One-way perspective digital printed material with bottom coated with BOPP membrane and process method

A one-way perspective, digital printing technology, applied in the field of advertising display and decorative materials, can solve the problems of wasting materials, affecting the appearance, complex process, etc., to achieve the effect of reducing cost, easy operation and complete process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below in conjunction with accompanying drawing, take the BOPP film of thickness 0.02mm as example, the present invention will be further described:

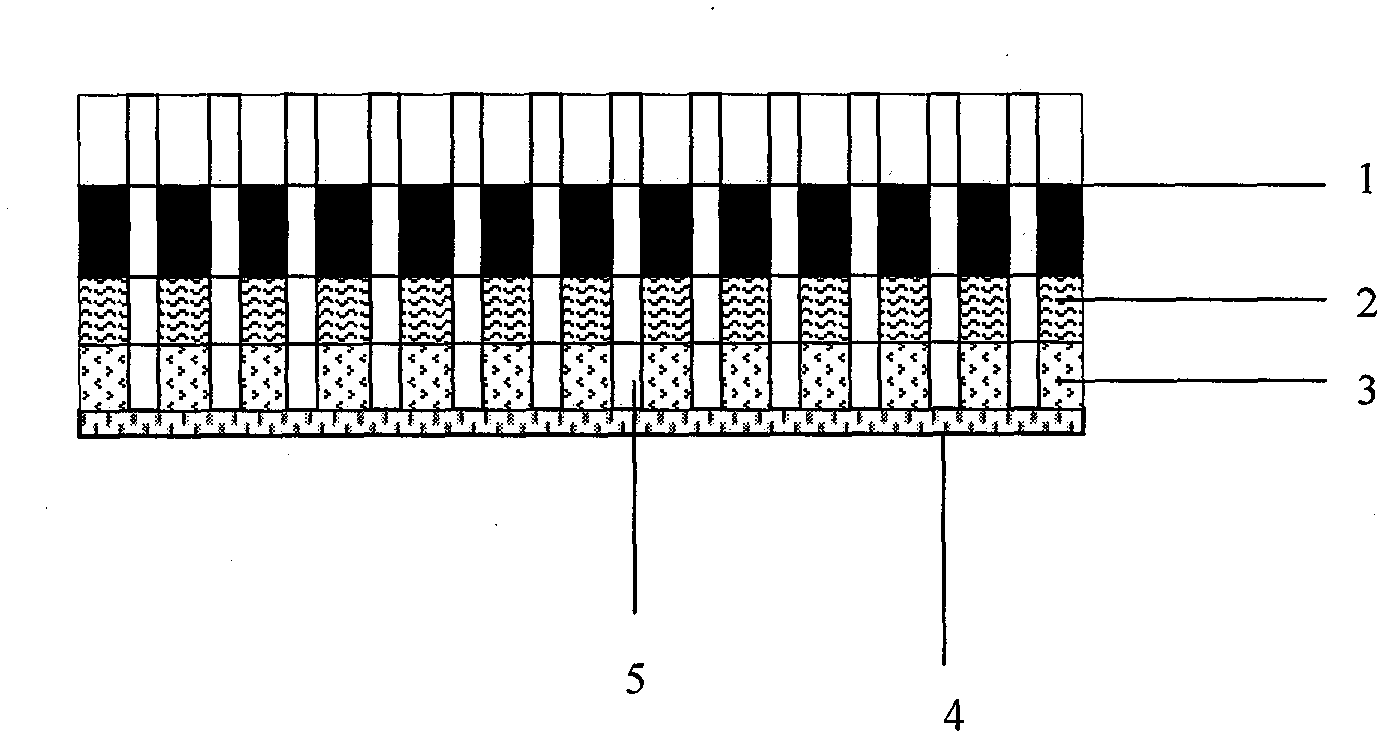

[0033] Such as figure 1 Shown: the layered structure of the PVC black and white film layer, glue layer, anti-adhesive release paper layer, and BOPP film bottom layer, the vertical planes of the PVC black and white film layer, glue layer, and anti-adhesive release paper layer are regularly arranged and transparent Light through hole, the aperture of the light through hole is Φ1.6mm, and the hole distance is 2.4mm.

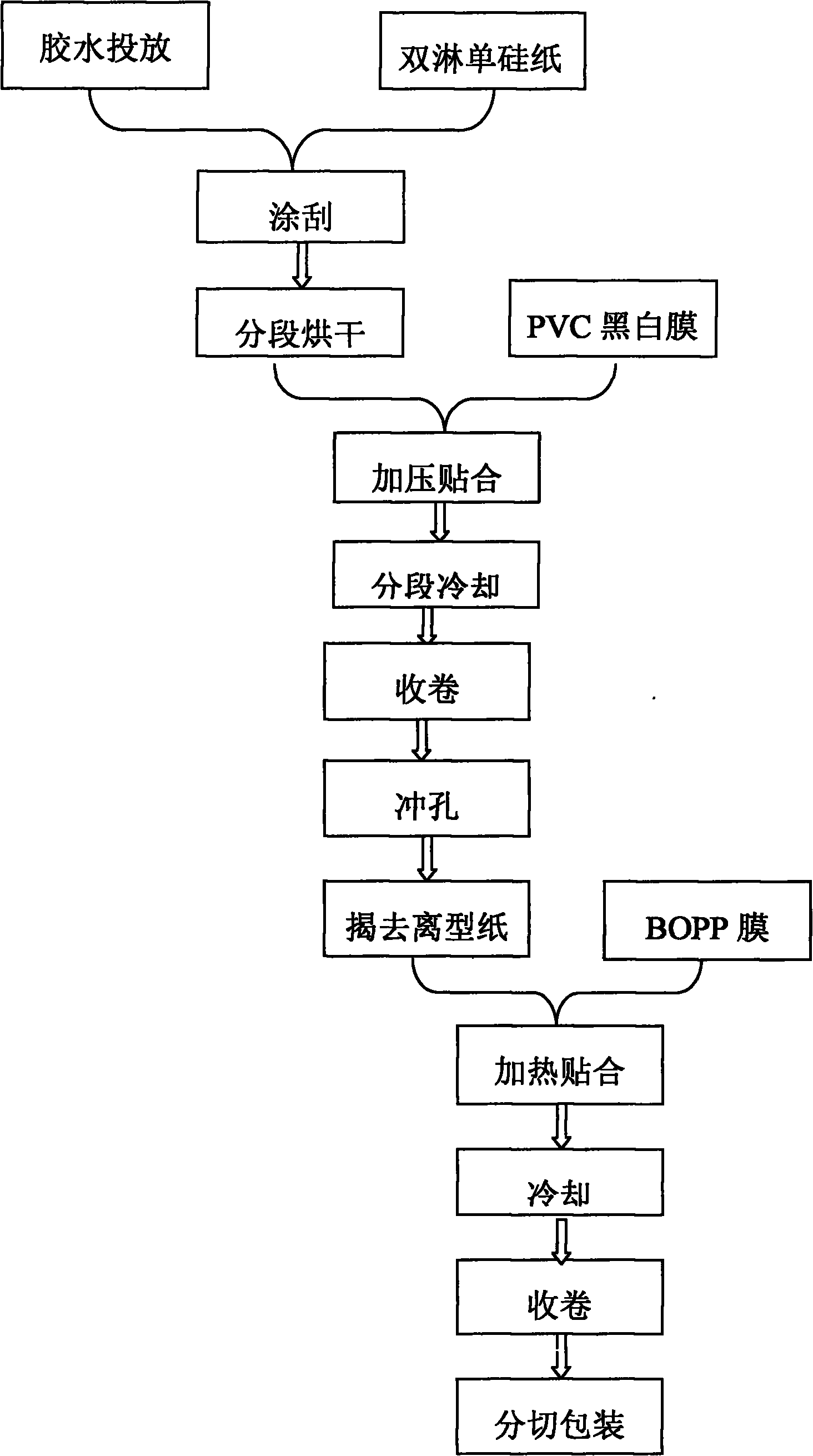

[0034] Its manufacturing process includes the following steps:

[0035] 1. PVC black and white film adhesive

[0036] 1) Put the large roll of double-drenched single-silicon release paper on the roller shaft and unwind it;

[0037] 2) Go to the gluing shaft and apply glue on the release surface of the release paper;

[0038] 3) Segmented drying, the segmental drying temperature of the oven is 95 ° C ± 5;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com