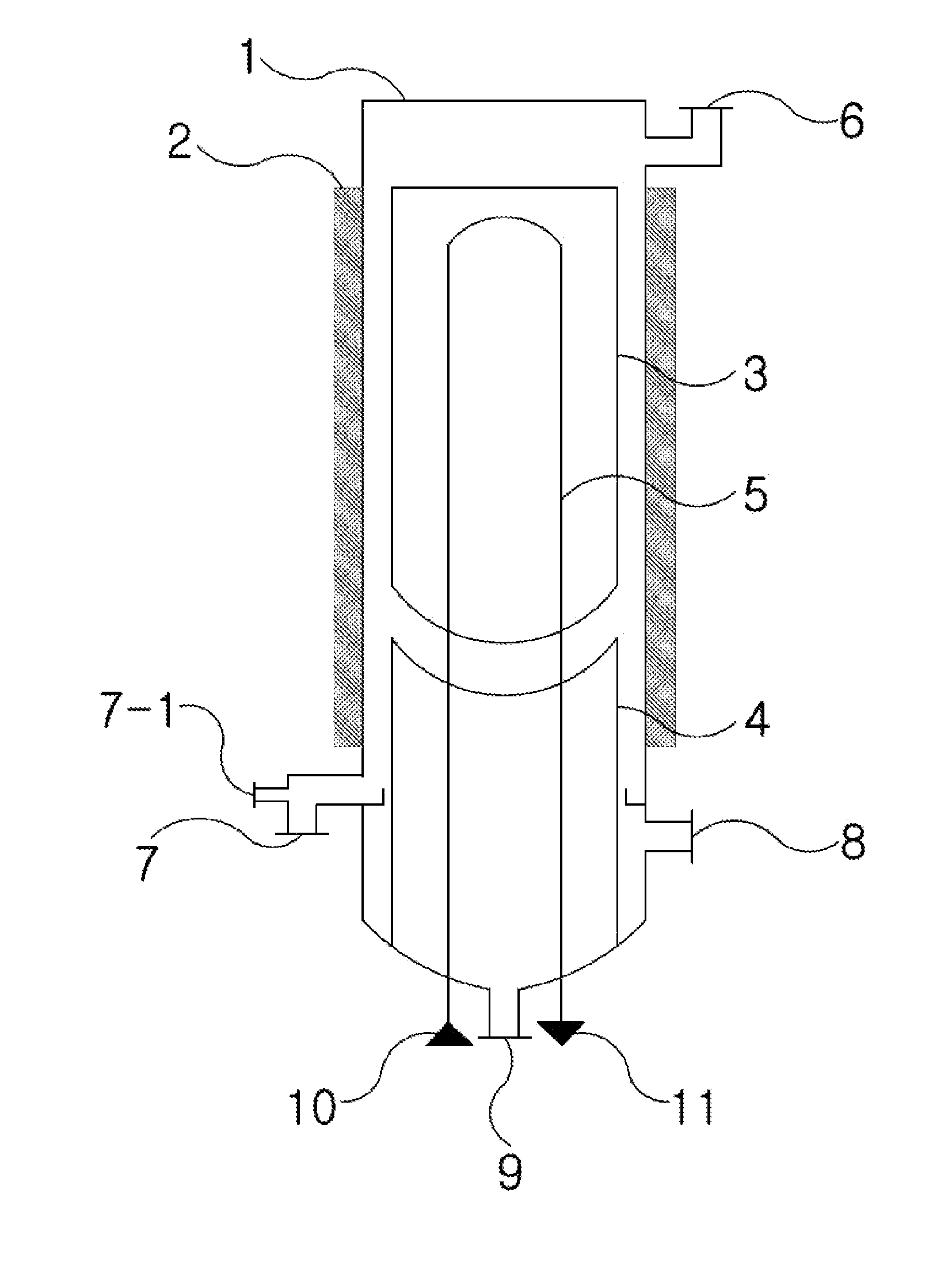

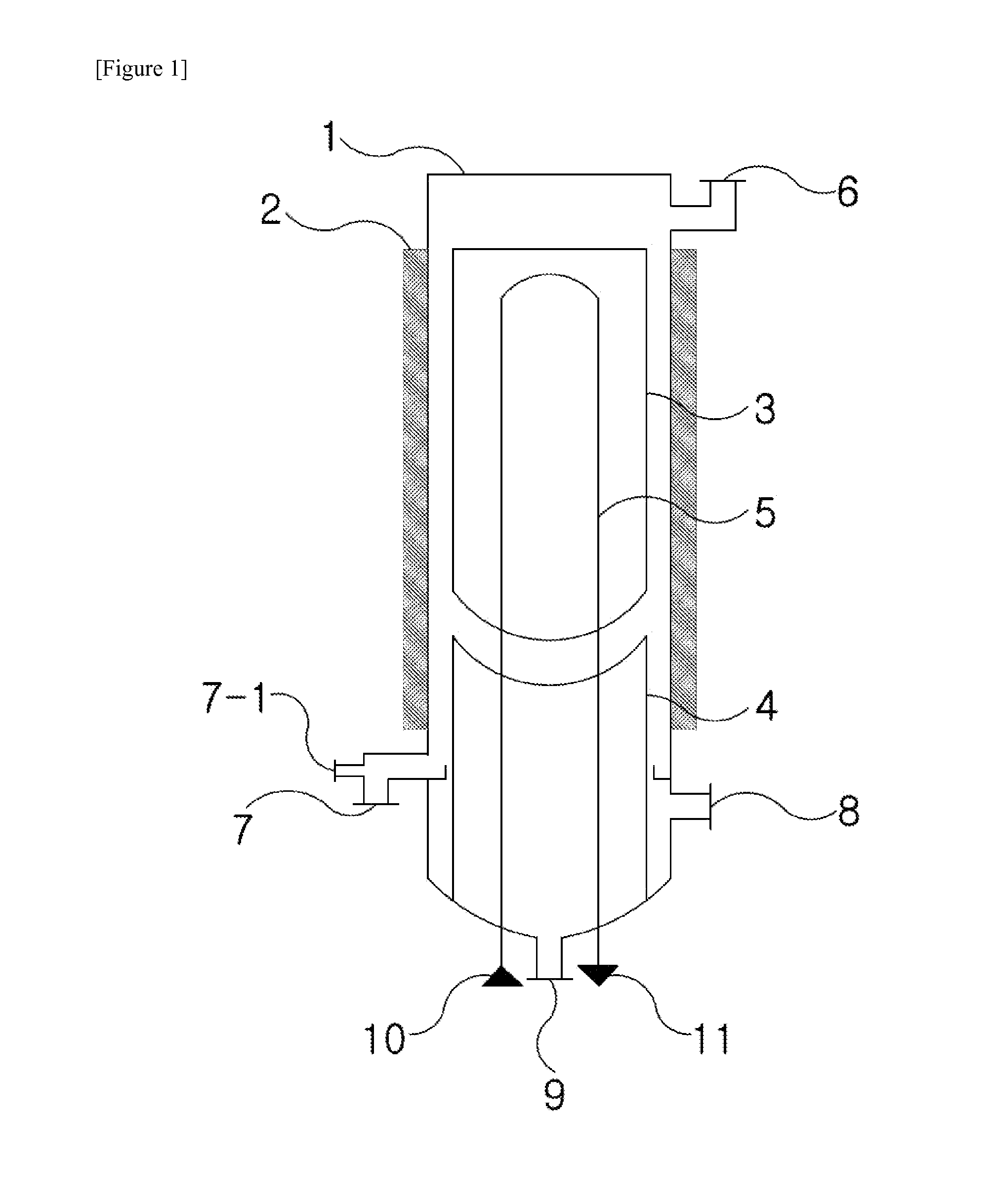

Synthesis rectifying method and equipment of methane chloride

ActiveCN109081767ALow yieldEliminate problems with CODEther separation/purificationHalogenated hydrocarbon separation/purificationGas phaseChloride

The invention discloses a synthesis rectifying method and equipment of methane chloride and belongs to the field of chemical methane chloride and organic silicon. According to the technical scheme, the method includes the steps of firstly, feeding raw material methanol and hydrogen chloride into a reactor, performing bubbling reaction to obtain a mixture of methanol, dimethyl ether, methane chloride, hydrogen chloride and water, and feeding the mixture into a reaction rectifying tower for rectifying; secondly, feeding the mixture discharged from the top of the reaction rectifying tower in thefirst step into a washing tower for washing so as to absorb the hydrogen chloride; thirdly, feeding the gas-phase material obtained after the second step into an alkali washing tower reactor to removeall the hydrogen chloride so as to obtain a gas-phase material at the top of the alkali washing tower; fourthly, feeding the gas-phase material obtained after the third step into an extraction rectifying tower to obtain the methane chloride at the top of the extraction rectifying tower. The method is low in investment, low in energy consumption, little in three waste, high in yield, capable of eliminating the environment pollution of an original process and capable of recovering the high-additional-value product.

Owner:南京佳华工程技术有限公司

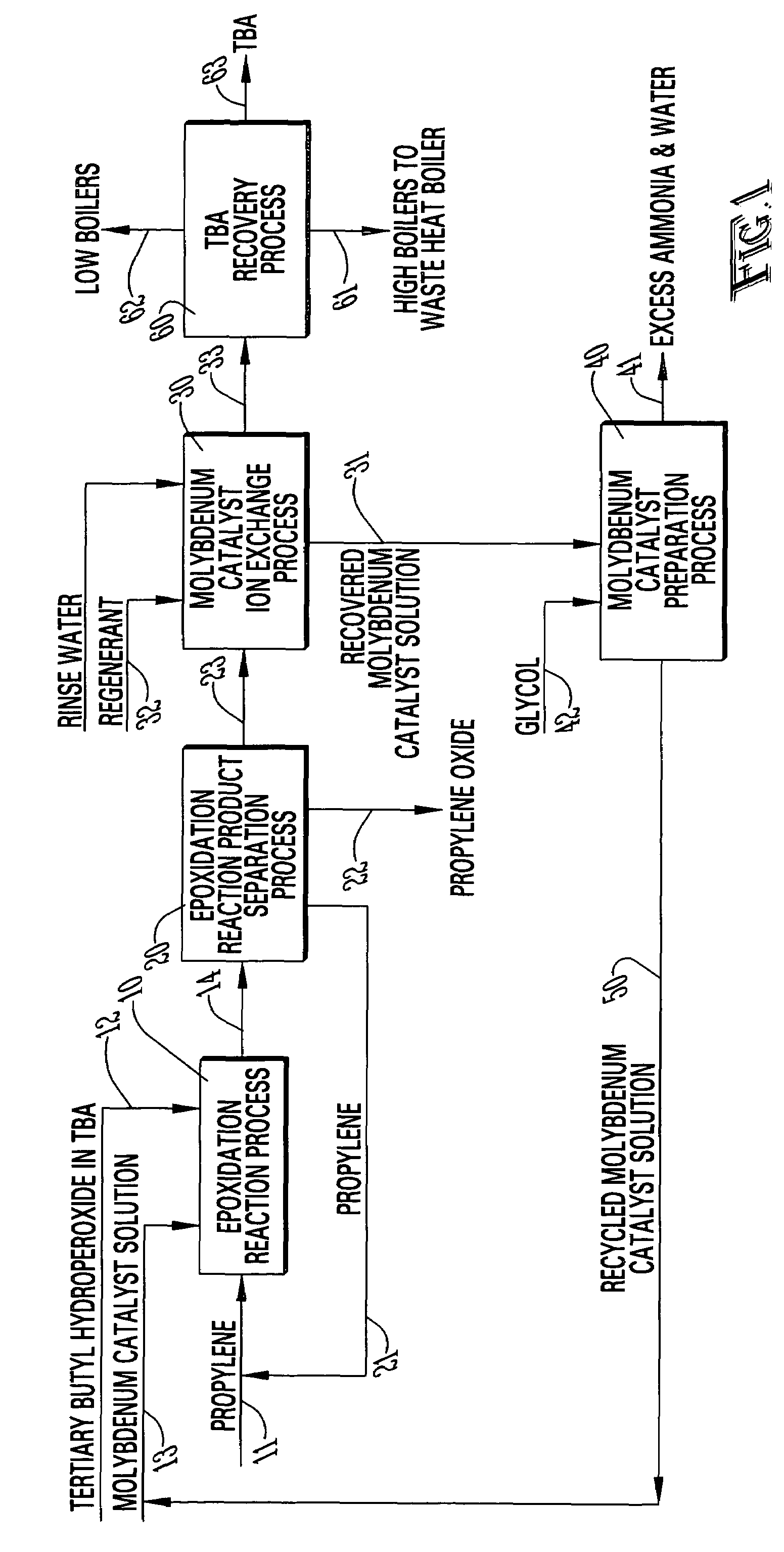

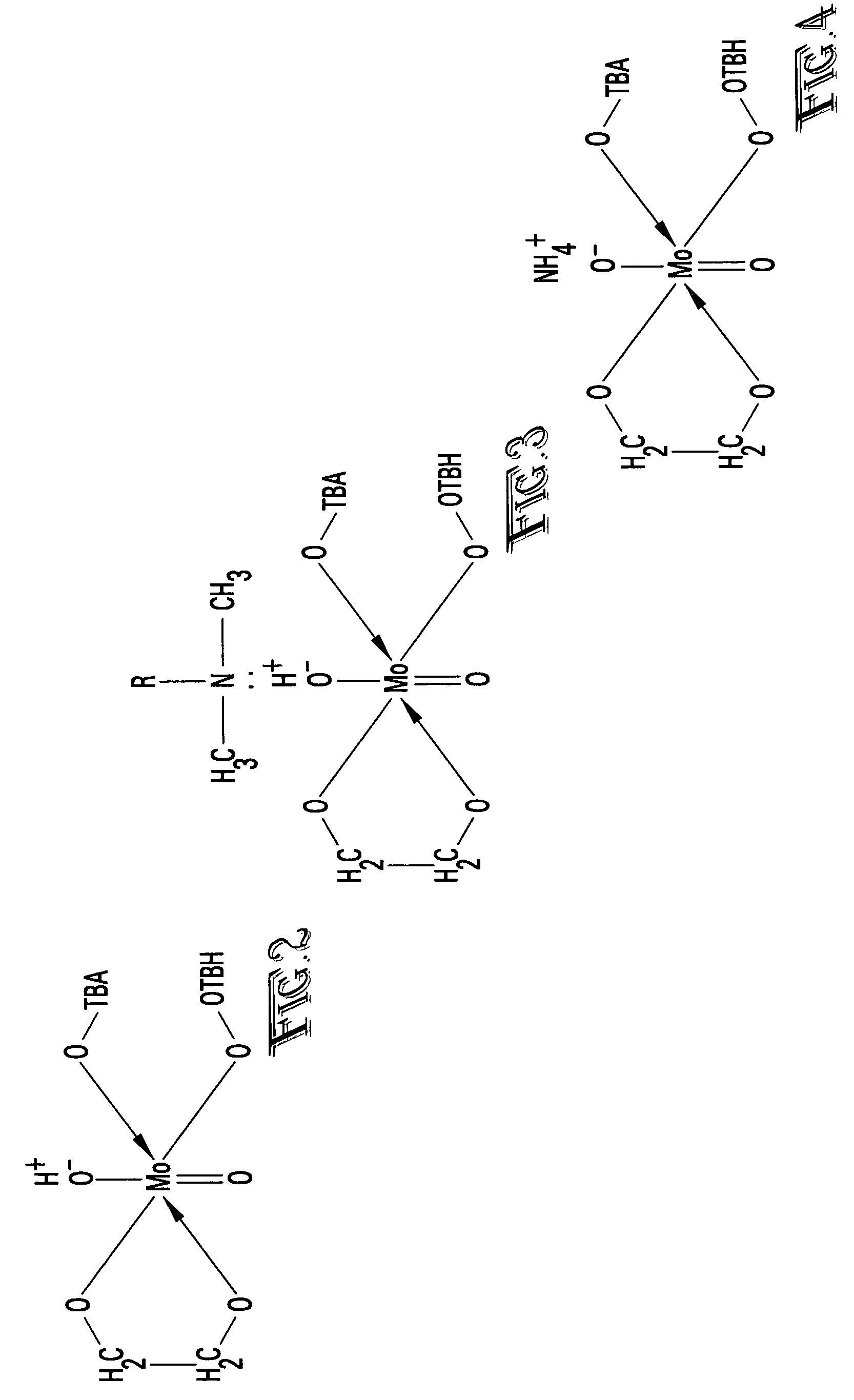

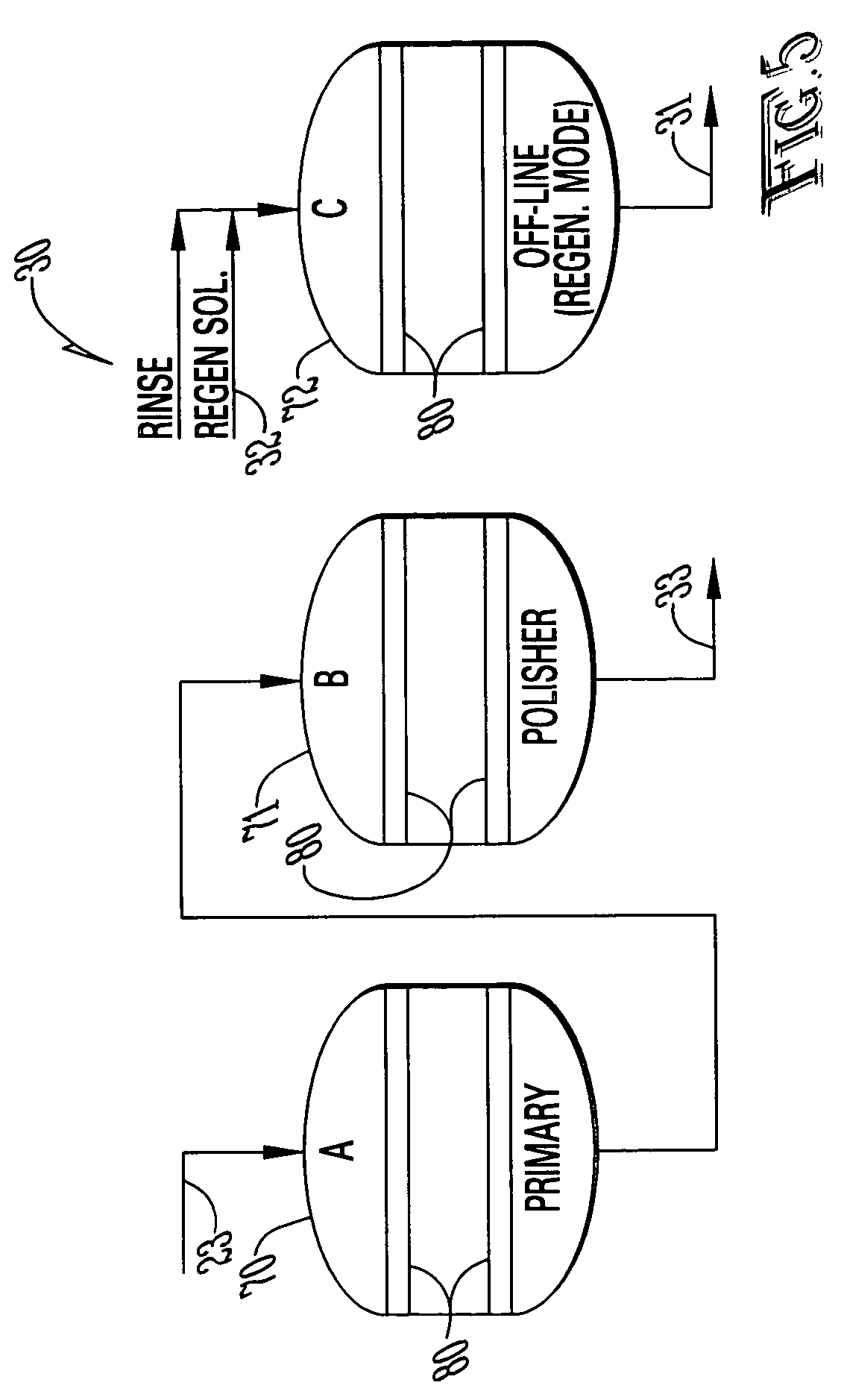

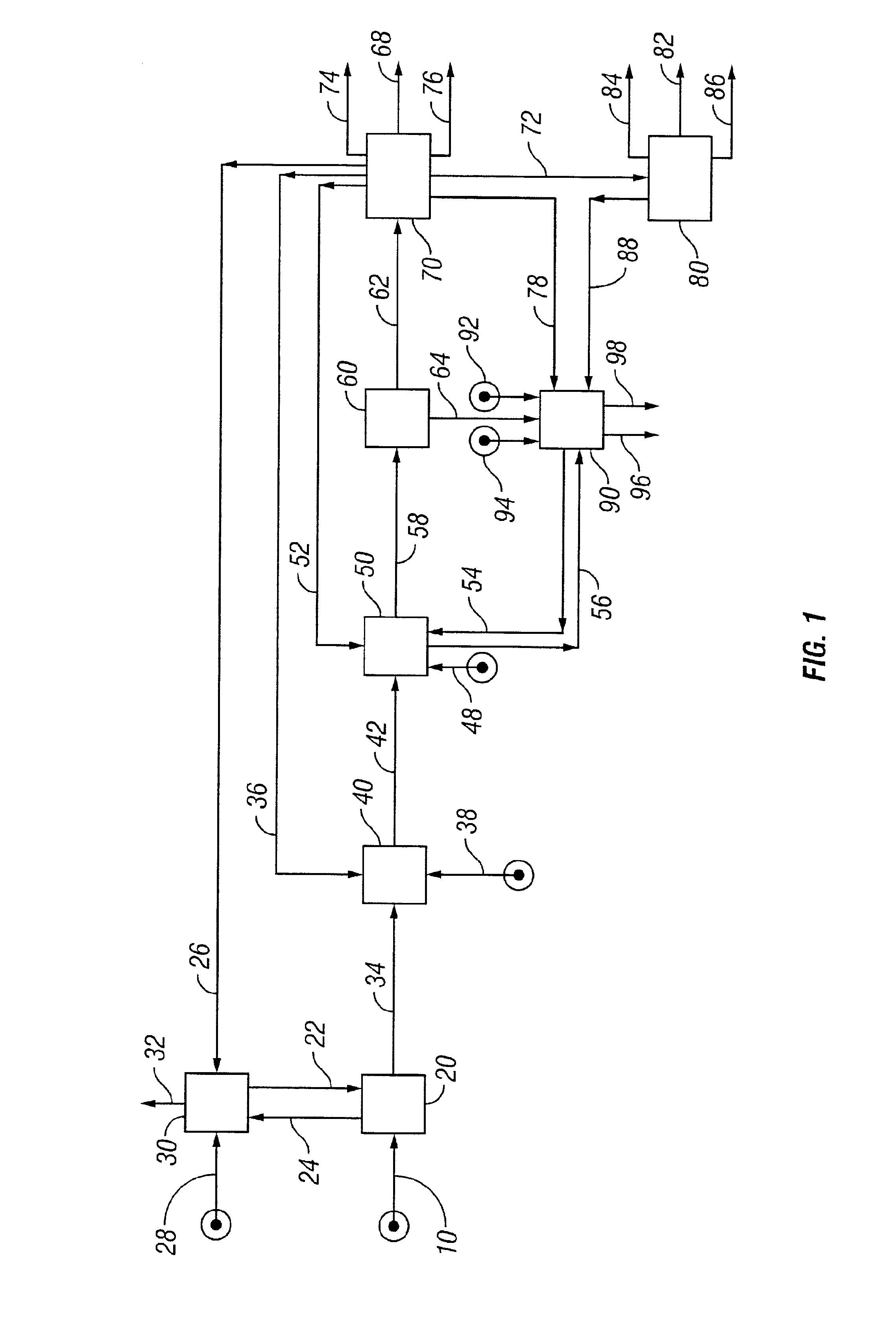

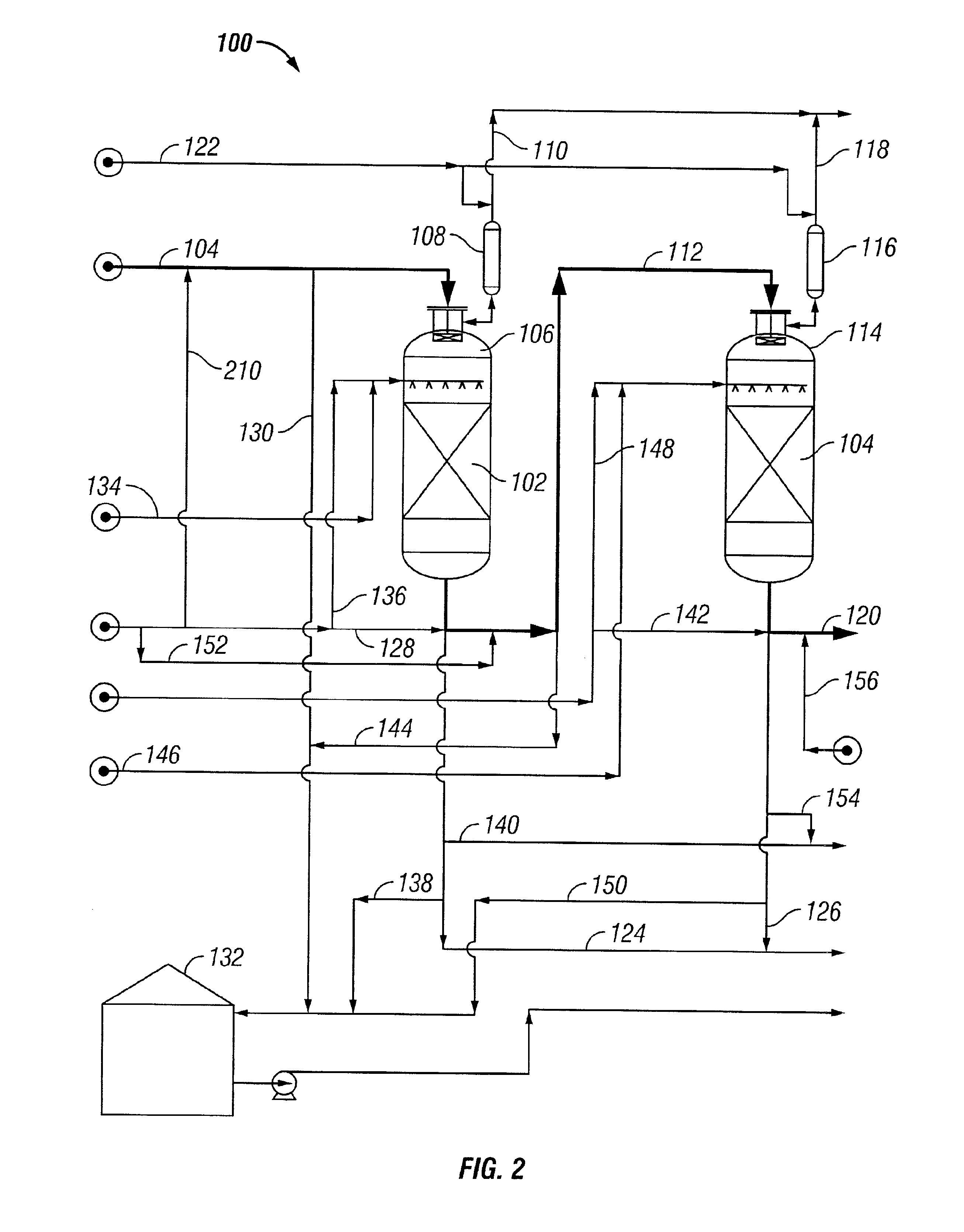

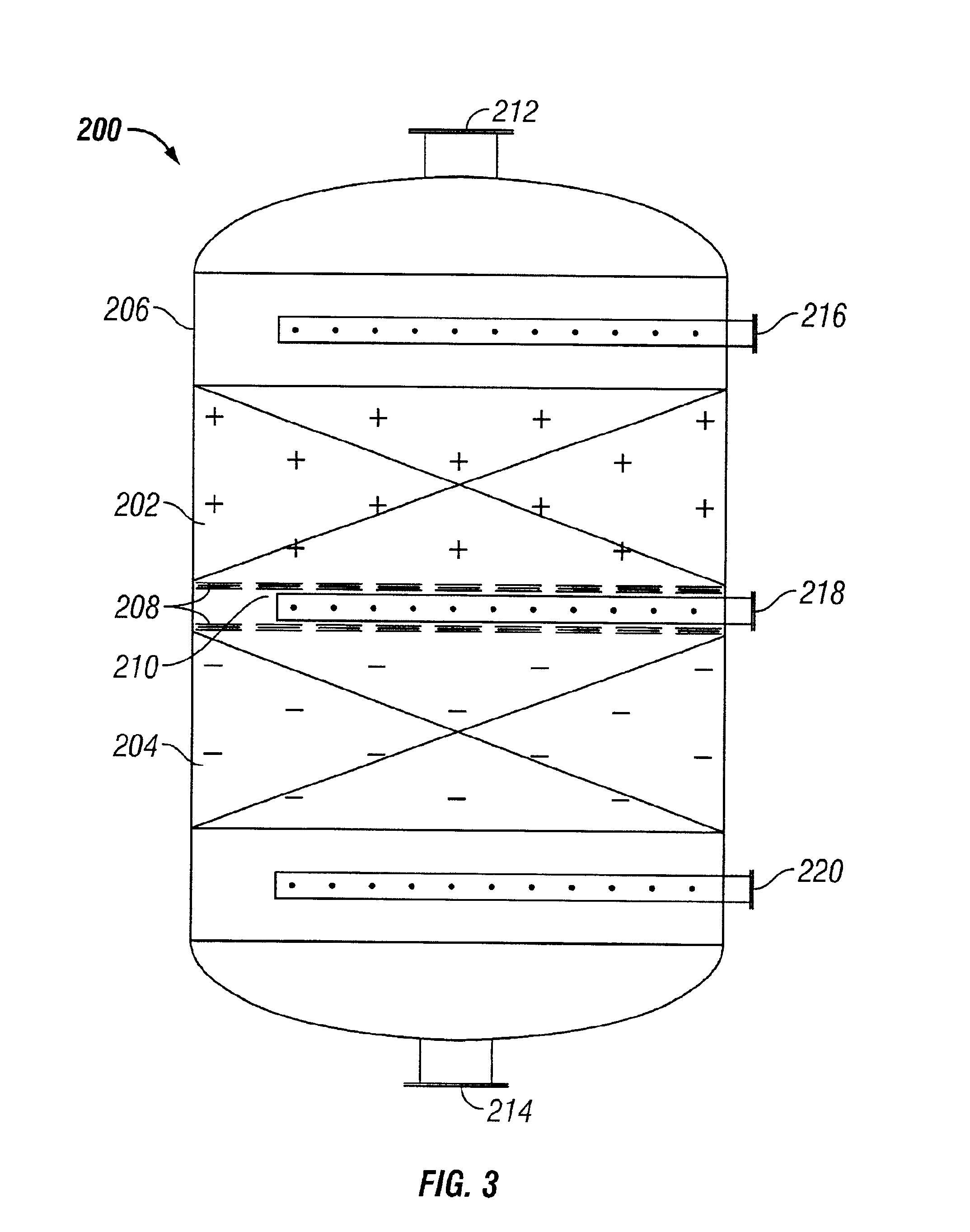

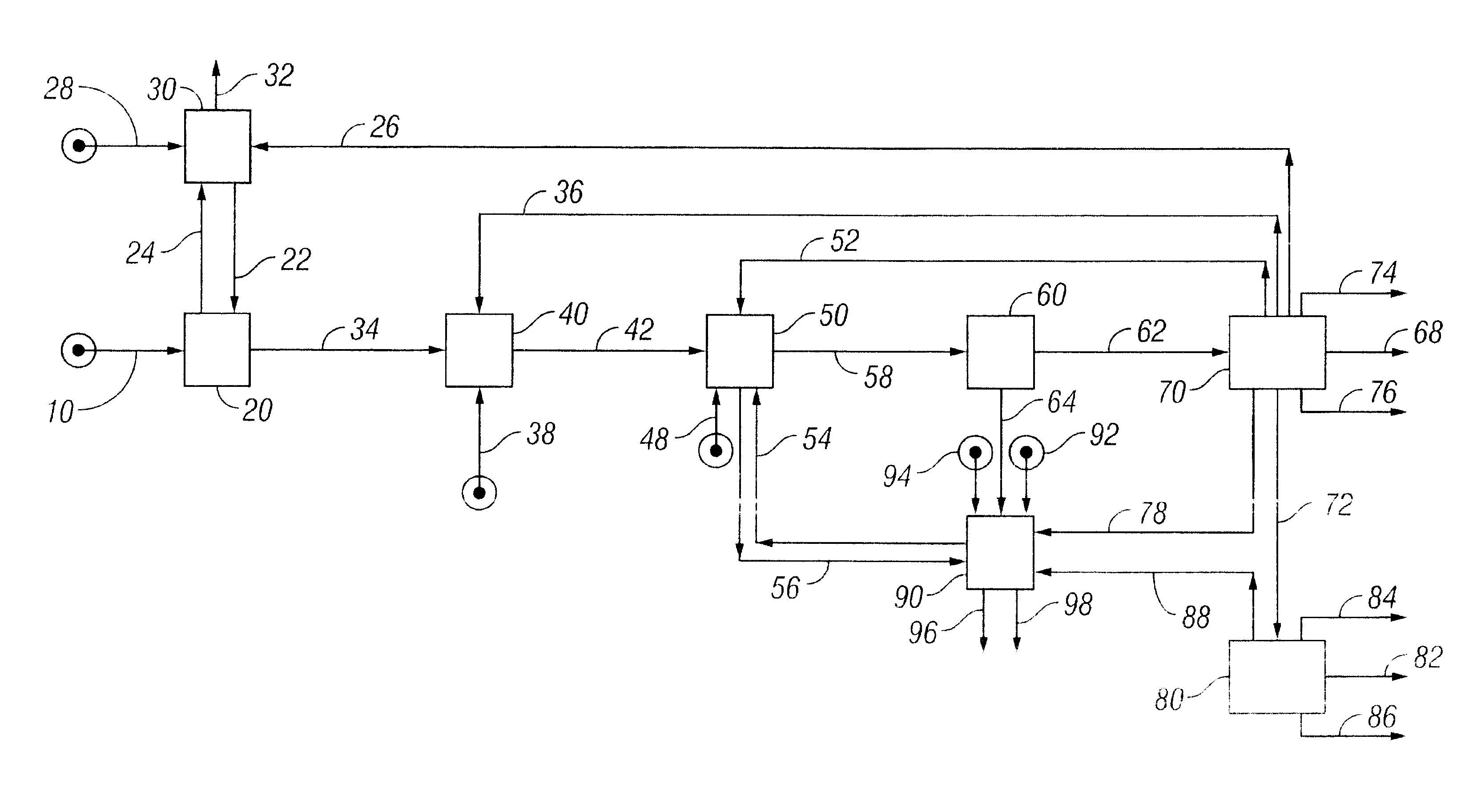

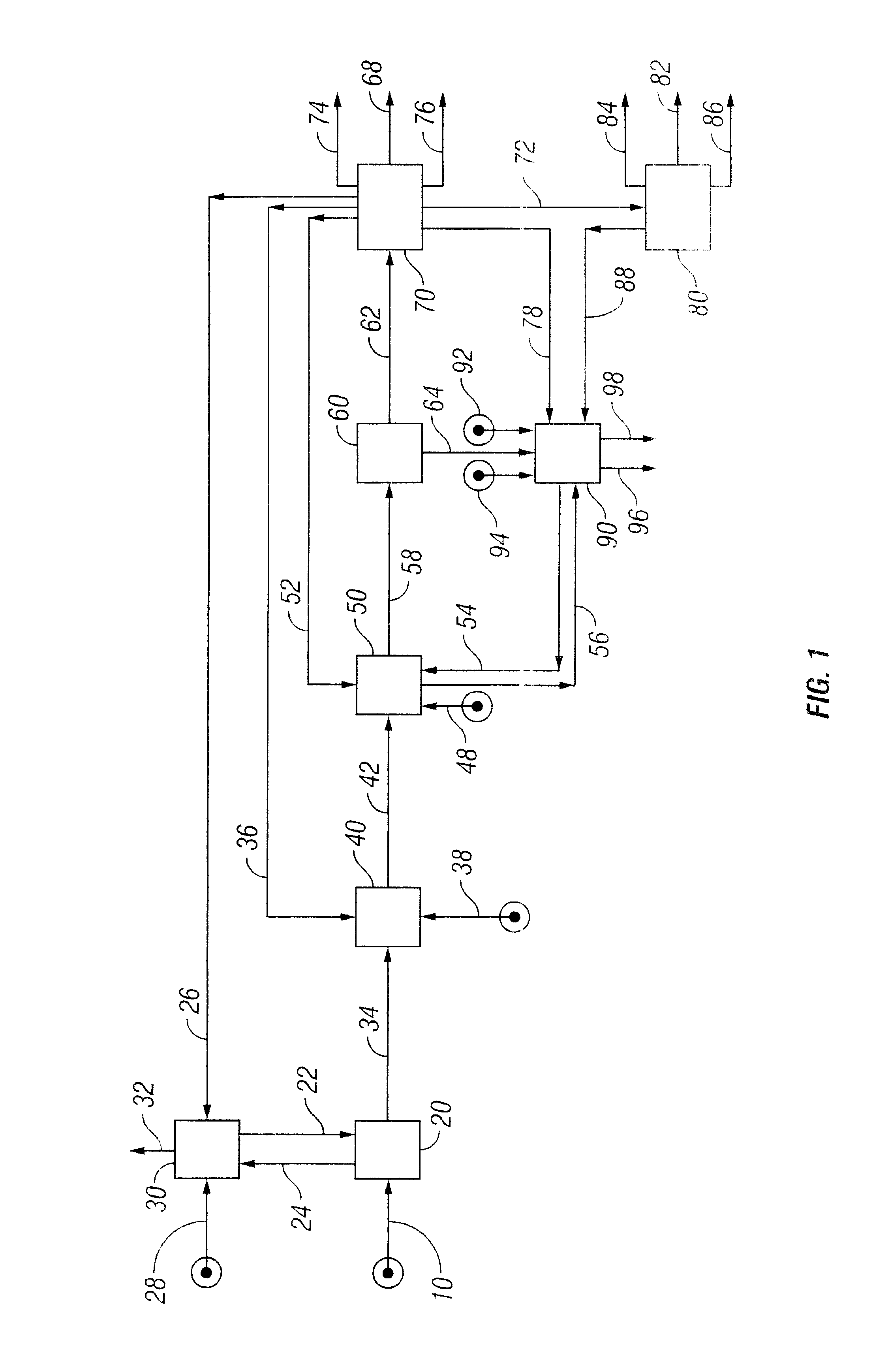

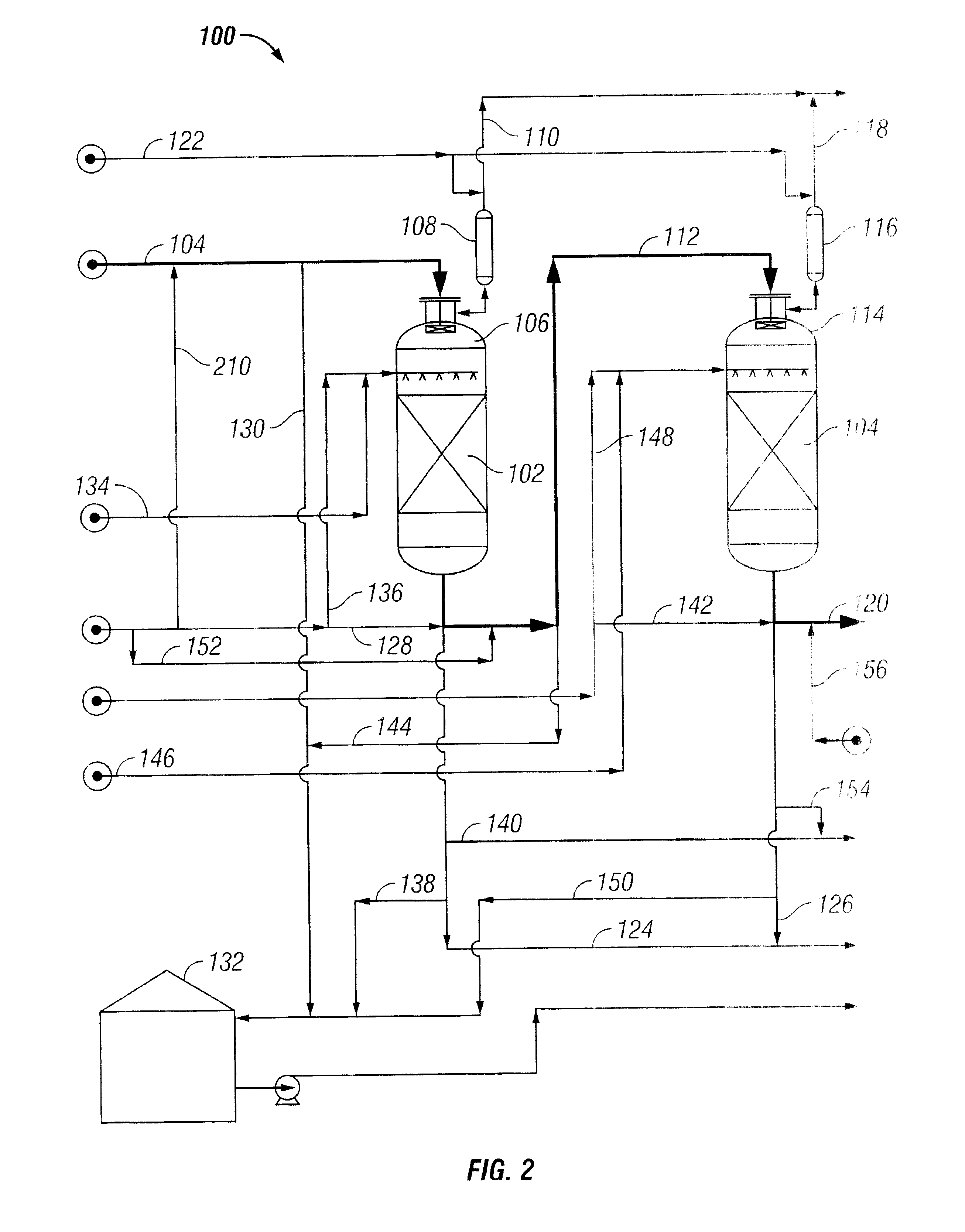

Process for manufacturing propylene oxide

InactiveUS7223875B2Maximum efficiencyPrevent leakageProductsOrganic chemistryIon exchangeIon-exchange resin

A process for the recovery of molybdenum catalyst from the epoxidation reaction product of olefins with organic hydroperoxides. The active form of the glycol-molybdate epoxidation catalyst is removed from the process stream with an anion ion exchange resin. The ion exchange resin can be either a weak base or strong base type. The preferred embodiment of the invention produces a concentrated epoxidation catalyst in the “ammonium” form that is suitable for recycle to the catalyst preparation vessel. The ammonia form is converted into the active form by evaporating the water and ammonia from the recovered catalyst in the presence of a glycol. The preferred configuration of the ion exchange process is a “Lead-Lag” system. Two vessels will be in service while the third is in the regeneration mode recovering the epoxidation catalyst. A fourth polishing vessel can also be included as a “guard bed” to prevent leakage of the molybdate catalyst into the process stream. Since the ion exchange kinetics are slow compared to an aqueous system, the preferred embodiment uses a fractal fluid distribution system.

Owner:HSBC BANK

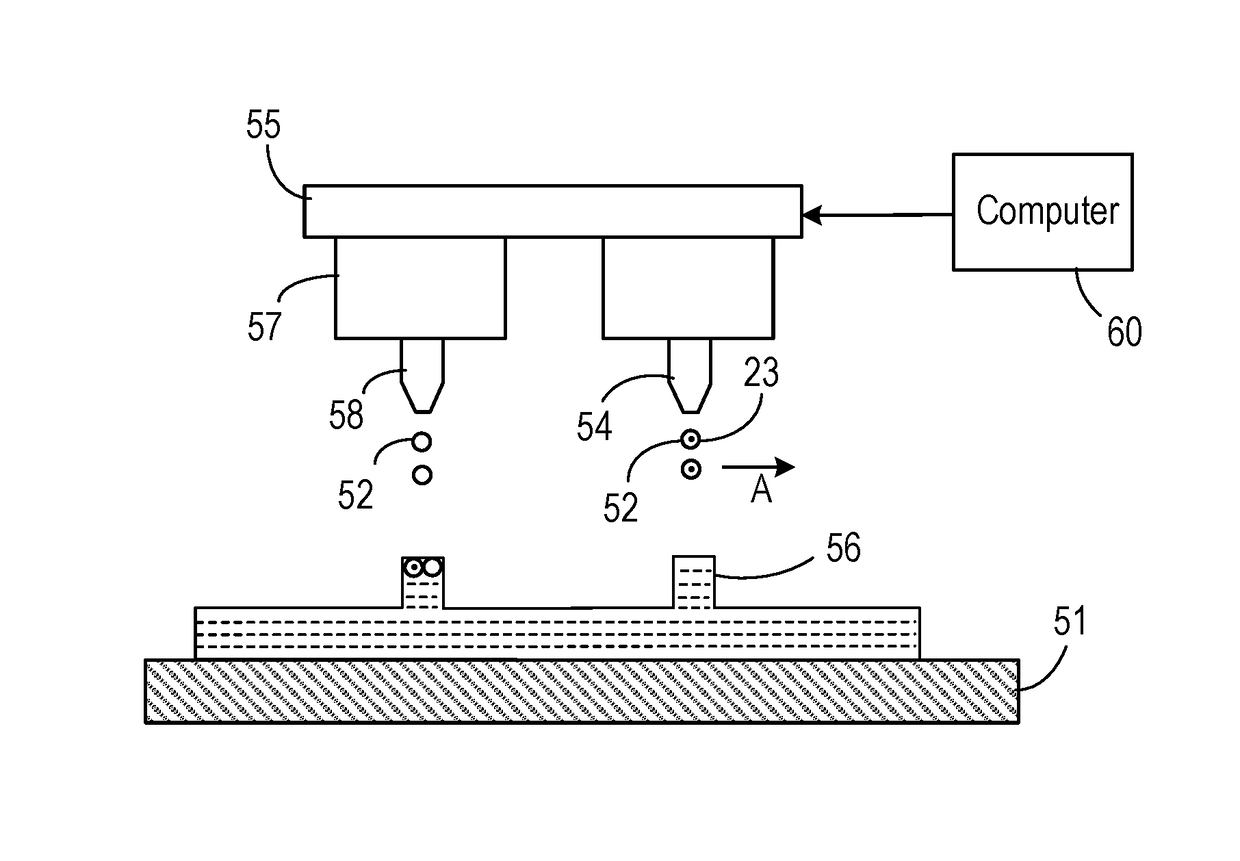

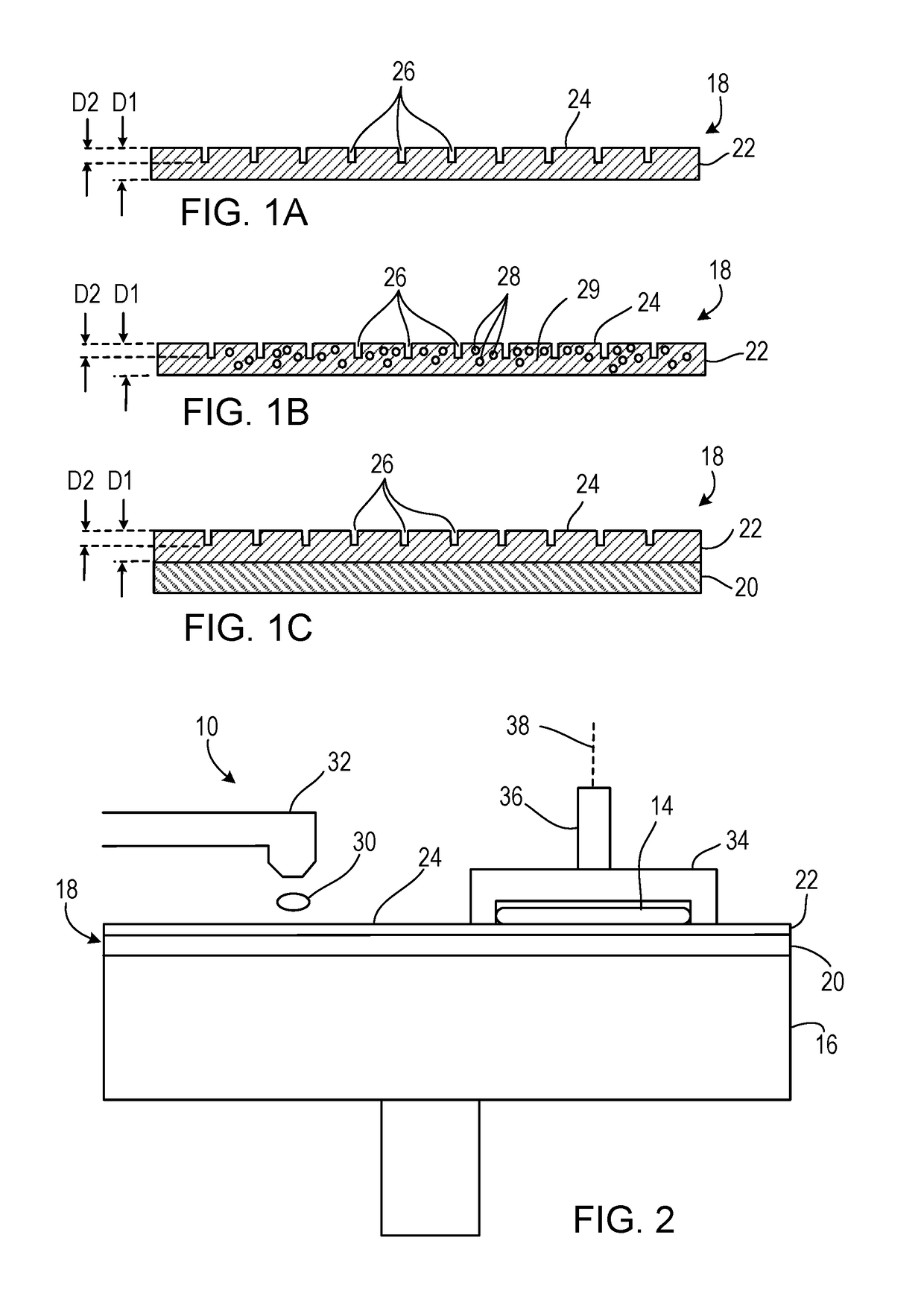

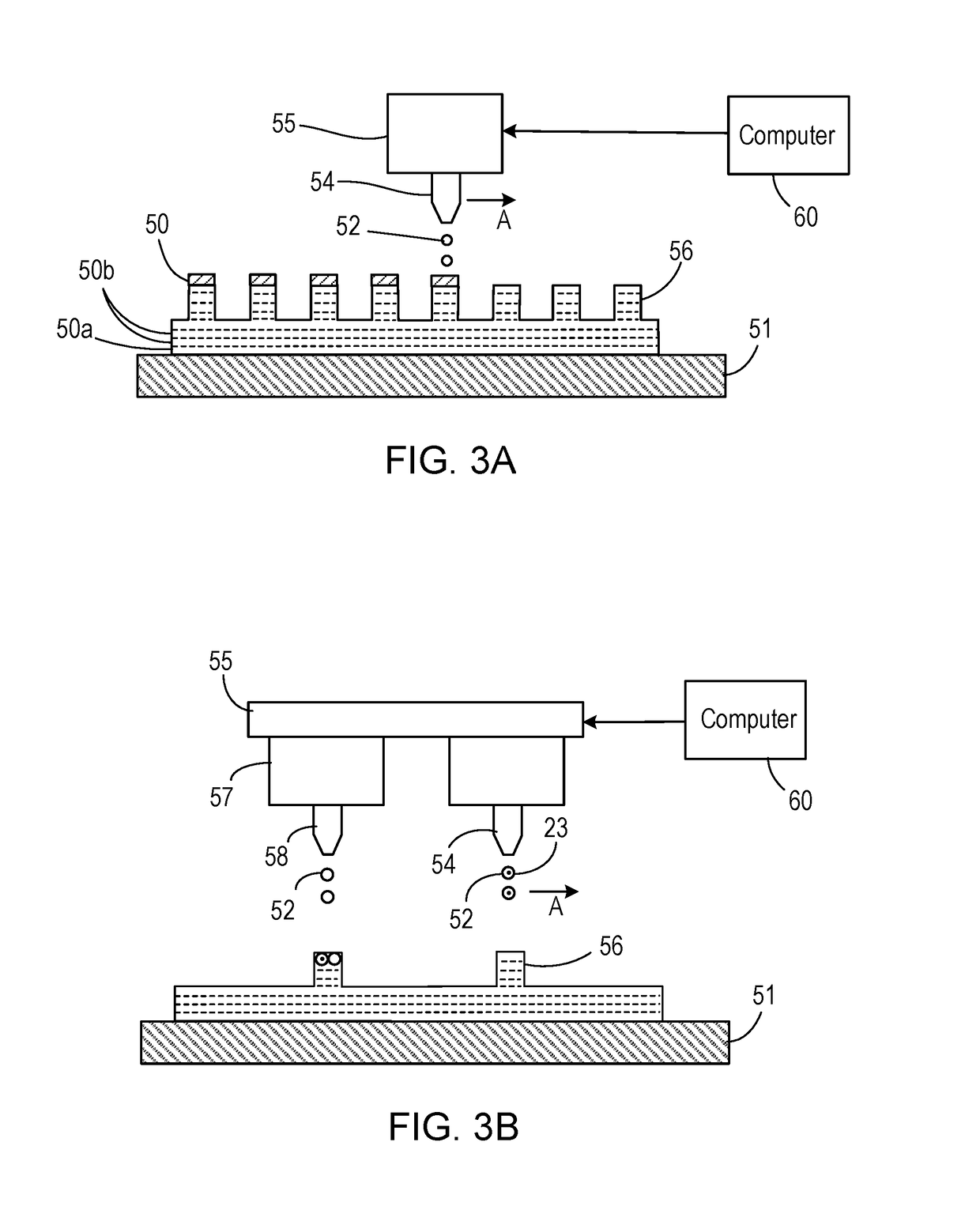

Printed chemical mechanical polishing pad having abrasives therein and system for printing

ActiveUS10016877B2Low costReduce waste disposalAbrasion apparatusSemiconductor/solid-state device manufacturingPolymer science3d printer

A method of fabricating a polishing layer of a polishing pad includes determining a desired distribution of particles to be embedded within a polymer matrix of the polishing layer. A plurality of layers of the polymer matrix is successively deposited with a 3D printer, each layer of the plurality of layers of polymer matrix being deposited by ejecting a polymer matrix precursor from a nozzle. A plurality of layers of the particles is successively deposited according to the desired distribution with the 3D printer. The polymer matrix precursor is solidified into a polymer matrix having the particles embedded in the desired distribution.

Owner:APPLIED MATERIALS INC

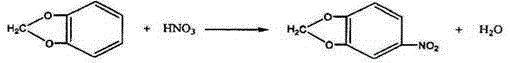

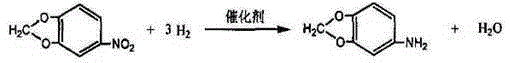

3,4-methylenedioxy aniline preparation method

A 3,4-methylenedioxy aniline preparation method applied to the field of chemosynthesis comprises the following steps: (1) adding dilute nitric acid into a reaction vessel for heating; (2) dropwise adding 1,2-methylenedioxy benzene into the reaction vessel slowly, carrying out intense stirring during the dropwise adding, and carrying out heat preservation after the dropwise adding is finished; (3) carrying out cooling and filtration to obtain a wet product of 3,4-methylenedioxy nitrobenzene, carrying out washing with purified water till the pH value of the wet product reaches 7, and carrying out vacuum drying to obtain 3,4-methylenedioxy nitrobenzene; (4) putting 3,4-methylenedioxy nitrobenzene, a nickel catalyst and one or more reaction solvents into a high-pressure reaction kettle for heating, injecting hydrogen, filtering out the nickel catalyst after the reaction is finished, carrying out high vacuum distillation after a low-boiling-point substance is removed through reduced pressure distillation, and collecting fractions to obtain 3,4-methylenedioxy aniline. The 3,4-methylenedioxy aniline preparation method has the advantages that nitrification reduction and hydrogenation reduction processes are adopted; less waste water, waste gas and solid waste are treated; the selectivity is high; the product treatment is easy; the product yield and the product quality are high; nitric acid, the hydrogenation catalyst and the hydrogenation organic solvents can be recovered for direct application.

Owner:NORTHEAST PHARMA GRP

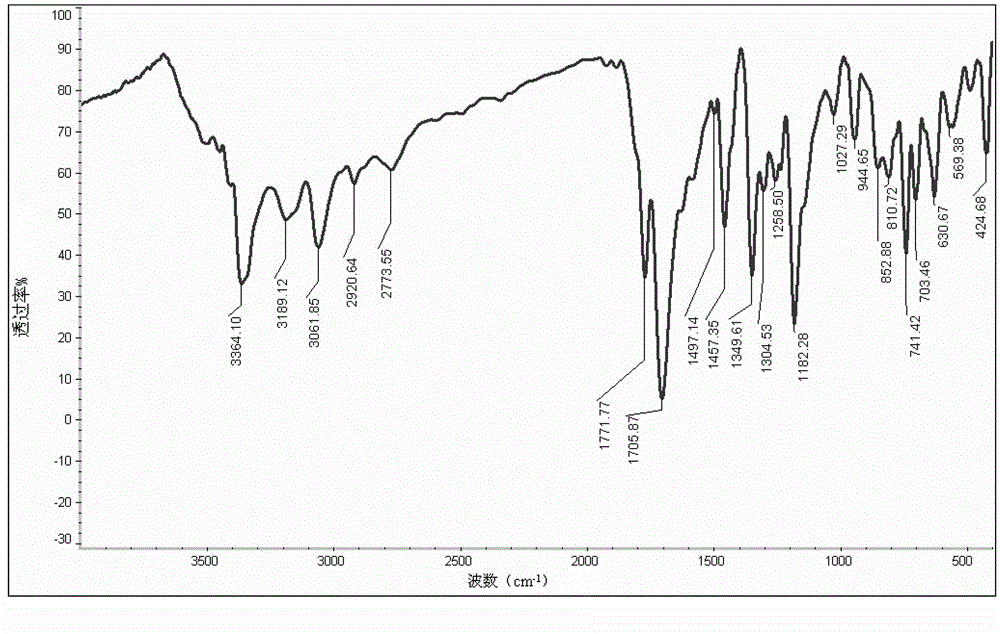

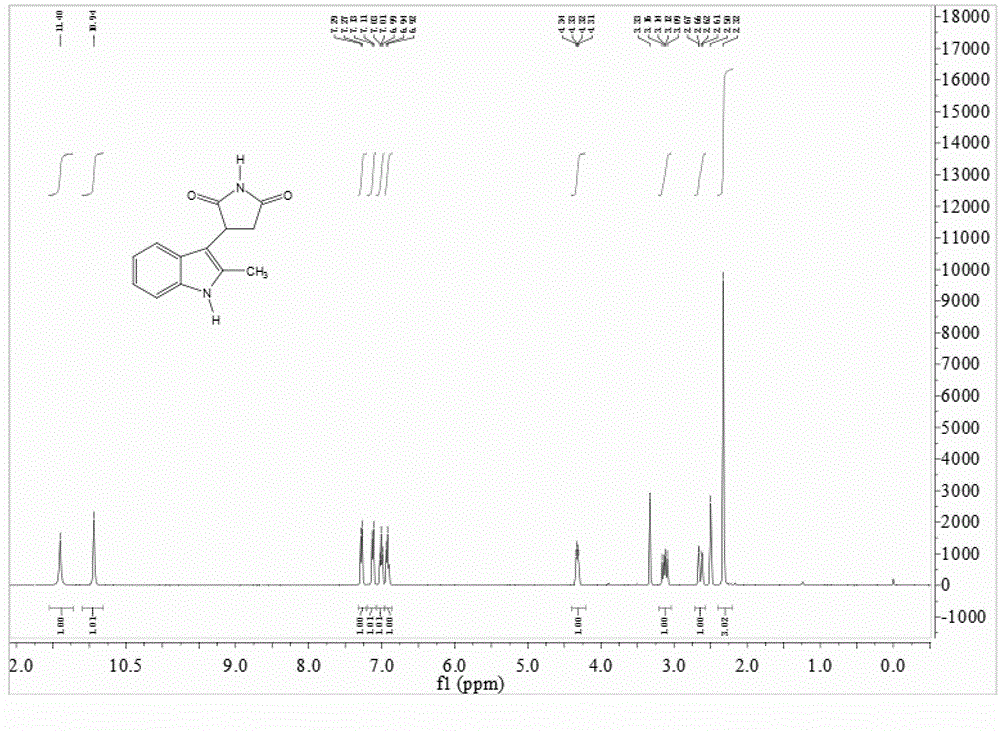

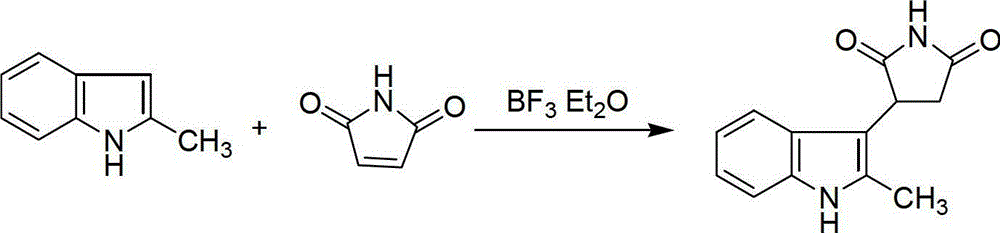

Preparation method of 3-(2-methylindolyl-3-)pyrryl-2,5-dione

The invention relates to a preparation method of 3-(2-methylindolyl-3-)pyrryl-2,5-dione, which comprises the following steps: (1) adding 2-methylindole, maleimide and Lewis acid in a mol ratio of 1.0:(1.0-1.5):(0.2-1.0) into reaction solvent, and reacting under reflux at room temperature to 100 DEG C for 5-24 hours, thereby obtaining a yellow white solution; and (2) evaporating to remove the solvent, adding water, stirring, carrying out vacuum filtration, and recrystallizing the obtained solid with ethanol to obtain the 3-(2-methylindolyl-3-)pyrryl-2,5-dione. In the process of preparing the 3-(2-methylindolyl-3-)pyrryl-2,5-dione, by using boron trifluoride and other Lewis acid as a catalyst, the reaction time is shortened, and the treatment of three wastes is lowered. The method has the advantages of higher yield, accessible raw materials, low cost, simple reaction operation and short reaction route, can easily implement industrial production, and has wide favorable application prospects.

Owner:DONGHUA UNIV

Multistage resource recycling integrated process for glyphosate mother liquor

ActiveCN106116705AReduce pressure on environmental protectionReduce waste disposalChemical industryAlkali metal chloridesChemistryMother liquor

The invention discloses a multistage resource recycling integrated process for glyphosate mother liquor. The multistage resource recycling integrated process comprises the following steps: the glyphosate mother liquor is fed into a membrane treatment device, and concentrated mother liquor and a permeate liquid I are obtained; one part of the concentrated mother liquor is used for glyphosate powder extraction, the other part of the concentrated mother liquor is subjected to primary oxidation and primary crystallization separation, a primary centrifugal filtrate is prepared and fed into a membrane treatment system, and a concentrated solution and a permeate liquid II are obtained; the concentrated solution obtained in the membrane treatment system is subjected to secondary crystallization separation, secondary oxidation and tertiary crystallization separation, a centrifugal filtrate is fed into a room-temperature oxidation device, and phosphorus paste is prepared. The multistage resource recycling integrated process adopts effective combination of membrane separation, two times of oxidation, three times of crystallization separation, room-temperature oxidation and the like, finally, room-temperature drained water is subjected to biochemical treatment and drained up to the standard, multistage resource treating and recycling of the glyphosate mother liquor are realized, discharge of three wastes and energy consumption are reduced, and cost control is facilitated.

Owner:福华通达化学股份公司

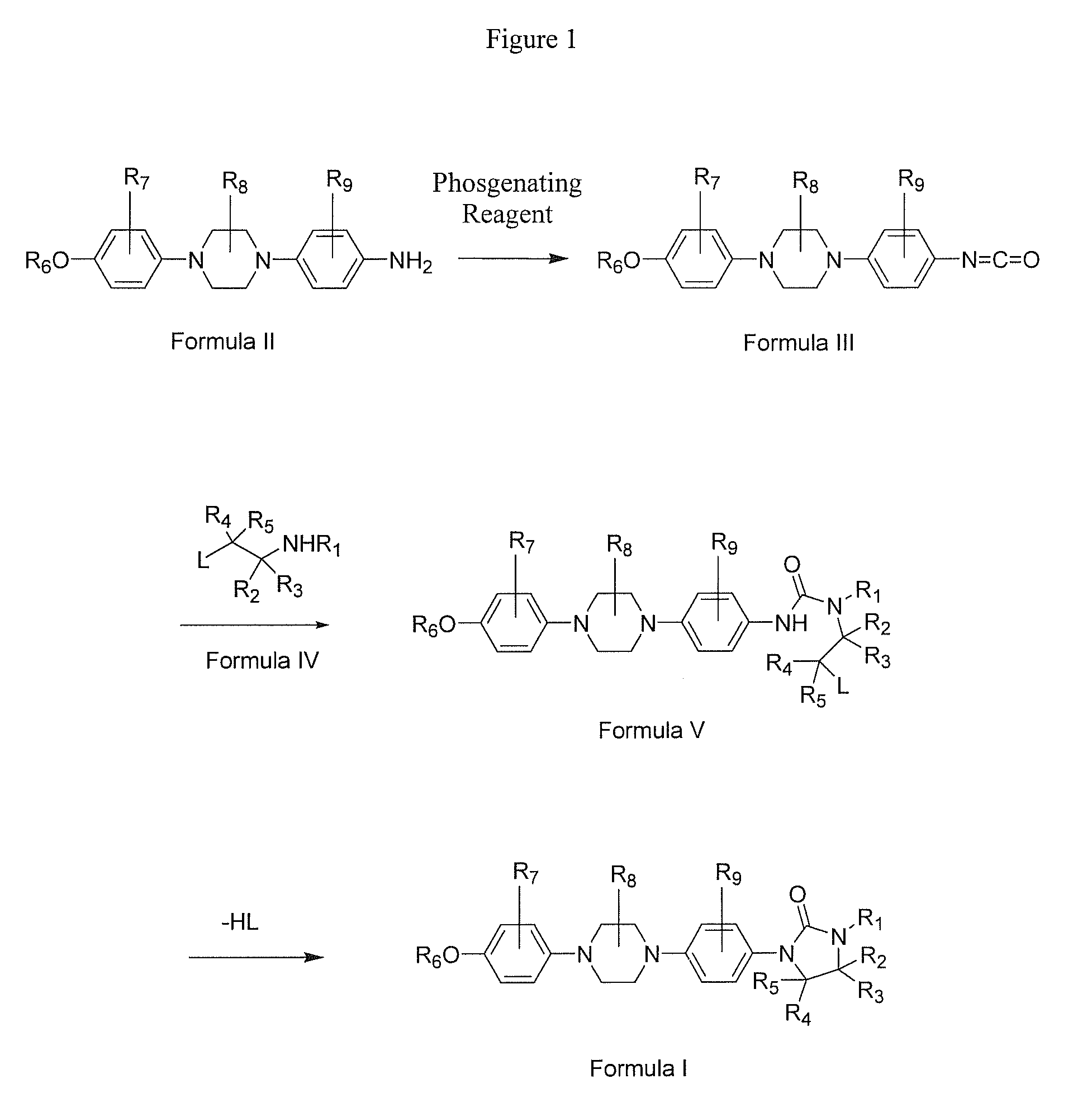

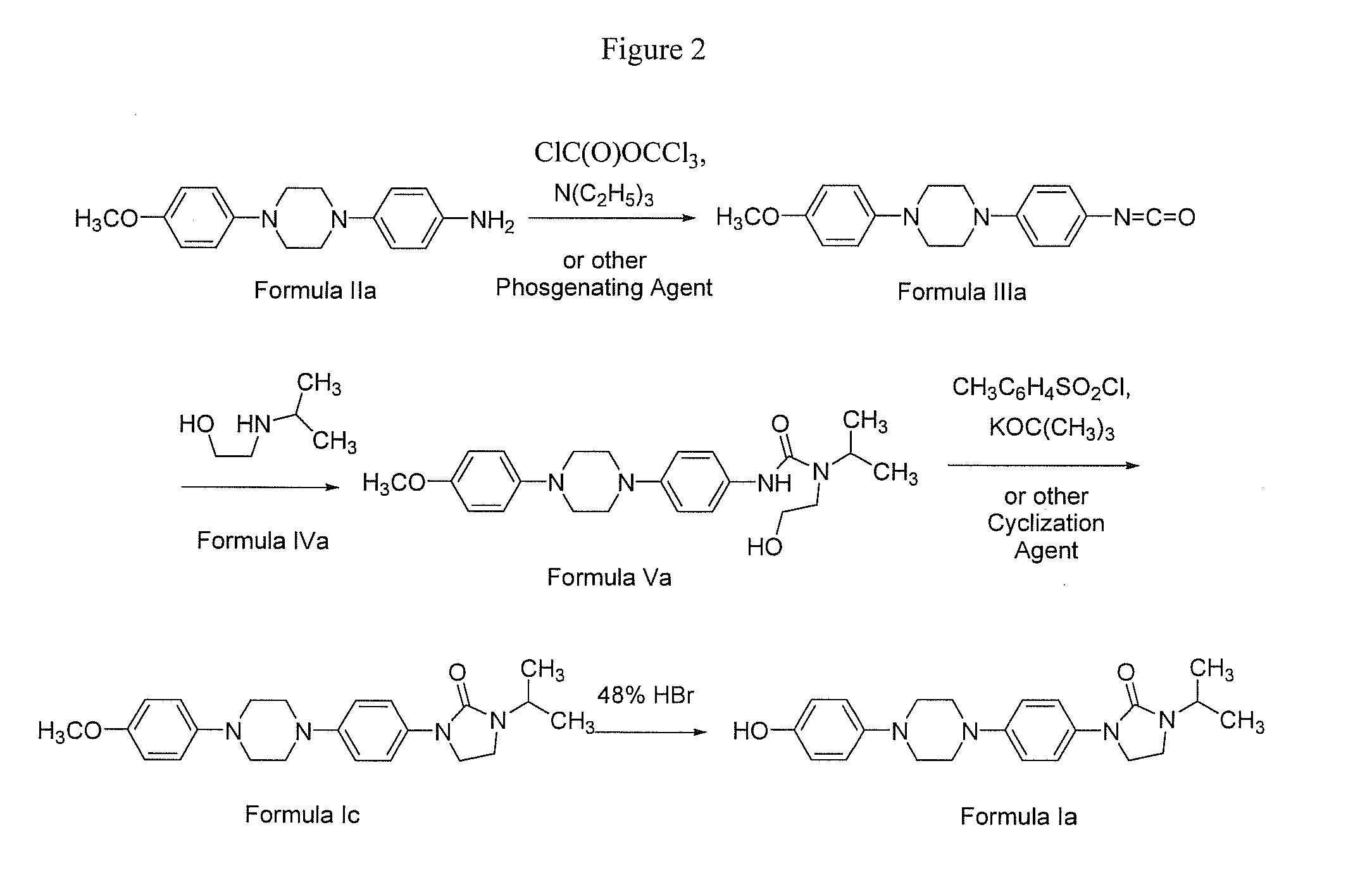

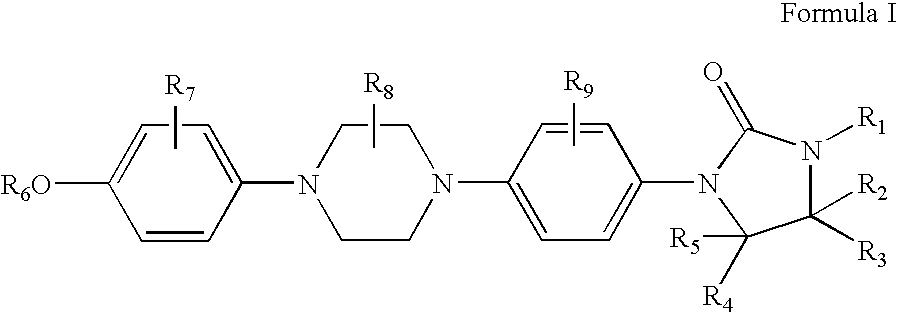

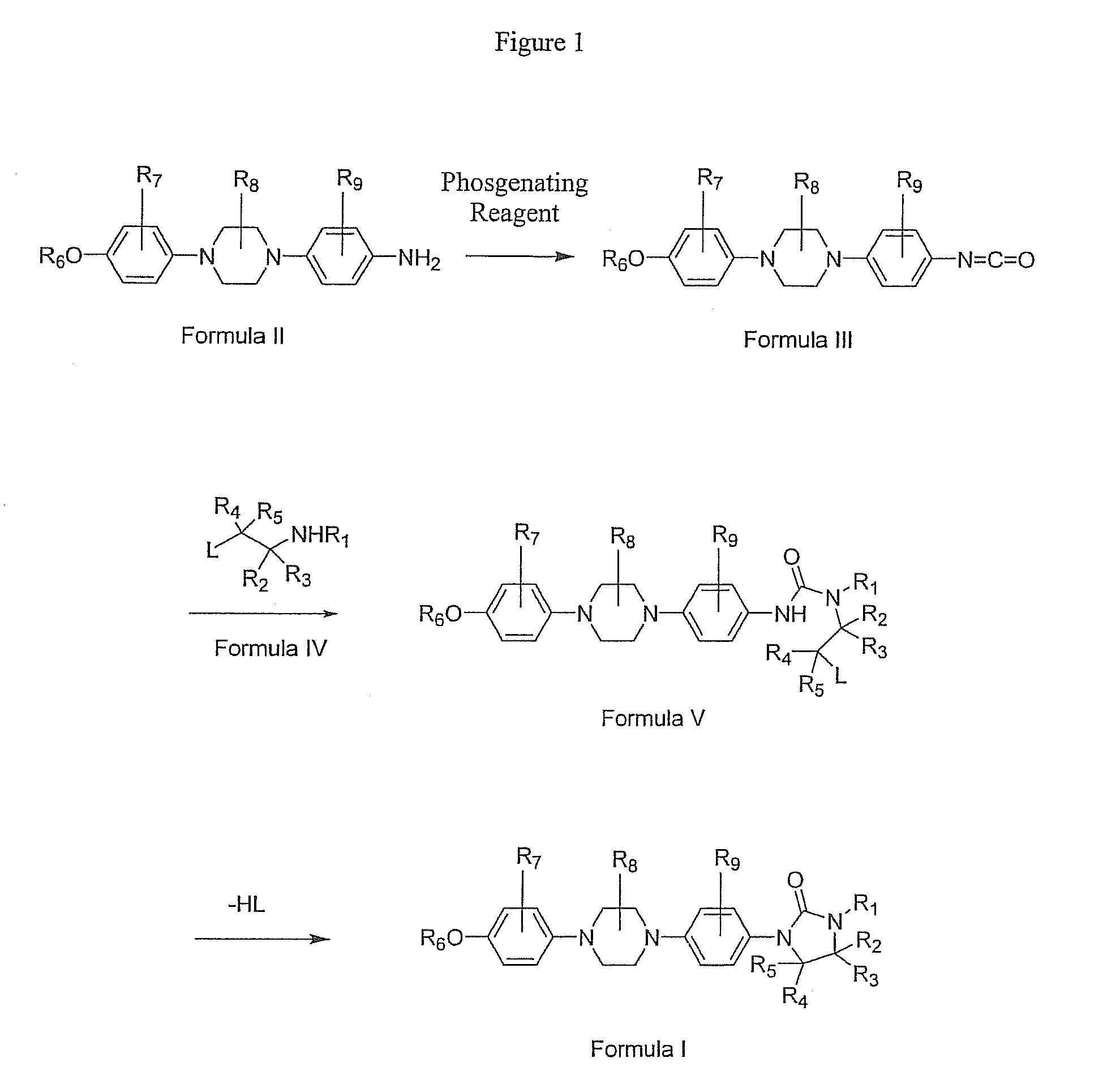

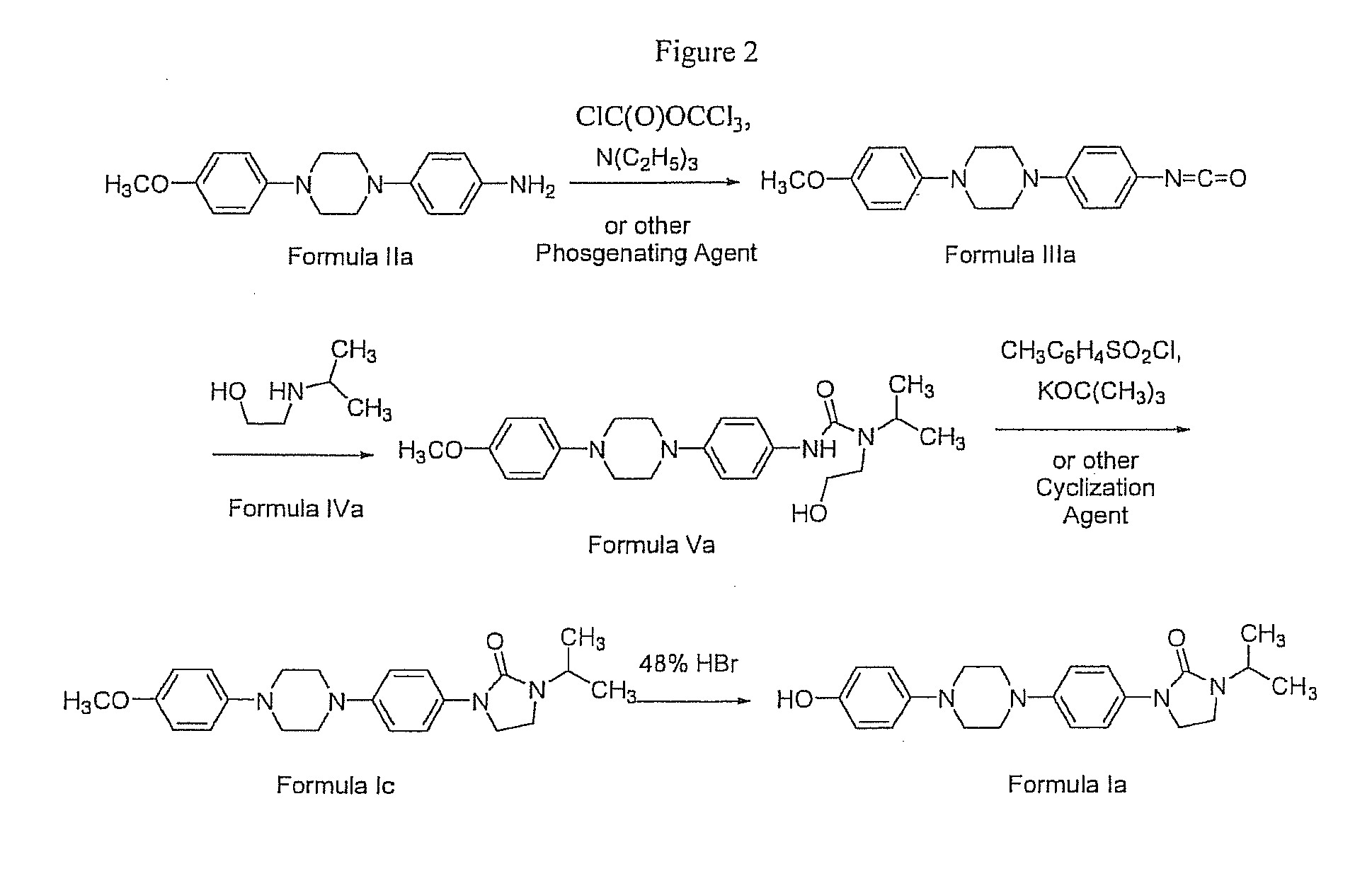

Method for Manufacture of 2-Oxoimidazolidines

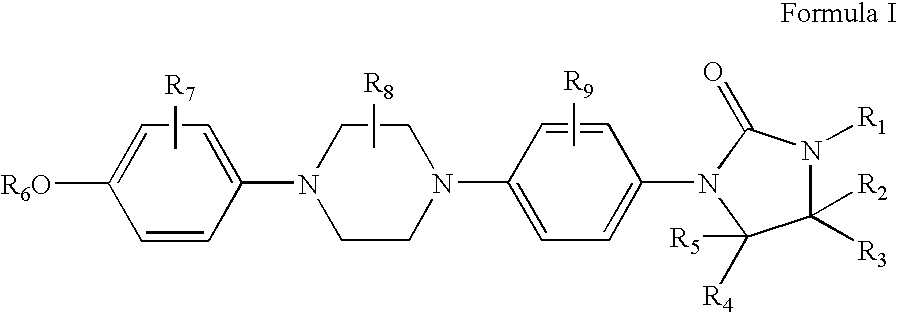

InactiveUS20100222588A1Reduce manufacturing costHigh atom efficiencyOrganic chemistryLeaving groupPramiconazole

There is provided a method for manufacture of 2-oxoimidazolidines of Formula I comprising one or more of the steps of converting an amine to an acylation agent, condensation of the acylation agent with a bi-functional compound of structure L-C(R4)(R5)—C(R2)(R3)—NHR1, wherein L is a leaving group, and ring closure of the resulting urea. In this manner, certain 2-oxoimidazolidines may be manufactured that are useful intermediates for the production of Pramiconazole and structurally related compounds.

Owner:VERTICHEM CORP

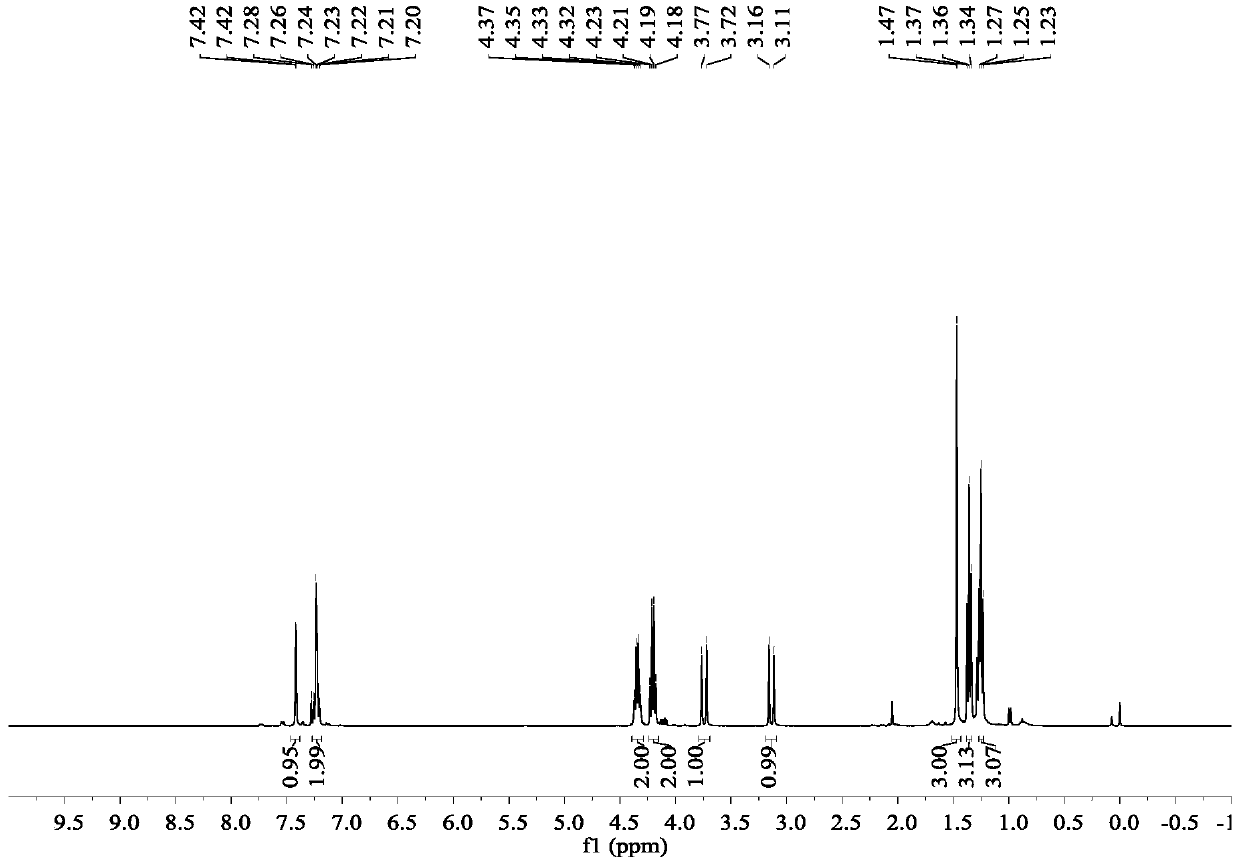

Low sodium cleavage product

InactiveUS6825387B2Poor recoveryReduce waste disposalOxygen-containing compound preparationOrganic compound preparationProduction rateHydrogen

Washed cleavage product (WCP) in a phenol manufacturing process is treated to remove sodium ions. The WCP is contacted with a cation exchange resin in hydrogen form, and then with anion exchange resin in free base or hydroxide form, to produce a WCP essentially free of sodium ions. The cation and anion exchange resins are regenerated with acid and caustic, respectively. The treatment improves productivity and product quality of new and existing phenol processes.

Owner:KELLOGG BROWN & ROOT INC

The preparation method of two [propyltriethoxysilane] disulfide

ActiveCN103772427BWide variety of sourcesLarge industrial production operation safetyGroup 4/14 element organic compoundsPtru catalystOrganic solvent

The object of the present invention is to provide a kind of method that does not contain buffering agent and synthesizes two [propyltriethoxysilane] disulfides under aqueous phase conditions, comprising the following steps: A, making sodium polysulfide aqueous solution, chloropropane Base triethoxysilane reacts under the aqueous phase condition of phase-transfer catalyst and water-insoluble organic solvent, produces reaction mixture; B, separates two [propyl triethoxysilane] disulfides from above-mentioned reaction mixture . The method for separating the product bis[propyltriethoxysilane] disulfide from the reaction mixture in the step B comprises the following steps: a, organic phase separation: the upper layer of the reaction mixture obtained in step A is an organic phase, and the lower layer is water phase, separate the organic phase; b, purify the organic phase: distill and purify the above organic phase to obtain the product bis[propyltriethoxysilane] disulfide. Using the method of the invention improves the yield, reduces the generation of three wastes, and eases the pressure on environmental protection.

Owner:南京曙光新材料有限公司

Synthesis method of mefenpyr-diethyl

ActiveCN110003107AStarting materials are readily availableShort reaction timeOrganic chemistryHydrazoneSynthesis methods

The invention relates to a synthesis method of mefenpyr-diethyl. The method comprises the steps of carrying out a reaction among 2,4-dichlorophenylhydrazine hydrochloride, ethyl glyoxalate and alkaliin a solvent, and carrying out a [3+2] cycloaddition reaction between obtained 2,4-dichlorophenylhydrazine ethyl glyoxylate hydrazone and ethyl methacrylate in a solvent under the function of a catalyst and an oxidant. According to the synthesis method, the starting raw materials are easy to obtain, the reaction time is shortened, the reaction path is short, the cost is low, the operation is simple, and three-waste treatment is lowered; under the same condition, the yield is higher, and industrial production is facilitated.

Owner:DONGHUA UNIV

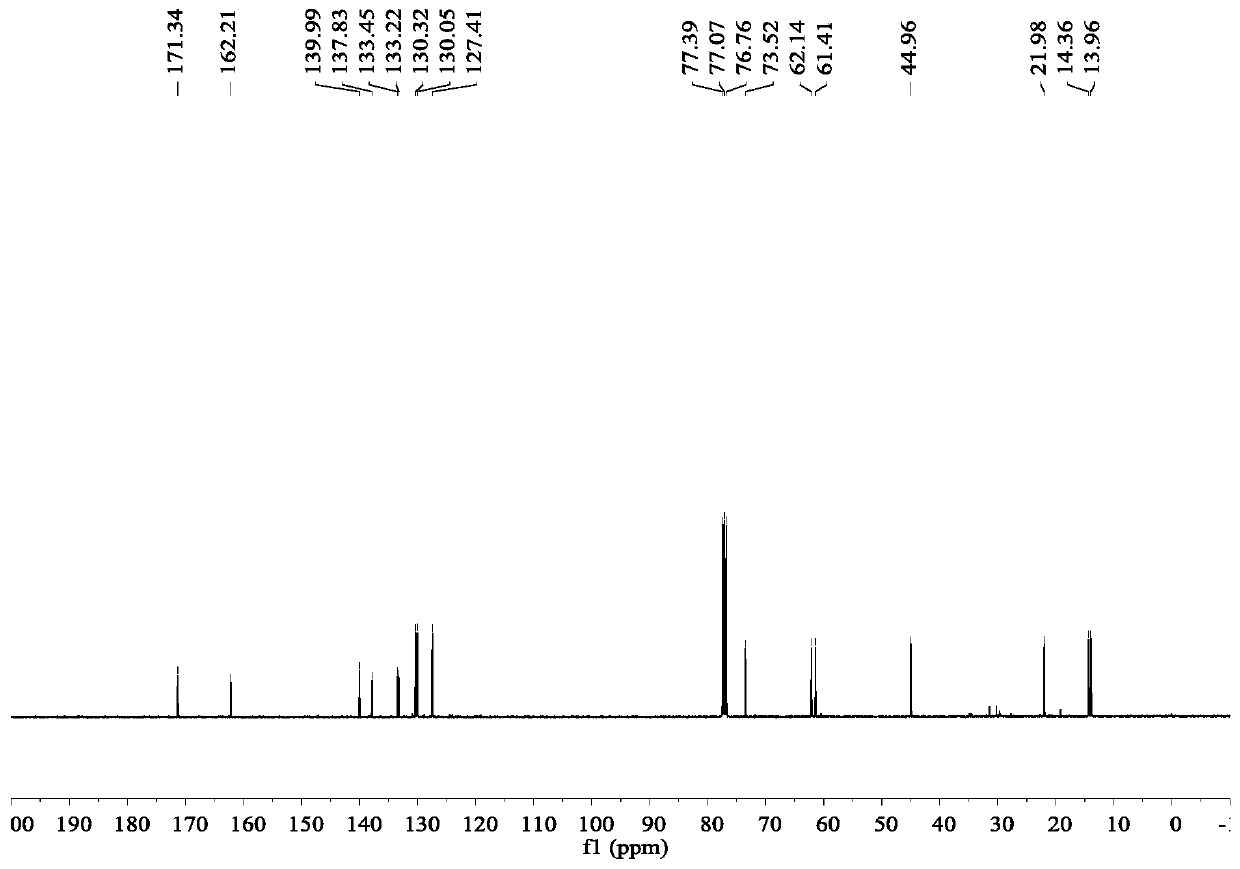

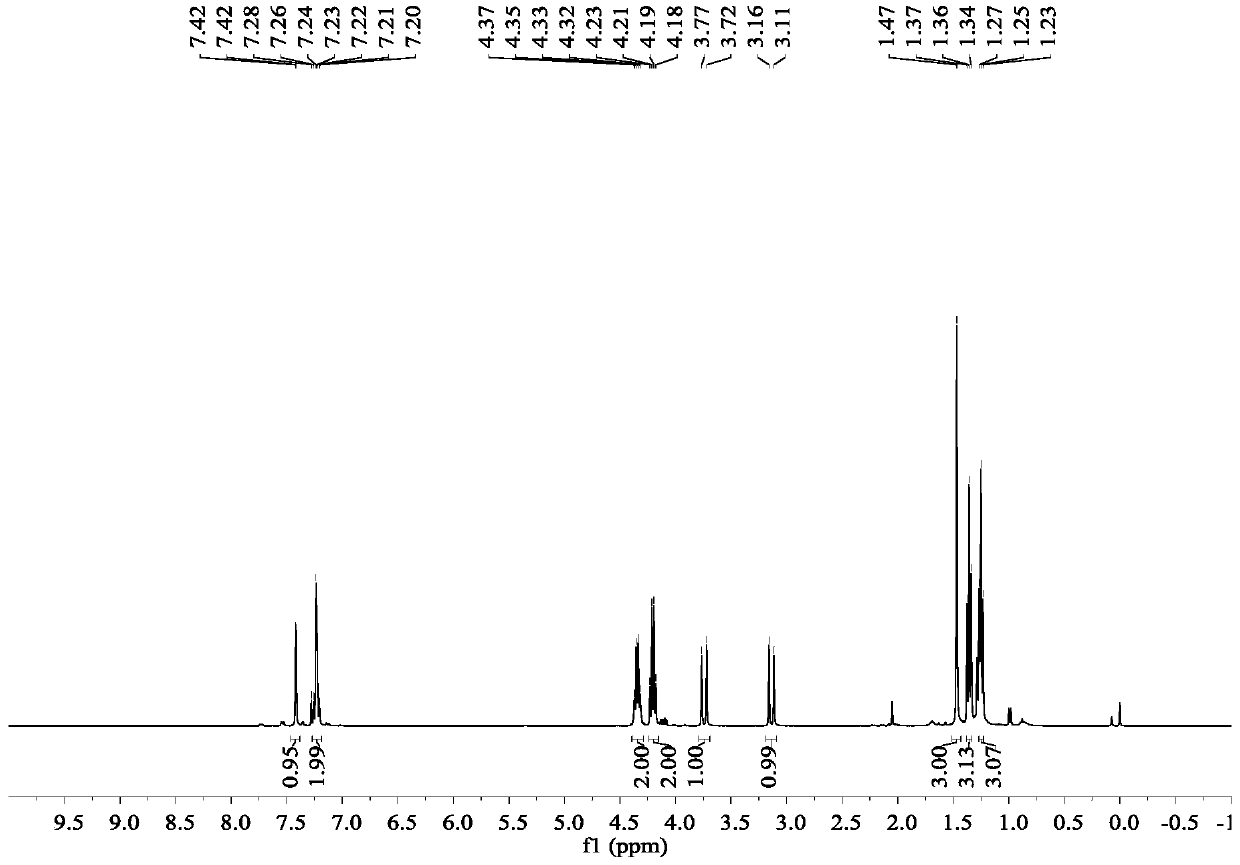

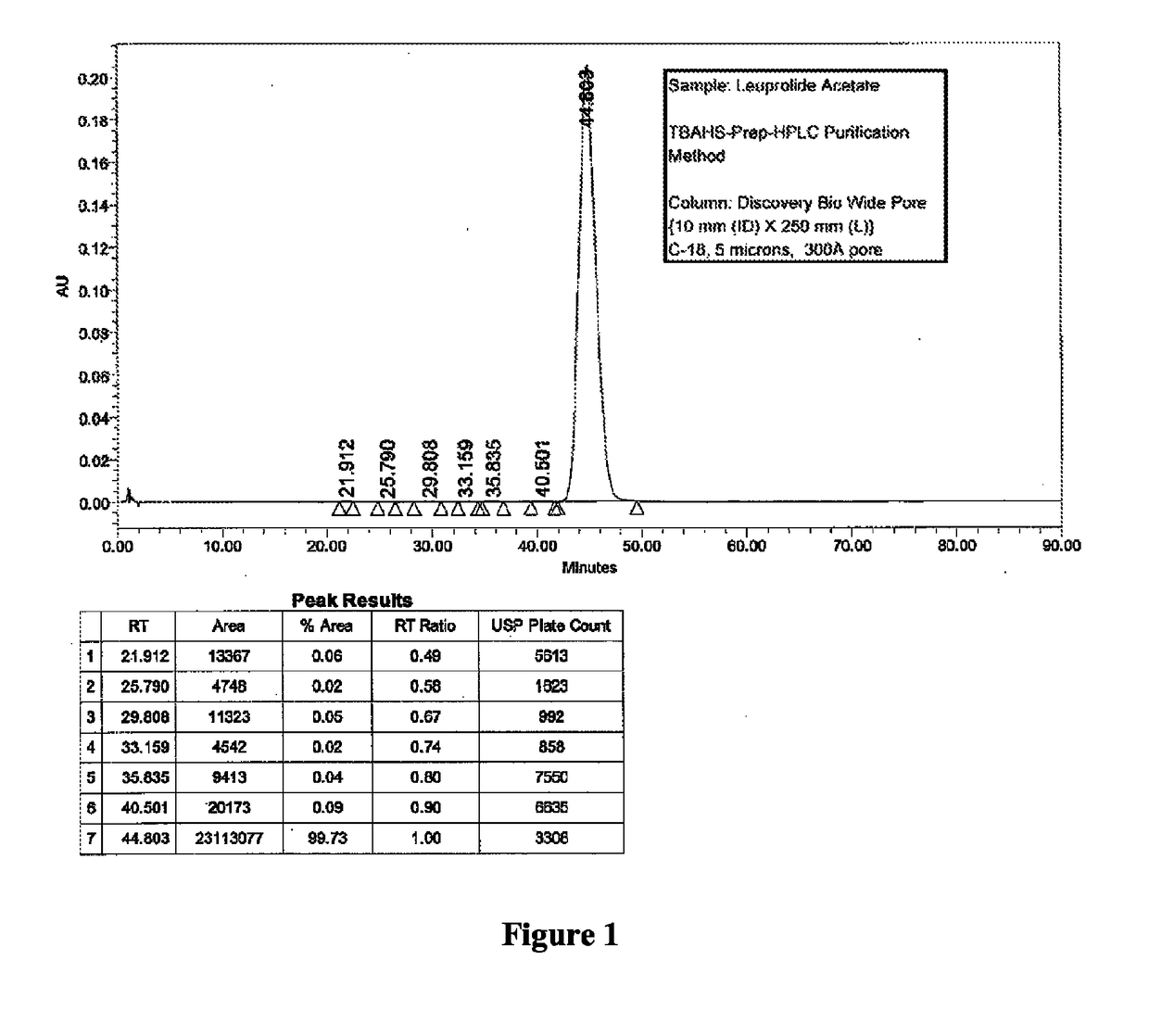

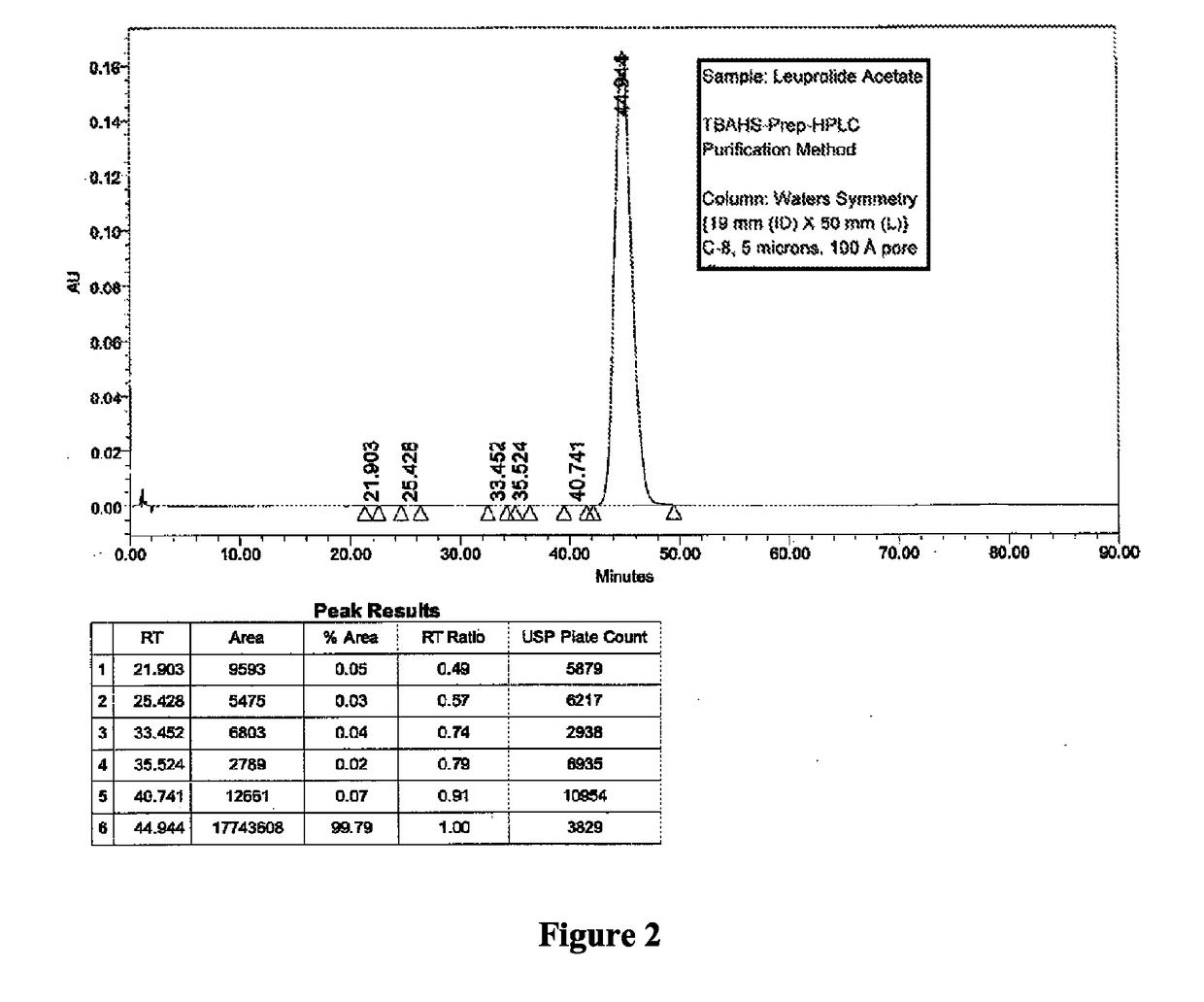

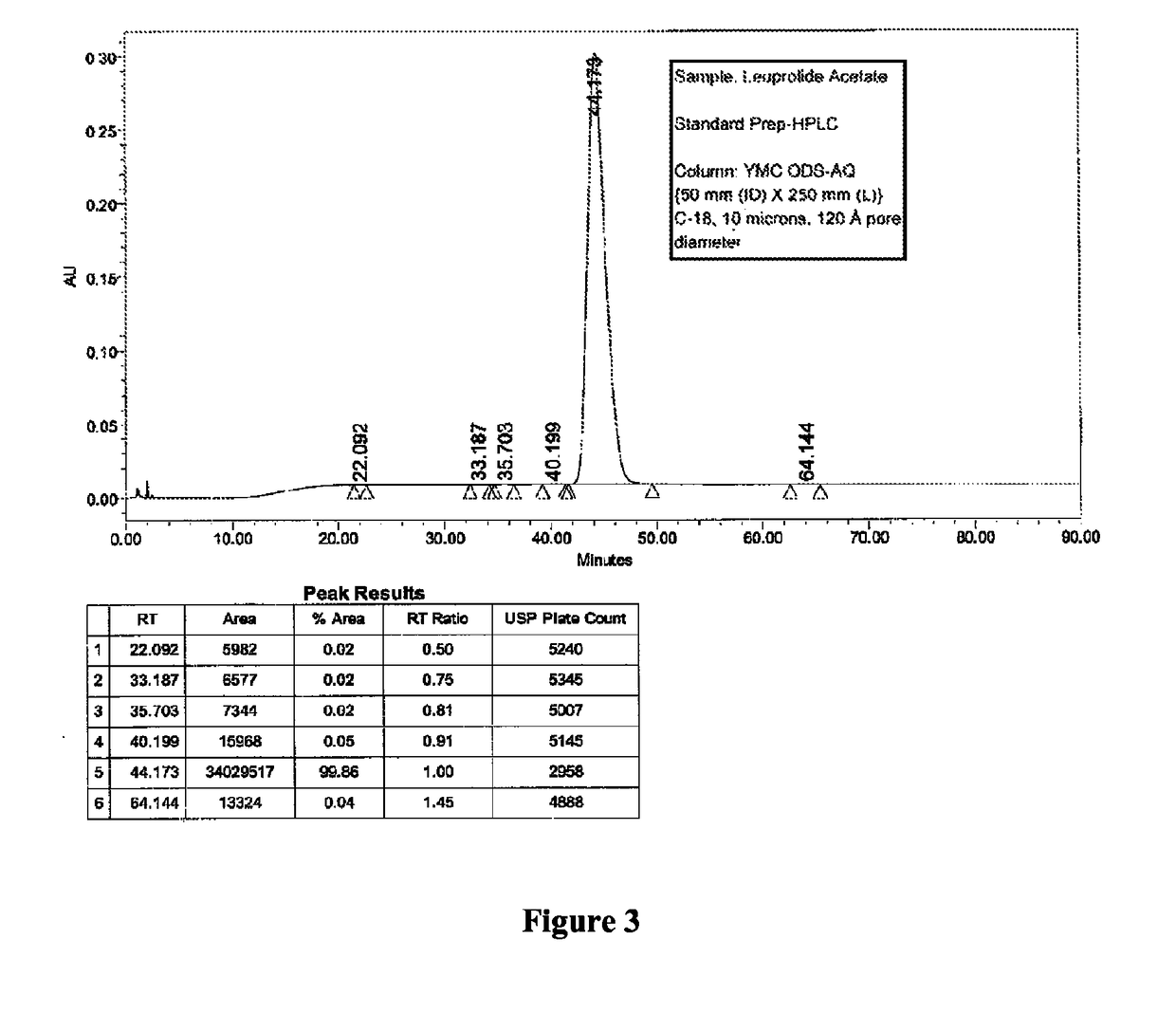

Purification of organic compounds using surrogate stationary phases on reversed phase columns

ActiveUS9724622B2Limited use of solventReduce waste disposalCation exchanger materialsComponent separationStationary phasePhosphonium salt

There are only two ways to increase the amount of sample that can be purified by preparative reversed phase high performance liquid chromatography (Prep-RP-HPLC) in a single run: (1) The traditional approach is to use a bigger column (greater amount of stationary phase); and (2) Use displacement chromatography which uses the stationary phase more effectively. This invention describes a unique Prep-RP-HPLC technique that uses a C-18 / C-8 derivatized silica coated with a hydrophobic quaternary ammonium salt or quaternary phosphonium salt to result in 7 to 12 fold increase in sample loading (of the crude mixture of organic compounds including synthetic crude peptides) in contrast to the conventional Prep-RP-HPLC technique. This increase in sample loading capacity and output is due to the additional surrogate stationary phase characteristic of the C-18 / C8 bound quaternary salt. The quaternary surfactant is bound to the C-18 / C-8 chains and silanols of the stationary phase.

Owner:NEULAND HEALTH SCI

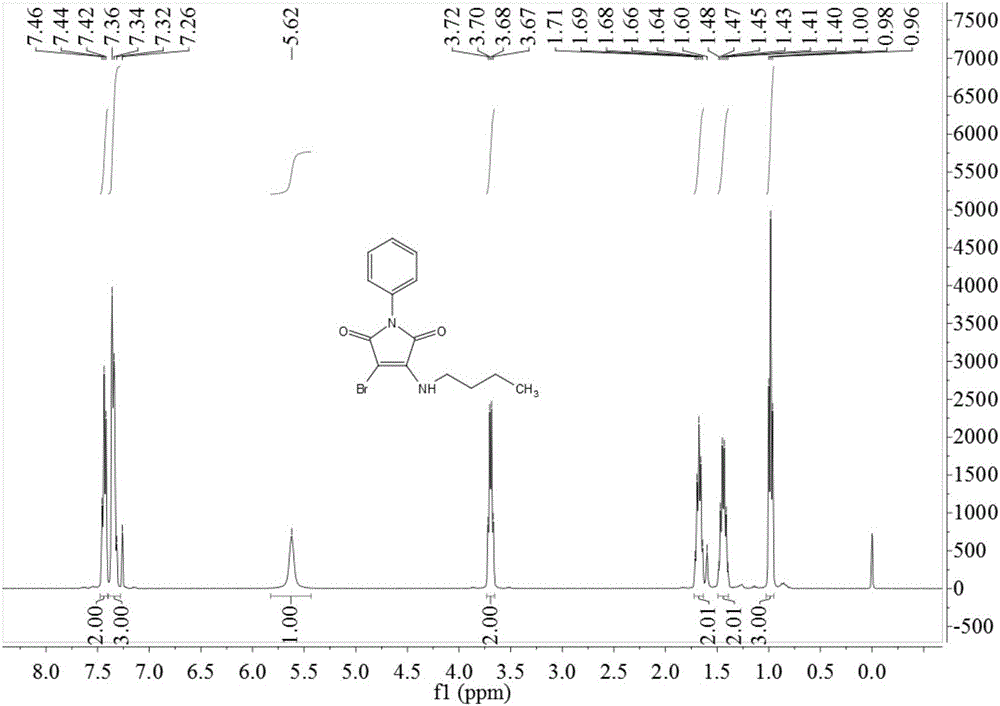

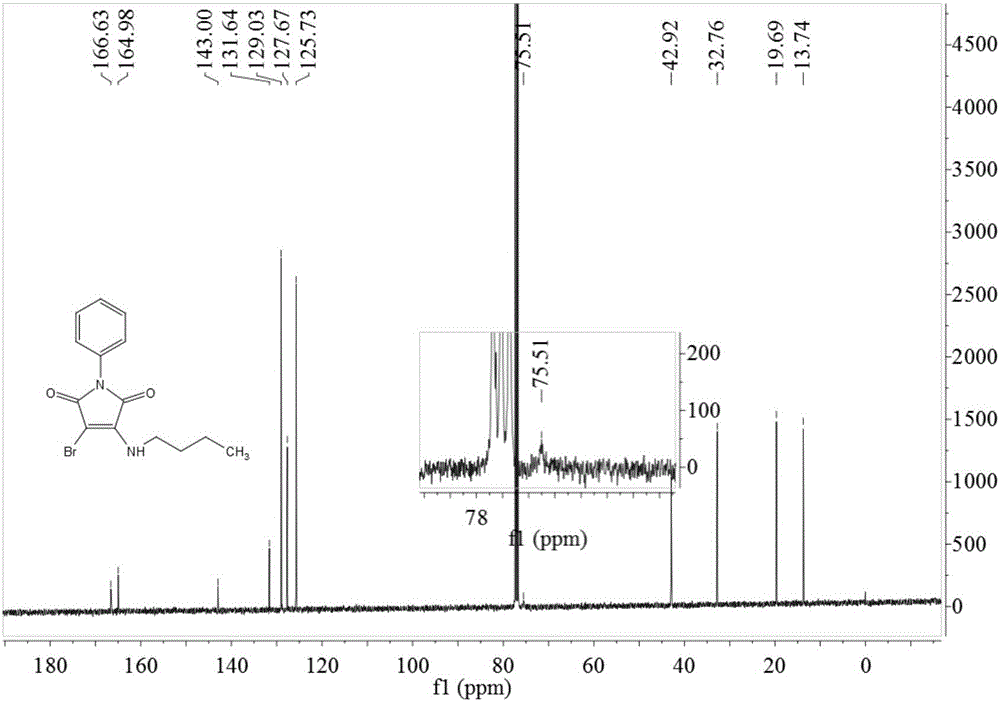

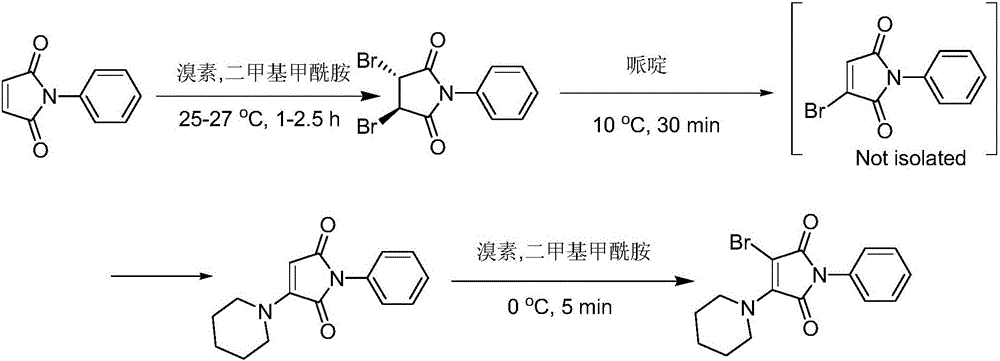

Preparation method of 3-n-butylamine-4-bromo-N-phenylmaleimide

InactiveCN106243009ADelayed reaction timeReduced responseOrganic chemistryN-phenylmaleimideWastewater

The invention relates to a preparation method of 3-n-butylamine-4-bromo-N-phenylmaleimide. the preparation method comprises the following steps: adding N-phenylmaleimide, n-butylamine and a brominating agent into a solvent, reacting at room temperature of minus 100 DEG C for 1-3 h, adding water and stirring after the end of the reaction, extracting, drying, concentrating, and recrystallizing to obtain 3-n-butylamine-4-bromo-N-phenylmaleimide. Yield of 3-n-butylamine-4-bromo-N-phenylmaleimide is high; reaction operation is simple; reaction route is short; and there is less ''three wastes'' (waste gas, wastewater and residue). The preparation method is easy for industrial production.

Owner:DONGHUA UNIV

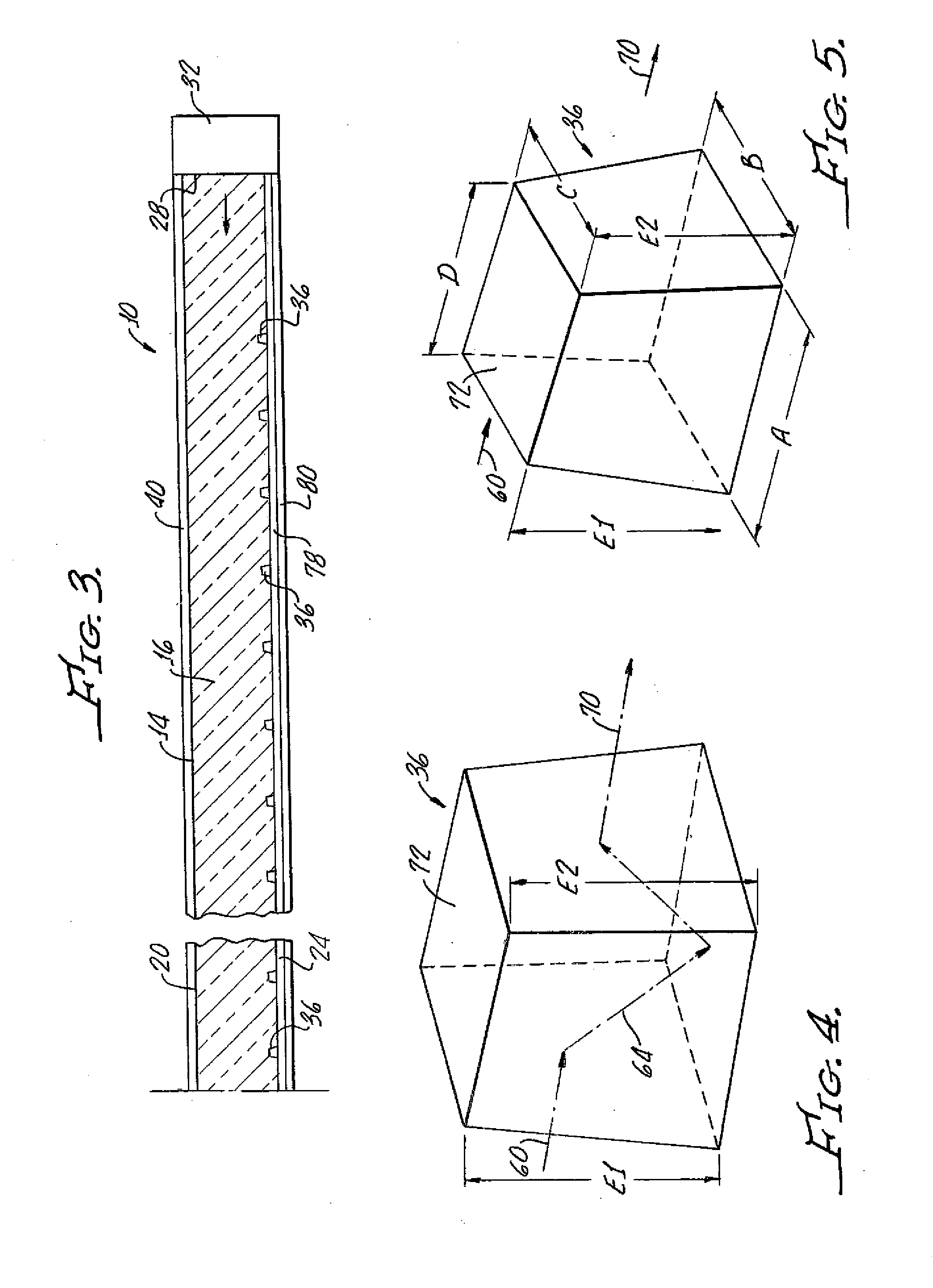

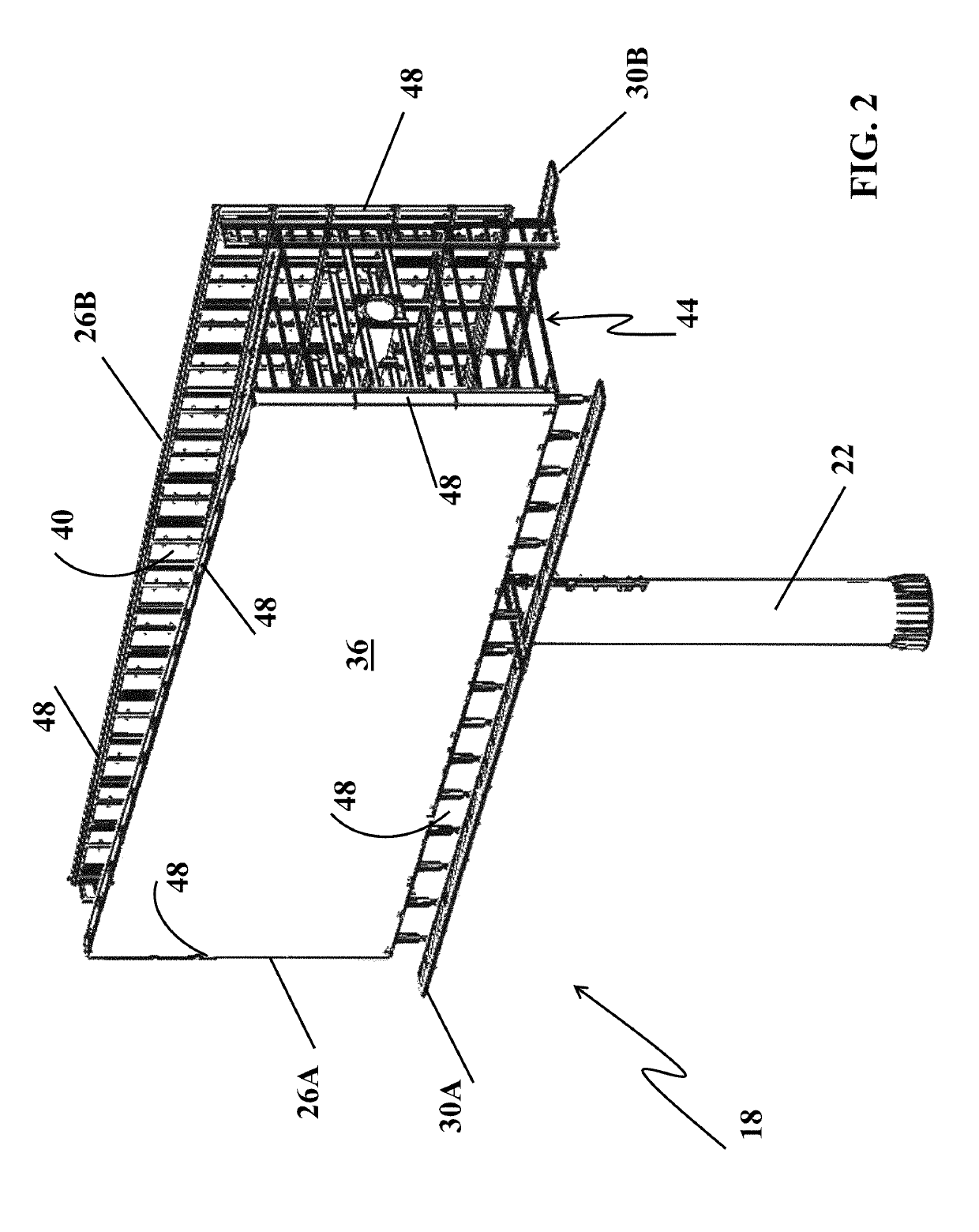

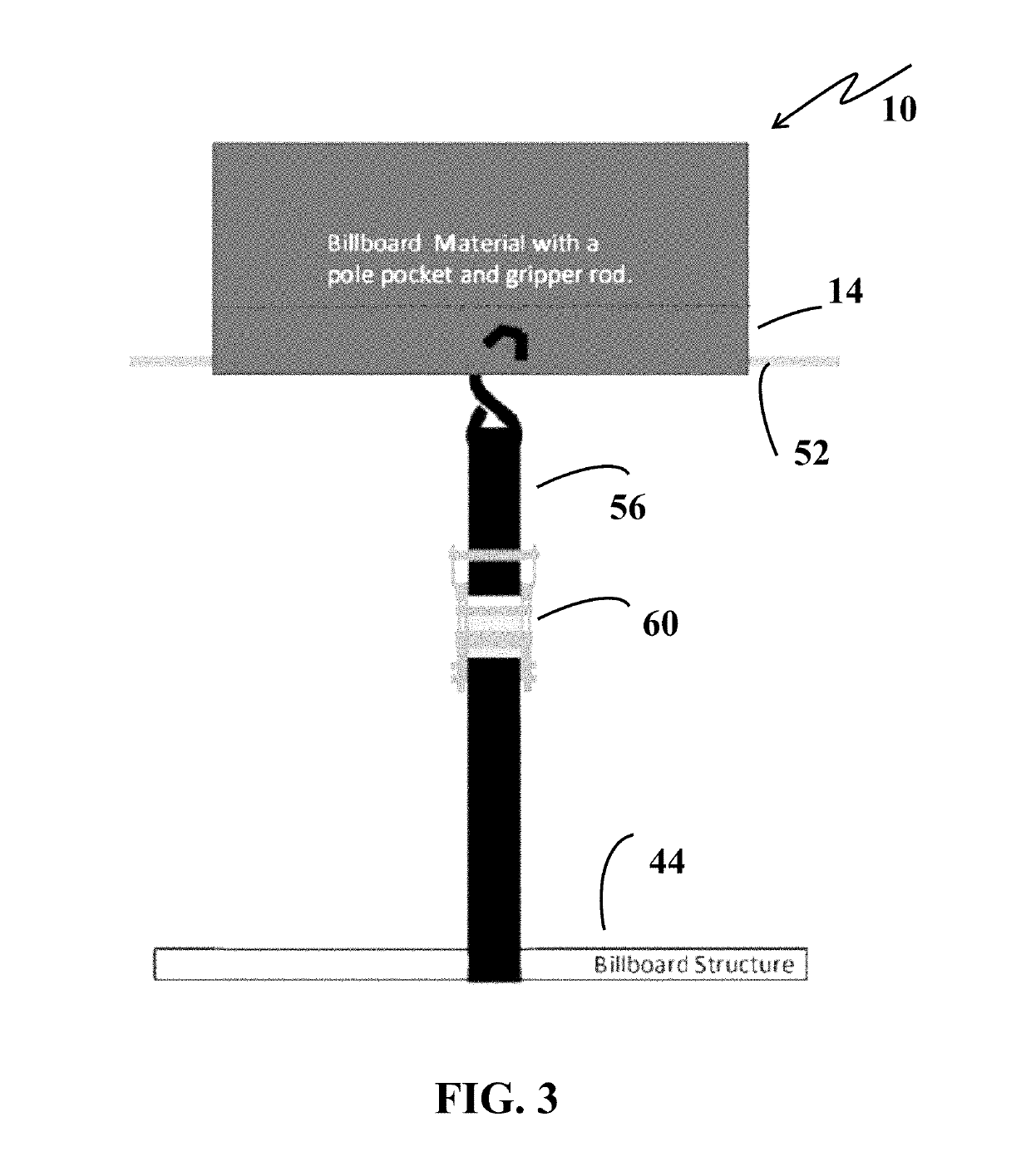

Billboard print material and installation method

A billboard advertising apparatus and installation method include an under-layer base and an overlying image layer. The under-layer provides an opaque white surface to a billboard panel as well as protection for the overlying image layer. The image layer is a thin translucent color layer with advertising or message copy. With the presence of a base or under-layer, the cost to make the image layer may be significantly reduced.

Owner:R2 BILLBOARDS LLC

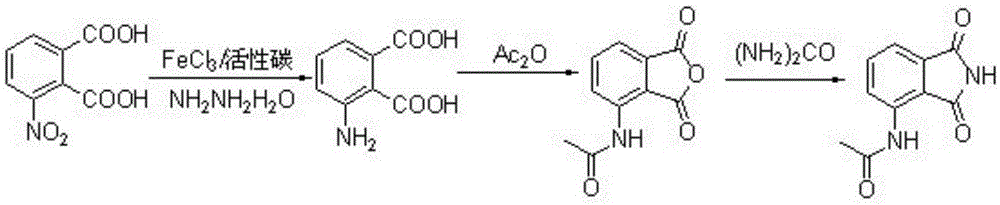

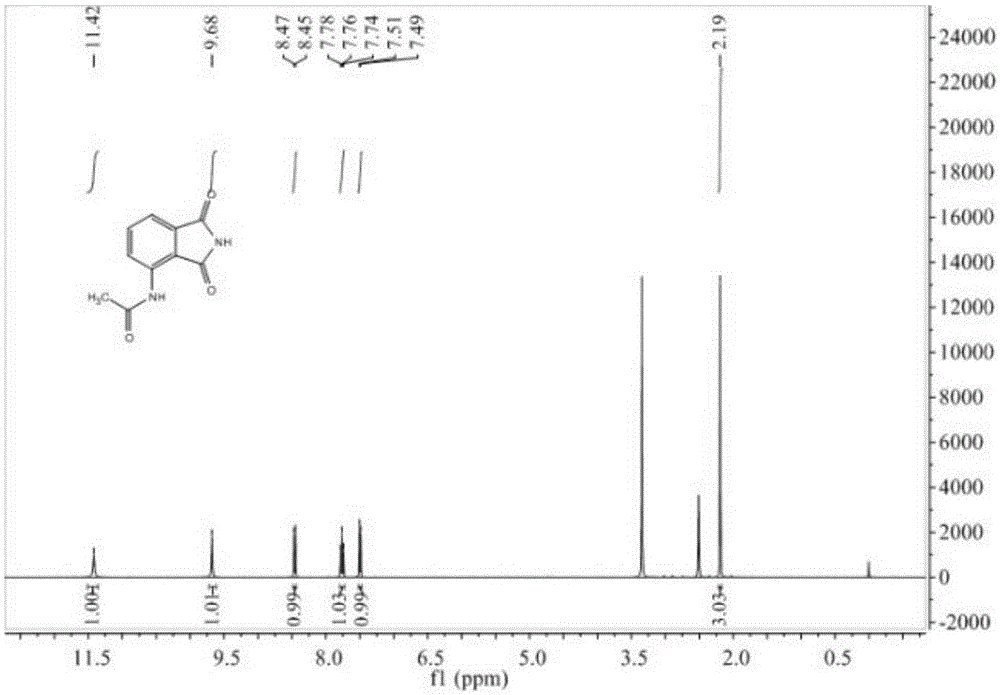

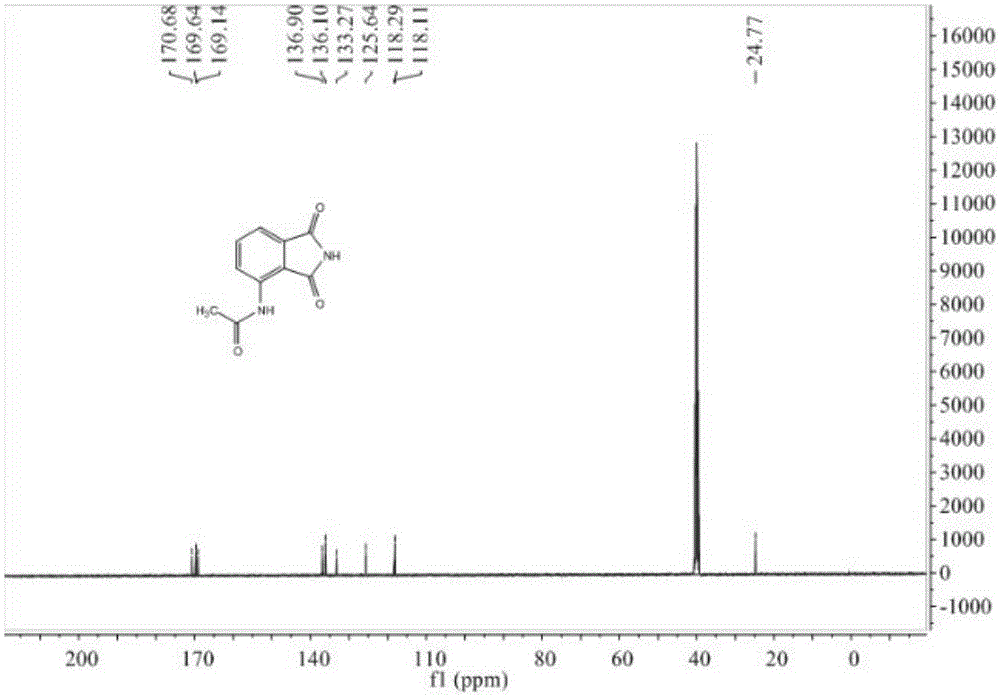

Preparation method of 3-acetyl aminophthalimide

InactiveCN105330587AShort reaction timeReduce waste disposalOrganic chemistryAcetic anhydrideAqueous sodium hydroxide

The invention relates to a preparation method of 3-acetyl aminophthalimide, comprising the following steps: dissolving 3-nitro phthalic acid in sodium hydroxide aqueous solution, then adding a reducer and a catalyst, heating to 70 to 80 DEG C, stirring and reacting for 1 to 20 hours, and recrystallizing to obtain 3-amino phthalic acid; stirring with acetic anhydride and performing reflux reaction for 1 to 10 hours to obtain N-(1,3-Dioxo-1,3-dihydro-2-benzofuran-4-yl)acetamide; dissolving the N-(1,3-Dioxo-1,3-dihydro-2-benzofuran-4-yl)acetamide in an organic solvent, adding an amino donor, and stirring and refluxing for 1 to 10 hours, thus obtaining the 3-acetyl aminophthalimide. The method is simple in operation, high in yield, short in reaction route, less in the three wastes (waste gas industrial residue), and easy for industrial production.

Owner:DONGHUA UNIV

Method for manufacture of 2-oxoimidazolidines

InactiveUS8431699B2Reduce manufacturing costHigh atom efficiencyOrganic chemistryLeaving groupPramiconazole

There is provided a method for manufacture of 2-oxoimidazolidines of Formula I comprising one or more of the steps of converting an amine to an acylation agent, condensation of the acylation agent with a bi-functional compound of structure L-C(R4)(R5)—C(R2)(R3)—NHR1, wherein L is a leaving group, and ring closure of the resulting urea. In this manner, certain 2-oxoimidazolidines may be manufactured that are useful intermediates for the production of Pramiconazole and structurally related compounds.

Owner:VERTICHEM CORP

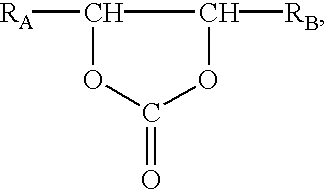

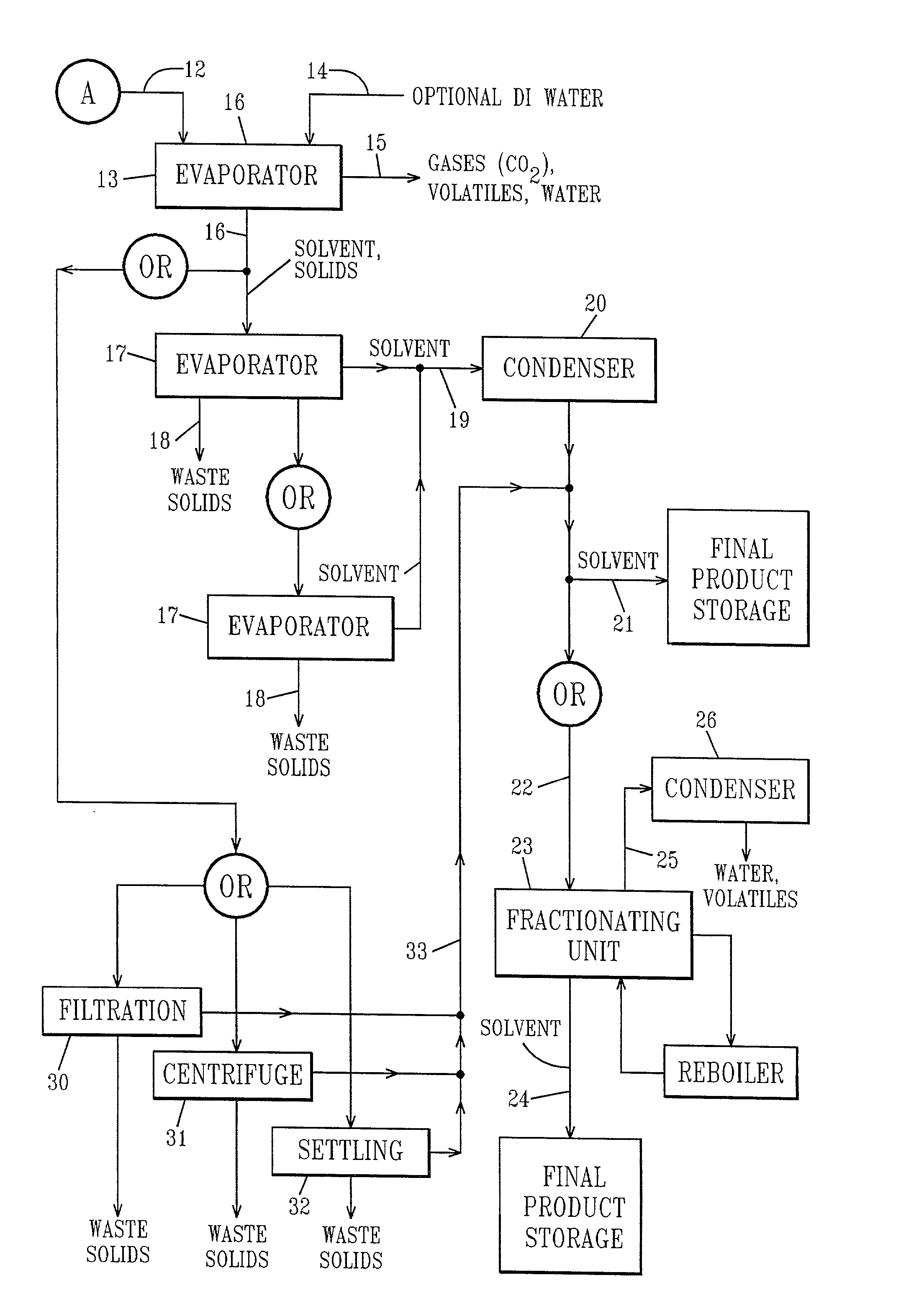

Method for recovering an organic solvent from a waste stream containing supercritical CO2

InactiveUS20030044340A1Reduce waste disposalReduce cost of purchaseDrying using combination processesLiquid surface applicatorsChemistryPollutant

An organic solvent is separated from a waste stream comprising supercritical CO2, an organic solvent and etchant contaminants. The process comprises separating the supercritical CO2 by subjecting the waste stream to elevated temperature and / or reduced pressure to thereby obtain a first composition containing the supercritical CO2 and a second stream containing the organic solvent and being substantially free of the supercritical CO2; and then removing non-volatile etching contaminants from the second stream search as by at least one of the following: evaporation; distillation; filtration; centrifugation; and settling.

Owner:GLOBALFOUNDRIES INC

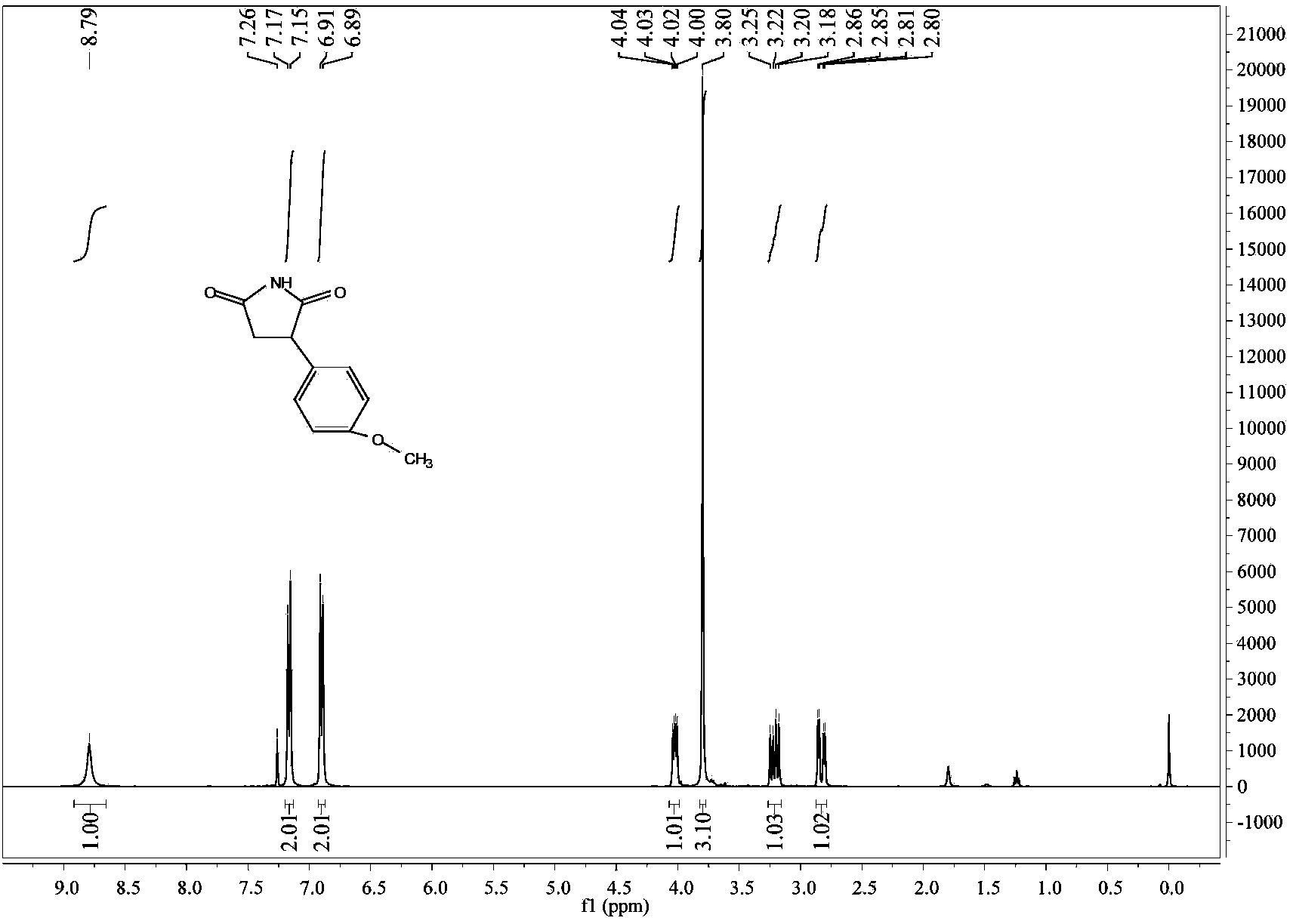

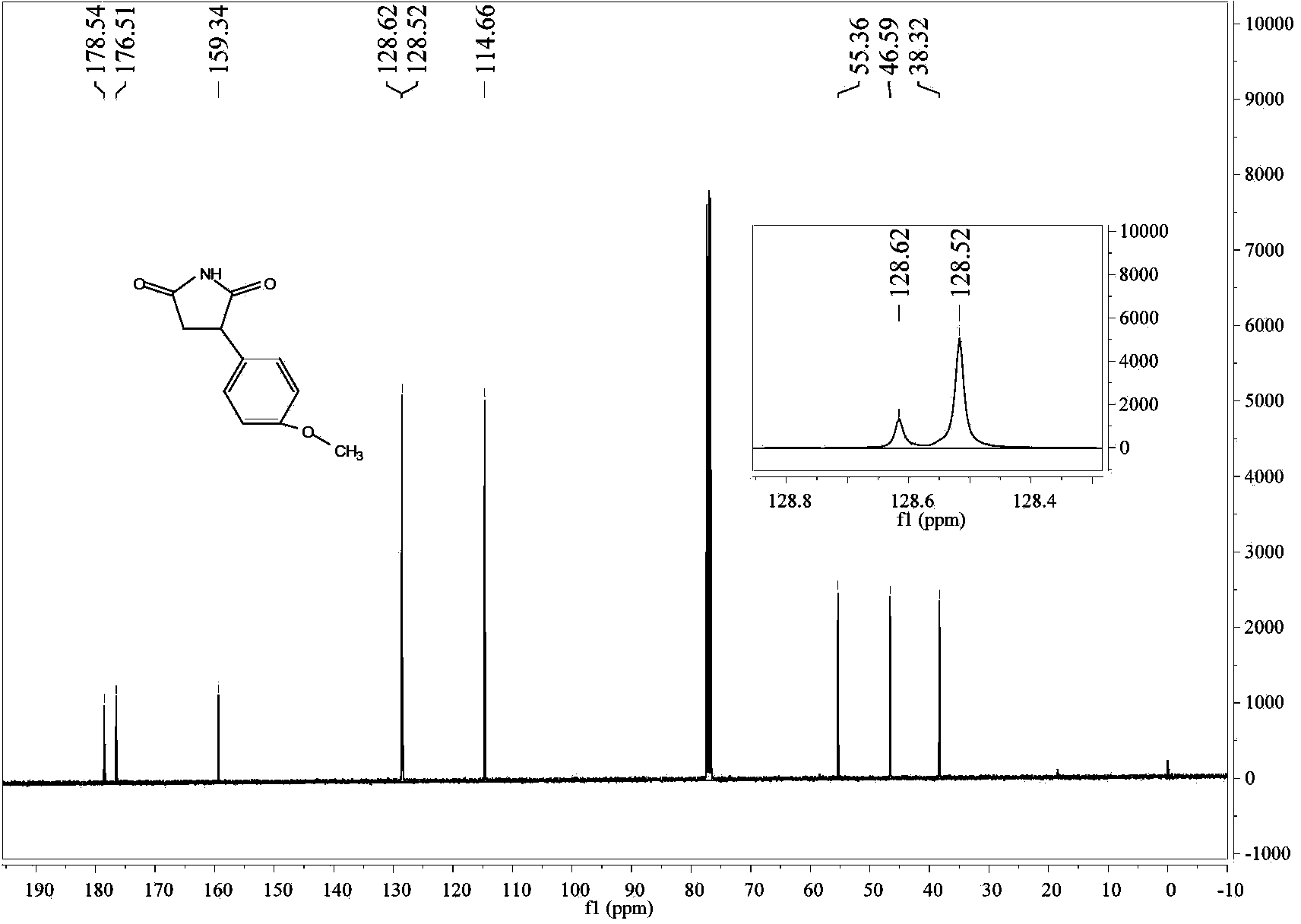

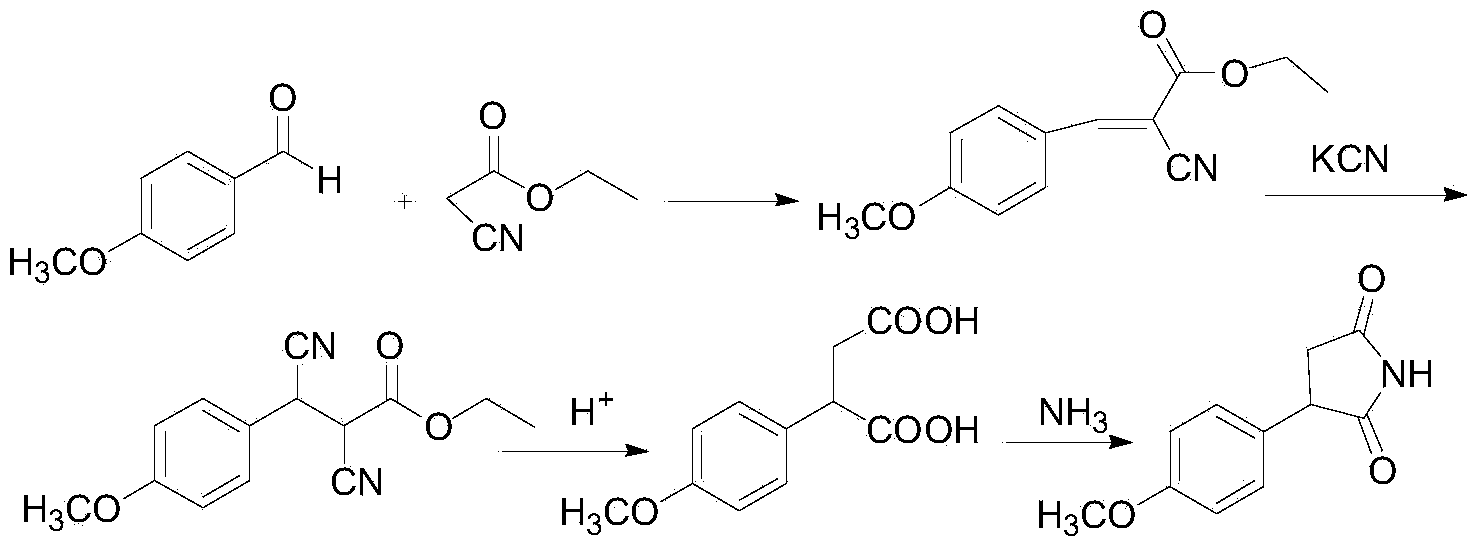

Method for preparing 3-(4-methoxyphenyl)-succinimide

The invention relates to a method for preparing 3-(4-methoxyphenyl)-succinimide. The method comprises the following steps: dissolving anisole, maleimide and lewis acid into a solvent; heating and refluxing to react for 3-20 hours; adding 2N hydrochloric acid, stirring, filtering and recrystallizing to obtain 3-(4-methoxyphenyl)-succinimide. The 3-(4-methoxyphenyl)-succinimide prepared by the method has high yield, low price, simple reaction operation, short reaction route, less three-wastes, and easiness for realization of industrial production.

Owner:DONGHUA UNIV

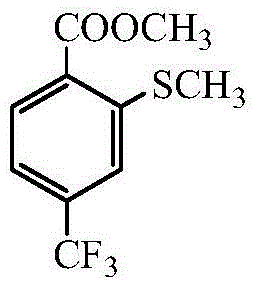

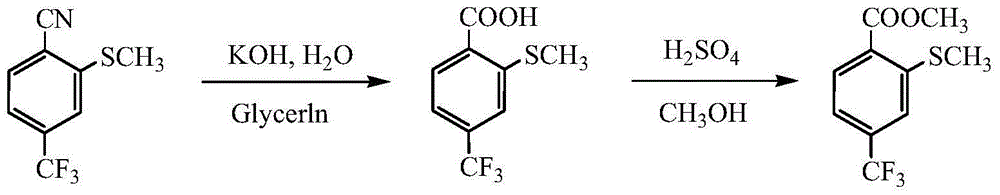

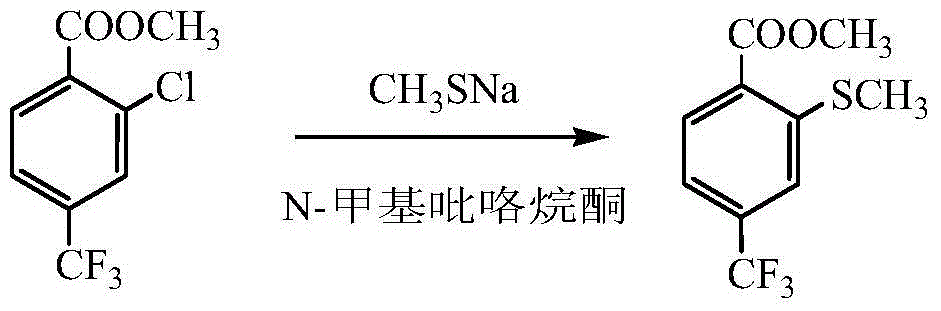

Preparation method for 2-methylmercapto-4-thrifluoromethyl benzoate

InactiveCN104926702AReduce waste disposalReduce the discharge of three wastesSulfide preparationSolventTrifluoromethyl

The invention discloses a preparation method for 2-methylmercapto-4-thrifluoromethyl benzoate. The method comprises the following steps: using 2-methylmercapto-4-trifluoromethylbenzonitrile as a raw material; then under atmospheric pressure, carrying out hydrolysis and esterification reactions with methanol as the raw material and a solvent under acid condition provided by a H2SO4 aqueous solution; and using a one-pot method so as to prepare 2-methylmercapto-4-thrifluoromethyl benzoate, wherein the 2-methylmercapto-4-thrifluoromethyl benzoate has a mass content of 96.8% to 99.2% and a yield of 92.9% to 98.5%, and has a reaction formula as shown in the specification. The preparation method provided by the invention improves and innovates synthetic raw materials and reaction conditions; and 2-methylmercapto-4-thrifluoromethyl benzoate is prepared by directly subjecting 2-methylmercapto-4-trifluoromethylbenzonitrile to hydrolysis and esterification reactions under the acid condition; thus, three-wastes treatment and three-wastes discharge are reduced; process operation flow is simplified; reaction steps are shortened; and reaction conversion rate and selectivity can reach more than 90%.

Owner:HUNAN HAILI CHEM IND

Low Sodium Cleavage Product

InactiveUS20040106831A1Increase capacityExtended operating periodOxygen-containing compound preparationOrganic compound preparationProduction rateHydrogen

Washed cleavage product (WCP) in a phenol manufacturing process is treated to remove sodium ions. The WCP is contacted with a cation exchange resin in hydrogen form, and then with anion exchange resin in free base or hydroxide form, to produce a WCP essentially free of sodium ions. The cation and anion exchange resins are regenerated with acid and caustic, respectively. The treatment improves productivity and product quality of new and existing phenol processes.

Owner:KELLOGG BROWN & ROOT INC

Preparation method of 6,6-dimethyl-3-oxadicyclo[3.1.0]hexane-2,4-diketone

The invention provides a preparation method of 6,6-dimethyl-3-oxadicyclo[3.1.0]hexane-2,4-diketone. The method comprises the following steps of: oxidizing first ethyl chrysanthemate serving as a raw material in water serving as a solvent by adopting potassium permanganate and adding sulfuric acid for hydrolyzing to generate 3,3-dimethyl-1,2-cyclopropane dicarboxylic acid; and performing cyclization on the 3,3-dimethyl-1,2-cyclopropane dicarboxylic acid in a system consisting of acetic anhydride and sodium acetate to generate the 6,6-dimethyl-3-oxadicyclo[3.1.0]hexane-2,4-diketone. The invention has the advantages that: water is taken as a reaction solvent, so that increase in cost and environmental pollution caused by the use of a large quantity of organic solvents are avoided; and a large amount of sulfur dioxide gas produced by the use of sodium metabisulfite is eliminated, so that environmental pollution and treatment of three wastes are greatly reduced. The method has the advantages of environmentally-friendly reaction process, low environmental pollution, simple process and low cost, thereby being beneficial to industrial production.

Owner:XIAN CAIJING OPTO ELECTRICAL SCI & TECH

Method for preparing high-purity anhydrosugar alcohol having improved yield by using waste from crystallization step

ActiveUS20150252054A1Increase productionImprove distillation efficiencyOrganic compound preparationChemical/physical/physico-chemical stationary reactorsAlcoholDistillation

The present invention relates to a technique for preparing an anhydrosugar alcohol using hydrogenated sugar as a raw material and, more specifically, to a technique for preparing a high-purity anhydrosugar alcohol by adding an acid to hydrogenated sugar (for example, hexitol) to convert same to an anhydrosugar alcohol, then distilling the converted liquid, and crystallizing the distilled liquid in a solvent, the technique removing a crystallization solvent from a crystallization mother liquor generated during a crystallization step and then introducing the resultant product together with the distilled liquid and the converted liquid into a distillation step, thereby being capable of improving the total distillation yield of the anhydrosugar alcohol, improving distillation efficiency by improving the mobility of a distillate, and further reducing the amount of generated waste and treatment costs and thus highly efficiently preparing the high-purity anhydrosugar alcohol at reduced costs.

Owner:SAMSANG CORP

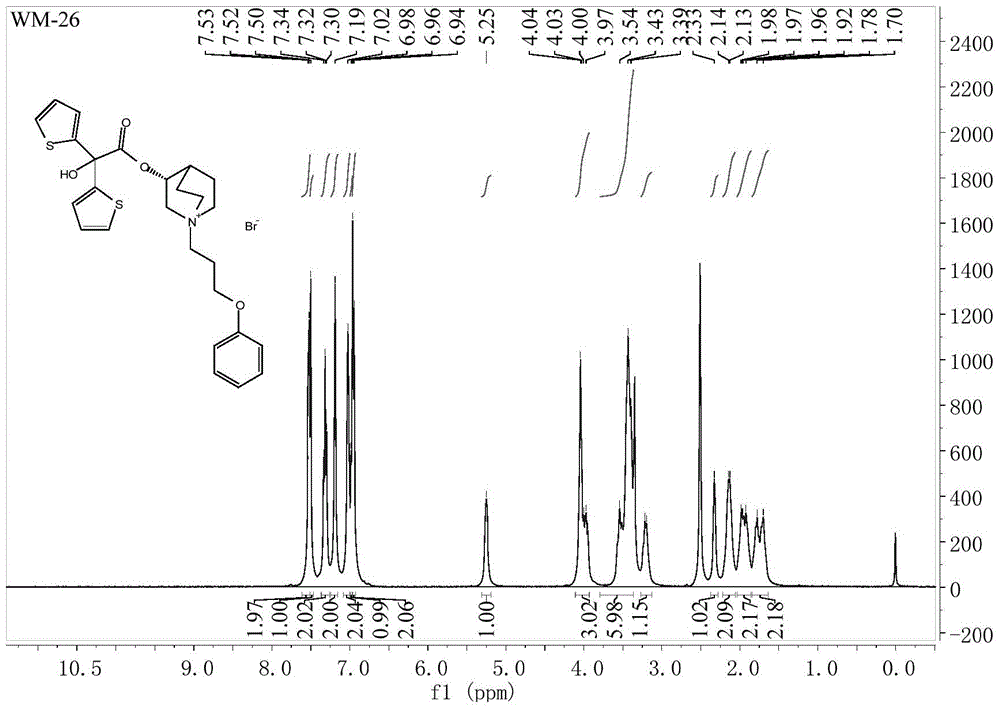

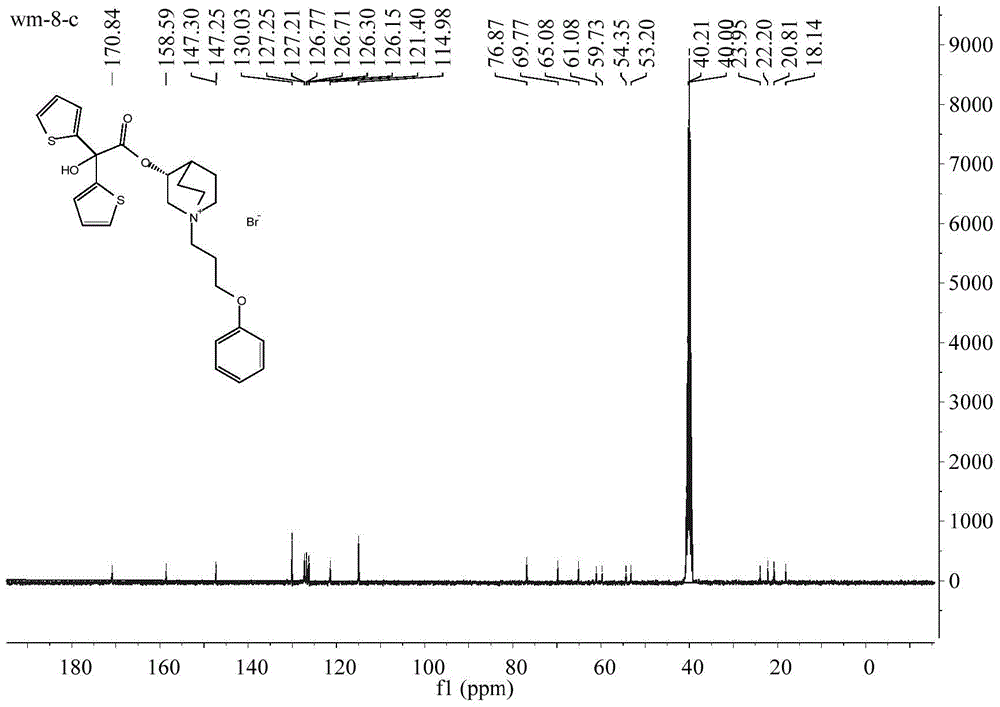

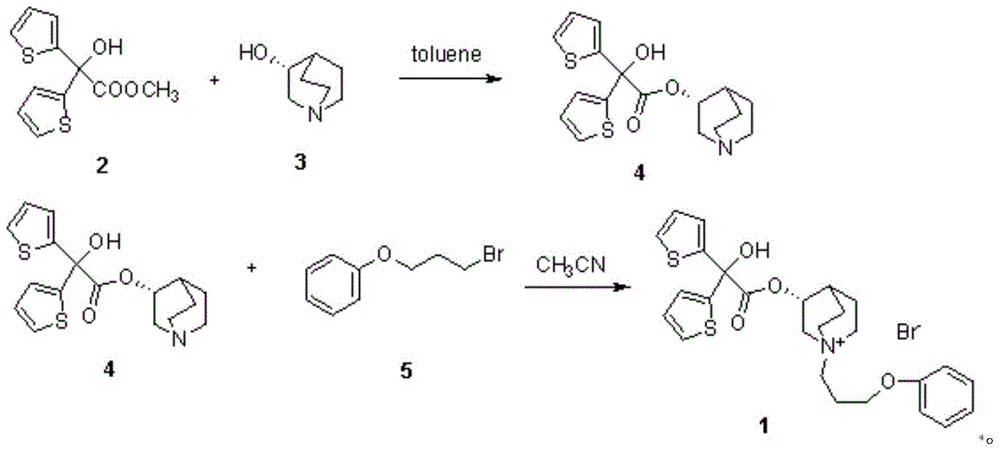

A kind of choline M receptor antagonist aclidinium bromide and preparation method thereof

InactiveCN104478871BShort reaction timeQuick costOrganic active ingredientsOrganic chemistryGrignard reagentStructural formula

The invention relates to choline M receptor antagonist aclidinium bromide and a preparation method thereof. The chemical structural formula of the choline M receptor antagonist aclidinium bromide is as shown in the specification. The preparation method comprises the following steps: mixing R-quinine-3 alcohol, alkali and an organic solvent, dripping methyl oxalyl chloride, after the methyl oxalyl chloride is completely dripped, heating, performing heating reflux for 1-20 hours, and separating and purifying, thereby obtaining a substance A; adding iodine into a tetrahydrofuran solution of 2-bromothiophene and magnesium powder to initiate reaction for 1-5 hours, thereby preparing a Grignard reagent of 2-bromothiophene, adding the substance A, stirring to react for 10-30 minutes at the room temperature, performing heating reflux for 4-6 hours, separating and purifying, thereby preparing 2,2-dithienyl-2-glycolic acid-R-quinine-3-base ester, and performing quaterisation reaction with 3-phenoxypropyl bromine, thereby obtaining aclidinium bromide. The aclidinium bromide provided by the invention is simple in reaction operation, high in yield, low in price, short in reaction route, small in waste generation and easy in industrialization production.

Owner:DONGHUA UNIV

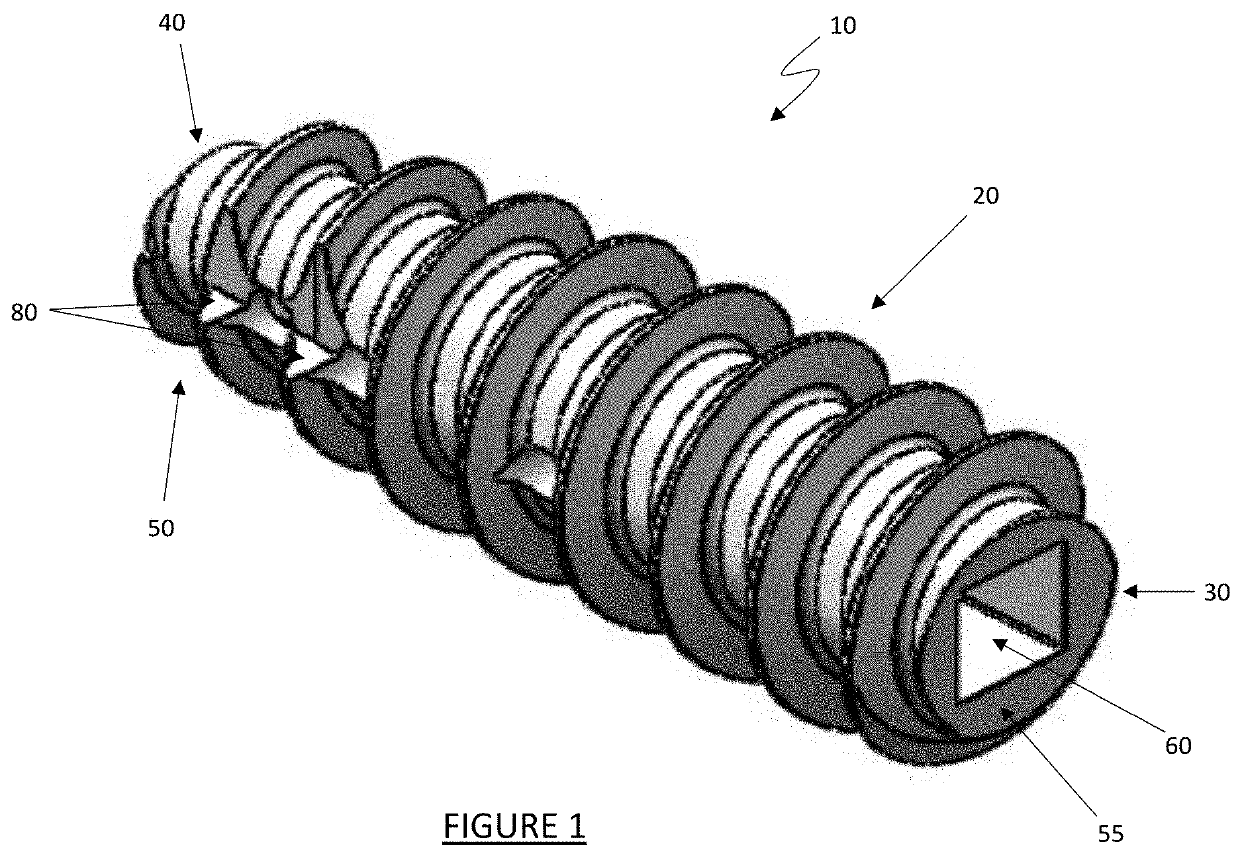

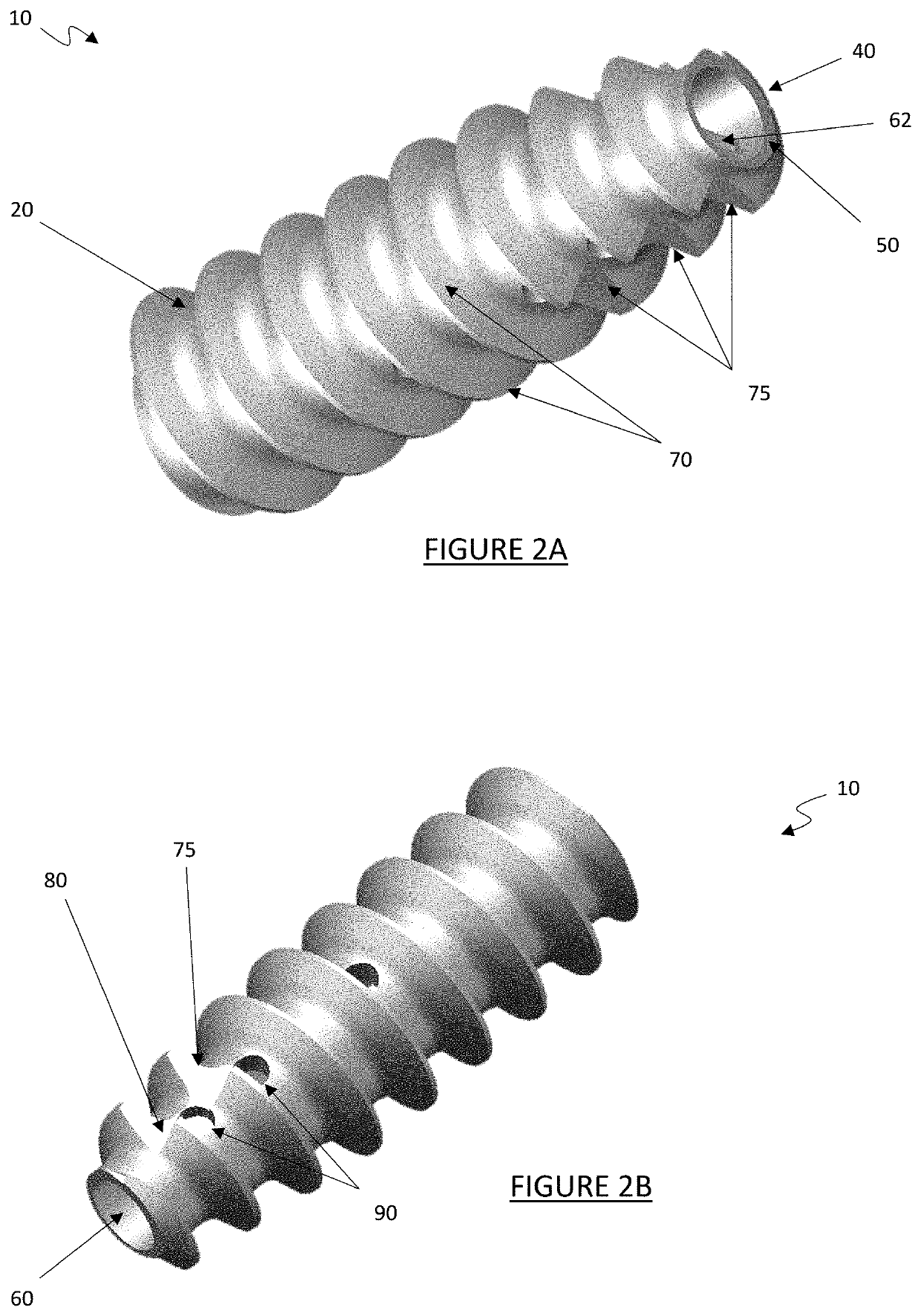

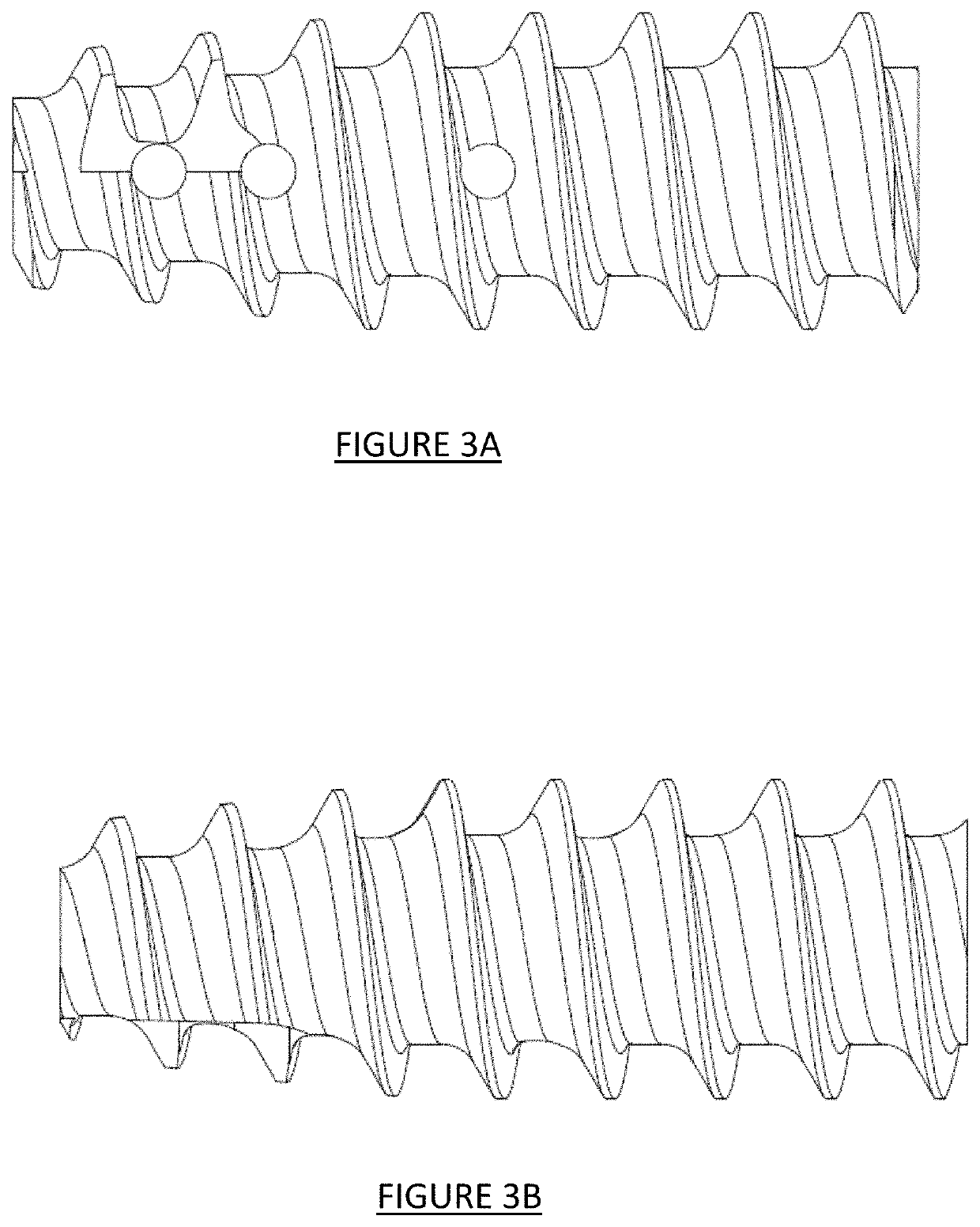

Medial twist anchor

Disclosed are devices, methods and / or systems for securing tissue to bone, including a suture anchor implant having a body with an internal cavity and one or more helical cutting flutes positioned on an external surface of the body which direct at least a portion of the cut bony material into the internal cavity as the body is rotated into bone.

Owner:TIGON MEDICAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com