Synthesis rectifying method and equipment of methane chloride

A technology of monochloromethane and process method, which is applied in the field of synthesis and rectification process method of monochloromethane and its equipment, can solve the problems of low reaction yield, high energy consumption of dimethyl ether extraction process, instability in the later stage of operation, etc. To achieve the effect of increasing the reaction yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

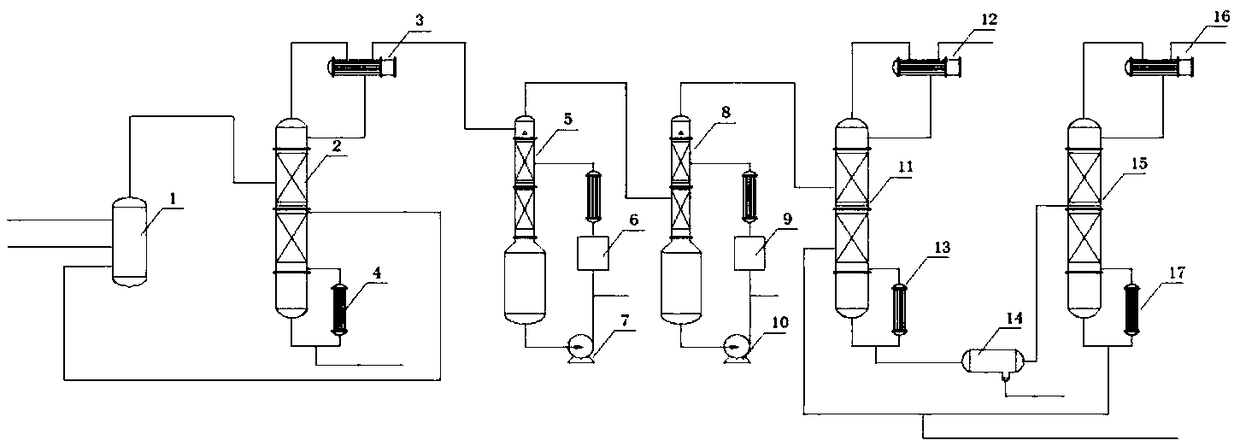

Embodiment 1

[0044] Embodiment 1: as figure 1 As shown, take 99.9%wt methanol 1mol and 99.5%wt hydrogen chloride 1.01mol, the feed pressure is 200kpag, the feed temperature is 150°C, the operating pressure of reactor 1 is 100kpag, the reaction temperature is 160°C, after bubbling reaction Afterwards, the top discharge of reactor 1 is hydrogen chloride 1.81%wt, methanol 32.3%wt, monochloromethane 47.6%wt, dimethyl ether 0.09%wt, water 17.4%wt enters reactive distillation tower 2, operating pressure 80kpag, tower top The temperature is 45°C, 45 theoretical plates, 15 plates at the feed plate position, the reflux ratio is 3.5:1, 10 plate positions for the side line production, and the mass ratio of the methanol flow rate of the side line production to the feed flow rate is 0.12%. The flow rate of methanol extracted from the side line of the reactive distillation tower is 32.84kg / h (circulation stream flow rate), the purity is 99.9%wt, the gas phase at the top of the tower is 51.22kg / h, and th...

Embodiment 2

[0045] Embodiment 2: as figure 1As shown, take 99.9%wt methanol 1mol and 99.5%wt hydrogen chloride 1.0mol, the feed pressure is 180kpag, the feed temperature is 170°C, the operating pressure of reactor 1 is 80kpag, and the reaction temperature is 170°C, after bubbling reaction Afterwards, the top discharge of reactor 1 is hydrogen chloride 1.56%wt, methyl alcohol 41.2%wt, monochloromethane 41.1%wt, dimethyl ether 0.01%wt, water 15.1%wt enters reactive distillation tower 2, operating pressure 70kpag, tower top The temperature is 42°C, 50 theoretical plates, 19 feed plate positions, 2.8:1 reflux ratio, 5 side line production plates, and the mass ratio of side line production methanol flow to feed flow is 0.11%. The methanol flow rate extracted from the side line of the reactive distillation tower is 48.06kg / h (circulation stream flow rate), the purity is 99.9%wt, the gas phase at the top of the tower is 50.94kg / h, and the composition is 3.6%wt of hydrogen chloride and 94.2%wt of...

Embodiment 3

[0046] Embodiment 3: as figure 1 As shown, take 99.9%wt methanol 1mol and 99.5%wt hydrogen chloride 1.0mol, the feed pressure is 220kpag, the feed temperature is 150°C, the operating pressure of reactor 1 is 110kpag, and the reaction temperature is 150°C, after bubbling reaction Afterwards, the top discharge of reactor 1 is hydrogen chloride 1.45%wt, methyl alcohol 31.9%wt, monochloromethane 48.2%wt, dimethyl ether 0.01%wt, water 17.6%wt enters reactive distillation tower 2, operating pressure 90kpag, tower top The temperature is 38°C, 38 theoretical plates, 16 plates at the position of the feed plate, the reflux ratio is 2.5:1, 10 plates at the position of the side line extraction plate, and the mass ratio of the methanol flow rate of the side line output to the feed flow rate is 0.1%. The methanol flow rate extracted from the side line of the reactive distillation tower is 32.04kg / h (circulation stream flow rate), the purity is 99.9%wt, the gas phase at the top of the tower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com