Method for preparing 3-(4-methoxyphenyl)-succinimide

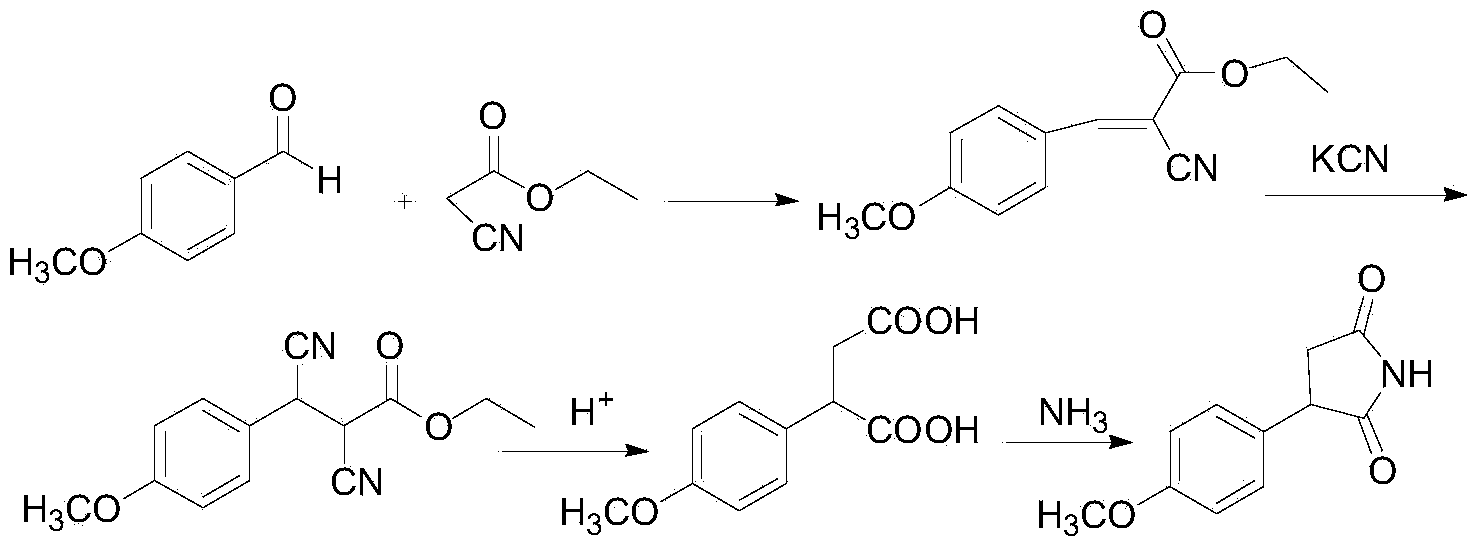

A technology of succinimide and methoxyphenyl, applied in the field of preparation of succinimide compounds, can solve the problems of long reaction route, excessive reaction route, harsh reaction conditions and the like, and achieves easy industrial production, The effect of simple reaction operation and shortened reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

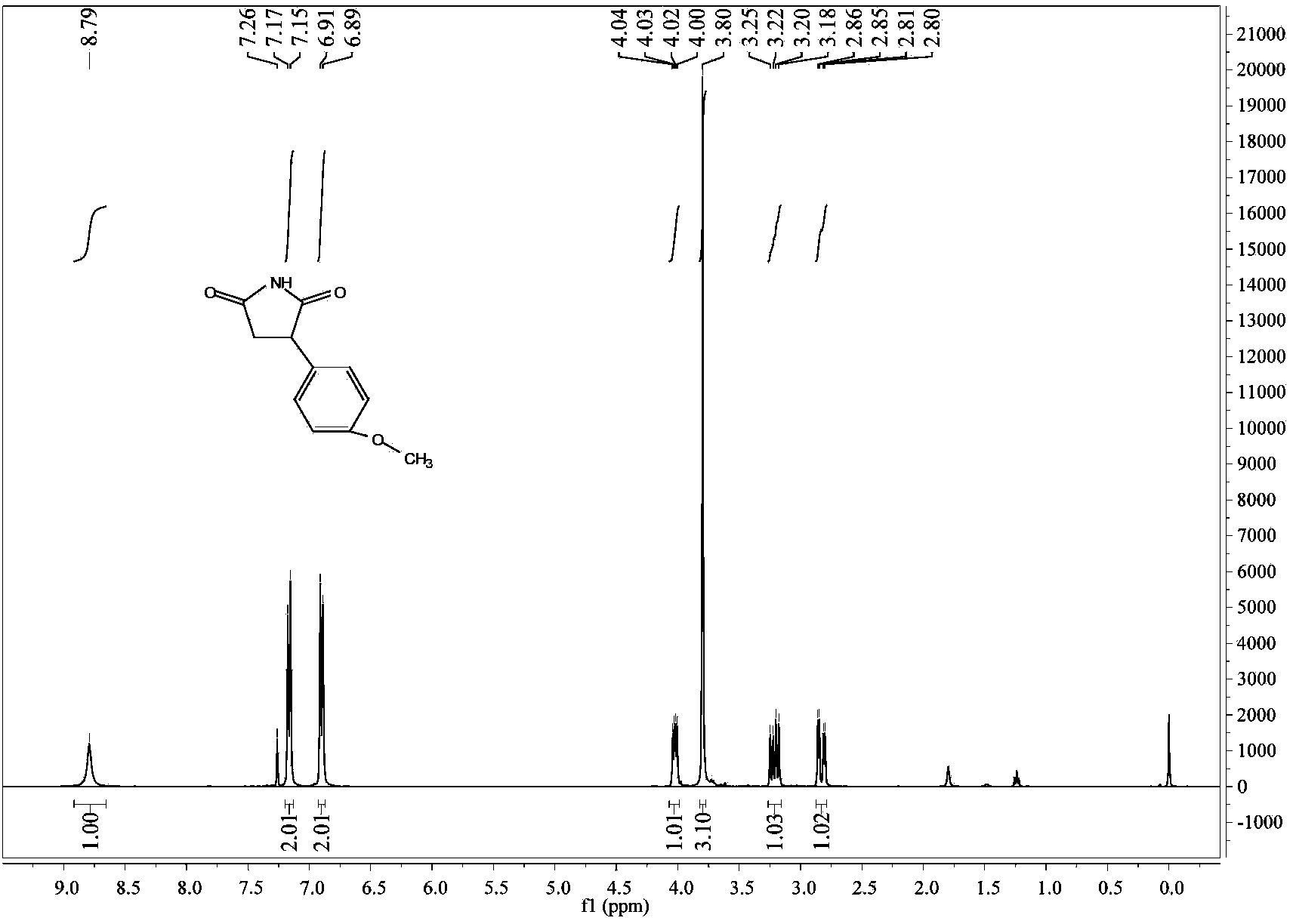

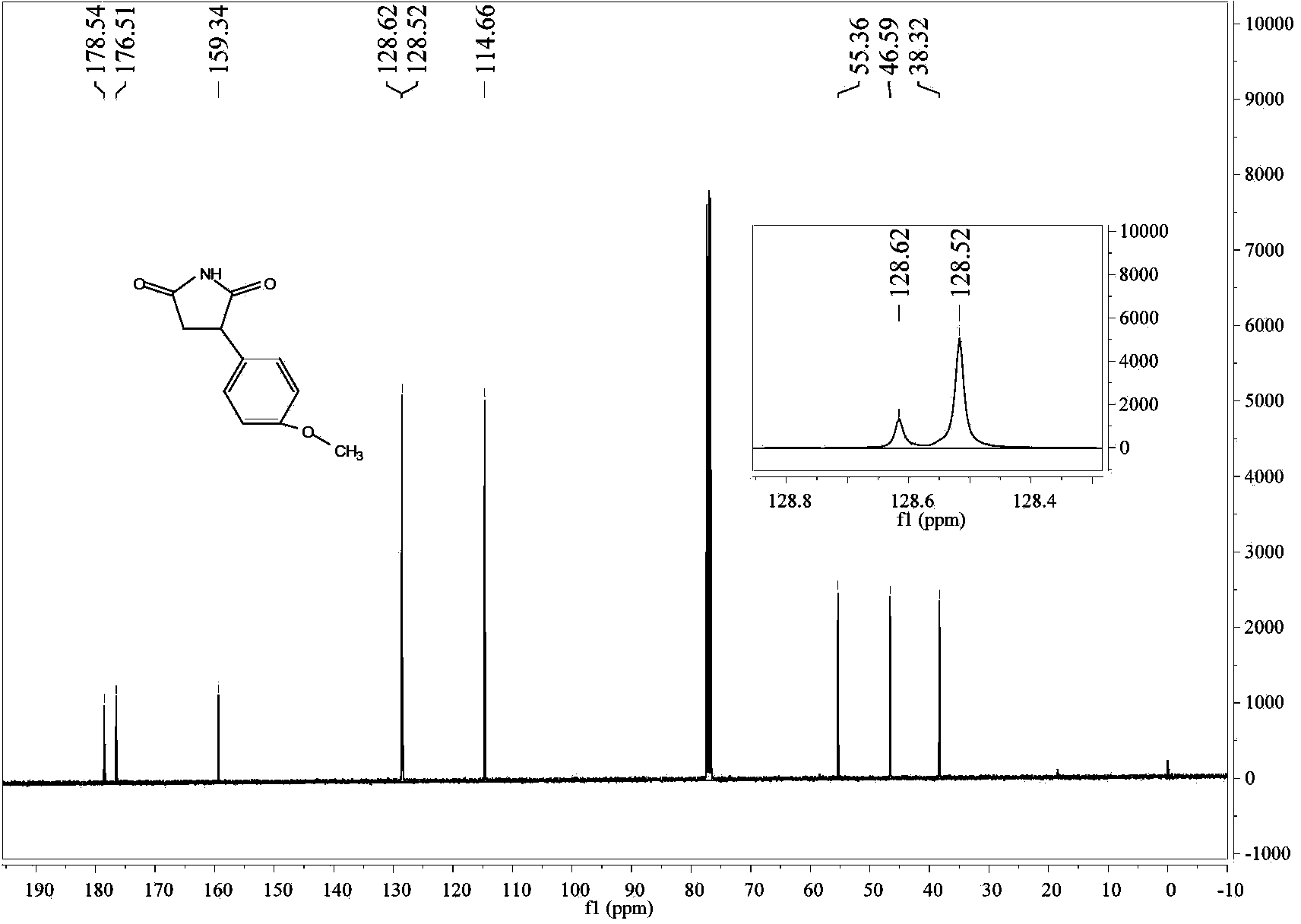

Embodiment 1

[0032] Take 54.1g (0.50mol) of anisole, 48.5g (0.50mol) of maleimide and 66.5g (0.5mol) of anhydrous aluminum trichloride and add them to a 1000mL round bottom flask, add 600mL of dichloroethane, Heat, stir and reflux for 8 hours. After the reaction is completed, add 500 mL of 2N hydrochloric acid to the reaction solution, stir for 10 minutes, filter with suction, and wash with water. The obtained solid is recrystallized with 95% ethanol to obtain 78.4 g of white solid, yield 76.5%, mp: 128 ~129°C.

Embodiment 2

[0034] Take 54.1g (0.50mol) of anisole, 48.5g (0.50mol) of maleimide and 133.0g (1.0mol) of anhydrous aluminum trichloride and add them to a 2000mL round bottom flask, add 600mL of dichloroethane, Heat, stir and reflux for 8 hours. After the reaction is complete, add 500 mL of 2N hydrochloric acid to the reaction solution, stir for 10 minutes, filter with suction, wash with water, and recrystallize the obtained solid with 95% ethanol to obtain 83.0 g of white solid, yield 81.0%, mp: 128~130°C .

Embodiment 3

[0036] Take 54.1g (0.50mol) of anisole, 97.0g (1.0mol) of maleimide and 133.0g (1.0mol) of anhydrous aluminum trichloride and add them to a 2000mL round bottom flask, add 800mL of dichloroethane, Heat, stir and reflux for 5 hours. After the reaction is complete, add 600 mL of 2N hydrochloric acid to the reaction solution, stir for 10 minutes, filter with suction, wash with water, and recrystallize the solid with 95% ethanol to obtain 88.5 g of white solid, yield 86.3%, mp: 128-130°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com