Multistage resource recycling integrated process for glyphosate mother liquor

A glyphosate mother liquor, resource utilization technology, applied in the chemical industry, phosphorus compounds, inorganic chemistry and other directions, can solve problems such as ecological environment and human harm, soil compaction, etc., to reduce the three wastes treatment, reduce the cost of caustic soda, reduce environmental protection pressure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

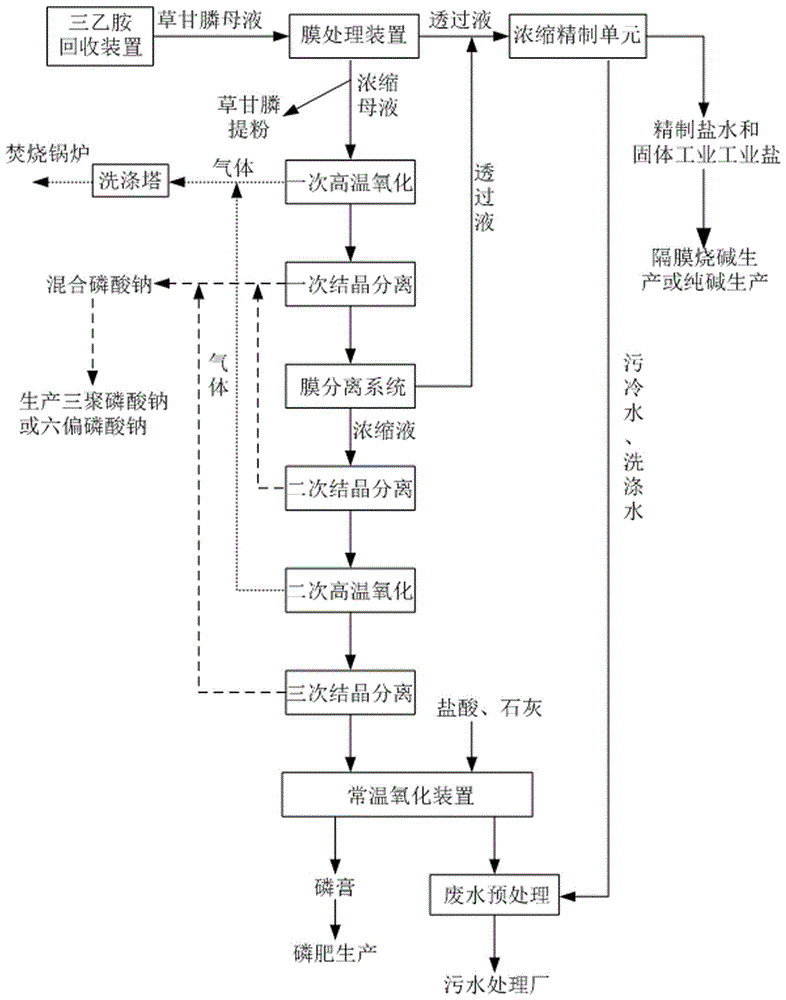

[0034] A kind of multi-stage resource recycling integrated process of glyphosate mother liquor, comprising the following steps:

[0035] A. Send the glyphosate mother liquor into the membrane treatment device to obtain concentrated mother liquor and permeate. In the concentrated mother liquor, 10% is used for glyphosate powder extraction, and 90% is used to complete the operation of step B;

[0036] B. After the concentrated mother liquor is oxidized once and separated by crystallization, a centrifuge filtrate is obtained, and the centrifuge filtrate is sent to a membrane separation system to obtain a concentrate and a permeate;

[0037] C. The concentrated solution obtained by the membrane separation system undergoes secondary crystallization separation, secondary oxidation, and tertiary crystallization separation in sequence, and the centrifugal filtrate is sent to a normal temperature oxidation device to obtain phosphopaste.

Embodiment 2

[0039] A kind of multi-stage resource recycling integrated process of glyphosate mother liquor, comprising the following steps:

[0040] A, sending the glyphosate mother liquor into the membrane treatment device to obtain concentrated mother liquor and permeate, in the concentrated mother liquor, 20% is used for glyphosate powder extraction, and 80% is used to complete the operation of step B;

[0041] B. After the concentrated mother liquor is oxidized once and separated by crystallization, a centrifuge filtrate is obtained, and the centrifuge filtrate is sent to a membrane separation system to obtain a concentrate and a permeate;

[0042] C. The concentrated solution obtained by the membrane separation system undergoes secondary crystallization separation, secondary oxidation, and tertiary crystallization separation in sequence, and the centrifugal filtrate is sent to a normal temperature oxidation device to obtain phosphopaste.

Embodiment 3

[0044] A kind of multi-stage resource recycling integrated process of glyphosate mother liquor, comprising the following steps:

[0045] A. Send the glyphosate mother liquor into the membrane treatment device to obtain concentrated mother liquor and permeate. In the concentrated mother liquor, 15% is used for glyphosate powder extraction, and 85% is used to complete the operation of step B;

[0046] B. After the concentrated mother liquor is oxidized once and separated by crystallization, a centrifuge filtrate is obtained, and the centrifuge filtrate is sent to a membrane separation system to obtain a concentrate and a permeate;

[0047] C. The concentrated solution obtained by the membrane separation system undergoes secondary crystallization separation, secondary oxidation, and tertiary crystallization separation in sequence, and the centrifugal filtrate is sent to a normal temperature oxidation device to obtain phosphopaste.

[0048] In this embodiment, the permeate obtaine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com